hmmwv-manuals

Army Tm 9-2320-280-10 Air Force To 36A12-1A-2091-1 Marine Corps Tm 2320-10/6B

(SUPERSEDES TM 9-2320-280-10, 18 JUNE 1991) OPERATOR'S MANUAL FOR TRUCK, UTILITY: CARGO/TROOP CARRIER, 1-1/4 TON, 4X4, M998 (2320-01-107-7155) (EIC: BBD); M998A1 (2320-01-371-9577) (EIC: BBN); TRUCK, UTILITY: CARGO/TROOP CARRIER, 1-1/4 TON, 4X4, W/WINCH, M1038 (2320-01-107-7156) (EIC: BBE); M1038A1 (2320-01-371-9578) (EIC: BBP); TRUCK, UTILITY: HEAVY VARIANT, 4X4, M1097 (2320-01-346-9317) (EIC: BBM); M1097A1 (2320-01-371-9583) (EIC: BBU); M1097A2 (2320-01-380-8604) (EIC: BB6); M1123 (2320-01-455-9593) (EIC: B6G); TRUCK, UTILITY: TOW CARRIER, ARMORED, 1-1/4 TON, 4X4, M966 (2320-01-107-7153) (EIC: BBC); M966A1 (2320-01-372-3932) (EIC: BBX); M1121 (2320-01-956-1282) (EIC: B6H); TRUCK, UTILITY: TOW CARRIER, ARMORED, 1-1/4 TON, 4X4, W/WINCH, M1036 (2320-01-107-7154) (EIC: BBH); TRUCK, UTILITY: TOW CARRIER, W/SUPPLEMENTAL ARMOR, 1-1/4 TON, 4X4, M1045 (2320-01-146-7191); M1045A1 (2320-01-371-9580) (EIC: BBR); M1045A2 (2320-01-380-8229) (EIC: BB5); TRUCK, UTILITY: TOW CARRIER, W/SUPPLEMENTAL ARMOR, 1-1/4 TON, 4X4, W/WINCH, M1046 (2320-01-146-7188); M1046A1 (2320-01-371-9582) (EIC: BBT); TRUCK, UTILITY: ARMAMENT CARRIER, ARMORED, 1-1/4 TON, 4X4, M1025 (2320-01-128-9551) (EIC: BBF); M1025A1 (2320-01-371-9584) (EIC: BBV); M1025A2 (2320-01-380-8233) (EIC: BB3); TRUCK, UTILITY: ARMAMENT CARRIER, ARMORED, 1-1/4 TON, 4X4, W/WINCH, M1026 (2320-01-128-9552) (EIC: BBG); M1026A1 (2320-01-371-9579) (EIC: BBQ); TRUCK, UTILITY: ARMAMENT CARRIER, W/SUPPLEMENTAL ARMOR, 1-1/4 TON, 4X4, M1043 (2320-01-146-7190); M1043A1 (2320-01-372-3933) (EIC: BBY); M1043A2 (2320-01-380-8213) (EIC: BB4); TRUCK, UTILITY: ARMAMENT CARRIER, W/SUPPLEMENTAL ARMOR, 1-1/4 TON, 4X4, W/WINCH, M1044 (2320-01-146-7189); M1044A1 (2320-01-371-9581) (EIC: BBS); TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1037 (2320-01-146-7193) (EIC: BBK); TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, W/WINCH, M1042 (2320-01-146-7187); TRUCK, AMBULANCE, 2-LITTER, ARMORED, 4X4, M996 (2310-01-111-2275) (EIC: BBB); M996A1 (2310-01-372-3935) (EIC: BB2); TRUCK, AMBULANCE, 4-LITTER, ARMORED, 4X4, M997 (2310-01-111-2274) (EIC: BBA); M997A1 (2310-01-372-3934) (EIC: BBZ); M997A2 (2310-01-380-8225) (EIC: BB8); TRUCK, AMBULANCE, 2-LITTER, SOFT TOP, 4X4, M1035 (2310-01-146-7194); M1035A1 (2310-01-371-9585) (EIC: BBW); M1035A2 (2310-01-380-8290) (EIC: BB9).

ARMY TM 9-2320-280-10

AIR FORCE TO 36A12-1A-2091-1 MARINE CORPS TM 2320-10/6B CHANGE HEADQUARTERS, DEPARTMENTS OF THE ARMY, NO. 3 THE AIR FORCE, AND MARINE CORPS WASHINGTON, D.C., 15 July 2004

Operator'S Manual

TRUCK, UTILITY: CARGO/TROOP CARRIER, 1-1/4 TON, 4X4, M998 (2320-01-107-7155) (EIC: BBD); M998A1 (2320-01-371-9577) (EIC: BBN); TRUCK, UTILITY: CARGO/TROOP CARRIER, 1-1/4 TON, 4X4, W/WINCH, M1038 (2320-01-107-7156) (EIC: BBE); M1038A1 (2320-01-371-9578) (EIC: BBP); TRUCK, UTILITY: HEAVY VARIANT, 4X4, M1097 (2320-01-346-9317) (EIC: BBM); M1097A1 (2320-01-371-9583) (EIC: BBU); M1097A2 (2320-01-380-8604) (EIC: BB6); M1123 (2320-01-455-9593) (EIC: B6G); TRUCK, UTILITY: TOW CARRIER, ARMORED, 1-1/4 TON, 4X4, M966 (2320-01-107-7153) (EIC: BBC); M966A1 (2320-01-372-3932) (EIC: BBX); M1121 (2320-01-456-1282) (EIC B6H); TRUCK, UTILITY: TOW CARRIER, ARMORED, 1-1/4 TON, 4X4, W/WINCH, M1036 (2320-01-107-7154) (EIC: BBH); TRUCK, UTILITY: TOW CARRIER, W/SUPPLEMENTAL ARMOR, 1-1/4 TON, 4X4, M1045 (2320-01-146-7191); M1045A1 (2320-01-371-9580) (EIC: BBR); M1045A2 (2320-01-380-8229) (EIC: BB5); TRUCK, UTILITY: TOW CARRIER, W/SUPPLEMENTAL ARMOR, 1-1/4 TON, 4X4, W/WINCH, M1046 (2320-01-146-7188); M1046A1 (2320-01-371-9582) (EIC: BBT); TRUCK, UTILITY: ARMAMENT CARRIER, ARMORED, 1-1/4 TON, 4X4, M1025 (2320-01-128-9551) (EIC: BBF); M1025A1 (2320-01-371-9584) (EIC: BBV); M1025A2 (2320-01-380-8233) (EIC: BB3); TRUCK, UTILITY: ARMAMENT CARRIER, ARMORED, 1-1/4 TON, 4X4, W/WINCH, M1026 (2320-01-128-9552) (EIC: BBG); M1026A1 (2320-01-371-9579) (EIC: BBQ); TRUCK, UTILITY: ARMAMENT CARRIER, W/SUPPLEMENTAL ARMOR, 1-1/4 TON, 4X4, M1043 (2320-01-146-7190) M1043A1 (2320-01-372-3933) (EIC: BBY); M1043A2 (2320-01-380-8213) (EIC: BB4); TRUCK, UTILITY: ARMAMENT CARRIER, W/SUPPLEMENTAL ARMOR, 1-1/4 TON, 4X4, W/WINCH, M1044 (2320-01-146-7189); M1044A1 (2320-01-371-9581) (EIC: BBS); TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1037 (2320-01-146-7193) (EIC: BBK); TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, W/WINCH, M1042 (2320-01-146-7187); TRUCK, AMBULANCE, 2-LITTER, ARMORED, 4X4, M996 (2310-01-111-2275) (EIC: BBB); M996A1 (2310-01-372-3935) (EIC: BB2); TRUCK, AMBULANCE, 4-LITTER, ARMORED, 4X4, M997 (2310-01-111-2274) (EIC: BBA); M997A1 (2310-01-372-3934) (EIC: BBZ); M997A2 (2310-01-380-8225) (EIC: BB8); TRUCK, AMBULANCE, 2-LITTER, SOFT TOP, 4X4, M1035 (2310-01-146-7194); M1035A1 (2310-01-371-9585) (EIC: BBW); M1035A2 (2310-01-380-8290) (EIC: BB9).

TM 9-2320-280-10

| Chapter | Description |

|---|---|

| CHAPTER 1. | INTRODUCTION |

| Section I. | General Information |

| Section II. | Equipment Description |

| CHAPTER 2. | OPERATING INSTRUCTIONS |

| Section I. | Description and Use of Operator's Controls and Indicators |

| Section II. | Preventive Maintenance Checks and Services |

| Section III | Operation Under Usual Conditions |

| Section IV. | Operation Under Unusual Conditions |

| Section V. | Cargo/Troop Carrier and S250 Shelter Carrier Operation |

| Section VI. | TOW/Armament Carrier Operation |

| Section VII. | Ambulance Operation |

| CHAPTER 3. | MAINTENANCE INSTRUCTIONS |

| Section I. | Lubrication |

| Section II. | Troubleshooting |

| Section III. | Maintenance Procedures |

| APPENDIX A. | REFERENCES |

| APPENDIX B. | COMPONENTS OF END ITEM AND BASIC ISSUE ITEMS LISTS |

| Section I. | Introduction |

| Section II. | Components of End Item |

| Section III. | Basic Issue Items |

| APPENDIX C. | ADDITIONAL AUTHORIZATION LIST |

| Section I. | Introduction |

| Section II. | Additional Authorization List |

| APPENDIX D. | EXPENDABLE/DURABLE SUPPLIES AND MATERIALS LIST |

| Section I. | Introduction |

| Section II. | Expendable/Durable Supplies and Materials List |

| APPENDIX E. | STOWAGE AND SIGN GUIDE |

| APPENDIX F. | ON-VEHICLE EQUIPMENT LOADING PLANS |

| APPENDIX G. | LUBRICATION INSTRUCTIONS |

| INDEX |

Chapter 1 Introduction

Section I. General Information

1-1. Scope

a. This manual contains instructions for operating and servicing M998 series vehicles.

These vehicles are:

(1) M998 and M998A1 Cargo/Troop Carriers (2) M1038 and M1038A1 Cargo/Troop Carriers, W/W (3) M1097, M1097A1, M1097A2, and M1123 Heavy Variants (4) M966, M966A1, and M1121 TOW Carriers, Armored (5) M1036 TOW Carrier, Armored, W/W (6) M1045, M1045A1, and M1045A2 TOW Carriers, W/Supplemental Armor (7) M1046 and M1046A1 TOW Carriers, W/Supplemental Armor, W/W (8) M1025, M1025A1, and M1025A2 Armament Carriers, Armored (9) M1026 and M1026A1 Armament Carriers, Armored, W/W (10) M1043, M1043A1, and M1043A2 Armament Carriers, W/Supplemental Armor (11) M1044 and M1044A1 Armament Carriers, W/Supplemental Armor, W/W (12) M1037 S250 Shelter Carrier (13) M1042 S250 Shelter Carrier, W/W (14) M996 and M996A1 2-Litter Ambulances, Armored (15) M997, M997A1, and M997A2 4-Litter Ambulances, Armored (16) M1035, M1035A1, and M1035A2 2-Litter Ambulances, Soft Top b. The material presented here provides operators with information and procedures needed to provide the safest and most efficient operation of these vehicles. This information includes: (1) Operator forms and records. (2) Descriptions of each vehicle and its operation. (3) The purpose of each vehicle. (4) Vehicle limitations. (5) The function of all controls and indicators. (6) Operating instructions for each vehicle. (7) Cautions and warnings to operators regarding safety to personnel and equipment.

(8) How and when to use special purpose kits. (9) Operator maintenance checks and service procedures.

(10) Troubleshooting procedures to be followed by operators if the vehicle malfunctions.

1-2. Maintenance Forms And Records

(Army) Department of the Army forms and procedures used for equipment maintenance will be those prescribed by DA Pam 738-750, The Army Maintenance Management System (TAMMS). (Marine Corps) Refer to TM 4700-15/1 series.

1-3. Hand Receipt Manual

This operator's manual has a companion document with a TM number followed by "-HR" (which stands for Hand Receipt). The TM 9-2320-280-10-HR consists of preprinted hand receipts (DA Form 2062) that list end item related equipment (i.e., COEI, BII, and AAL) you must account for. As an aid to property accountability, additional -HR manuals may be requisitioned from the following source in accordance with procedures in chapter 12, AR 25-30: Commander U.S. Army Publications Distribution Center 2800 Eastern Blvd. Baltimore, MD 21220-2896

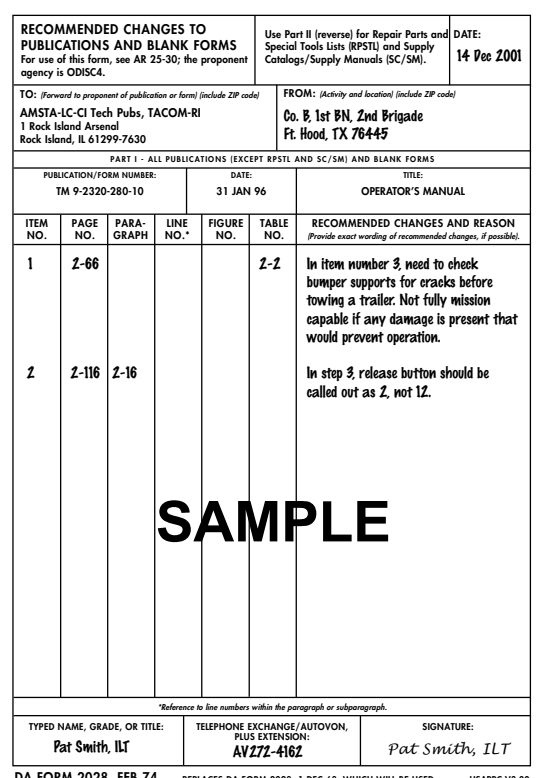

1-4. Reporting Equipment Improvement Recommendations (Eir)

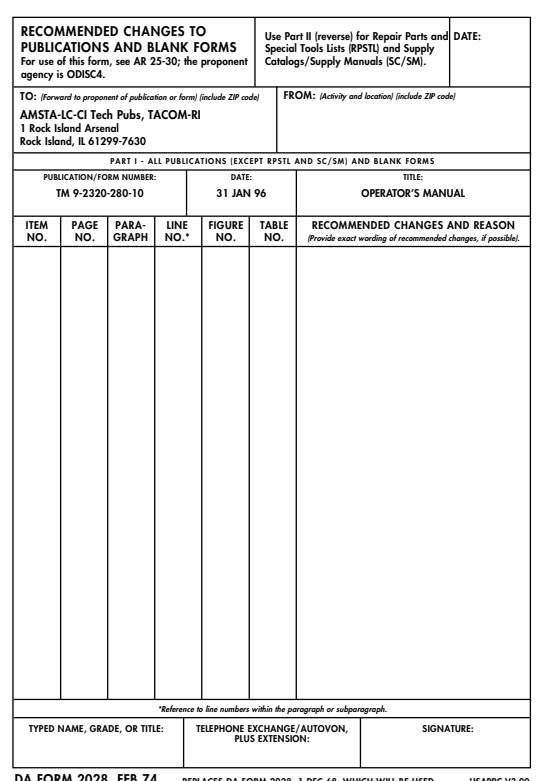

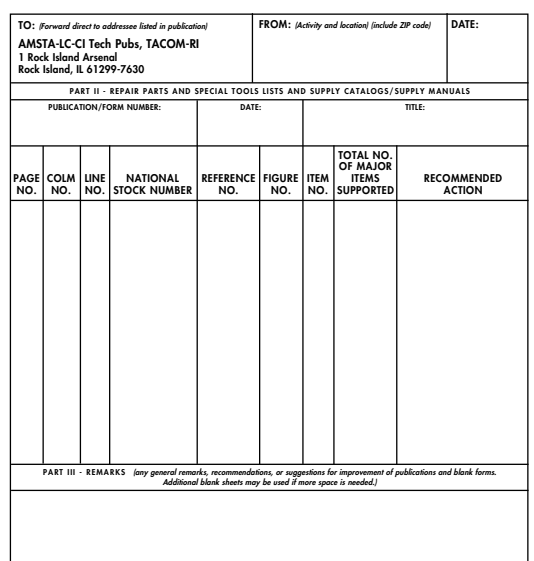

If your vehicle needs improvement, let us know. Send us an EIR. You, the user, are the only one who can tell us what you don't like about your equipment. Let us know why you don't like the design or performance. The preferred method for submitting QDRs is through the Army Electronic Product Support (AEPS) website under the Electronic Deficiency Reporting System (EDRS). The web address is: https://aeps.ria.army.mil. This is a secured site requiring a password that can be applied for on the front page of the website. If the above method is not available to you, put it on an SF 368, Product Quality Deficiency Report (PQDR), and mail it to us at: Department of the Army, U.S. Army Tankautomotive and Armaments Command, ATTN: AMSTA-TR-E/PQDR MS 267, 6501 E. 11 Mile Road, Warren, MI 48397-5000. We'll send you a reply. 1-2 Change 3

1-5. Equipment Improvement Report And Maintenance Digest (Eir Md)

The quarterly Equipment Improvement Report and Maintenance Digest, TB 43-0001-62 series, contains valuable field information on the equipment covered in this manual. The information in the TB 43-0001-62 series is compiled from some of the Equipment Improvement Reports that you prepared on the vehicles covered in this manual. Many of these articles result from comments, suggestions, and improvement recommendations that you submitted to the EIR program. The TB 43-0001-62 series contains information on equipment improvements, minor alterations, proposed Modification Work Orders (MWOs), warranties (if applicable), actions taken on some of your DA Form 2028s (Recommended Changes to Publications), and advance information on proposed changes that may affect this manual. The information will help you in doing your job better and will help in keeping you advised of the latest changes to this manual. Also refer to DA Pam 25-30, Consolidated Index of Army Publications and Blank Forms, and appendix A, References, of this manual. (Marine Corps) Submit QDR's in accordance with MCO 4855-10. For those with access to the World Wide Web (WWW), the EIR MD can be viewed through the Army Electronic Product Support. The site is http://aeps.ria.army.mil.

1-6. Break-In Service

Upon receipt of vehicle, or after engine replacement, break-in precautions must be observed during the first 500 miles (805 kilometers) of operation. For breakin procedure, refer to paragraph 2-9.

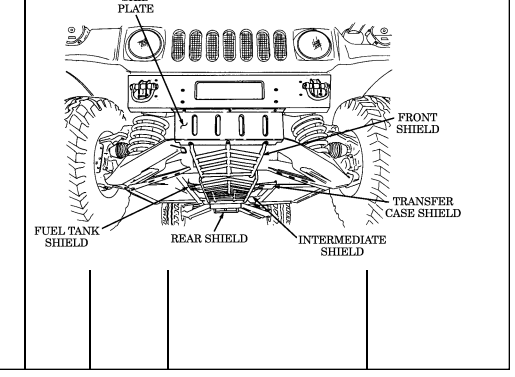

Section Ii. Equipment Description 1-7. Equipment Characteristics, Capabilities, And Features

The 1-1/4 ton, 4x4, M998 series vehicles are tactical vehicles designed for use over all types of roads, as well as cross-country terrain in all weather conditions. The vehicles have four driving wheels powered by a V-8 liquid-cooled diesel engine. Four-wheel hydraulic service brakes and a mechanical parking brake are common to all models in the M998 series. All vehicles are equipped with a pintle hook for towing. Tiedown and lifting eyes are provided for air, rail, or sea shipment.

1-8. Metric System

The equipment/system described herein contains metric components and requires metric, common, and special tools; therefore, metric units in addition to standard units will be used throughout this publication. In addition, a metric conversion table is located on the inside back cover of this publication.

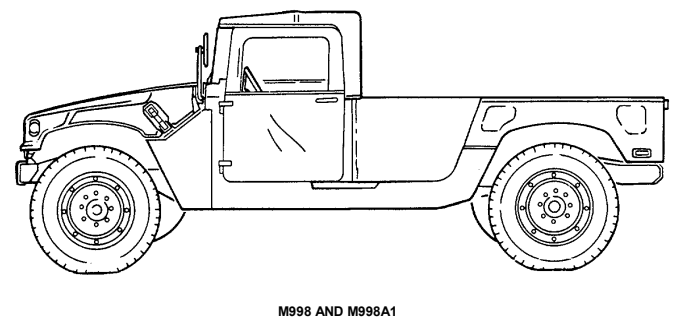

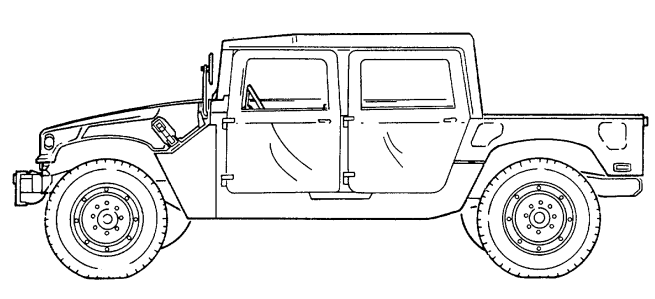

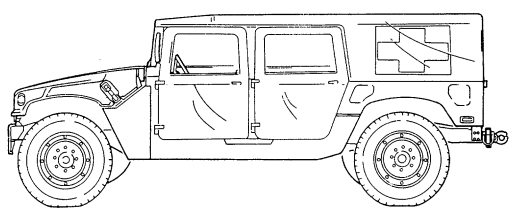

1-9. Cargo/Troop Carriers

(M998, M998A1, M1038, And M1038A1)

a. Differences. The only difference between the M998 and M998A1 cargo/troop carriers and the M1038 and M1038A1 cargo/troop carriers is that the M998 and M998A1 do not have winches and the M1038 and M1038A1 do. This difference affects: •Vehicle Length •Vehicle Weight •Shipping Dimensions •Approach Angle •Special Winch-Assisted Operations It does not affect the basic purpose, performance, or special limitations of the vehicles.

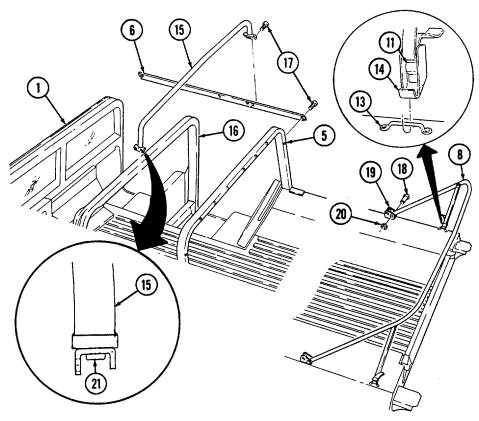

b. Purpose of the Vehicle. M998, M998A1, M1038, and M1038A1 cargo/ troop carriers are used to transport equipment, materials, and/or personnel. The cargo carrier is capable of transporting a payload (including crew) of 2,500 pounds (1,134 kilograms). The troop carrier is capable of transporting a two-man crew and eight passengers. Both use a troop seat kit for troop transport operations. The cargo/troop carrier also has a four-man crew configuration. The M1038 and M1038A1 are equipped with winches. This feature permits recovery operations of similar vehicles.

c. Performance. Fully-loaded M998, M998A1, M1038, and M1038A1 cargo/ troop carriers will climb road grades as steep as 60% (31°) and traverse a side slope of up to 40% (22°). The vehicle fords hard bottom water crossing up to 30 inches (76 centimeters) without a deep water fording kit and 60 inches (152 centimeters) with the kit. Refer to table 1-15 for cruising range.

d. Special Limitations. None. e. Special Instructions in the Manual.

(1) Refer to paragraph 2-2, Controls, Indicators, and Equipment. (2) Refer to paragraph 2-44, Troop Seat Kit Operation. (3) Refer to chapter 2, section V, Cargo/Troop Carrier and S250 Shelter Carrier Operation.

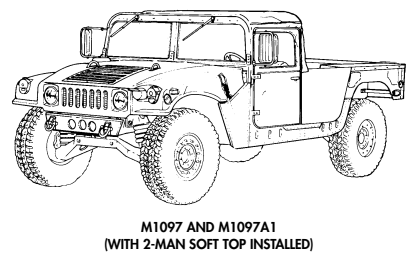

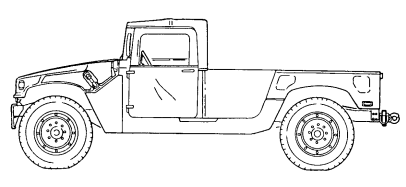

(WITH 2-MAN SOFT TOP INSTALLED) M1038 AND M1038A1 W/WINCH (WITH 4-MAN SOFT TOP INSTALLED) 1-5

1-10. Heavy Variant Cargo/Troop Carriers (M1097, M1097A1, M1097A2, And M1123)

a. Differences. The difference between the M998 and M998A1 cargo/troop carriers and the M1097, M1097A1, M1097A2, and M1123 heavy variant cargo/troop carriers is that the M1097, M1097A1, M1097A2, and M1123 are specifically designed to accommodate a higher payload capacity. The M1123 and A2 models have new bumpers, which make the vehicles slightly longer. A 9,000 lb winch is also available for the M1123 and A2 models as an option. These differences affect:

- Approach Angle - Special Winch-Assisted Operations - Vehicle Length - Vehicle Weight - Shipping Dimensions It does not affect the basic purpose, performance, or special limitations of the vehicles.

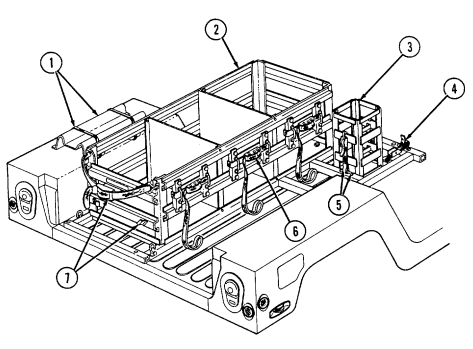

b. Purpose of the Vehicle. M1097, M1097A1, M1097A2, and M1123 heavy variant cargo/troop carriers are used to transport equipment, materials, and/or personnel. The heavy variant troop carrier is capable of transporting a two-man crew and eight passengers. The heavy variant cargo carrier is capable of transporting a payload (including crew) of 4,400 pounds (1,998 kilograms). The M1097, M1097A1, M1097A2, and M1123 use a troop seat kit for troop transport operations, a 200 ampere umbilical power cable to power shelter equipment, and stowage racks for ammunition and equipment. For higher payload capacity, the M1097, M1097A1, M1097A2, and M1123 are equipped with a reinforced frame, crossmembers, lifting shackles, heavy-duty rear springs, shock absorbers, reinforced control arms, heavy-duty tires and rims, and a transfer case and differential with a modified gear ratio.

c. Performance. Fully-loaded M1097, M1097A1, M1097A2, and M11 2 3 heavy variant cargo/troop carriers will climb road grades as steep as 60% (31°) and traverse a side slope of up to 40% (22°). The vehicle fords hard bottom water crossing up to 30 inches (76 centimeters) without a deep water fording kit and 60 inches (152 centimeters) with the kit. Refer to table 1-15 for cruising range.

d. Special Limitations. None.

e. Special Instructions in the Manual.

(1) Refer to paragraph 2-2, Controls, Indicators, and Equipment. (2) Refer to paragraph 2-44, Troop Seat Kit Operation. (3) Refer to chapter 2, section V, Cargo/Troop Carrier and S250 Shelter Carrier Operation (if equipped).

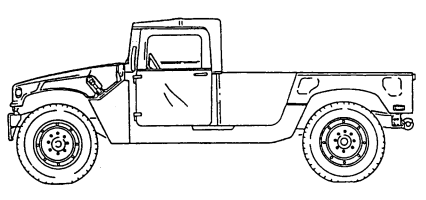

M1097A2

M1123 Change 1 1-7

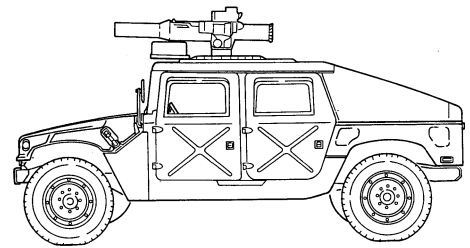

1-11. Tow Carriers, Armored (M966, M966A1, M1036, And M1121)

a. Differences. The only difference between the M966, M966A1, and M1121 TOW carrier armored vehicles and the M1036 TOW carrier armored vehicle is that the M966, M966A1, and M1121 do not have winches and the M1036 does. This difference affects:

- Vehicle Length - Vehicle Weight - Shipping Dimensions - Approach Angle - Special Winch-Assisted Operations It does not affect the basic purpose, performance, or special limitations of the vehicles.

b. Purpose of the Vehicle. M966, M966A1, M1036, and M1121 TOW carriers are used to mount and operate the TOW missile launcher system with armor protection for crew, TOW system components, and ammunition. The M1036 is equipped with a winch. This feature permits recovery operations of similar vehicles.

c . Performance. Fully-loaded M966, M966A1, M1036, and M1121 T O W carriers will climb road grades as steep as 60% (31°) and traverse a side slope of up to 40% (22°). The vehicles ford hard bottom water crossings up to 30 inches (76 centimeters) without a deep water fording kit and 60 inches (152 centimeters) with the kit. Refer to table 1-15 for cruising range.

d. Special Limitations. Weapon station azimuth is limited to 300° left and right of vehicle centerline when Vehicle Power Conditioner (VPC) cables are connected. With launcher installed, elevation is limited to 20° and depression is limited to 10°.

e. Special Instructions in the Manual.

(1) Refer to paragraph 2-2, Controls, Indicators, and Equipment. (2) Refer to chapter 2, section VI, TOW/Armament Carrier Operation.

1-8 Change 1

M966, M966A1, AND M1121

■

M1036 W/WINCH

Change 1

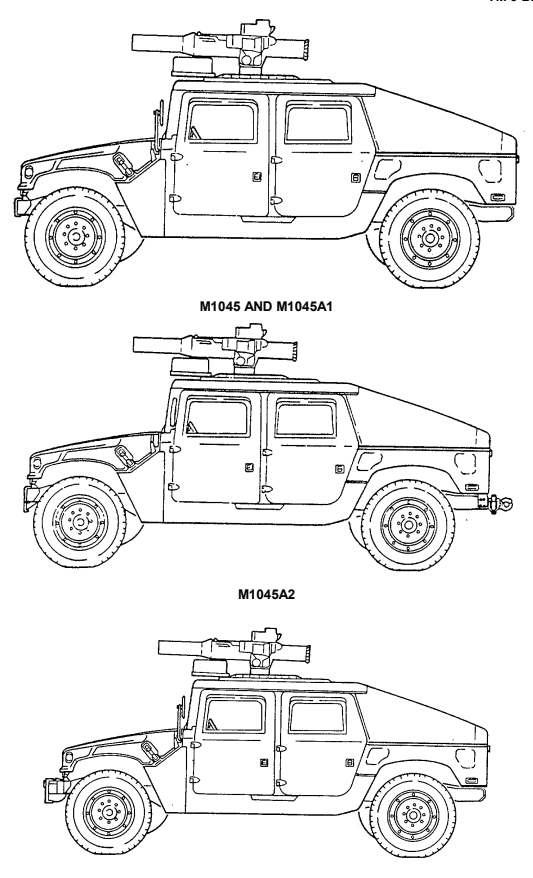

1-12. Tow Carriers, W/Supplemental Armor (M1045, M1045A1, M1045A2, M1046, And M1046A1)

a. Differences. The difference between the M1045, M1045A1, and M1045A2 TOW carriers w/supplemental armor and the M1046 and M1046A1 TOW carriers w/supplemental armor is that the M1045, M1045A1, and M1045A2 do not have winches and the M1046 and M1046A1 do. The A2 models have new bumpers, which make the vehicles slightly longer. A 9,000 lb winch is also available for the A2 models as an option. These differences affect:

- Vehicle Length - Vehicle Weight - Shipping Dimensions

- Approach Angle

- Special Winch-Assisted Operations It does not affect the basic purpose, performance, or special limitations of the vehicles.

b. Purpose of the Vehicle. The M1045, M1045A1, M1045A2, M1046, and M1046A1 provide added ballistic protection for TOW system components, crew, and ammunition. The M1046 and M1046A1 are equipped with winches. This feature permits recovery operations of similar vehicles.

c. Performance. Fully-loaded M1045, M1045A1, M1045A2, M1046, and M1046A1 TOW carriers w/supplemental armor will climb road grades as steep as 60% (3-1°) and traverse a side slope of up to 40% (220). The vehicles ford hard bottom water crossings up to 30 inches (76 centimeters) without a deepwater fording kit and 60 inches (152 centimeters) with the kit. Refer to table 1-15 for cruising range.

d. Special Limitations. Weapon station azimuth is limited to 300° left and right of vehicle centerline when Vehicle Power Conditioner (VPC) cables are connected. With launcher installed, elevation is limited to 20° and depression is limited to 10°.

e. Special Instructions in the Manual. (1) Refer to paragraph 2-2, Controls, Indicators, and Equipment. (2) Refer to chapter 2, section VI, TOW/Armament Carrier Operation.

1-10

M1046 AND M1046A1 W/WINCH

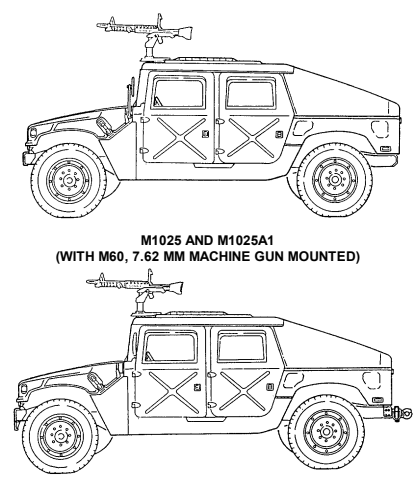

1-13. Armament Carriers, Armored (M1025, M1025A1, M1025A2, M1026, And M1026A1)

a. Differences. The difference between the M1025, M1025A1, and M1025A2 armament carriers and the M1026 and M1026A1 armament carriers is that the M1025 and M1025A1 do not have winches and the M1026 and M1026A1 do. The A2 models have new bumpers, which make the vehicles slightly longer. A 9,000 lb winch is also available for the A2 models as an option. These differences affect:

- Vehicle Length

- Vehicle Weight

- Shipping Dimensions - Approach Angle - Special Winch-Assisted Operations It does not affect the basic purpose, performance, or special limitations of the vehicles.

b. Purpose of the Vehicle. The M1025, M1025A1, M1025A2, M1026, and M1026A1 armament carriers provide mounting and firing of the MK19 automatic grenade launcher; M2, caliber .50 machine gun; and M60, 7.62 mm machine gun; ring-mounted with 360° arc of fire, with armor protection for crew, weapon components, and ammunition. The M1026 and M1026A1 are equipped with winches. This feature permits recovery operations of similar vehicles. c. Performance. Fully-loaded M1025, M1025A1, M1025A2, M1026, and M1026A1 armament carriers will climb road grades as steep as 60% (31°) and traverse a side slope of up to 40% (22°). The vehicles ford hard bottom water crossings up to 30 inches (76 centimeters) without a deep water fording kit and 60 inches (152 centimeters) with the kit. Refer to table 1-15 for cruising range.

d. Special Limitations. None. e. Special Instructions in the Manual. (1) Refer to paragraph 2-2, Controls, Indicators, and Equipment. (2) Refer to chapter 2, section VI, TOW/Armament Carrier Operation.

1-12

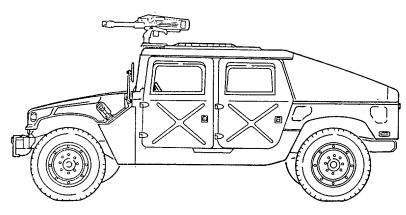

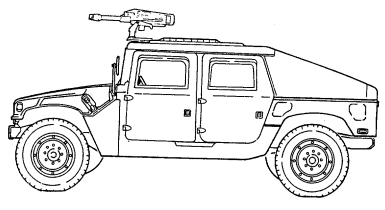

M1025A2 (WITH M60, 7.62 MM MACHINE GUN MOUNTED)

M1026 AND M1026A1 W/WINCH (WITH MK19 GRENADE LAUNCHER MOUNTED)

1-13

1-14. Armament Carriers, W/Supplemental Armor (M1043, M1043A1, M1043A2, M1044, And M1044A1)

a. Differences. The difference between the M1043, M1043A1, and M1043A2 armament carriers w/supplemental armor and M1044 and M1044A1 armament carriers w/supplemental armor is that the M1043, and M1043A1, do not have winches and the M1044 and M1044A1 do. The A2 models have new bumpers which make the vehicles slightly longer. A 9,000 lb winch is also available for the A2 models as an option. These differences affect:

- Vehicle Length

- Vehicle Weight

- Shipping Dimensions - Approach Angle - Special Winch-Assisted Operations It does not affect the basic purpose, performance, or special limitations of the vehicles.

b. Purpose of the Vehicle. The M1043, M1043A1, M1043A2, M1044, and M1044A1 armament carriers w/supplemental armor provide added ballistic protection for armament components, crew, and ammunition. The M1044 and M1044A1 are equipped with winches. This feature permits recovery operations of similar vehicles.

c. Performance. Fully-loaded M1043, M1043A1, M1043A2, M1044, and M1044A1 armament carriers w/supplemental armor will climb road grades as steep as 60% (31°) and traverse a side slope of up to 40% (220). The vehicles ford hard bottom water crossings up to 30 inches (76 centimeters) without a deep-water fording kit and 60 inches (152 centimeters) with the kit. Refer to table 1-15 for cruising range.

d. Special Limitations. None. e. Special Instructions in the Manual.

(1) Refer to paragraph 2-2, Controls, Indicators, and Equipment. (2) Refer to chapter 2, section VI, TOW/Armament Carrier Operation.

1-14

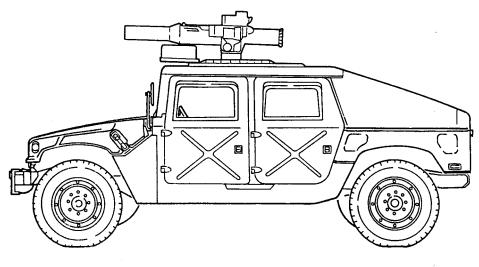

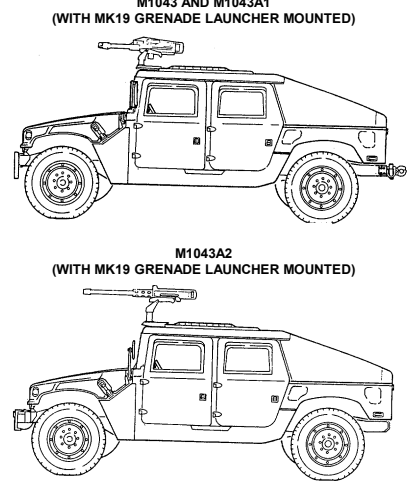

M1043 AND M1043A1

M1044 AND M1044AI W/WINCH (WITH M2, CAUBER .50 MACHINE GUN MOUNTED) 1-15

1-15. S250 Shelter Carriers (M1037 And M1042)

a. Differences. The only difference between the M1037 shelter carrier and the M1042 shelter carrier is that the M1037 does not have a winch and the M1042 does. This difference affects:

- Vehicle Length

- Vehicle Weight - Shipping Dimensions

- Approach Angle - Special Winch-Assisted Operations It does not affect the basic purpose, performance, or special limitations of the vehicles.

b. Purpose of the Vehicle. The M1037 and M1042 shelter carriers provide the capability to secure and transport the S250 electrical equipment shelter with a total payload (including crew) of 3,600 pounds (1,634 kilograms). The M1042 is equipped with a winch. This feature permits recovery operations of similar vehicles.

c. Performance. Fully-loaded M1037 and M1042 shelter carriers will climb road grades as steep as 60% (31°) and traverse a side slope of up to 40% (22°). The vehicles ford hard bottom water crossings up to 30 inches (76 centimeters) without a deepwater fording kit and 60 inches (152 centimeters) with the kit. Refer to table 1-15 for cruising range.

d. Special Limitations. None.

e. Special Instructions in the Manual. (1) Refer to paragraph 2-2, Controls, Indicators, and Equipment. (2) Refer to chapter 2, section V, Cargo/Troop Carrier and S250 Shelter Carrier Operation.

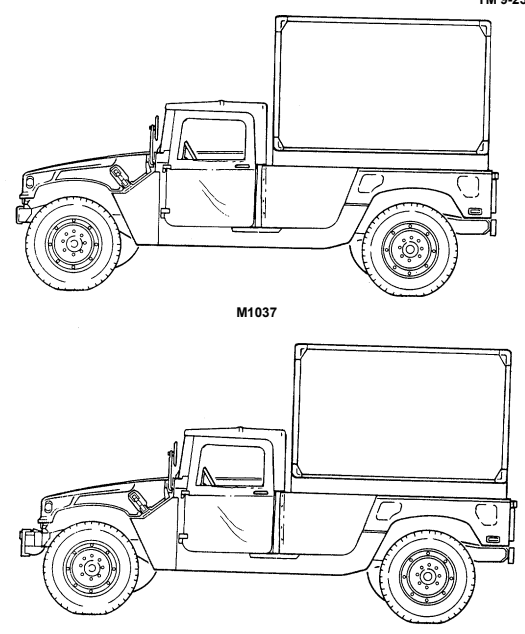

1-16

M1042 W/WINCH 1-17

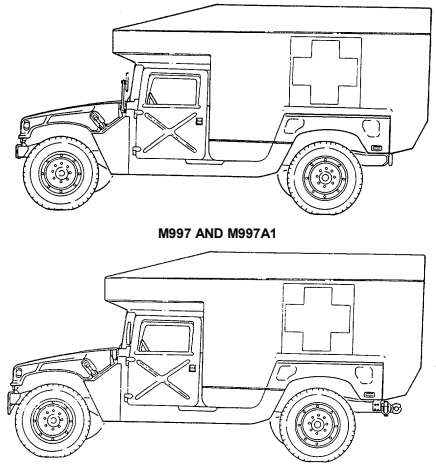

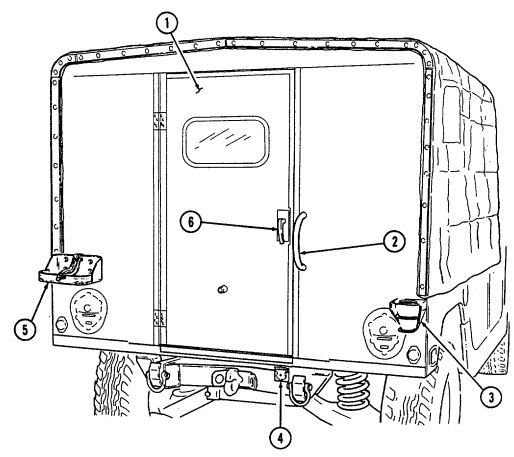

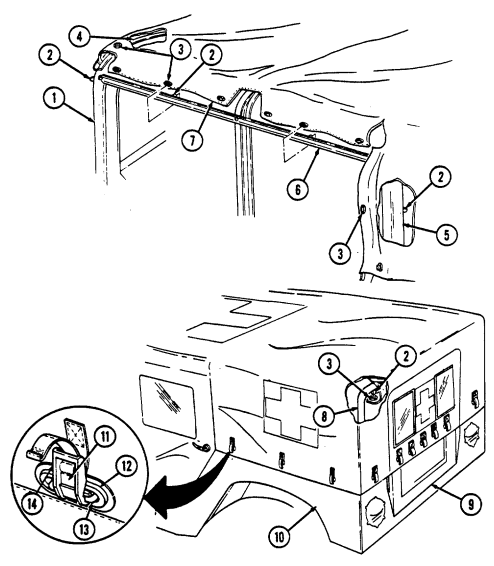

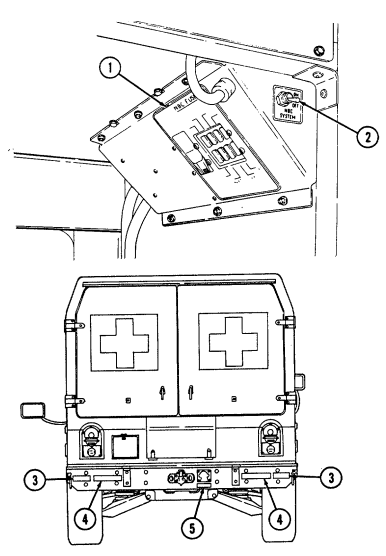

1-16. 2-ULITTER AMBULANCES, ARMORED (M996 AND M996A1); 4-LITTER AMBULANCES, ARMORED (M997, M997A1, AND M997A2) a. Differences. The M996 and M996A1 are armored 2-litter ambulances. The M997, M997A1, and M997A2 are 4-litter ambulances with armor protection and air conditioning for crew and patients. The A2 models have new bumpers, which make the vehicles slightly longer. A 9,000 lb winch is also available for the A2 models as an option. These differences affect:

- Approach Angle - Special Winch-Assisted Operations - Vehicle Length

- Vehicle Weight

- Shipping Dimensions

B. Purpose Of The Vehicle.

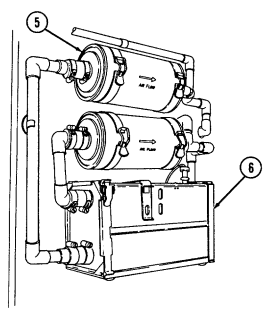

(1) M996 and M996A1 Armored 2-Litter Ambulances. The M996 and M996A1 ambulances are capable of transporting up to two litter patients, six ambulatory patients, or a combination of litter and ambulatory patients. Additionally, medical personnel, equipment, and a driver can be accommodated in the vehicle. The patient compartment is heated with a vehicle-mounted fuel burning heater. For operation in an NBC environment, the M996 and M996A1 are equipped with a Gas-Particulate Filter Unit (GPFU) with heaters capable of supporting up to five personnel equipped with either M25 series protective masks or M13 series patient protective masks. The GPFU forces temperature-controlled, filtered air to the mask facepieces, which increases protection, eases breathing, and reduces stress and heat fatigue during extended periods of NBC operation.

(2) M997, M997A1, and M997A2 Armored 4-Litter Ambulances. The M997, M997A1, and M997A2 ambulances are capable of transporting up to four litter patients, eight ambulatory patients, or a combination of litter and ambulatory patients. Additionally, medical personnel, equipment, and a driver can be accommodated in the vehicle. The ambulance can be heated, ventilated, or air conditioned, depending on environmental conditions. For operation in an NBC environment, the M997, M997A1, and M997A2 are equipped with a Gas- Particulate Filter Unit (GPFU) with heaters capable of supporting up to seven personnel equipped with either M25 series protective masks or M13 series patient protective masks. The GPFU forces temperature-controlled, filtered air to the mask facepieces, which increases protection, eases breathing, and reduces stress and heat fatigue during extended periods of NBC operation.

c. Performance. Fully-loaded M996, M996A1, M997, M997A1, and M997A2 ambulances will climb road grades as steep as 60% (31°) and traverse a side slope of up to 40% (220). The vehicles ford hard bottom water crossings up to 30 inches (76 centimeters) without a deep water fording kit and 60 inches (152 centimeters) with the kit. Refer to table 1-15 for cruising range.

d. Special Limitations. None. e. Special Instructions in the Manual.

(1) Refer to paragraph 2-2, Controls, Indicators, and Equipment. (2) Refer to chapter 2, section VII, Ambulance Operation.

1-18

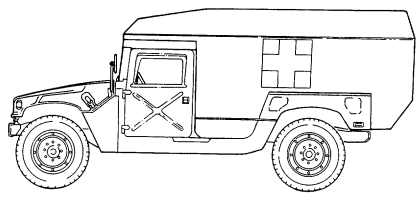

M996 AND M996A1

M997A2 1-19

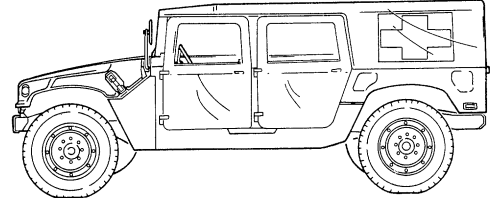

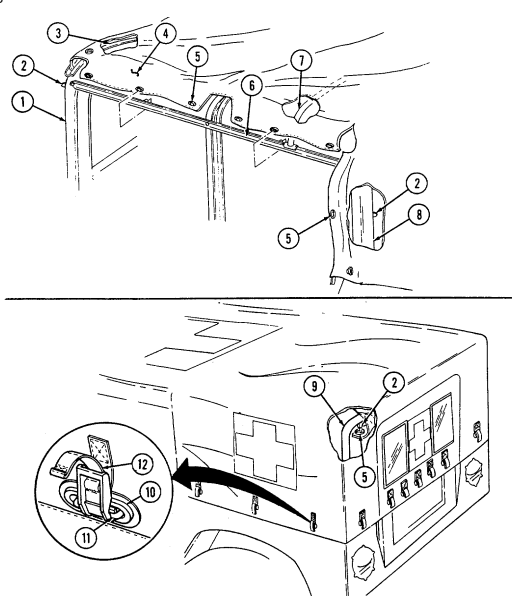

1-17. 2-Litter Ambulances, Soft Top (M1035, M1035A1, And M1035A2)

a. Differences. The difference between the M1035, M1035A1, and M1035A2 2-litter soft top ambulances is that the M1035A2 is longer, due to new bumpers, and can be equipped with an optional 9,000 lb winch. These differences affect:

- Approach Angle

- Special Winch-Assisted Operations

- Vehicle Length - Vehicle Weight - Shipping Dimensions b. Purpose of the Vehicle. The M1035, M1035A1, and M1035A2 ambulances are 2-litter soft tops which have no armor protection for crew and patients.

c. Performance. Fully-loaded M1035,'M1035A1, and M1035A2 ambulances will climb road grades as steep as 60% (31°) and traverse a side slope of up to 40% (22°). The vehicles ford hard bottom water crossings up to 30 inches (76 centimeters) without a deep water fording kit and 60 inches (152 centimeters) with the kit. Refer to table 1-15 for cruising range.

d. Special Limitations. None. e. Special Instructions in the Manual. (1) Refer to paragraph 2-2, Controls, Indicators, and Equipment. (2) Refer to chapter 2, section VII, Ambulance Operation.

1-20

M1035 AND M1035A1

M1035A2 1-21

1-18. Tabulated Data

| Table 1-1. Differences Between Models | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Equipment/Function | ||||||||||||||||

| Personnel/Cargo | x | x | x | |||||||||||||

| Operations | ||||||||||||||||

| TOW Launcher | x | x | x | x | ||||||||||||

| Mounting | ||||||||||||||||

| Armament Mounting | x | x | x | x | ||||||||||||

| S250 Shelter | x | x | x | |||||||||||||

| Configuration | ||||||||||||||||

| Ambulance: | ||||||||||||||||

| Two Litter Patients | x | x | ||||||||||||||

| Four Litter Patients | x | |||||||||||||||

| Eight Ambulatory Patients | x | |||||||||||||||

| Six Ambulatory Patients | x | |||||||||||||||

| Two Litter and Four Ambulatory Patients | x | |||||||||||||||

| One Litter and Three Ambulatory Patients | x | |||||||||||||||

| Vehicle Winch | * | * | x | * | x | x | x | * | x | * | x | * | ||||

| Communications: | ||||||||||||||||

| AN/GRC-160 | x | x | x | x | x | x | x | x | x | x | x | x | ||||

| AN/VRC-12 Series | x | x | ||||||||||||||

| Collective NBC | x | x | ||||||||||||||

| Protection | ||||||||||||||||

| Basic Armor | x | x | x | x | x | x | ||||||||||

| Supplemental Armor | x | x | x | x | ||||||||||||

| Howitzer Prime Mover | x | |||||||||||||||

| * | Identifies an optional winch available for A2 models. |

This paragraph organizes vehicle specifications, special equipment, and model differences in table form for easy reference by operators.

1-22 Change 1

| Table 1-2. Capacities | |||

|---|---|---|---|

| Vehicle | Description | Capacity | |

| Standard | Metric | ||

| All | Cooling system | 26 qt | 24.6 L |

| All | Engine (crankcase only) | 7 qt | 6.6 L |

| All | Engine (crankcase with new filter) | 8 qt | 7.6 L |

| All | Differential (each) | 2 qt | 1.9 L |

| All | Transmission (3L80) | 6 qt | 5.7 L |

| (Except M1123 and A2) | (drain and refill) | ||

| M1123 and A2 Series Vehicles | Transmission (4L80-E) (drain and refill) | 7.7 qt | 7.3 L |

| All (Except M1097, A1, A2, and M1123 | Transfer case (218) | 3.5 qt | 3.3 L |

| Series Vehicles) | |||

| M1097, A1, A2, and M1123 Series Vehicles | Transfer case (242) | 3.35 qt | 3.17 L |

| All | Fuel tank | 25 gal. | 94.6 L |

| All | Steering system | 1 qt | 0.95 L |

| All | Steering system (with steering cooler) | 1.25 qt | 1.18 L |

| All (Except M1097, A1, A2, and M1123 Series Vehicles) | Brake master cylinder | 0.69 pt | 0.33 L |

| M1097, A1, A2, and | Brake master cylinder | 1.12 pt | 0.53 L |

| M1123 Series Vehicles | |||

| All (Except M1097, A1, A2, and M1123 | Total brake system | 1.2 pt | 0.57 L |

| Series Vehicles) | |||

| M1097, A1, A2, and | Total brake system | 1.63 pt | 0.77 L |

| M1123 Series Vehicles | |||

| All | Windshield washer | 1 qt | 0.95 L |

| All | Geared hub | 1 pt | 0.47 L |

| Vehicle | Description | Expected Temperatures | ||

|---|---|---|---|---|

| Above +15° | +40° to -15°F | +40° to -65°F | ||

| (above -9°C) | (+4° to -26°C) | (+4° to -54°C) | ||

| All | Cooling system | 1/4 ethylene | 2/5 ethylene | 3/5 ethylene |

| glycol, | glycol, | glycol, | ||

| 3/4 water | 3/5 water | 2/5 water | ||

| All | Engine | OE/HDO 30 | OE/HDO 10 | OEA |

| All | Fuel tank | DF1, DF2 | DF1 | DF1, DFA* |

| All Temp. Alternate JP-8 | ||||

| All | Differentials | GO 80/90 | GO 80/90 | GO 80/90 |

| All | Geared hubs | GO 80/90 | GO 80/90 | GO 80/90 |

| Transmission | Dexron® II or | Dexron® II or | Dexron® II or | |

| (3L80) | Dexron® III | Dexron® III | Dexron® III | |

| All | Transmission | Dexron® III | Dexron® III | Dexron® III |

| (4L80-E) | ||||

| All | Transfer case | Dexron® II or | Dexron® II or | Dexron® II or |

| Dexron® III | Dexron® III | Dexron® III | ||

| All | Steering system | Dexron® II or | Dexron® II or | Dexron® II or |

| Dexron® III | Dexron® III | Dexron® III | ||

| All | Brake system | Brake Fluid | Brake Fluid | Brake Fluid |

| Silicone (BFS) | Silicone (BFS) | Silicone (BFS) | ||

| All | Windshield | 1/3 cleaning | 1/2 cleaning | 2/3 cleaning |

| washer | compound, | compound, | compound, | |

| reservoir | 2/3 water | 1/2 water | 1/3 water |

Table 1-3. General Service Data Table 1-4. Engine Data (6.2 L)

| Type | 6.2 liter diesel, naturally-aspirated, liquid-cooled |

|---|---|

| Cylinders | 8(V) |

| Brake horsepower | 1 50 horsepower @ 3600 rpm |

| Idle speed (engine rpm) | 650 ± 25 rpm |

| Operating speed (engine rpm) 1500-2300 rpm | |

| Oil pressure at idle | 1 5 psi (103 kPa) |

| Normal operating oil pressure | 40-50 psi (276-345 kPa) |

| Type 6.5 liter diesel, naturally-aspirated, liquid-cooled |

|---|

| Cylinders 8(V) |

| Brake horsepower 1 60 horsepower @ 3400 rpm |

| Idle speed (engine rpm) 700 ± 25 rpm |

| Operating speed (engine rpm) 1500-2300 rpm |

| Oil pressure at idle 1 0 psi (69 kPa) |

| Normal operating oil pressure 40-50 psi (276-345 kPa) |

| Surge tank cap pressure 1 5 psi (103 kPa) |

|---|

| Thermostat: |

| Starts to open 1 90°F (88°C) |

| Fully open 21 2°F (1 00°C) |

| Radiator Downflow type |

| Fan 1 0 blade, 19 inch (48 cm) |

| Normal operating coolant temperature 190°-230°F (88°-110°C) |

Table 1-5. Engine Data (6.5 L) Table 1-6. Cooling System Data Tm 9-2320-280-10

| General Information | |

|---|---|

| Model Turbo Hydra-Matic 3L80 | |

| Type Three-speed automatic | |

| Oil type Dexron® II or Dexron III® | |

| Transmission Range Selection | |

| Recommended Shift Lever Position | Operating Condition |

| "R" (reverse) | Clear of traffic and obstructions, using |

| ground guide. | |

| "N" (neutral) | Vehicle stopped with parking brake applied. |

| "D" (drive) | Normal driving and fording. |

| "2" (second) | Hill climbing and "engine braking" to slow |

| vehicle when descending steep hills. | |

| "1" (first) | Maximum "engine braking" when descending |

| very steep hills, climbing steep hills, or | |

| driving through deep mud, sand, or snow. |

Table 1-7. Transmission Data (3L80)

| General Information | |

|---|---|

| Model Turbo Hydra-Matic 4L80-E | |

| Type Four-speed automatic | |

| Oil type Dexron® III | |

| Transmission Range Selection | |

| Recommended Shift Lever Position | Operating Condition |

| "P" (park) | Vehicle stopped with parking brake applied. |

| "R" (reverse) | Clear of traffic and obstructions, using |

| ground guide. | |

| "N" (neutral) | Vehicle stopped with parking brake applied. |

| " D " (overdrive) | Normal driving and fording. |

| "D" (drive) | Hilly terrain and towing a trailer. |

| "2" (second) | Hill climbing and "engine braking" to slow |

| vehicle when descending steep hills. | |

| "1" (first) | Maximum "engine braking" when descending |

| very steep hills, climbing steep hills, or | |

| driving through deep mud, sand, or snow. |

Table 1-8. Transmission Data (4L80-E)

| General Information |

|---|

| Model New Process Gear 218 (MOD) |

| Type Two-speed, locking, chain driven |

| Oil type Dexron® II |

| CAUTION |

| Damage to drivetrain will occur if transfer case ranges are not selected properly. Refer to paragraph 2- |

| 11, Placing Vehicle in Motion, and paragraph 2-29, Operating on Unusual Terrain, for specific |

| instructions. |

| Transfer Case Range Selection |

| Recommended Shift Lever Position Operating Condition |

| "H" (high range) This drive range shall be selected whenever possible. |

| High range should be used when operating on all |

| primary, secondary, and off-road surfaces, where little |

| or no wheel slippage exists. This range is also to be |

| used when encountering sharp, continuous turns on |

| high traction surfaces. |

| "H/L" (high lock range) This drive range shall be selected only when |

| continuous wheel slippage is evident; i.e., when |

| operating in mud, snow, loose sand, or on ice, and |

| increased control or additional traction is required. |

| "L" (low range) This drive range shall be selected only when high |

| ranges do not provide sufficient power to negotiate |

| steep hills or downgrades. This range shall also be |

| used when the vehicle is mired and cannot be |

| extracted using the high lock range. |

| "N" (neutral) Vehicle is disabled and must be towed. |

| General Information | |

|---|---|

| Model | New Process Gear 242 (MOD) |

| Type | Two-speed, locking, chain driven |

| Oil type | Dexron® II |

| CAUTION | |

| 11 for specific instructions on Placing Vehicle in Motion, and paragraph 2-29, Operating on Unusual | Damage to drivetrain will occur if transfer case ranges are not selected properly. Refer to paragraph 2- |

| Terrain. | |

| Transfer Case Range Selection | |

| Recommended Shift Lever Position | Operating Condition |

| "H" (high range) | This drive range shall be selected whenever possible. |

| High range should be used when operating on all | |

| primary, secondary, and off-road surfaces, where little | |

| or no wheel slippage exists. This range is also to be | |

| used when encountering sharp, continuous turns on | |

| high traction surfaces. | |

| "H/L" (high lock range) This drive range shall be selected for off- highway hilly | |

| terrain or when continuous wheel slippage is evident; | |

| i.e., when operating in mud, snow, loose sand, or on | |

| ice, and increased control or additional traction is | |

| required. | |

| "L" (low range) This drive range shall be selected only when high | |

| ranges do not provide sufficient power to negotiate | |

| steep hills or downgrades. This range shall also be | |

| used when the vehicle is mired and cannot be | |

| extracted using the high lock range. | |

| "N" (neutral) Vehicle is disabled and must be towed. |

Table 1-11. Maximum Vehicle Operating Speeds (3L80 Transmission)

| Transmission | Transfer Case Range Selection | ||

|---|---|---|---|

| Range Selection | "L" Low Range | "H" High Range | "H/L" High Lock Range |

| "R" (reverse) | 11 mph | 29 mph | 11 mph |

| (18 kph) | (47 kph) | (18 kph) | |

| "D" (drive) | 27 mph | 55 mph | 55 mph |

| (43 kph) | (88 kph) | (88 kph) | |

| "2" (second) | 19 mph | 48 mph | 48 mph |

| (31 kph) | (77 kph) | (77 kph) | |

| "1" (first) | 11 mph | 29 mph | 29 mp |

| (18 kph) | (47 kph) | (47 kph) |

| Transmission | Transfer Case Range Selection | ||

|---|---|---|---|

| Range Selection | "L" Low Range | "H" High Range | "H/L" High Lock Range |

| "R" (reverse) | 11 mph | 29 mph | 11 mph |

| (18 kph) | (47 kph) | (18 kph) | |

| " D " (overdrive) | 27 mph | 55 mph | 55 mph |

| (43 kph) | (88 kph) | (88 kph) | |

| "D" (drive) | 27 mph | 55 mph | 55 mph |

| (43 kph) | (88 kph) | (88 kph) | |

| "2" (second) | 19 mph | 48 mph | 48 mph |

| (31 kph) | (77 kph) | (77 kph) | |

| "1" (first) | 11 mph | 29 mph | 29 mph |

| (18 kph) | (47 kph) | (47 kph) |

Table 1-12. Maximum Vehicle Operating Speeds (4L80-E Transmission)

Tm 9-2320-280-10

| Table 1-13. | Vehicle Dimensions (All except M1123 and A2 Vehicles) | |||||

|---|---|---|---|---|---|---|

| Length Overall | Height Overall* | Height Minimum Reducible | ||||

| Vehicle | Inches | Centimeters | Inches | Centimeters | Inches | Centimeters |

| M966/M966A1 | 180 | 457 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M996/M996A1 | 202 | 513 | 86 | 218 | 77 | 196 |

| M997/M997A1 | 202 | 513 | 102 | 259 | 102 | 259 |

| M998/M998A1 | 180 | 457 | 69 | 175 | 55 | 140 |

| M1025/M1025A1 | 180 | 457 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M1026/M1026A1 | 185 | 470 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M1035/M1035A1 | 180 | 457 | 69 | 175 | 55 | 140 |

| M1036 | 185 | 470 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M1037 | 189 | 480 | 69 | 175 | 55 | 140 |

| M1038/M1038A1 | 185 | 470 | 69 | 175 | 55 | 140 |

| M1042 | 185 | 470 | 69 | 175 | 55 | 140 |

| M1043/M1043A1 | 180 | 457 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M1044/M1044A1 | 185 | 470 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M1045/M1045A1 | 180 | 457 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M1046/M1046A1 | 185 | 470 | 73 | 185 | 71 | 180 |

| M1097/M1097A1 | 180 | 457 | 69** | 175 | 55 | 140 |

| M1121 | 180 | 457 | 73 | 185 | 71 | 180 |

| Width Overall | Ground Clearance | |||||

| Under Axle | Under Chassis | |||||

| Vehicle | Inches | Centimeters | Inches | Centimeters | Inches | Centimeters |

| All | 85 | 216 | 16 | 41 | 24 | 61 |

- Height covers basic vehicle only. ** Height when weapon station is removed.

Tm 9-2320-280-10

| Table 1-14. | Vehicle Dimensions | (M1123 and A2 Vehicles) | ||||

|---|---|---|---|---|---|---|

| Vehicle | Length Overall | Height Overall* | Height | |||

| Minimum Reducible | ||||||

| Inches Centimeters | Inches Centimeters | Inches | Centimeters | |||

| M997A2 | 204.5 | 519.5 | 102 | 259 | 102 | 259 |

| M1025A2 | 190.5 | 483.9 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M1035A2 | 190.5 | 483.9 | 69 | 175 | 55 | 140 |

| M1043A2 | 190.5 | 483.9 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M1045A2 | 190.5 | 483.9 | 73 | 185 | 71 | 180 |

| 69** | 175 | |||||

| M1097A2 | 190.5 | 483.9 | 69 | 175 | 55 | 140 |

| M1123 | 182.5 | 463.6 | 69 | 175 | 55 | 140 |

| Width Overall | Ground Clearance | |||||

| Under Axle | Under Chassis | |||||

| Vehicle | Inches Centimeters | Inches Centimeters | Inches | Centimeters | ||

| All | 85 | 216 | 16 | 41 | 24 | 61 |

- Height covers basic vehicle only. ** Height when weapon station is removed.

Tm 9-2320-280-10

Table 1-15. Vehicle Cruising Range

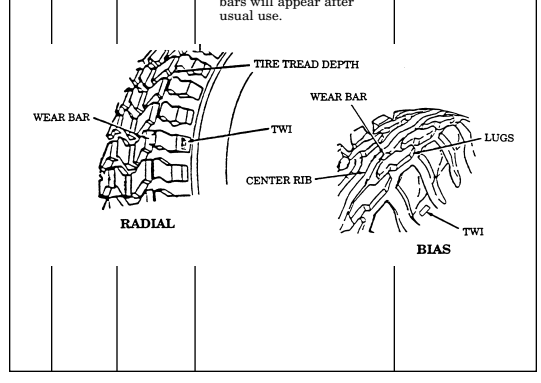

When vehicle is driven on hard surface and hilly terrain at a speed of 30-40 mph (48-64 kph), the ranges shown in this table can be expected when using bias ply tires. Cruising range may increase by approximately 30 miles (48 km) when using radial tires.

| Vehicles | Gross Vehicle Weight (GVW) | Cruising Range |

|---|---|---|

| M998, M1035, M1038 | 7,700 lb (3,496 kg) | 337 mi (542 km) |

| M966, M1025, M1026, M1036, M1121 | 8,200 lb (3,723 kg) | 320 mi (515 km) |

| M1043, M1044, M1045, | 8,400 lb (3,814 kg) | 312 mi (502 km) |

| M1046 | ||

| M996, M1037, M1042 | 8,660 lb (3,932 kg) | 300 mi (483 km) |

| M997 | 9,100 lb (4,131 kg) | 275 mi (442 km) |

| M1097 | 10,000 lb (4,540 kg) | 275 mi (442 km) |

| M998A1, M1035A1, M1038A1 | 7,880 lb (3,578 kg) | 337 mi (542 km) |

| M966A1, M1025A1, | 8,380 lb (3,805 kg) | 320 mi (515 km) |

| M1026A1 | ||

| M1043A1, M1044A1, | 8,580 lb (3,895 kg) | 312 mi (502 km) |

| M1045A1, M1046A1 | ||

| M996A1 | 8,840 lb (4,013 kg) | 300 mi (483 km) |

| M997A1 | 9,280 lb (4,213 kg) | 275 mi (442 km) |

| M1097A1 | 10,000 lb (4,540 kg) | 275 mi (442 km) |

| M1035A2 | 10,300 lb (4,676 kg) | 337 mi (542 km) |

| M1025A2 | 10,300 lb (4,676 kg) | 320 mi (515 km) |

| M1043A2, M1045A2 | 10,300 lb (4,676 kg) | 312 mi (502 km) |

| M997A2 | 9,280 lb (4,213 kg) | 275 mi (442 km) |

| M1097A2, M1123 | 10,300 lb (4,676 kg) | 275 mi (442 km) |

| NOTE |

|---|

TM 9-2320-280-10

| Capacities | |||

|---|---|---|---|

| Vehicle | Description | Standard | Metric |

| M1026, M1036, | Max. Load | 3,360 lb | 1,525 kg |

| M1038, M1042, | (Fifth Layer) | ||

| M1044, M0146, | Max. Load | 3,780 lb | 1,716 kg |

| M1026A1, | (Fourth Layer) | ||

| M1038A1, | |||

| M1044A1, M1046A1 | Max. Load | 4,310 lb | 1,957 kg |

| (Third Layer) | |||

| Max. Load | 5,020 lb | 2,279 kg | |

| (Second Layer) | |||

| Max. Load | 6,000 lb | 2,724 kg | |

| (First Layer) |

| Table 1-17. 9,000 lb Winch Data (Optional) | |||

|---|---|---|---|

| Capacities | |||

| Vehicle | Description | Standard | Metric |

| M1097A2, M1025A2, | Max. Load | 6,200 lb | 2,815 kg |

| M1043A2, M1123, | (Fifth Layer) | ||

| M1045A2, | Max. Load | 7,000 lb | 3,178 kg |

| M997A2, | (Fourth Layer) | ||

| M1035A2 | |||

| Max. Load | 8,000 lb | 3,632 kg | |

| (Third Layer) | |||

| Max. Load | 8,500 lb | 3,859 kg | |

| (Second Layer) | |||

| Max. Load | 9,000 lb | 4,086 kg | |

| (First Layer) |

| Capacities | |||

|---|---|---|---|

| Vehicle | Description | Standard | Metric |

| Min. Load | 4,700 lb | 2,134 kg | |

| All vehicles except | Max. Load | 5,200 lb | 2,361 kg |

| M966, M996, M997, | (Fifth Layer) | ||

| M1035, M1121, | Min. Load | 5,600 lb | 2,542 kg |

| M966A1, M996A1, | |||

| M997A1, M1035A1, | Max. Load | 6,000 lb | 2,724 kg |

| M997A2, M1035A2 | (Fourth Layer) | ||

| Min. Load | 6,800 lb | 3,087 kg | |

| Max. Load | 8,500 lb | 3,859 kg | |

| (Third Layer) | |||

| Min. Load | 8,700 lb | 3,950 kg | |

| Max Load | 9,600 lb | 4,358 kg | |

| (Second Layer) | |||

| Min. Load | 9,620 lb | 4,367 kg | |

| Max. Load | 10,500 lb | 4,767 kg | |

| (First Layer) |

Table 1-16. 6,000 lb Winch Data

Table 1-17.1. 10,500 lb Winch Data (Optional)

Tm 9-2320-280-10

| Table 1-18. Curb Weight | |||

|---|---|---|---|

| Vehicle | Curb Weight | Vehicle | Curb Weight |

| M998 | 5,200 lb (2,361 kg) | M997 | 7,180 lb (3,260 kg) |

| M1038 | 5,327 lb (2,418 kg) | M1045 | 6,438 lb (2,923 kg) |

| M966 | 6,051 lb (2,747 kg) | M1046 | 6,565 lb (2,981 kg) |

| M1025 | 5,960 lb (2,706 kg) | M1043 | 6,411 lb (2,911 kg) |

| M1026 | 6,087 lb (2,763 kg) | M1044 | 6,538 lb (2,968 kg) |

| M1037 | 5,425 lb (2,463 kg) | M1035 | 5,297 lb (2,405 kg) |

| M996 | 6,748 lb (3,064 kg) | M1042 | 5,551 lb (2,520 kg) |

| M1036 | 6,178 lb (2,805 kg) | M1097 | 5,600 lb (2,542 kg) |

| M998A1 | 5,380 lb (2,443 kg) | M997A1 | 7,360 lb (3,341 kg) |

| M1038A1 | 5,507 lb (2,500 kg) | M1045A1 | 6,618 lb (3,005 kg) |

| M966A1 | 6,231 lb (2,829 kg) | M1046A1 | 6,745 lb (3,062 kg) |

| M1025A1 | 6,140 lb (2,788 kg) | M1043A1 | 6,591 lb (2,992 kg) |

| M1026A1 | 6,267 lb (2,845 kg) | M1044A1 | 6,718 lb (3,050 kg) |

| M996A1 | 6,928 lb (3,145 kg) | M1035A1 | 5,477 lb (2,487 kg) |

| M1097A1 | 5,600 lb (2,542 kg) | M1025A2 | 6,780 lb (3,078 kg) |

| M1045A2 | 7,258 lb (3,295 kg) | M1043A2 | 7,230 lb (3,282 kg) |

| M1097A2 | 5,900 lb (2,679 kg) | M1035A2 | 6,100 lb (2,769 kg) |

| M997A2 | 7,660 lb (3,478 kg) | M1121 | 6,051 lb (2,747kg) |

| M1123 | 5,900 lb (2,679 kg) |

Refer to FM 5-36 for information on trailer weights.

| Loaded | |||

|---|---|---|---|

| Model | Empty | Cross-Country | Highway |

| M966, M966A1, M996, M996A1, M997, | 3 | 4 | 4 |

| M997A1, M997A2, M998, M998A1, M1025, | |||

| M1025A1, M1025A2, M1026, M1026A1, | |||

| M1036, M1044, M1044A1, M1045, M1045A1, | |||

| M1045A2, M1046, M1046A1, M1121 | |||

| M1035, M1035A1, M1035A2 | 2 | 3 | 3 |

| M1037, M1038, M1038A1, M1042, M1043, | 2 | 4 | 4 |

| M1043A1, M1043A2, M1097, M1097A1, | |||

| M1097A2, M1123 |

Table 1-19. Vehicle Bridge Classification

| Less Payload and Crew | GVW | |||||

|---|---|---|---|---|---|---|

| Front | Rear | Front | Rear | |||

| Axle | Axle | Total | Axle | Axle | Total | |

| lbs. | lbs. | lbs. | lbs. | lbs. | lbs. | |

| Vehicle | (kgs) | (kgs) | (kgs) | (kgs) | (kgs) | (kgs) |

| M966 | 3,111 | 2,940 | 6,051 | 3,550 | 4,650 | 8,200 |

| (1,412) | (1,335) | (2,747) | (1,612) | (2,111) | (3,723) | |

| M966A1 | 3,191 | 3,040 | 6,231 | 3,628 | 4,752 | 8,380 |

| (1,449) | (1,380) | (2,829) | (1,647) | (2,157) | (3,805) | |

| M996 | 3,063 | 3,685 | 6,748 | 3,673 | 4,987 | 8,660 |

| (1,391) | (1,673) | (3,064) | (1,667) | (2,264) | (3,932) | |

| M996A1 | 3,143 | 3,785 | 6,928 | 3,750 | 5,090 | 8,840 |

| (1,427) | (1,718) | (3,145) | (1,703) | (2,311) | (4,013) | |

| M997 | 3,253 | 3,945 | 7,180 | 3,860 | 5,240 | 9,100 |

| (1,477) | (1,791) | (3,260) | (1,752) | (2,379) | (4,131) | |

| M997A1 | 3,315 | 4,045 | 7,360 | 3,936 | 5,344 | 9,280 |

| (1,505) | (1,836) | (3,341) | (1,787) | (2,426) | (4,213) | |

| M997A2 | 3,565 | 4,205 | 7,770 | N/A | N/A | 10,300 |

| (1,619) | (1,909) | (3,528) | (4,676) | |||

| M998 | 2,900 | 2,300 | 5,200 | 3,350 | 4,350 | 7,700 |

| (1,317) | (1,044) | (2,361) | (1,521) | (1,975) | (3,495) | |

| M998A1 | 2,980 | 2,400 | 5,380 | 3,429 | 4,451 | 7,880 |

| (1,353) | (1,089) | (2,443) | (1,557) | (2,021) | (3,578) | |

| M1025 | 3,122 | 2,848 | 5,960 | 3,685 | 4,515 | 8,200 |

| (1,417) | (1,293) | (2,706) | (1,673) | (2,050) | (3,723) | |

| M1025A1 | 3,192 | 2,948 | 6,140 | 3,766 | 4,614 | 8,380 |

| (1,449) | (1,338) | (2,788) | (1,710) | (2,095) | (3,805) | |

| M1025A2 | 3,350 | 3,430 | 6,780 | N/A | N/A | 10,300 |

| (1,521) | (1,557) | (3,078) | (4,676) | |||

| M1026 | 3,259 | 2,828 | 6,087 | 3,840 | 4,360 | 8,200 |

| (1,480) | (1,284) | (2,763) | (1,743) | (1,979) | (3,723) | |

| M1026A1 | 3,339 | 2,928 | 6,267 | 3,925 | 4,435 | 8,380 |

| (1,516) | (1,329) | (2,847) | (1,782) | (2,013) | (3,805) | |

| M1035 | 2,890 | 2,407 | 5,297 | 3,350 | 4,350 | 7,700 |

| (1,312) | (1,092) | (2,405) | (1,521) | (1,975) | (3,496) | |

| M1035A1 | 2,970 | 2,507 | 5,477 | 3,429 | 4,451 | 7,880 |

| (1,349) | (1,138) | (2,487) | (1,557) | (2,021) | (3,578) | |

| M1035A2 | 3,330 | 2,770 | 6,100 | N/A | N/A | 10,300 |

| (1,512) | (1,258) | (2,769) | (4,676) | |||

| M1036 | 3,253 | 2,925 | 6,178 | 3,700 | 4,500 | 8,200 |

| (1,477) | (1,328) | (2,805) | (1,680) | (2,043) | (3,723) | |

| M1037 | 2,720 | 2,480 | 5,200 | 3,362 | 5,298 | 8,660 |

| (1,235) | (1,126) | (2,360) | (1,526) | (2,405) | (3,932) | |

| M1038 | 3,052 | 2,275 | 5,327 | 3,400 | 4,300 | 7,700 |

| (1,386) | (1,032) | (2,418) | (1,544) | (1,952) | (3,496) | |

| M1038A1 | 3,132 | 2,375 | 5,507 | 3,480 | 4,400 | 7,880 |

| (1,422) | (1,078) | (2,500) | (1,580) | (1,998) | (3,578) | |

| M1042 | 2,866 | 2,454 | 5,320 | 3,387 | 5,273 | 8,660 |

| (1,301) | (1,114) | (2,415) | (1,538) | (2,394) | (3,932) |

Table 1-20. Axle Weights.

Change 3 1-35

TM 9-2320-280-10

| Table 1-20. Axle Weights (Cont'd). | ||||||

|---|---|---|---|---|---|---|

| Less Payload and Crew | GVW | |||||

| Front Axle | Rear Axle | Total | Front Axle | Rear Axle | Total | |

| lbs. | lbs. | lbs. | lbs. | lbs. | lbs. | |

| Vehicle | (kgs) | (kgs) | (kgs) | (kgs) | (kgs) | (kgs) |

| M1043 | 3,300 | 3,111 | 6,411 | 3,961 | 4,439 | 8,400 |

| (1,498) | (1,412) | (2,911) | (1,798) | (2,015) | (3,814) | |

| M1043A1 | 3,380 | 3,211 | 6,591 | 4,045 | 4,535 | 8,580 |

| (1,535) | (1,458) | (2,993) | (1,836) | (2,059) | (2,895) | |

| M1043A2 | 3,680 | 3,530 | 7,210 | N/A | N/A | 10,300 |

| (1,671) | (1,603) | (3,273) | (4,676) | |||

| M1044 | 3,445 | 3,093 | 6,538 | 4,092 | 4,308 | 8,400 |

| (1,564) | (1,404) | (2,968) | (1,858) | (1,956) | (3,814) | |

| M1044A1 | 3,525 | 3,193 | 6,718 | 4,180 | 4,400 | 8,580 |

| (1,600) | (1,450) | (3,050) | (1,898) | (1,998) | (3,895) | |

| M1045 | 3,265 | 3,173 | 6,438 | 3,725 | 4,675 | 8,400 |

| (1,482) | (1,441) | (2,923) | (1,691) | (2,122) | (3,814) | |

| M1045A1 | 3,346 | 3,272 | 6,618 | 3,805 | 4,775 | 8,580 |

| (1,520) | (1,485) | (3,005) | (1,727) | (2,168) | (3,895) | |

| M1045A2 | 3,679 | 3,585 | 7,264 | N/A | N/A | 10,300 |

| (1,670) | (1,628) | (3,298) | (4,676) | |||

| M1046 | 3,407 | 3,158 | 6,565 | 3,850 | 4,550 | 8,400 |

| (1,547) | (1,434) | (2,981) | (1,748) | (2,066) | (3,814) | |

| M1046A1 | 3,487 | 3,258 | 6,745 | 3,932 | 4,648 | 8,580 |

| (1,583) | (1,479) | (3,062) | (1,785) | (2,110) | (3,895) | |

| M1097 | 2,950 | 2,650 | 5,600 | 3,500 | 6,500 | 10,000 |

| (1,339) | (1,203) | (2,542) | (1,589) | (2,951) | (4,540) | |

| M1097A1 | 2,950 | 2,650 | 5,600 | 3,500 | 6,500 | 10,000 |

| (1,339) | (1,203) | (2,542) | (1,589) | (2,951) | (4,540) | |

| M1097A2 | 3,160 | 2,740 | 5,900 | N/A | N/A | 10,300 |

| (1,435) | (1,244) | (2,679) | (4,676) | |||

| M1121 | 3,111 | 2,940 | 6,051 | 3,550 | 4,650 | 8,200 |

| (1,412) | (1,335) | (2,747) | (1,612) | (2,111) | (3,723) | |

| M1123 | 3,220 | 2,630 | 5,850 | N/A | N/A | 10,300 |

| (1,462) | (1,194) | (2,656) | (4,676) |

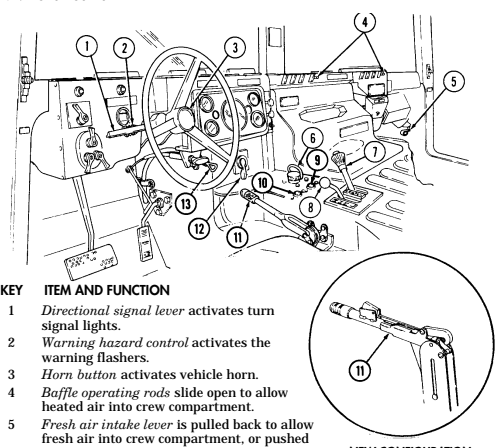

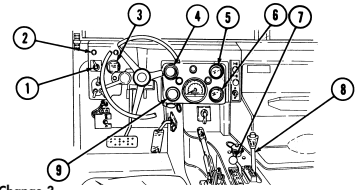

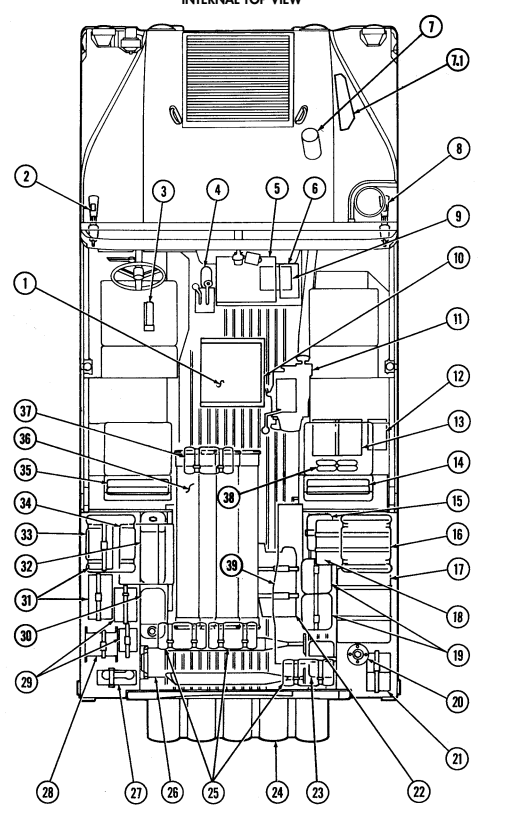

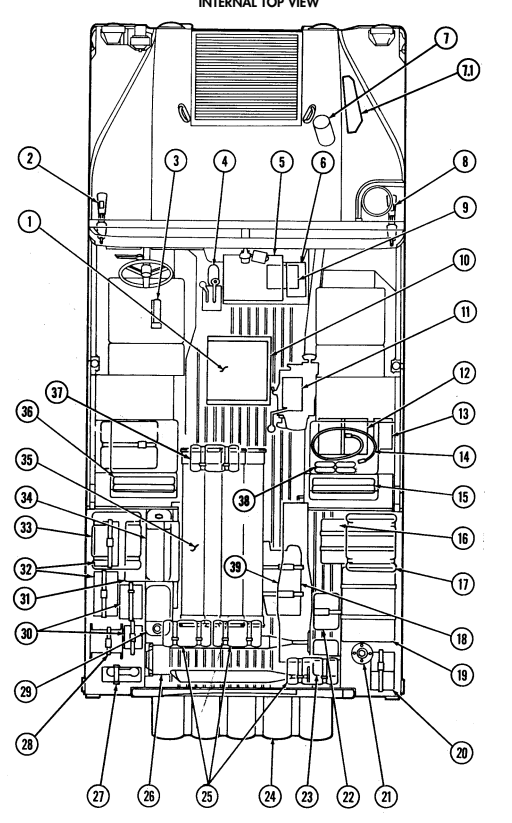

Chapter 2 Operating Instructions Section I. Description And Use Of Operator'S Controls And Indicators

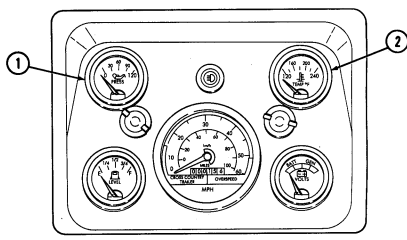

2-1. Know Your Controls And Indicators

Before you attempt to operate your equipment, be sure you are familiar with the location and function of all controls and indicators. The location and function of the controls and indicators are described in this section.

· This vehicle has been designed to operate safely and efficiently within the limits specified in this TM. Operation beyond these limits is prohibited IAW AR 750-1 without written approval from the Commander, U.S. Army Tank-automotive and Armaments Command, ATTN: AMSTA-CM-S, Warren, MI 48397-5000.

· Do not use the hand throttle as an automatic speed or cruise control. The hand throttle does not automatically disengage when brake is applied, resulting in increased stopping distances and possible hazardous and unsafe operation. Injury to personnel or damage to equipment may result.

· Except where noted, the controls and indicators in this section are applicable to all vehicles covered in this manual.

· In this manual, the term "left" indicates the driver side of the vehicle. The term "right" indicates the opposite side of the vehicle.

2-1

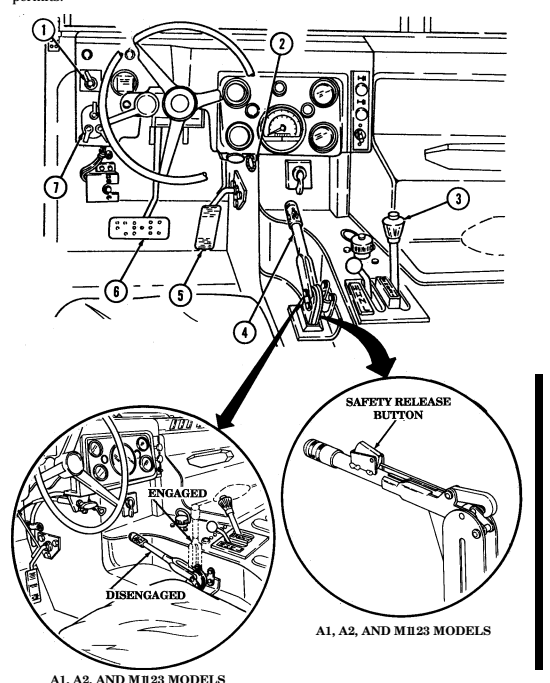

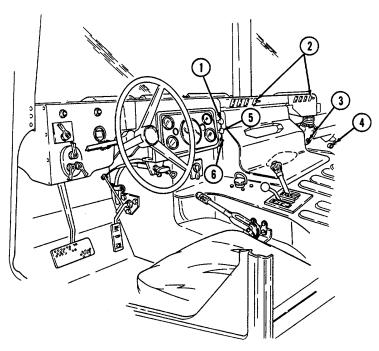

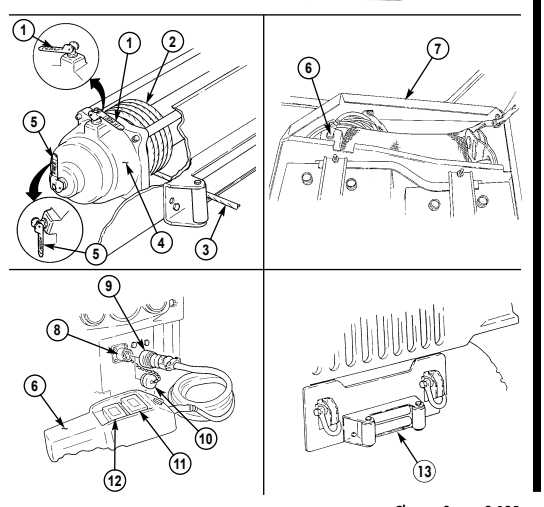

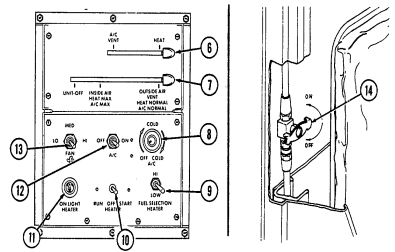

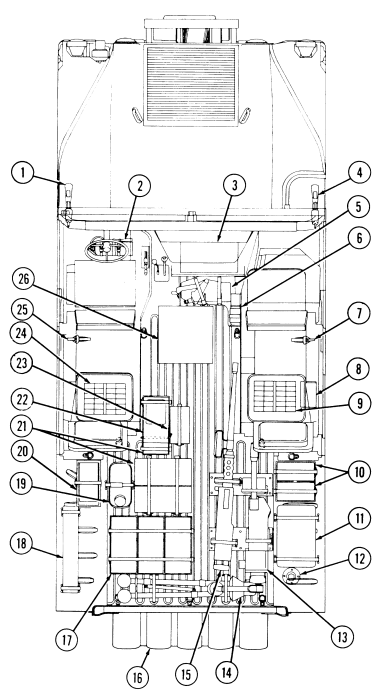

2-2. Controls, Indicators, And Equipment

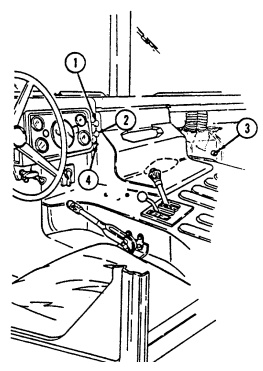

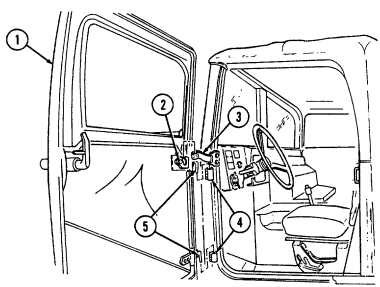

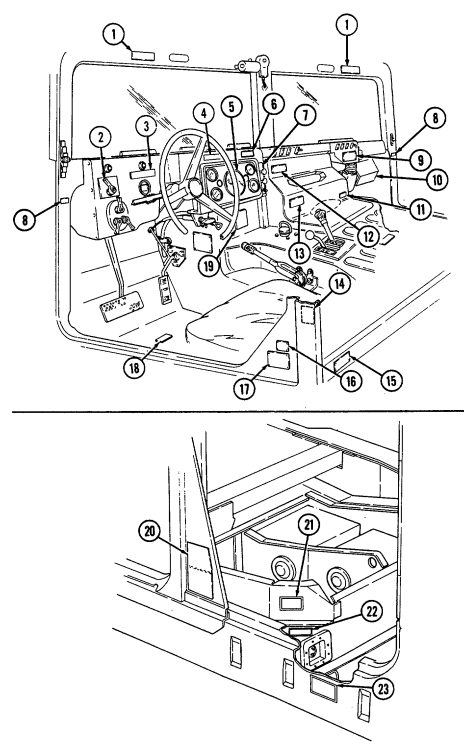

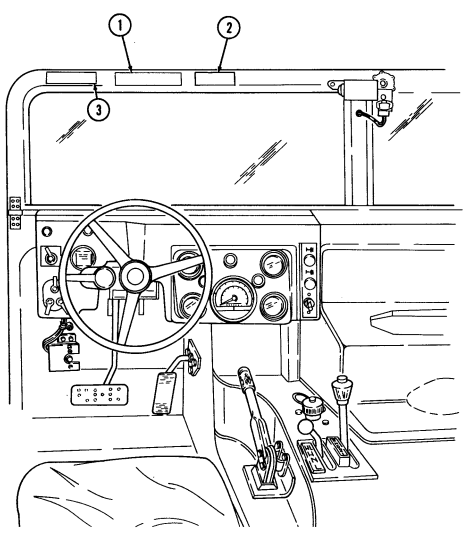

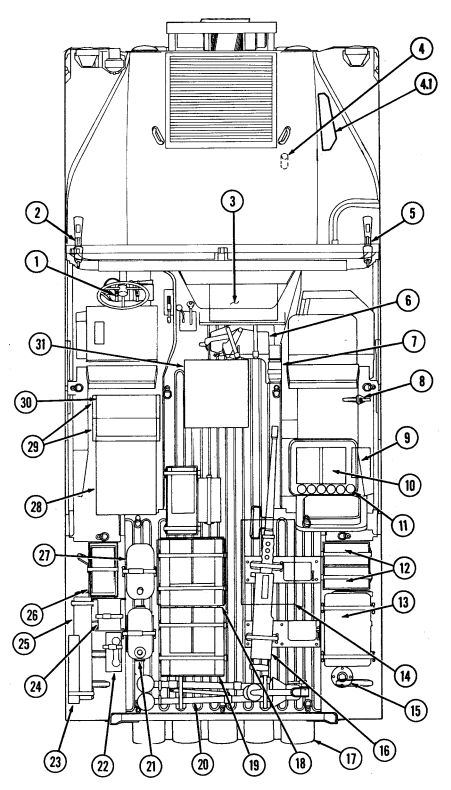

A. Driver'S Compartment.

Key Item And Function

1 Rotary switch has "ENG STOP," 'RUN," and "START." When positioned to "RUN," glow plugs are activated to heat engine precombustion chambers. When positioned to "START," the starter will engage and crank the engine.

2 Wait-to-start lamp assembly illuminates when glow plugs are activated, goes out when engine is ready to be started.

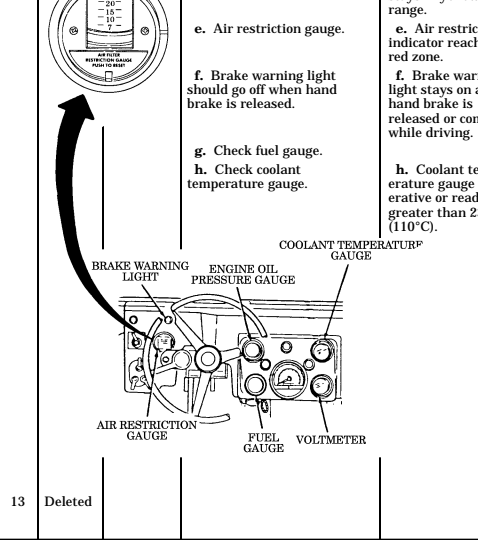

3 Brake warning lamp assembly illuminates if parking brake is applied or if a hydraulic imbalance (leak, etc.) exists between the front and rear brake systems.

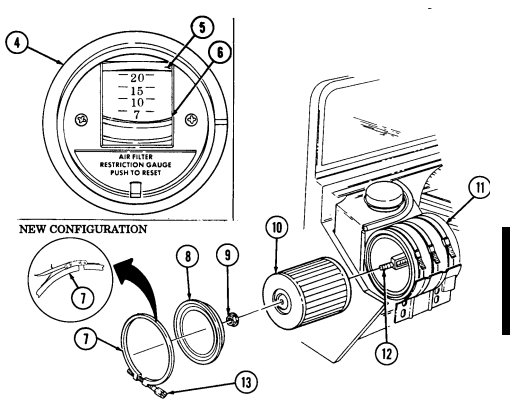

4 Air restriction gauge signals the operator that a restriction exists in the air cleaner.

Key Item And Function

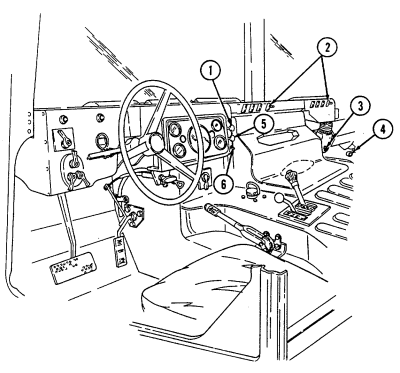

5 Engine oil pressure gauge indicates the oil pressure when the engine is running.

6 High beam lamp assembly illuminates when front headlights are switched to high beam position. 7 Coolant temperature gauge indicates engine coolant temperature.

8 Defroster control knob directs heated air to the windshield for defrosting. 9 Instrument panel lights illuminate instrument panel gauges.

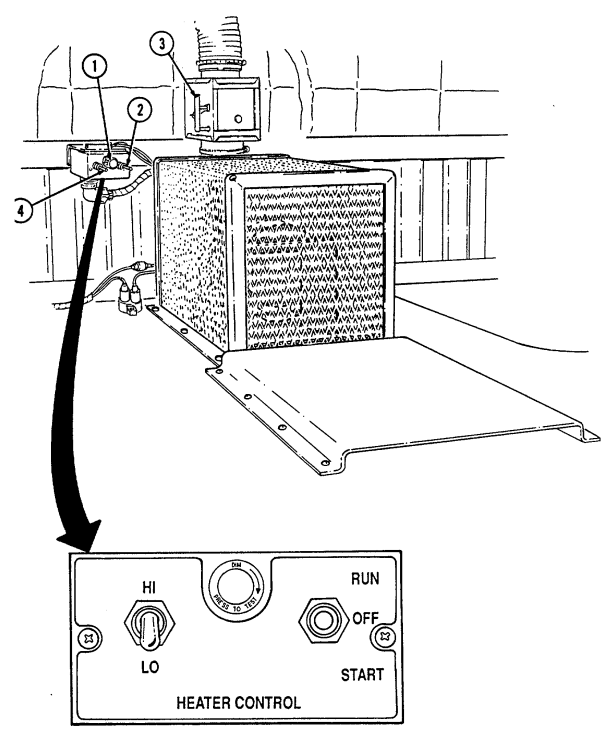

10 Heater control knob varies temperature of heated air into vehicle. 11 Heater fan switch controls the blower motor speed. The switch has "HI" (high), "OFF", and 'LO" (low) settings to regulate defroster and heater air flow into vehicle.

12 Voltmeter indicates the charging level and activity of the battery charging system. 13 Speedometer/odometer indicates vehicle speed and accumulated mileage.

14 Fuel gauge indicates amount of fuel in fuel tank.

15 Hand throttle increases engine speed for use during cold weather starting, winch operation, deep water fording, and to obtain maximum alternator output for communications/electrical requirements, and is not to be used as an automatic speed or cruise control.

16 Accelerator pedal is the operator's foot control for varying engine speed.

17 Service brake pedal is depressed to slow or stop vehicle.

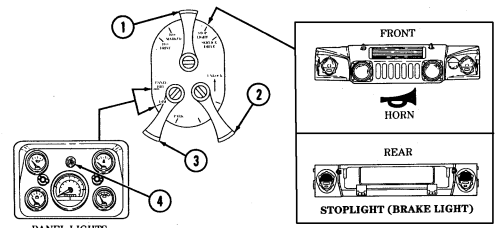

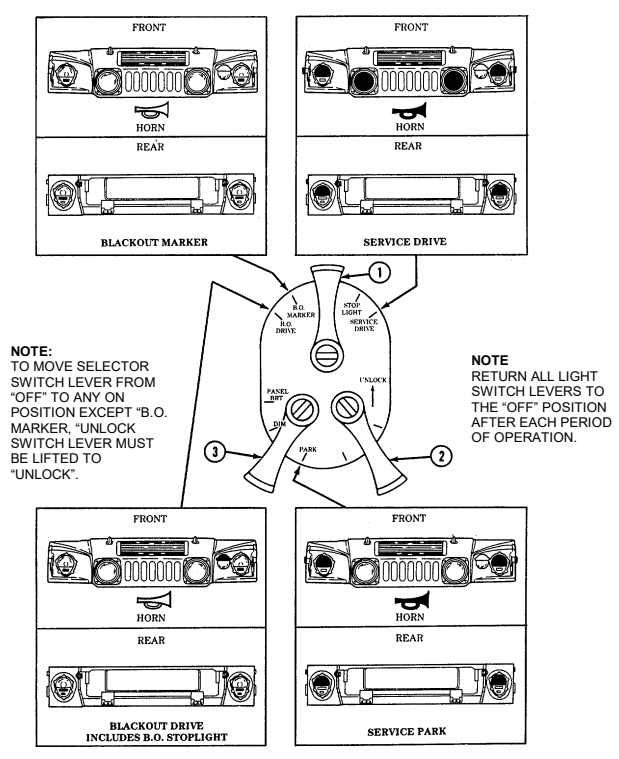

18 Dimmer switch permits the operator to select high or low headlight beam. 19 Light switch controls operation of vehicle service lights and blackout lights. 20 Directional signal /emergency flasher indicator light illuminates during directional signal or emergency flasher use.

forward to close.

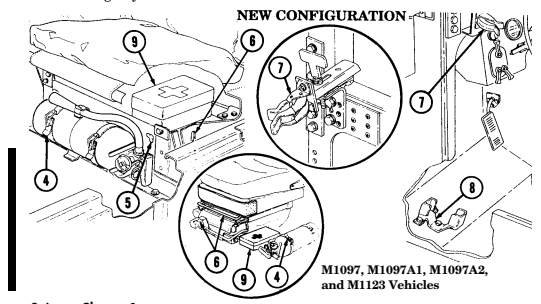

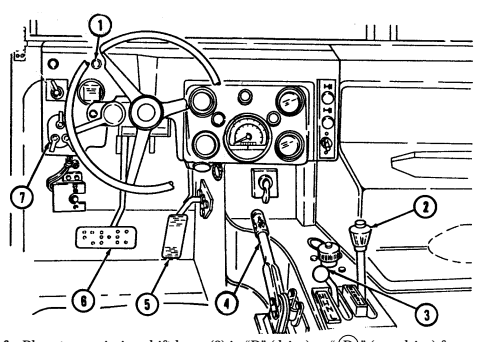

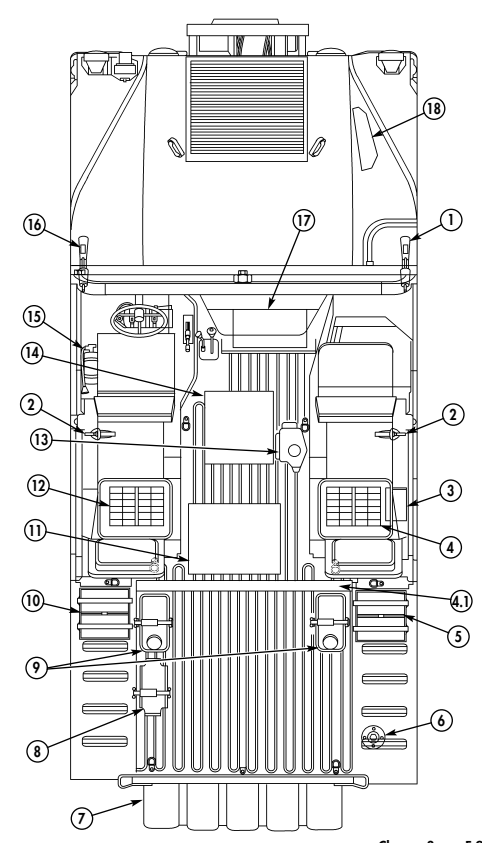

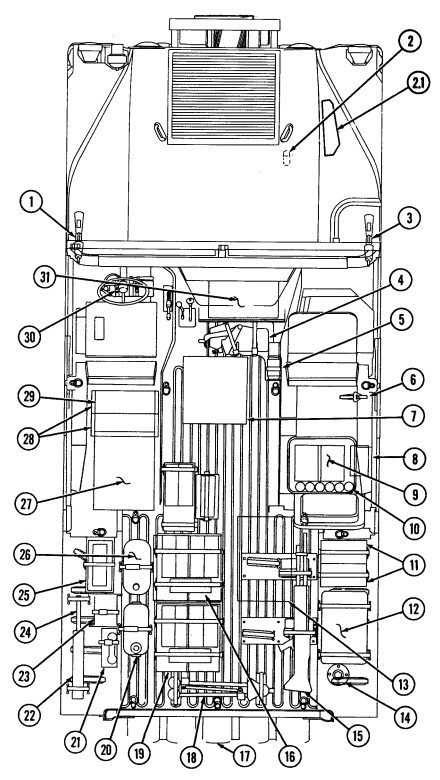

6 Simplified Test Equipment/Internal Combustion Engine-Reprogrammable (STE/ICE-R) diagnostic connector is attaching point for the vehicle test meter (VTM) to facilitate vehicle electrical and engine systems diagnoses.

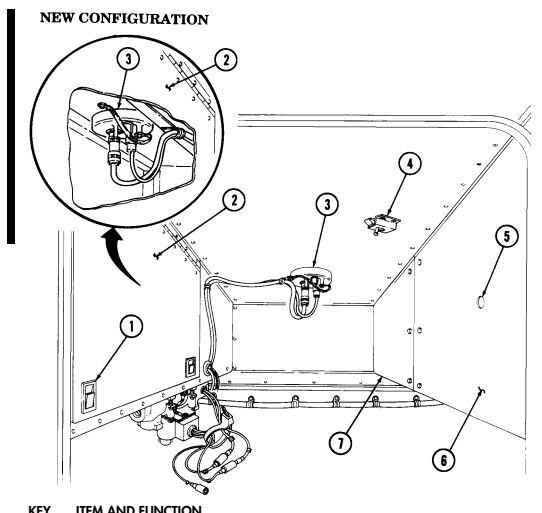

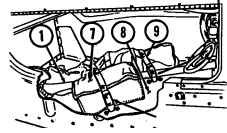

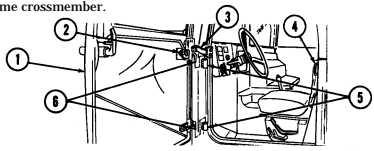

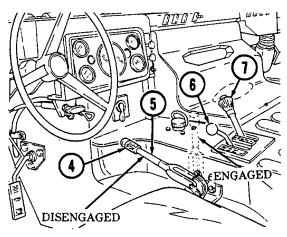

7 Transmission shift lever is used to select vehicle driving range, "R" (reverse), "N" (neutral), "D" (drive), " oD " (overdrive) (M1123 and A2 vehicles only), "2" (second), "1" (first), and "P" (park).

8 Transfer case shift lever is used to select vehicle driving range, "L" (low range), "N" (neutral), "H" (high range), and "H/L" (high lock range).

9 Transmission indicator lamp comes on when ignition switch is turned on, and goes off when ignition switch is turned off. It is used to flash the diagnostic trouble codes when the transmission control module (TCM) is placed in the diagnostic mode.

10 Transfer case indicator lamp illuminates when transfer case has completed the low-range shift and high lock range shift.

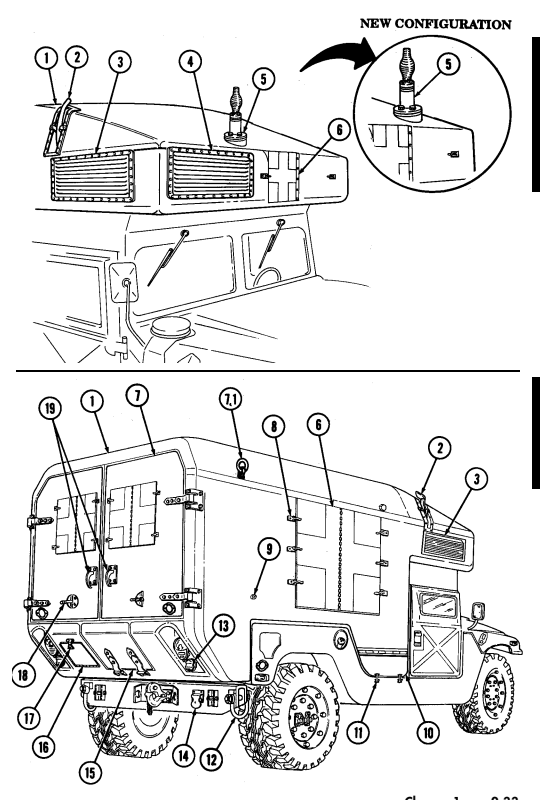

11 Parking brake lever is used to apply parking brake. Safety release button must be depressed to release parking brake in new configuration.

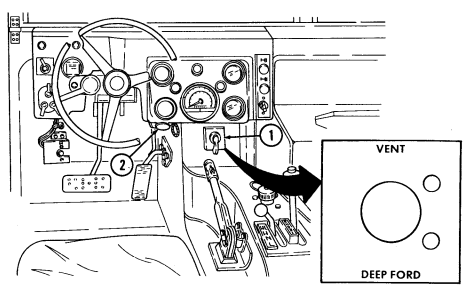

12 Fording control switch (deep water fording kit only) allows operator to select "VENT" during normal operating conditions or "DEEP FORD" for deep water fording.

13 Steering wheel lock cable permits steering wheel to be locked to prevent unauthorized use of vehicle.

NEW CONFIGURATION

2-4 Change 1

Key Item And Function

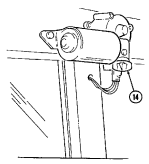

14 Windshield washer/wiper control knob operates a two-speed electric wiper motor and when

depressed operates windshield washer.

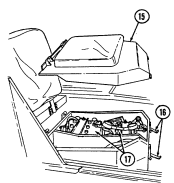

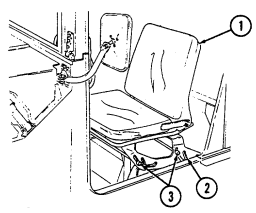

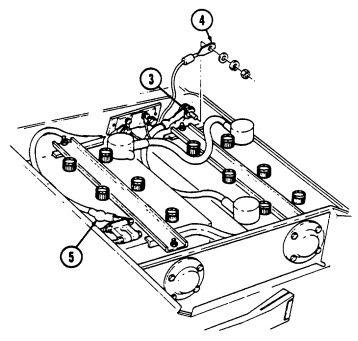

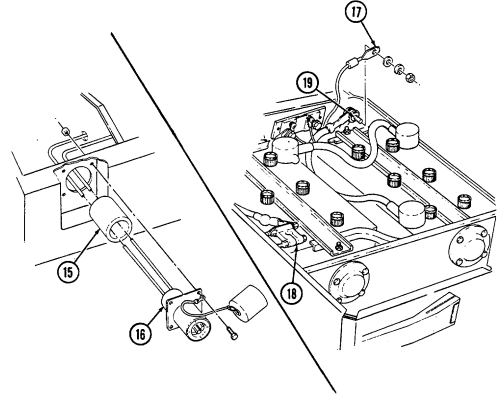

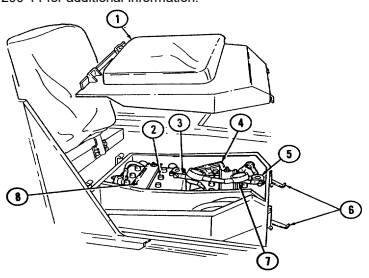

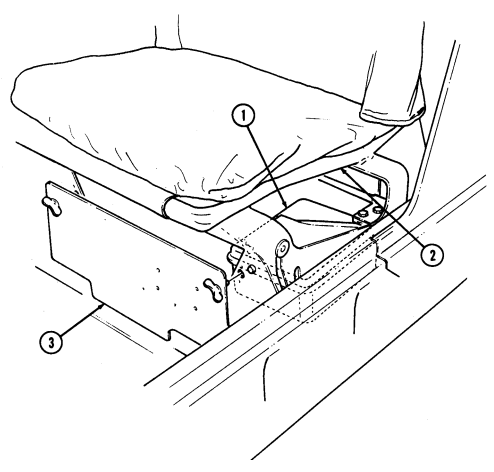

15 Companion seat is removed to provide access to batteries.

16 Battery box latches release to permit removal of companion seat for access to batteries. 17 Batteries provide 24-volt power to vehicle electrical system.

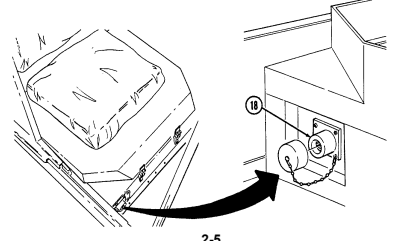

18 Slave receptacle is located at outside front of battery box. It is the connecting point for the slave

cable for slave-starting the vehicle.

2-5

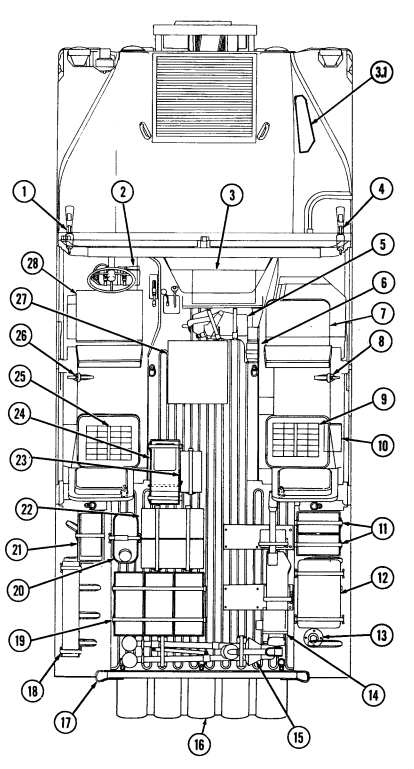

Tm 9-2320-280-10 Key Item And Function

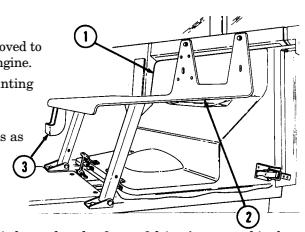

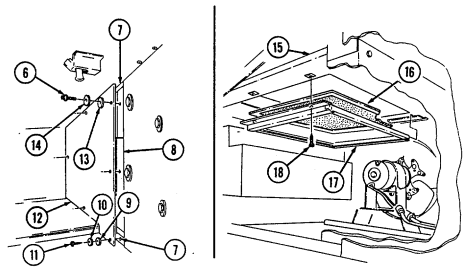

1 Engine access cover is removed to

provide access to rear of engine.

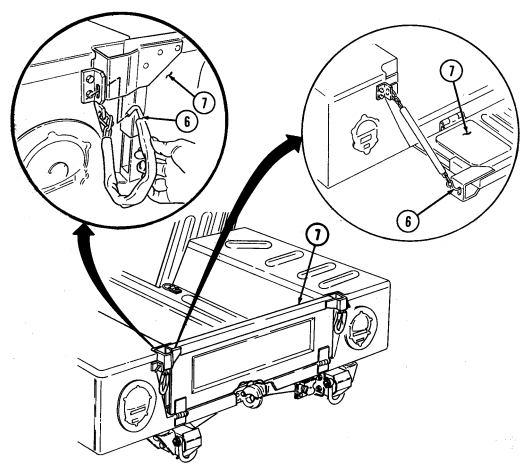

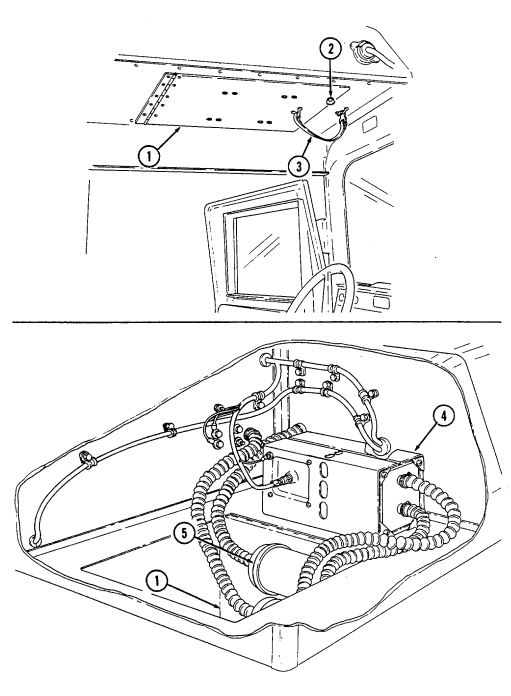

2 Radio rack serves as mounting point for AN/GRC-160 or AN/VRC-12 radios.

3 Microphone bracket serves as mounting point for microphone.

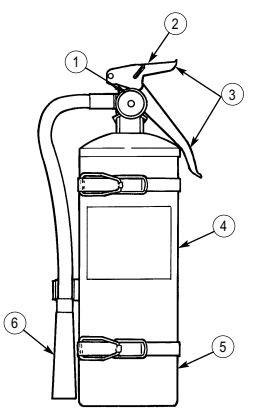

4 Fire extinguisher bracket is located under front of driver's seat and is the stowage location for fire extinguisher. For new configuration vehicles, the bracket is located on the side of the driver's seat.

5 Wing head screws (two each) secure front access plate for stowage area under driver's seat.

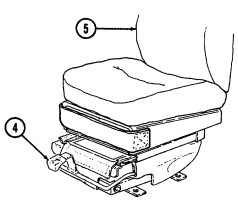

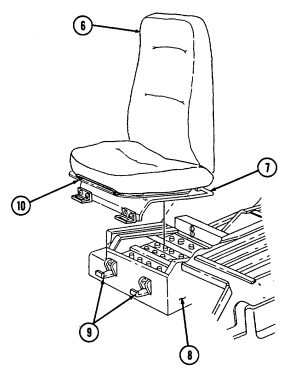

6 Driver's seat adjusting slots permit driver's seat to be locked in a forward or rearward position. For the new configuration vehicles, the adjusters are located on front of driver's seat.

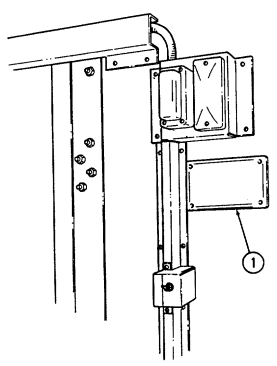

7 Catch assembly holds M16A1 rifle safely in place for travel. Adjustable catch assembly configuration holds M16A1 rifle when positioned all the way in or M203 grenade launcher when extended out.

8 Stock brace holds stock end of M16A1 rifle or M203 grenade launcher in position for travel.

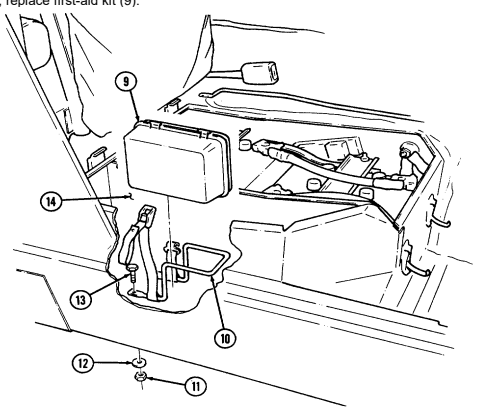

9 First aid kit is located underneath the driver's seat and is used for crew emergency first aid treatment.

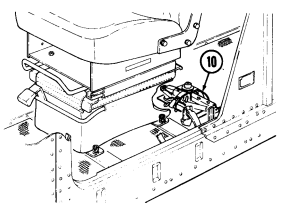

2-6 Change 1

10 Jack retaining strap (M1097 only) is located behind the driver's seat and is used to secure the jack firmly to the vehicle floor.

Change 1 2-7

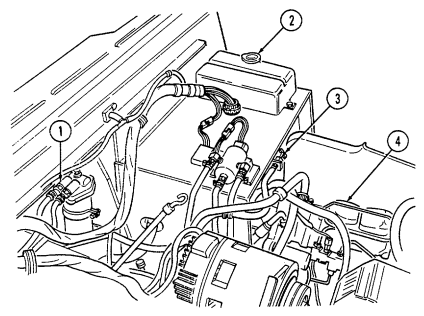

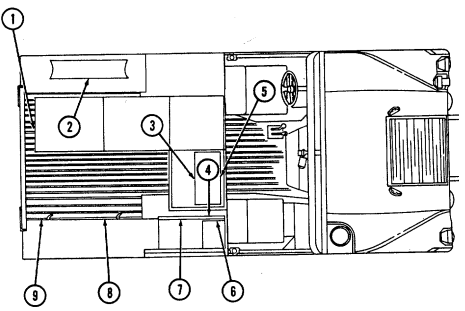

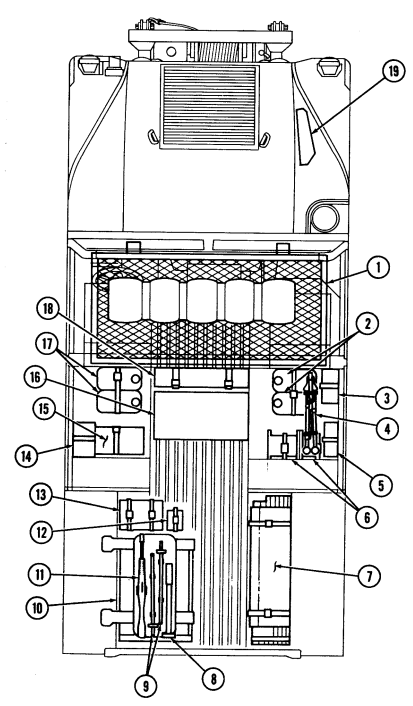

Key Item And Function

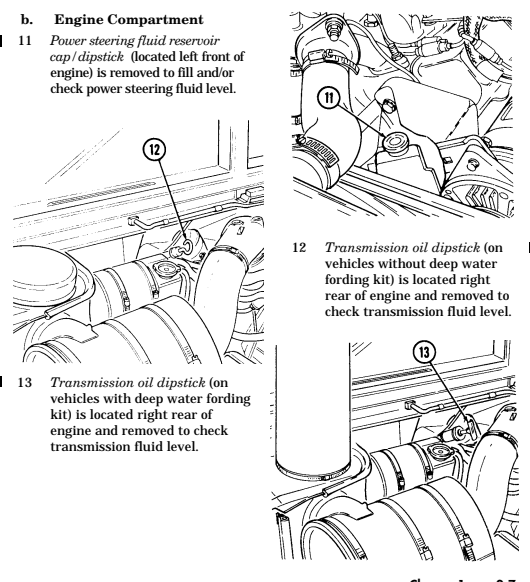

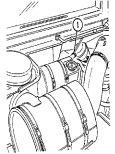

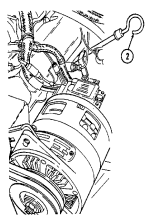

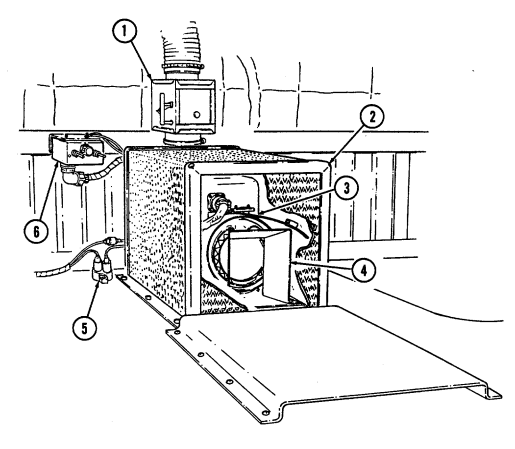

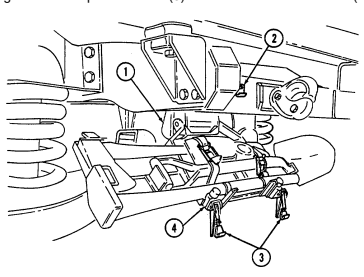

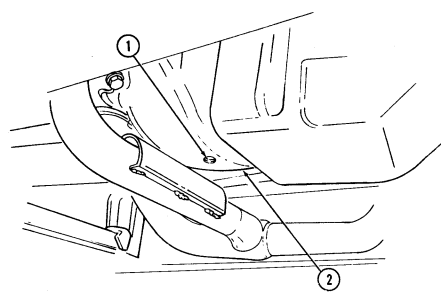

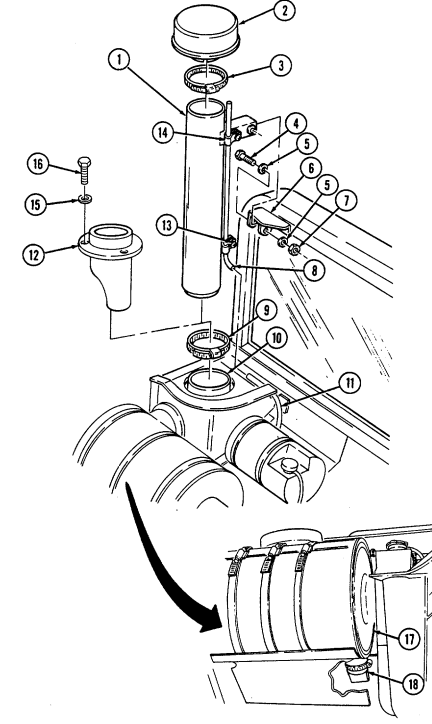

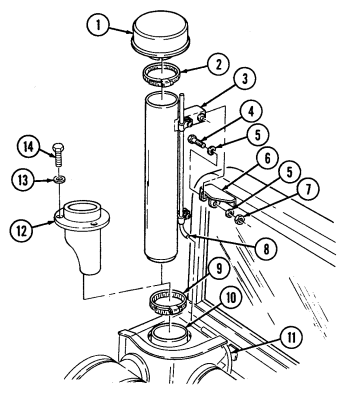

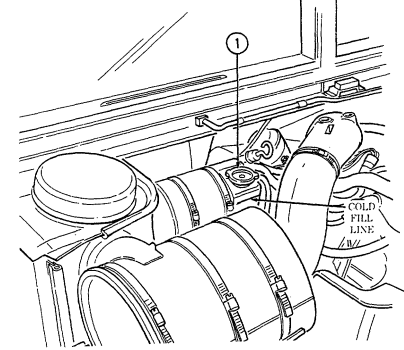

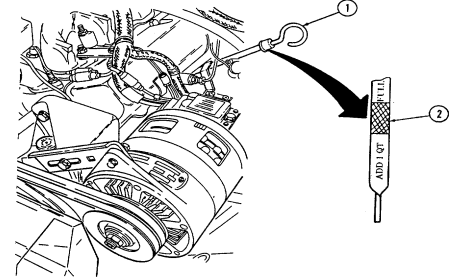

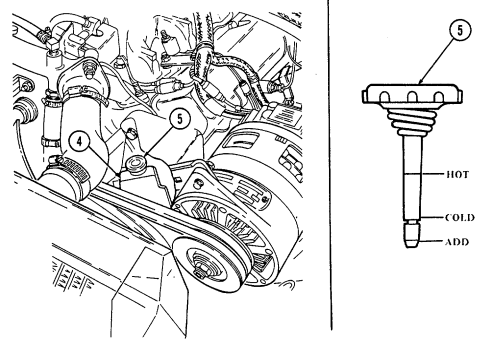

1 Transmission oil dipstick tube (located right rear of engine) is fill point for transmission fluid.

2 Engine oil dipstick (on vehicles without deep water fording kit) is located behind alternator on left

side of engine and removed to check engine oil level.

3 Engine oil dipstick (on vehicles with deep water fording kit) is located behind alternator on left side

of engine and is removed to check engine oil level.

4 Engine oil filler cap (located front center of engine) is removed from oil filler neck to add oil to engine.

Key Item And Function

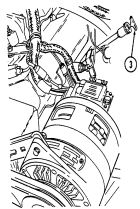

5 Radiator drainvalve (located beneath right front of engine on lower radiator crossover pipe) is

turned counterclockwise to drain coolant from the radiator.

6 Coolant surge tank cap (located right rear of engine) is removed from surge tank to add coolant to

cooling system.

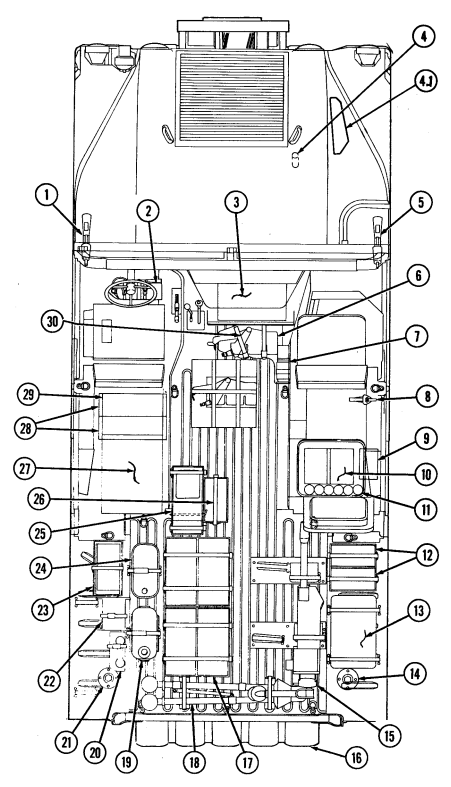

2-9

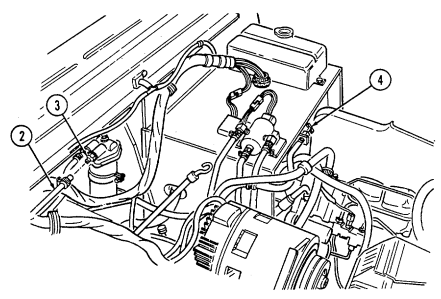

Key Item And Function

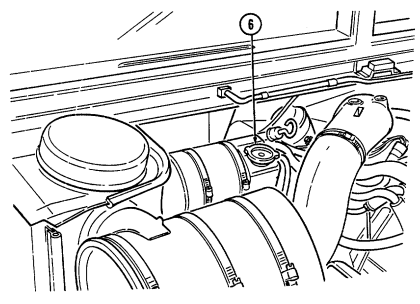

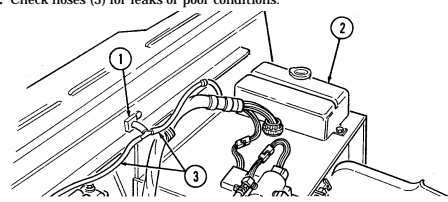

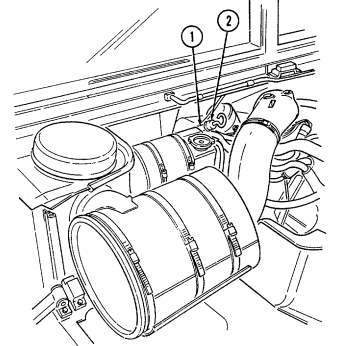

1 Fuel filter (located left rear of engine on firewall) filters water from fuel system.

2 Windshield washer reservoir cap (located left rear of engine) unsnaps to add windshield washer fluid to reservoir.

3 Fuel filter drainvalve (located left rear of engine compartment on cowl, beneath and in front of windshield washer reservoir) is draining point for water collected in fuel filter.

4 Master cylinder cover (located left of engine) is removed to fill and/or check brake fluid level.

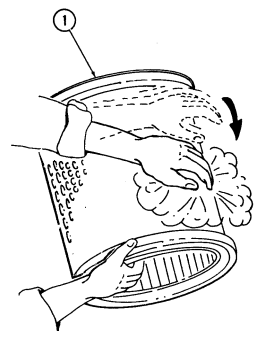

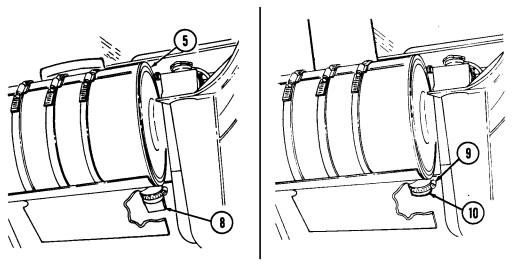

5 Air cleaner assembly (located right rear of engine) houses air cleaner element which filters dirt and

dust from air before it enters combustion chamber.

6 Air cleaner dump valve when squeezed, releases dirt, mud, or water from air cleaner body assembly.

Key Item And Function

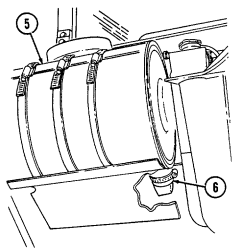

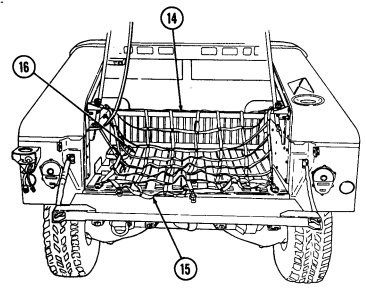

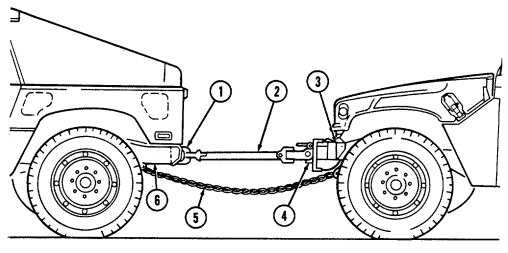

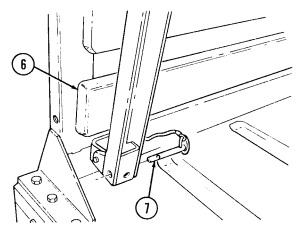

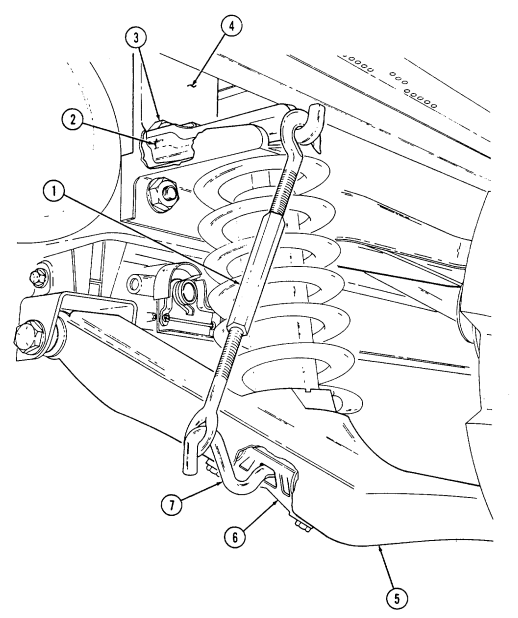

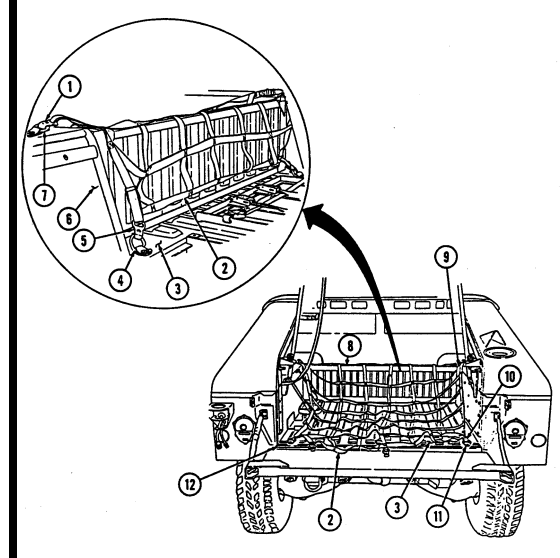

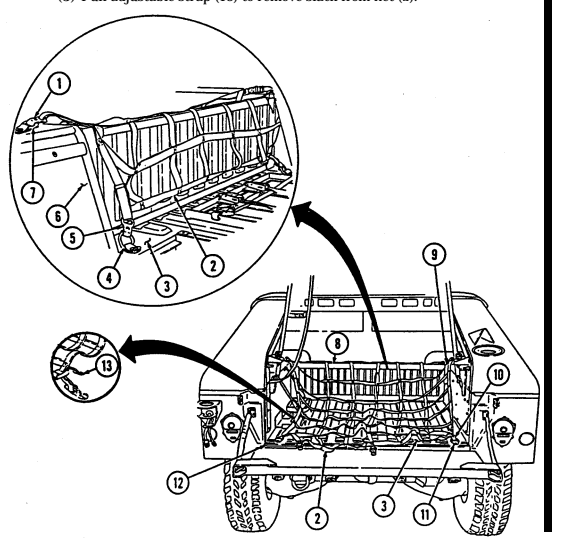

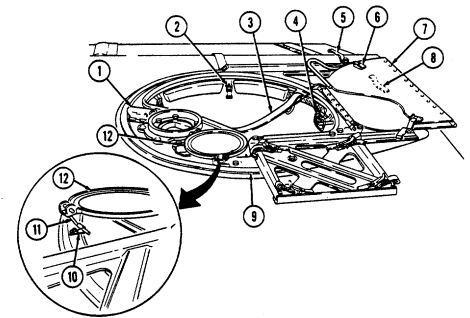

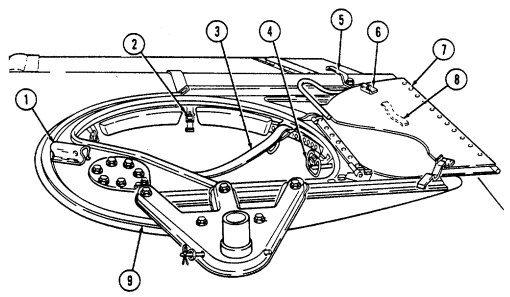

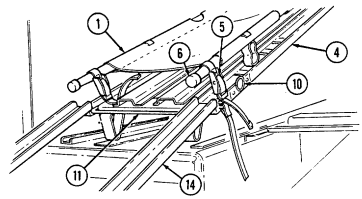

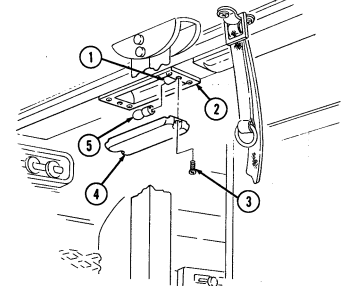

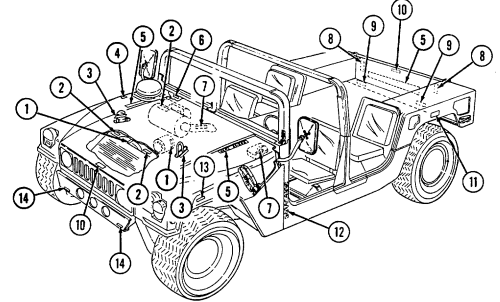

7 Cargo tiedowns (eight each) provide tiedown points for use in cargo operations (M998, M998A1, M1038, and M1038A1 only).

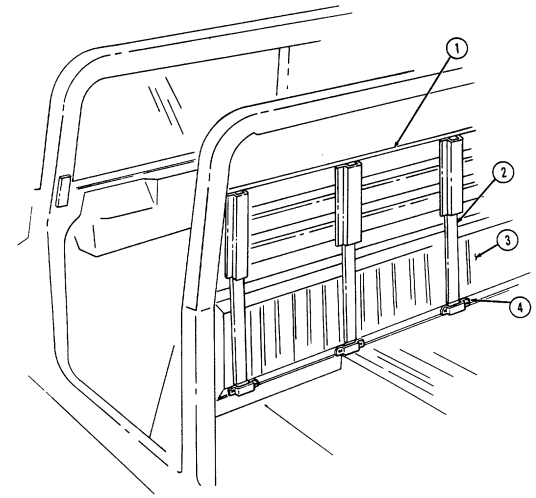

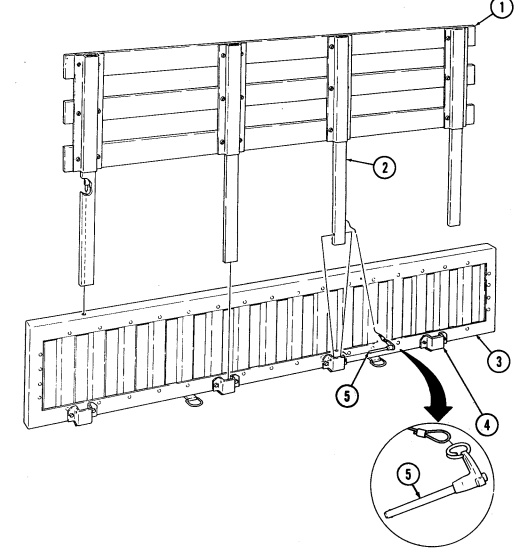

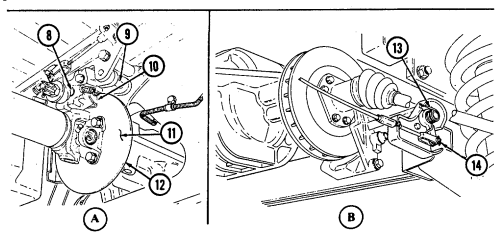

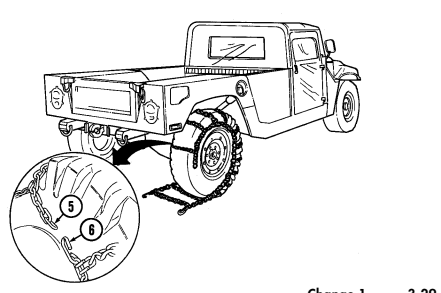

8 Tailgate chains and hooks secure tailgate to rear of vehicle body (all except M996, M996A1, M997, M997A1, and M997A2).

9 Tailgate opens and closes to allow access to vehicle cargo area (all except M996, M996A1, M997, M997A1, and M997A2).

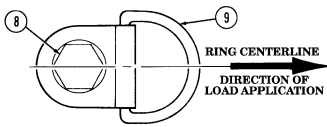

10 Lifting shackles (located at front and rear of vehicle) are used to lift or tie down vehicle.

11 Trailer receptacle provides electrical power for towed equipment. 12 Towing pintle (rear bumper) provides connection point for towing.

13 Pintle pin locks pintle latch to towing pintle.

14 Pintle latch pulls up to open towing pintle and pushes down to lock towing pintle.

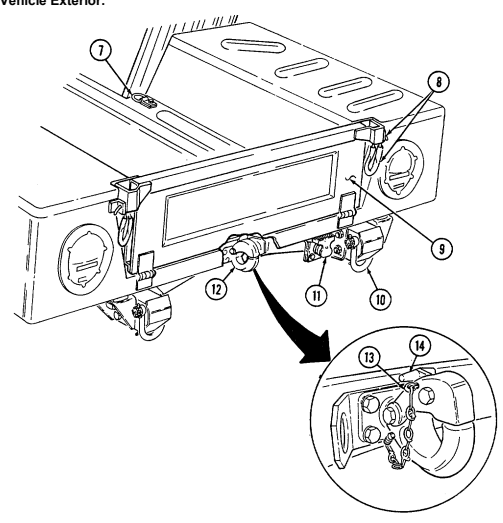

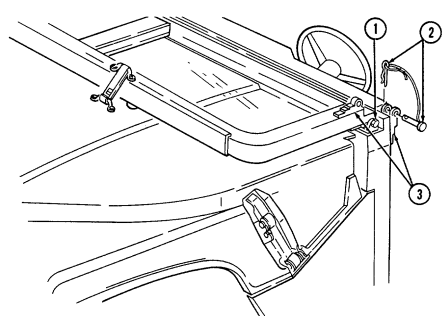

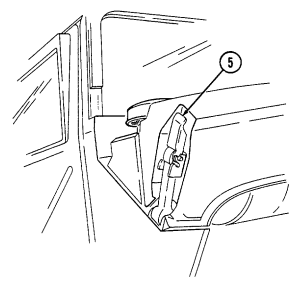

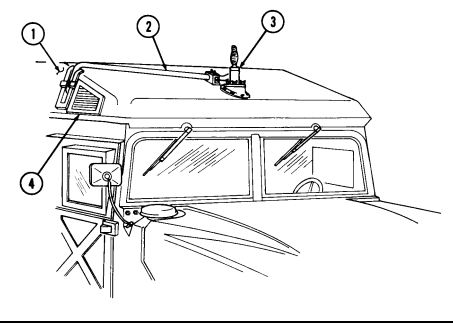

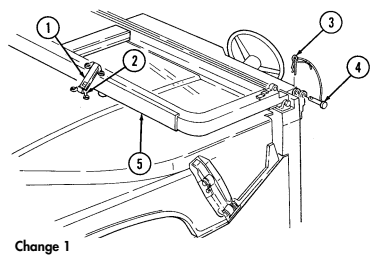

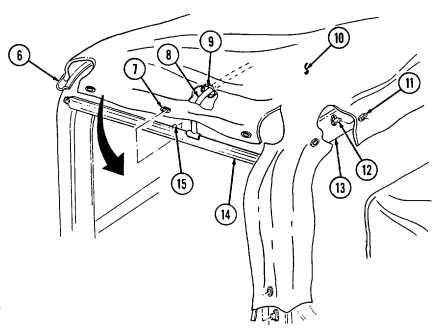

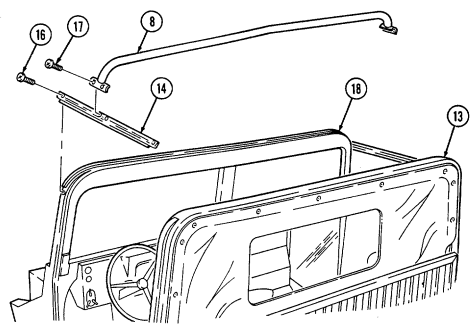

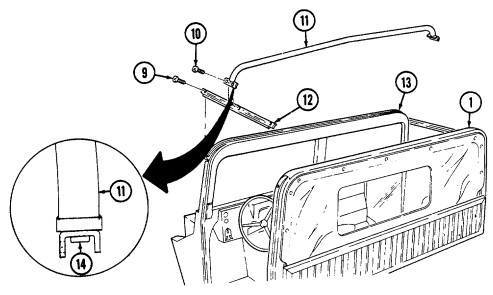

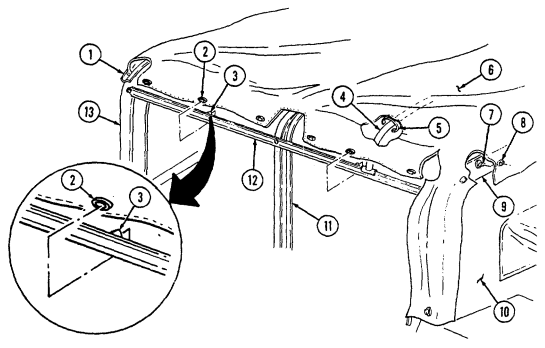

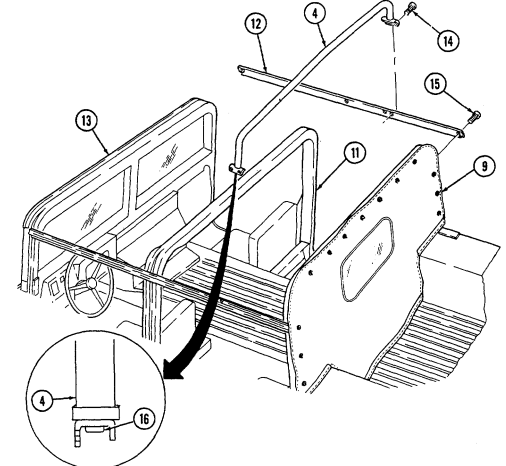

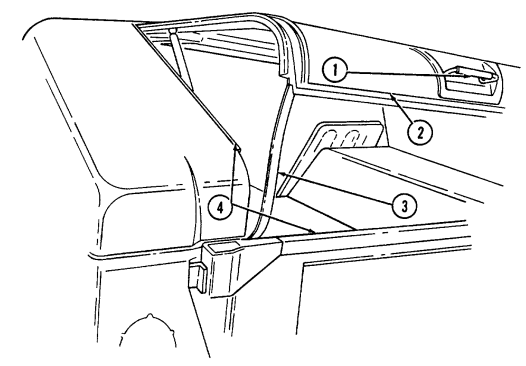

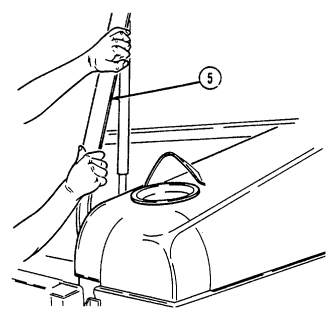

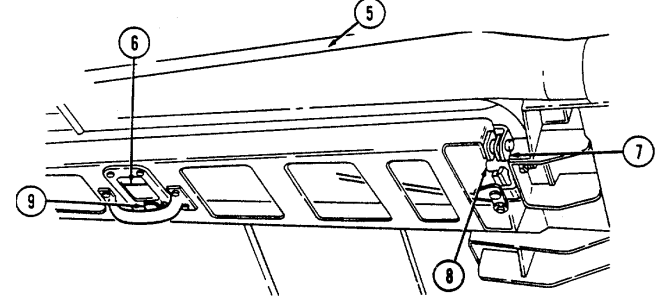

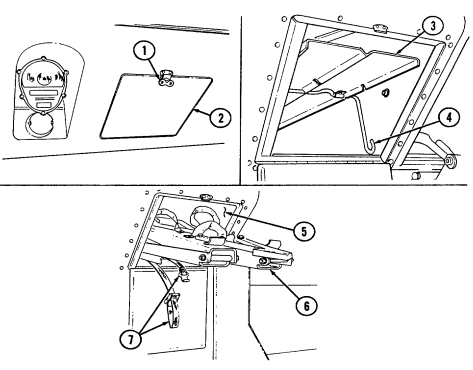

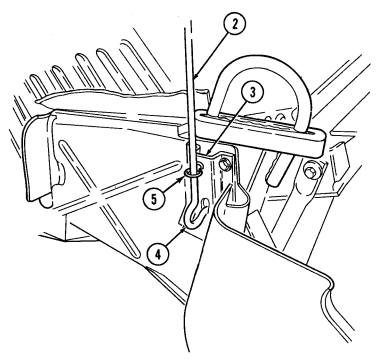

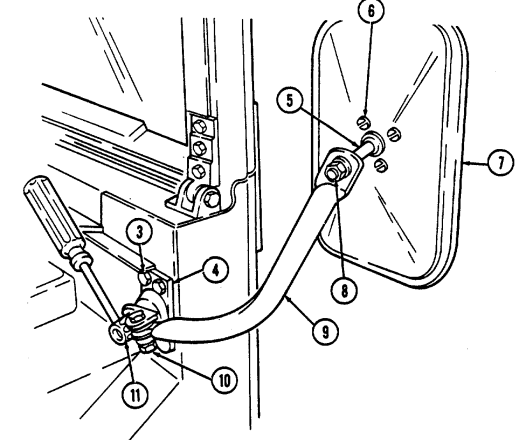

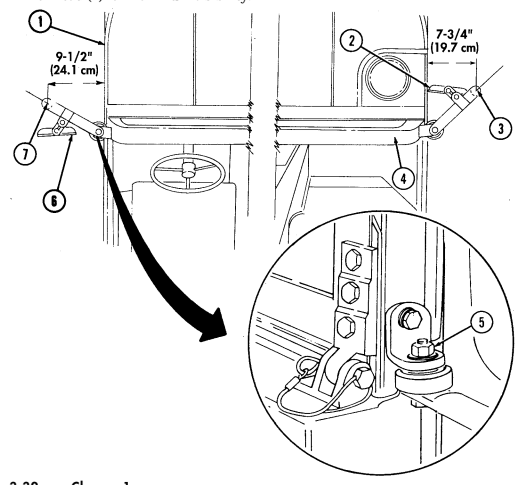

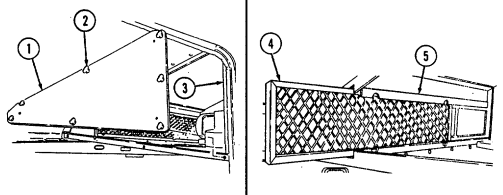

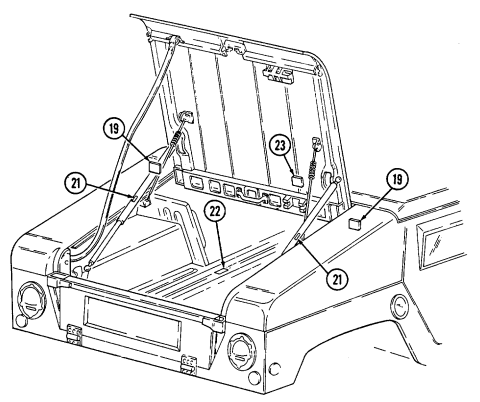

1 Windshield folddown hinges (soft top models only) are used as a hinge point when lowering windshield. Hinge pins are removed when detaching windshield assembly.

2 Hitch pin and hinge pin are removed to allow windshield to be lowered or detached. 3 Windshield hinges (soft top models only) secure windshield in the raised (up) position with hinge

pins installed. Hinge pins are removed when lowering or detaching windshield.

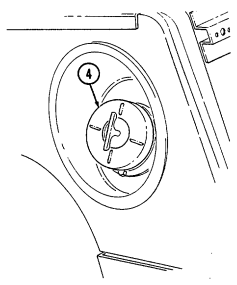

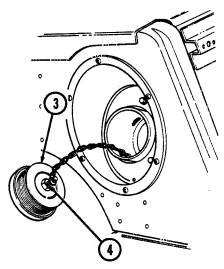

4 Fuel tank filler cap (located at right rear side of vehicle) is removed to permit fuel servicing.

2-12

Key Item And Function

5 Hood latches (one on each side of hood) unlatch to release hood.

6 Hood support rod supports hood in the raised position.

2-13

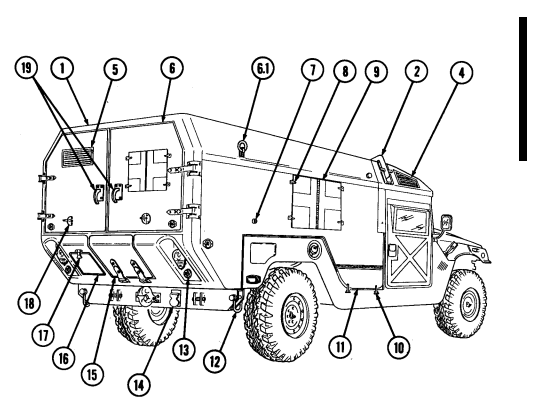

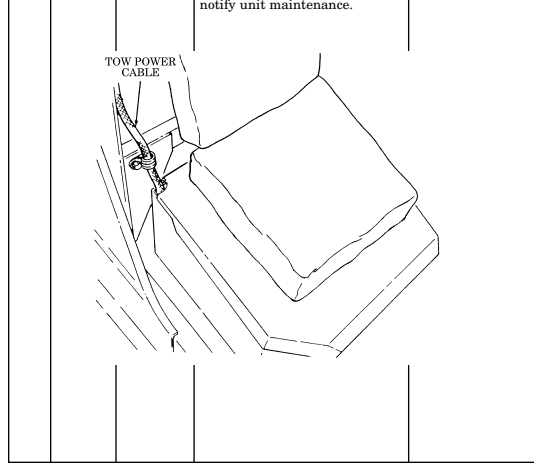

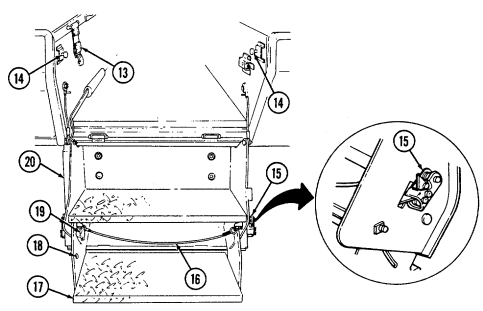

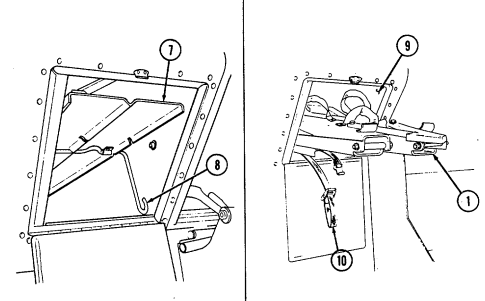

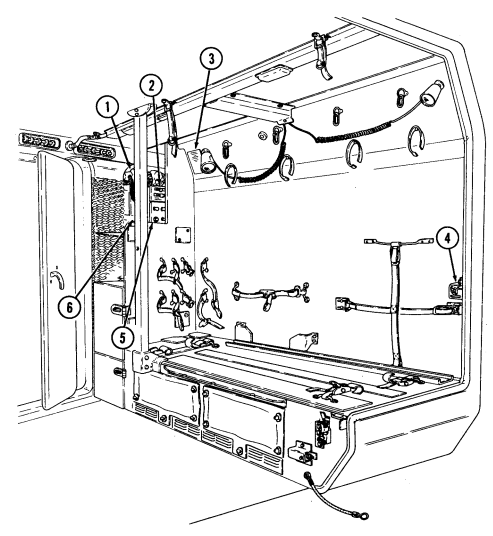

D. Tow Carrier (M966, M996A1, M1036, M1045, M1045A1, M1045A2, M1046, And M1046A1) Equipment. Warning Note Key Item And Function 2-14

Never open one end of the cargo shell door without first ensuring that the opposite end is securely closed. Not doing so may cause both ends to open at same time causing damage to equipment, mission abort, or injury to personnel.

This manual identifies HMMWV equipment which permits the mounting and operation of the TOW launcher system. Specific instructions for employing the TOW and TOW 2 launcher on the HMMWV are covered in TM 9-1425-450-12 and TM 9-1425-472-12.

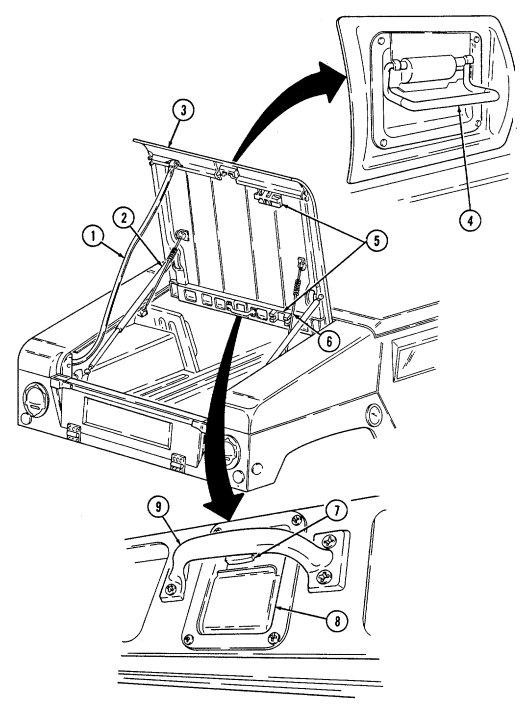

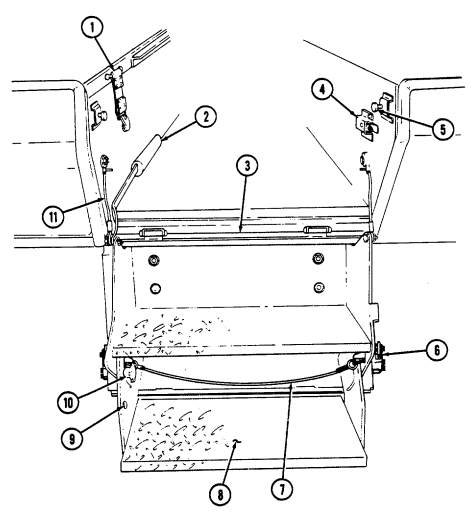

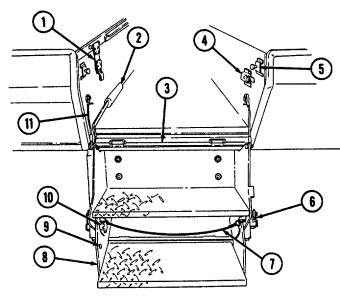

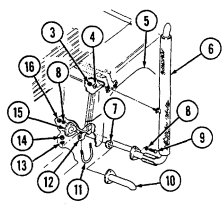

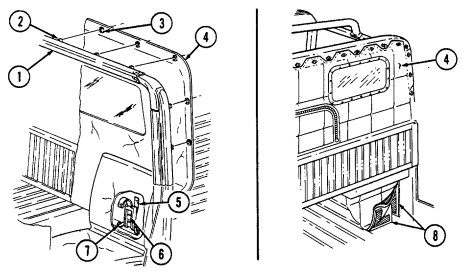

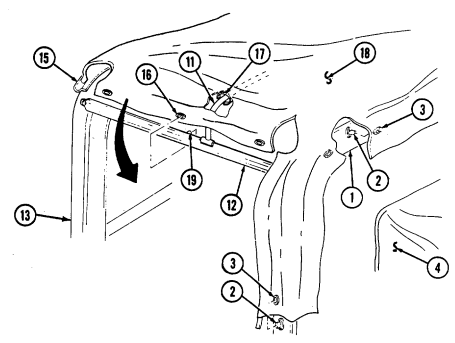

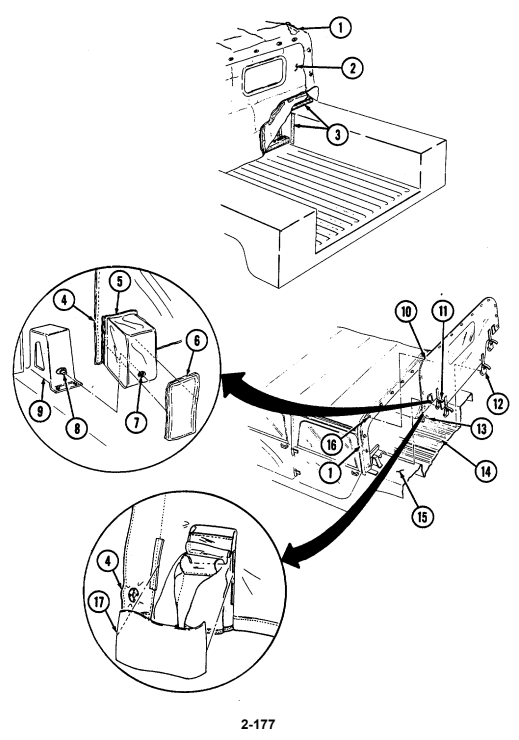

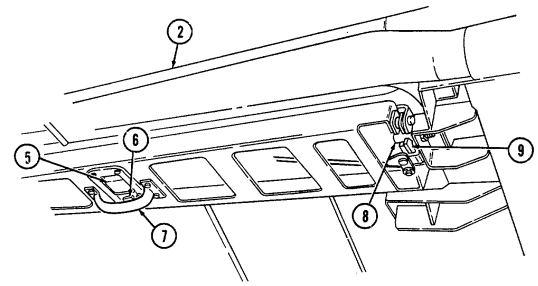

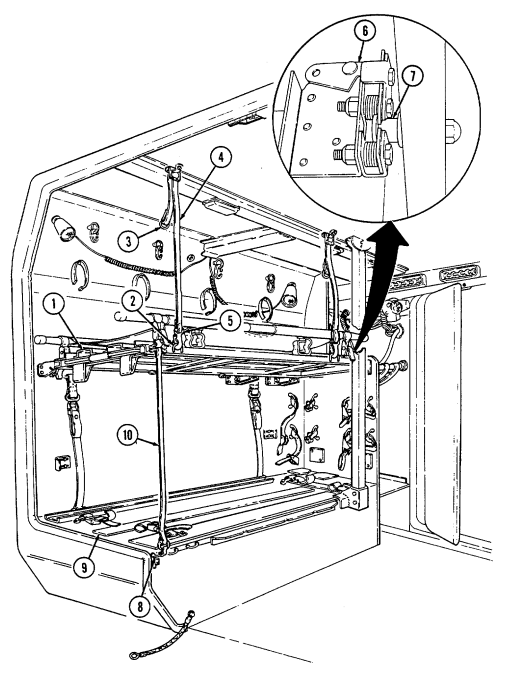

1 Cargo shell door strap serves as a grab strap to lower cargo shell door.

2 Cargo shell door assist cylinders provide a lift boost for raising and holding cargo shell door open.

3 Cargo shell door is a double-actuating door which pivots at either end. When door forward latch is released from inside vehicle, door opens rearward and functions as a TOW loader's door to facilitate mounting of TOW launcher and missile loading. When door rear latch is released, door opens forward and permits access to cargo area from rear of vehicle for stowing TOW launcher and equipment or ground mounting TOW launcher.

4 Cargo shell door rear latch is pulled upward to open cargo shell door from rear of vehicle.

5 Launch tube brackets (located on underside of cargo shell door) serve as stowage points for missile launch tube.

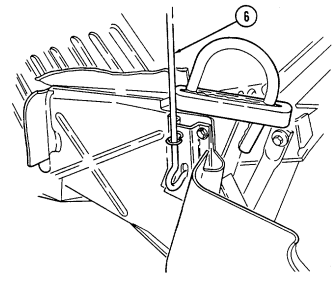

6 Cargo shell door retaining cables limit cargo shell door travel when opened from either end.

7 Cargo shell door forward latch locking device prevents accidental opening of cargo shell door from inside vehicle.

8 Cargo shell door forward latch is pulled downward to open door from inside vehicle. 9 Cargo shell door front grab handle serves as a grabbing point for lowering door when inside vehicle.

2-15

Key Item And Function

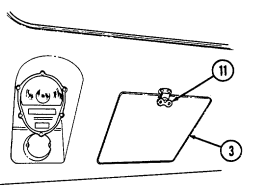

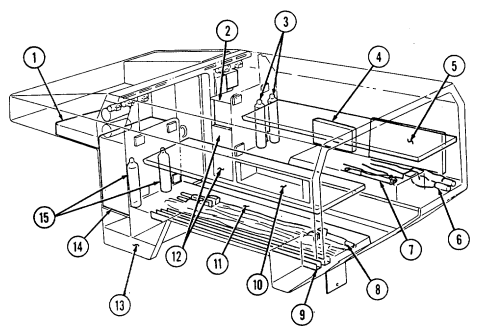

1 Telephone set footman loops (two each) and strap secure telephone set beneath rear of left cargo shell.

2 Cable reel footman loops (two each) and strap secure cable reel forward of telephone set stowage location.

3 M16 ammo box rack serves as stowage base for two M16 ammo boxes and is located forward of the cable reel stowage location.

4 M16 ammo box footman loops and straps (four each) secure two M16 ammo boxes to ammo rack.

5 Combat ration footman loops (four each) and straps (three each) secure one case of combat rations right rear of M16 ammo rack.

6 Fuel can footman loops (two each) and strap secure fuel can to fuel can stowage bracket.

7 Fuel can stowage bracket located between the left wheelhouse and missile rack permits vertical stowage of fuel can.

8 Tripod head mounting bracket secured to left rear wheelhouse permits mounting of traversing unit end of tripod in the stowed position.

2-16

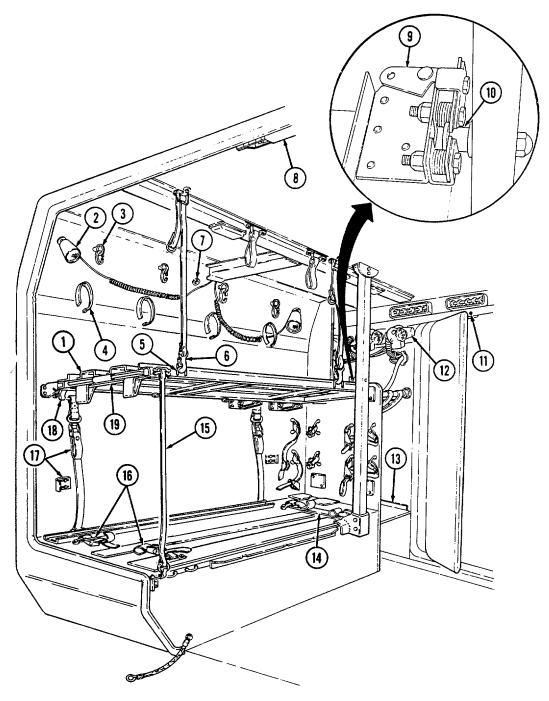

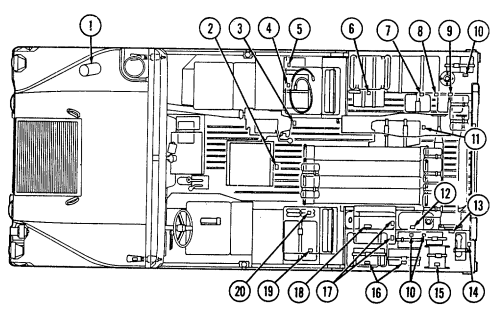

Key Item And Function

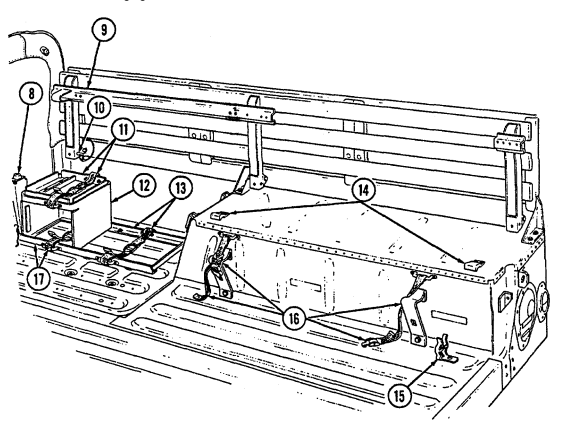

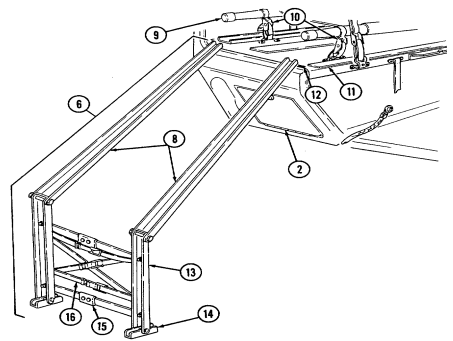

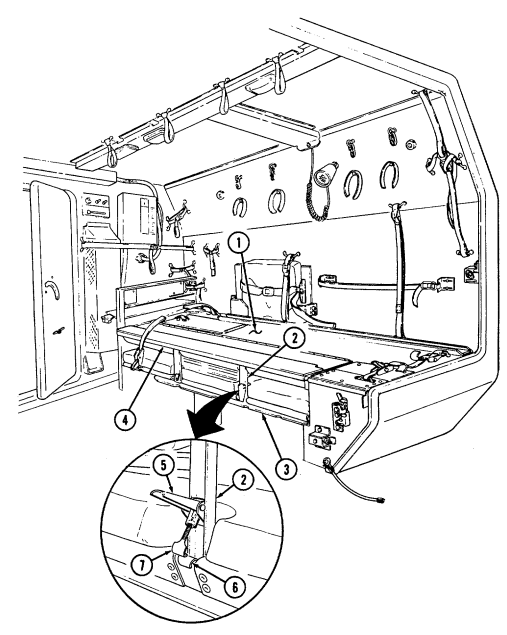

9 Missile stowage rack provides stowage for six TOW missile rounds. It consists of a base, a first tier, and a second tier. Tiers pivot upward to facilitate missile stowage and quick access to missiles during reload operations. Missiles are mounted in each rack with warheads facing front of vehicle. Missiles stowed between rack base and second tier are held in without straps. Missiles mounted on top of the second tier are secured with straps located fore and aft of rack.

10 Second tier mounting straps (four each) located fore and aft of missile rack secure two missile rounds to second tier of rack.

11 Missile guidance set (MGS) battery stowage boxes provide stowage for two MGS batteries. 12 Water can footman loops and straps (two each) secure stowed water can between missile rack and left wheelhouse.

13 Missile rack tier retaining springs (two each) retain raised first or second tiers of missile rack to permit stowage of missiles or access to missiles for reloading operations.

14 Missile rack second tier locking latches (two each) located fore and aft of missile rack secure second tier of missile rack to first tier of missile rack.

15 Missile rack first tier locking latches (two each) located right side of missile rack secure first tier of missile rack to rack base.

16 Missile rack support braces (two each) support first and second missile rack tiers and pivot to outside to allow easy access to missiles for stowage or reloading.

2-17

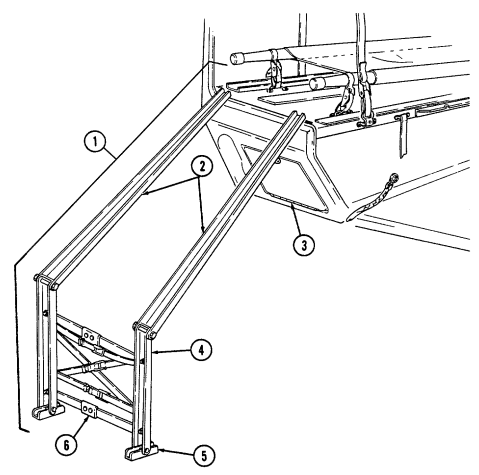

Key Item And Function

1 Night sight battery case stowage brackets (two each) provide mounting locations for night sight battery cases.

2 Night sight battery case footman loops and straps (four each) secure two night sight battery cases to night sight battery case stowage brackets.

3 Night sight battery case mounting bracket footman loops (two each) and straps (four each) provide stowage of night sight case to top front of right wheelhouse.

4 Boresight collimator case footman loops and straps (four each) secure boresight collimator case to top rear of right wheelhouse.

5 Combat ration footman loops and straps (two each) secure one case of combat rations.

6 Night sight coolant cartridge case stowage bracket provides mounting location for night sight coolant cartridge cases.

7 Night sight coolant cartridge case footman loops and straps (four each) secure two night sight coolant cartridge cases to night sight coolant cartridge case stowage bracket.

8 Tripod legs mounting bracket and strap provide stowage for leg end of tripod.

9 Day sight and carrying bag stowage bracket provide stowage location for day sight and carrying bag in front of tripod.

10 Day sight and carrying bag footman loops and straps (four each) secure day sight to day sight stowage bracket.

2-18

Key Item And Function

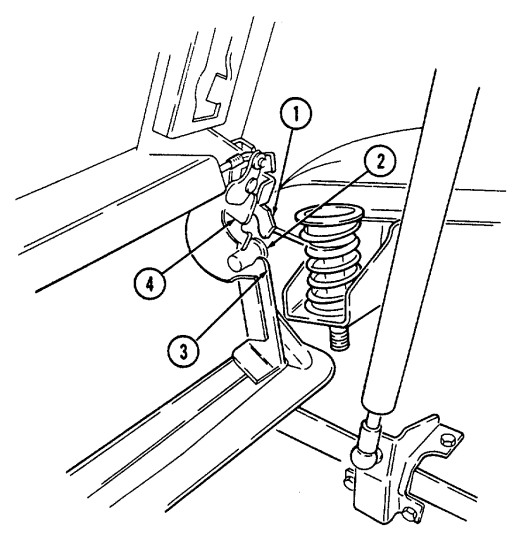

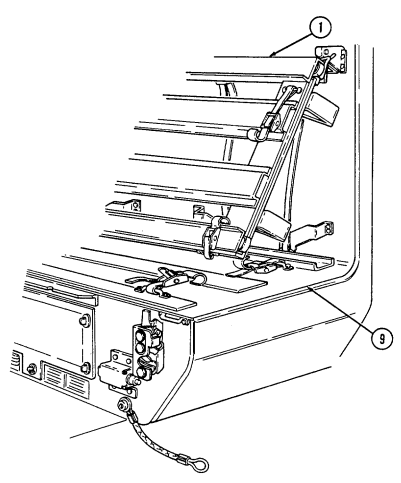

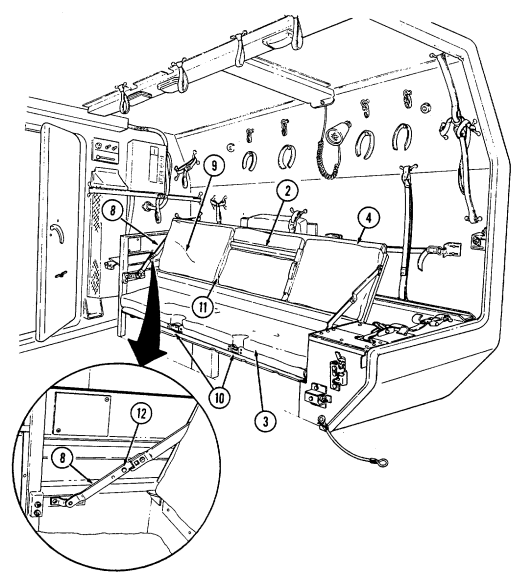

11 Gunner's platform provides an adjustable non-slip platform for TOW gunner. Also serves as mounting base for the MGS in the stowed position.

12 Missile guidance set footman loops and straps secure MGS to the gunner's platform during extended travel mode.

13 Gunner's platform locking pins (two each) secure gunner's platform to selected height risers.

15 Traversing unit stowage pedestal provides mounting base for TU mount adapter. 16 Lower traversing unit mount adapter clamp secures TU mount adapter to the stowage pedestal or weapon station pedestal mount.

17 Upper traversing unit mount adapter clamp secures TU to TU mount adapter. 18 Gunner's platform risers provide support and height adjustment for gunner's platform.

19 Gunner's platform locking lugs and holes (two each) secure gunner's platform to fully lowered position when locking pin is installed.

14 Traversing unit (TU) mount adapter adapts TU to the TU stowage pedestal or weapon station pedestal mount.

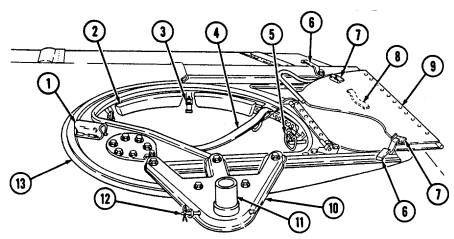

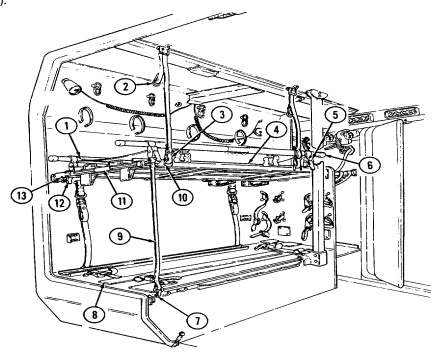

Key Item And Function

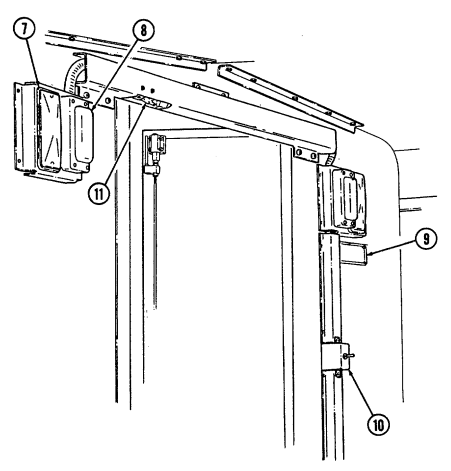

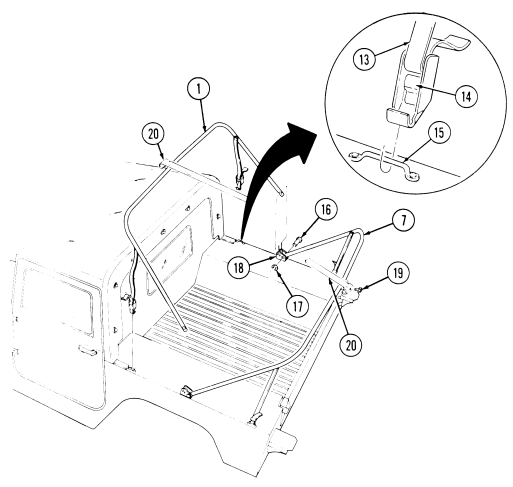

1 Turret positioning handle provides positive right-hand grip to rotate weapon station. Hole in handle serves as securing point for weapon station pedestal mount cover.

2 Gunner's backrest provides back support for a gunner positioned in weapon station.

3 Hatch cover securing latches (three each) secure cover to weapon station. 4 Gunner's sling serves as seat rest or restraint for a gunner positioned in weapon station.

5 Weapon station brake handle locks the weapon station at the gunner's desired azimuth. Handle is placed in the down position for locking and pulled up when traversing the weapon station.

6 Hatch cover retaining latches (two each) secure to latch catches for retaining station cover in the open position.

7 Hatch cover retaining catches (two each) are connection points for retaining latches.

8 Hatch cover handle is grab handle to assist gunner in opening and closing station cover. 9 Weapon station hatch cover provides sealed protective covering for roof opening when TOW is not mounted to weapon station.

Key Item And Function

10 Missile guidance set retaining latches (four each) secure MGS to MGS weapon station mounting tray.

11 Missile guidance set weapon station mounting tray is mounting point for the MGS when the TOW launcher is assembled on the weapon station.

12 TOW carrier level gauge (inclinometer) measures levelness of the vehicle to alert TOW crew when vehicle is beyond recommended side slope operation.

13 Weapon station pedestal mount cover retainer secures pedestal mount cover in the open position. 14 Weapon station pedestal mount cover protects pedestal mount opening when TOW launcher is not mounted.

15 Weapon station pedestal mount is mounting point for TU adapter bracket and TOW launcher. 16 Weapon station serves as rotating mounting platform for TOW components during the launcher mode of operation. It can be continuously rotated 360° without vehicle power conditioner (VPC) cables connected.

17 Vehicle power conditioner (VPC) mounting plate provides a mounting point for the VPC. This bracket is mounted to the radio rack.

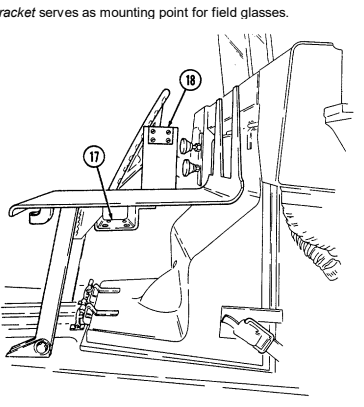

18 Field glasses bracket serves as mounting point for field glasses.

2-21 Key Item And Function

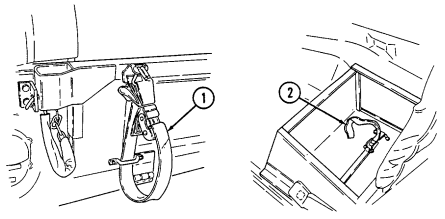

1 Camouflage screen stowage straps (four each) secure camouflage screen and support to tailgate.

2 NBC overgarments straps (two each) secure two sets of NBC overgarments and four sets of gloves

to floor (under left rear passenger seat).

3 NBC overgarments straps (eight each) secure two sets of overgarments (one set on each side) to cargo shell.

4 Night sight vision goggles stowage straps secure two sets of night sight vision goggles to floor (under right rear passenger seat).

5 Radiac meter stowage straps secure radiac meter to floor (under right rear passenger seat).

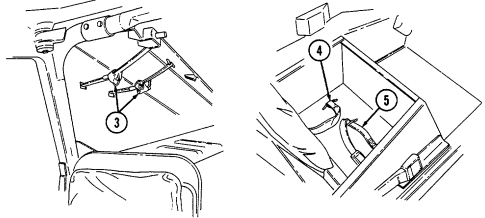

2-22

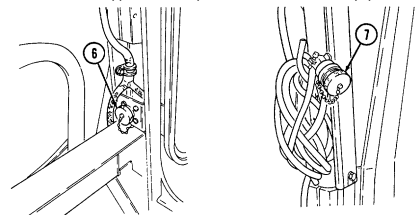

Key Item And Function

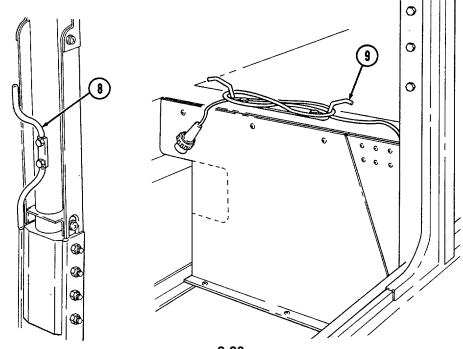

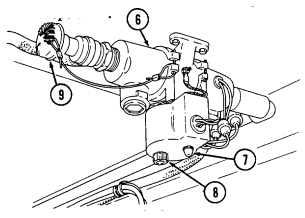

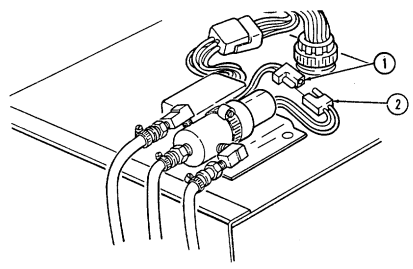

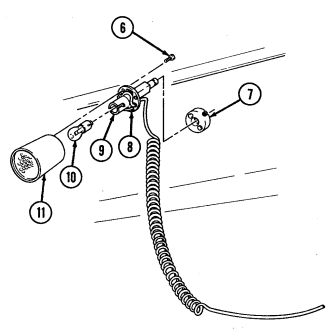

6 Power connector is located lower right side of "B" pillar and supplies power for vehicle power conditioner (VPC).

7 Power conditioner cable supplies vehicle power to TOW launcher equipment.

8 Vehicle power conditioner cable cleat (for vehicles with serial numbers 99,999 and below) secures the VPC cable to the inner right side of the "B" pillar when the cable is not connected to the power conditioner.

9 Vehicle power conditioner cable cleat (for vehicles with serial numbers 100,000 and above) secures

the VPC cable behind the passenger seat when the cable is not connected to the power conditioner.

2-23 e. Armament Carrier (M1025, M1025A1, M1025A2, M1026, M1026A1,

M1043, M1043A1, M1043A2, M1044, and M1044A1) Equipment.

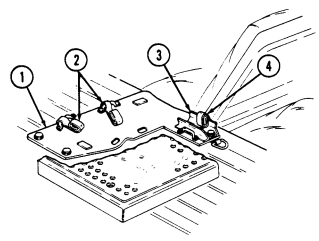

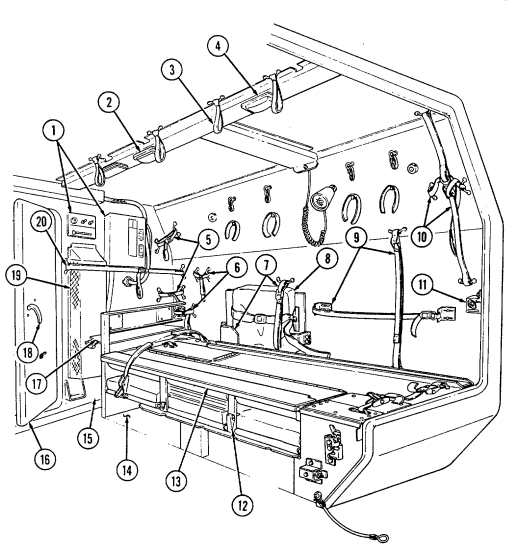

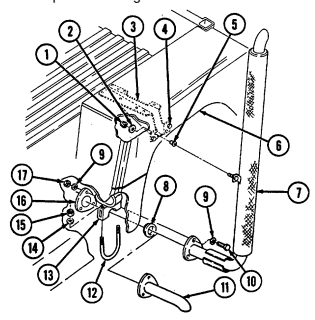

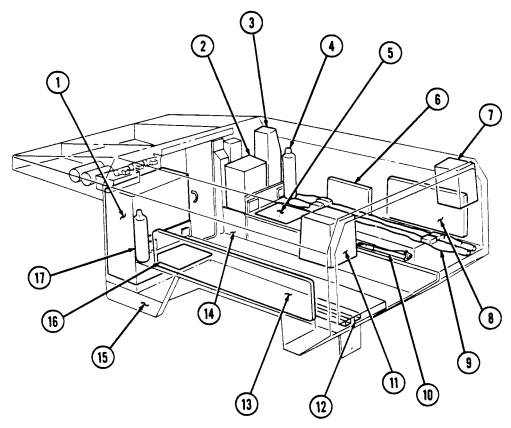

Key Item And Function

1 Turret positioning handle provides positive right-hand grip to rotate weapon station.

2 Gunner's backrest provides back support for a gunner positioned in weapon station. 3 Hatch cover securing latches (three each) secure cover to weapon station. 4 Gunner's sling serves as seat rest or restraint for a gunner positioned in weapon station.

5 Weapon station brake handle locks the weapon station at the gunner's desired azimuth. Handle is placed in the down position for locking.

6 Hatch cover retaining latches (two each) secure to latch catches for retaining station cover in the open position.

7 Hatch cover retaining catches (two each) are connection points for retaining latches.

8 Hatch cover handle is grab handle to assist gunner in opening and closing station cover.

9 Weapon station hatch cover provides sealed protective covering for roof opening when weapons are not mounted to weapon station.

10 Armament mount is mounting bracket for weapon adapter.

11 Universal weapons adapter provides mounting base for the M60 7.62 mm machine gun, M2 caliber .50 machine gun, and MK19 grenade launcher.

12 Universal weapons adapter pin assembly secures weapon adapter to the armament mount.

13 Weapon station serves as rotating mounting platform for weapon components. Can be continuously rotated 360 degrees.

Operation and identification of cargo shell door components and gunner's platform can be found in para. 2-2d.

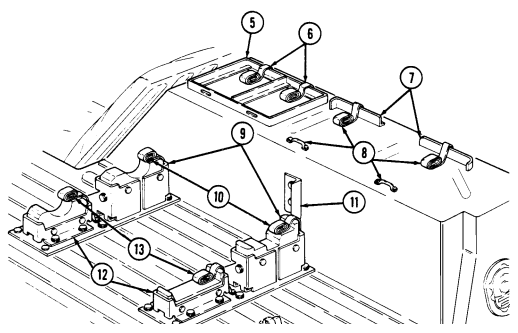

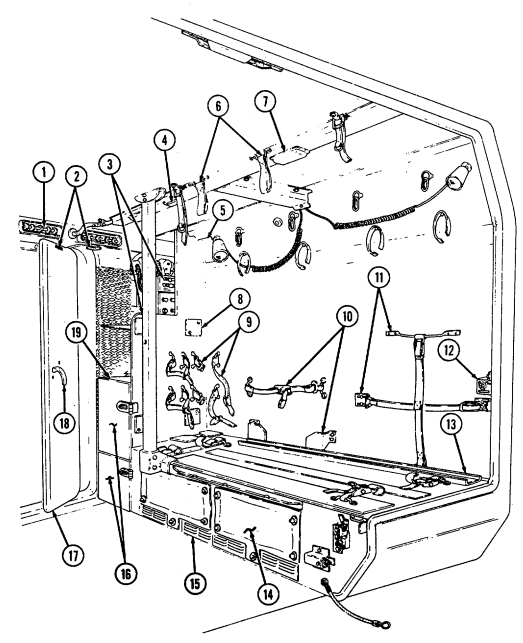

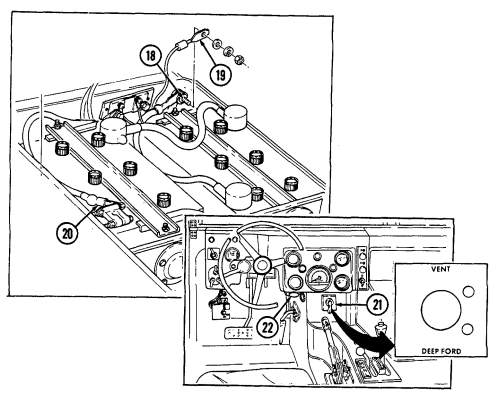

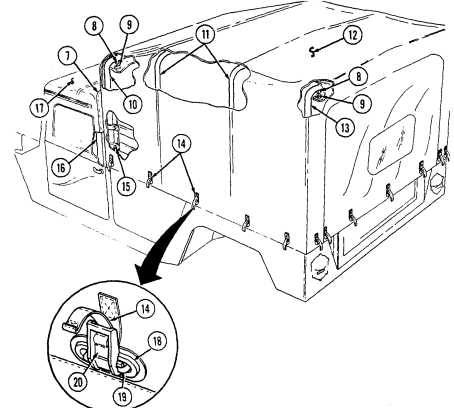

Key Item And Function

14 Spare barrel and cleaning kit footman loops and straps (two each) secure spare barrel and cleaning kit for M2 caliber .50 machine gun.

15 Ammo box rack provides stowage base for caliber .50 ammo box. 16 Ammo box footman loop and strap secure caliber .50 ammo box to ammo box rack. 17 Water can footman loop and strap secure 5 gal. water can to water can bracket; 18 Water can bracket provides stowage base for 5 gal. water can.

19 Ammo box rack provides stowage base for 40 mm ammo box. 20 Ammo box footman loops and straps (two each) secure 40 mm ammo box to ammo box rack.

21 Ammo box rack provides stowage base for caliber .50 ammo box.

22 Ammo box footman loop and strap secure caliber .50 ammo box to ammo box rack. 23 Ammo box rack provides stowage base for two 40 mm ammo boxes. 24 Ammo box footman loops and straps (two each) secure two 40 mm ammo boxes to ammo box rack.

25 Ammo box rack provides stowage base for three 40 mm ammo boxes.

26 Tripod mounting bracket and straps (two each) provide stowage for M3 tripod. 27 Ammo box footman loops and straps (two each) secure three 40 mm ammo boxes to ammo box rack.

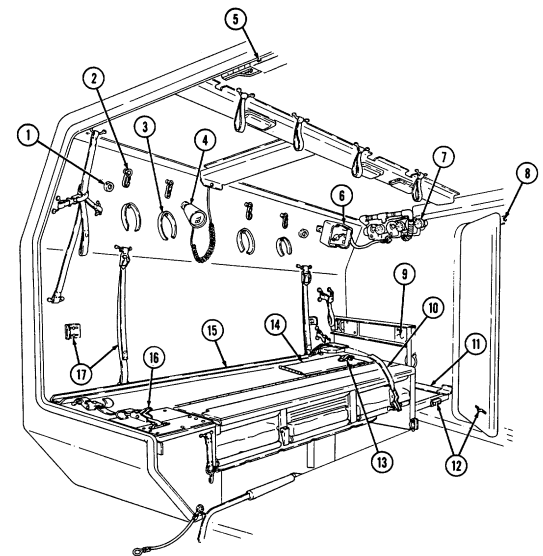

Key Item And Function

1 Gun mount adapter plate provides mounting base for stowage of 40 mm gun mount adapter.

2 Gun mount footman loops and straps (two each) secure 40 mm gun mount adapter to gun mount adapter plate.

3 Pintle adapter bracket provides mounting base for stowage of pintle adapter.

4 Pintle adapter footman loop and strap secure pintle adapter to pintle adapter bracket.

5 Ammo box rack serves as stowage base for two caliber .50 ammo boxes. 6 Ammo box footman loops and straps (two each) secure two caliber .50 ammo boxes to ammo box rack.

7 Night sight case stowage brackets (two each) provide mounting for night sight case.

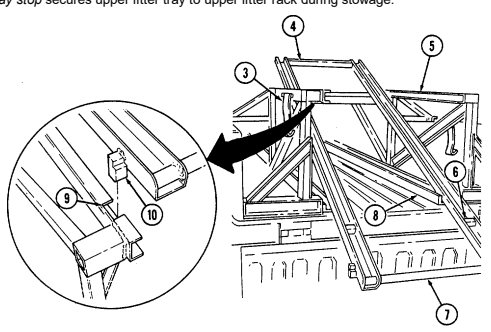

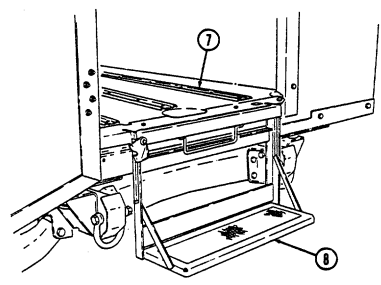

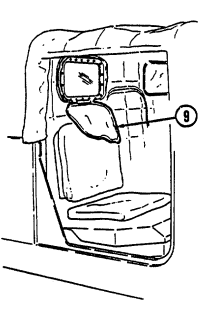

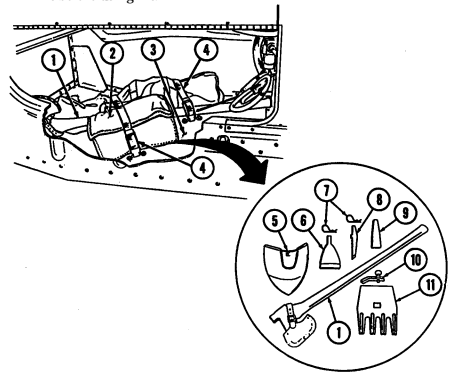

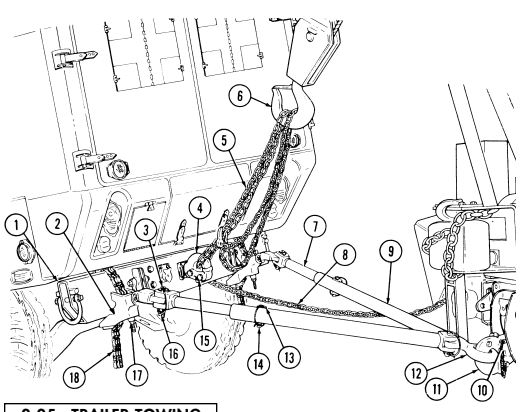

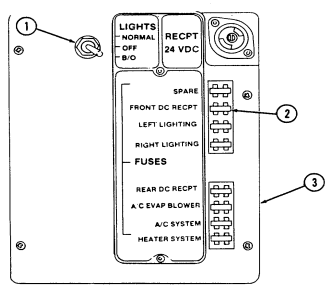

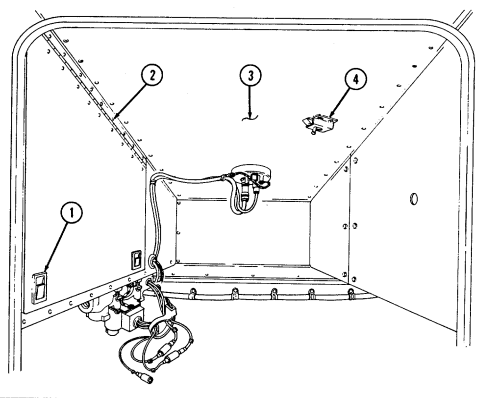

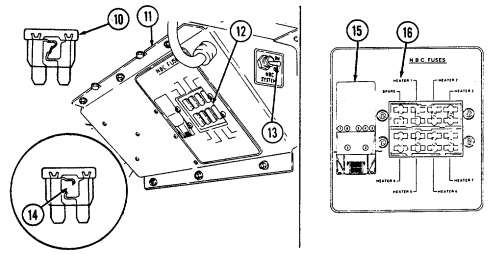

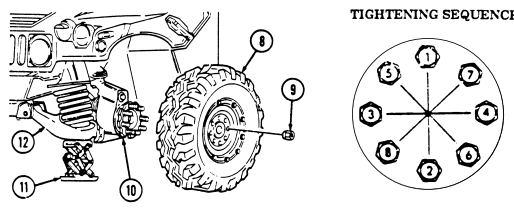

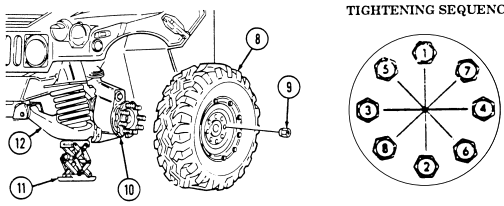

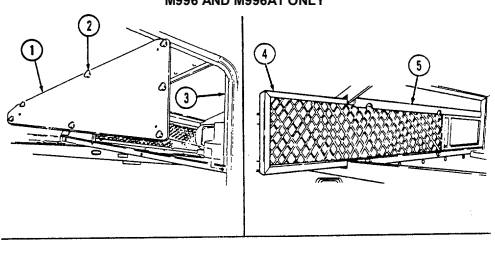

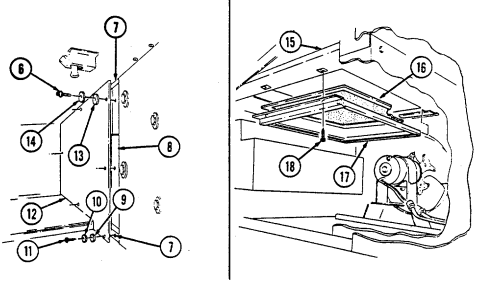

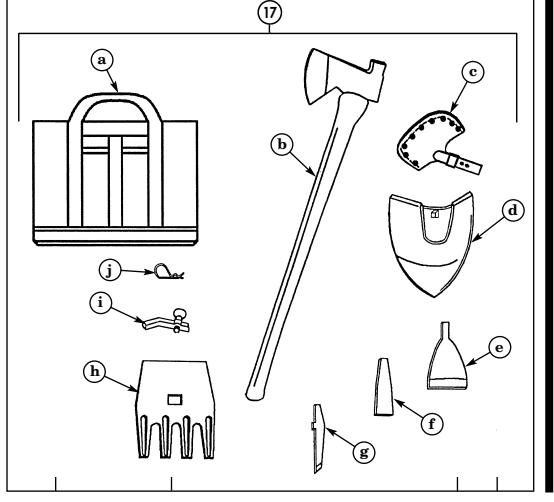

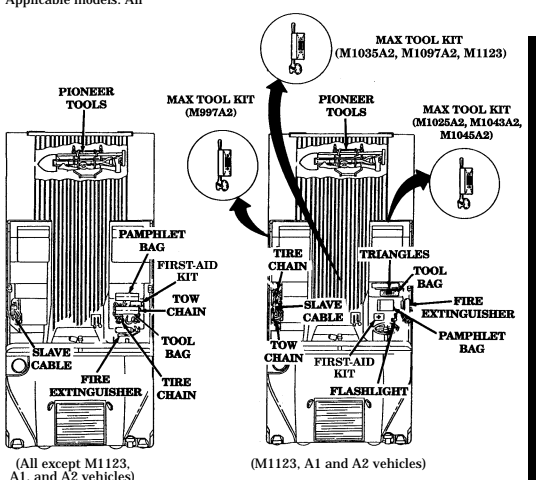

8 Night sight case footman loops and straps (two each) secure night sight case to night sight stowage brackets.