hmmwv-manuals

ARMY TM 9-2815-237-34 AIR FORCE TO 38V1-6-2 MARINE CORPS TM 2815-34/3 A (SUPERSEDES TM 9-2815-237-34, 25 June 1985) TECHNICAL MANUAL DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE ENGINE, DIESEL: 8 CYLINDER, NATURALLY ASPIRATED, FUEL-INJECTED, WATER COOLED, DDA MODEL 6.2 LITER (PRE-1990) (NSN 2815-01-231-3672), (POST-1990) (NSN 2815-01-314-7940); DDA MODEL 6.5 LITER (NSN 2815-01-410-9710) (1995,1996), (NSN 2815-01-439-6665) (1997), (NSN 2815-01-453-7403) (1998); ENGINE, DIESEL: 8 CYLINDER, NATURALLY ASPIRATED, DETUNED, FUEL-INJECTED, WATER COOLED, DDA MODEL 6.5 LITER (NSN 2815-01-406-6675) (1996), (NSN 2815-01-439-6664) (1997), (NSN 2815-01-453-7404) (1998); ENGINE, DIESEL: 8 CYLINDER, TURBOCHARGED, FUEL-INJECTED, WATER COOLED, (NSN 2815-01-420-4180) (1996), (NSN 2815-01-439-8164) (1997), (NSN 2815-01-453-7402) (1998).

Approved for public release; distribution is unlimited.

HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS JANUARY 1996

Warning Exhaust Gases Can Kill

Brain damage or death can result from heavy exposure. Precautions must be followed to ensure personnel safety when the engine is operated for any purpose.

- DO NOT operate your vehicle engine in enclosed area. 2. BE ALERT at all times for exhaust odors. 3. BE ALERT for exhaust poisoning symptoms. They are:

- Headache - Dizziness - Sleepiness - Loss of muscular control 4. If YOU SEE another person with exhaust poisoning symptoms:

- Remove person from area - Expose to open air - Keep person warm - Do not permit person to move - Administer artificial respiration, if necessary* - Notify a medic

- For artificial respiration, refer to FM 21-11 5. BE AWARE, the field protective mask for nuclear-biological-chemical (NBC) protection will not protect you from exhaust poisoning. THE BEST DEFENSE AGAINST EXHAUST POISONING IS ADEQUATE VENTILATION.

Warning Summary

-

Always wear eyeshields when using compressed air. Failure to wear eyeshields may result in eye injury. - Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personal protective equipment (goggles/shield, gloves, etc.).

-

Do not use compressed air to dry bearings. Spinning a dry bearing with compressed air may cause injury to personnel or damage to equipment.

-

Improper cleaning methods and use of unauthorized cleaning solutions will injure personnel and damage equipment. See TM 9-247 for correct information.

-

Drycleaning solvent is flammable and will not be used near an open flame. A fire extinguisher will be kept nearby when the solvent is used. Use only in well-ventilated places. Failure to do this may result in injury to personnel and/or damage to equipment.

-

When steam cleaning, protective clothing must be used. Failure to use protective clothing may result in serous injury.

-

Diesel fuel is highly flammable. Do not perform this procedure near fire, flame, or sparks. Severe injury or death may result.

-

Cylinder block must be supported during removal and installation from engine stand. Failure to support cylinder block may cause injury to personnel or damage to equipment.

-

Crankshaft must be supported during removal and installation. Failure to support crankshaft may cause injury to personnel or damage to equipment.

-

Do not place hands or arms near nozzle during testing. Penetrating force of oil may cause serious injury or death.

-

Direct personnel to stand clear during hoisting operation. Failure to do this may cause injury to personnel. - Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be removed with a scraper or putty knife and then disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

CHANGE NO. 2 ARMY TM 9-2815-237-34 AIR FORCE TO 38V1-6-2 MARINE CORPS TM 2815-34/3 A HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS Washington, D.C., 15 July 2004 TECHNICAL MANUAL DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE ENGINE, DIESEL: 8 CYLINDER, NATURALLY ASPIRATED, FUEL-INJECTED, WATER COOLED, DDA MODEL 6.2 LITER (PRE-1990) (NSN 2815-01-231-3672), (POST-1990) (NSN 2815-01-314-7940); DDA MODEL 6.5 LITER (NSN 2815-01-410-9710) (1995,1996), (NSN 2815-01-439-6665) (1997), (NSN 2815-01-453-7403) (1998); ENGINE, DIESEL: 8 CYLINDER, NATURALLY ASPIRATED, DETUNED, FUEL-INJECTED, WATER COOLED, DDA MODEL 6.5 LITER (NSN 2815-01-406-6675) (1996), (NSN 2815-01-439-6664) (1997), (NSN 2815-01-453-7404) (1998); ENGINE, DIESEL: 8 CYLINDER, TURBOCHARGED, FUEL-INJECTED, WATER COOLED, (NSN 2815-01-420-4180) (1996), (NSN 2815-01-439-8164) (1997), (NSN 2815-01-453-7402) (1998) TM 9-2815-237-34, 31 January 1996, is changed as follows:

- Remove old pages and insert new pages as indicated below. 2. New or changed material is indicated by a vertical bar in the margin of the page.

| Remove pages | Insert pages |

|---|---|

| A/(B blank) | A/(B blank) |

| i and ii | i and ii |

| 1-1 and 1-2 | 1-1 and 1-2 |

| 1-5/(1-6 blank) | 1-5/(1-6 blank) |

| 2-23 and 2-24 | 2-23 and 2-24 |

| 2-85 through 2-90 | 2-85 through 2-90 |

| 2-101 and 2-102 | 2-101 and 2-102 |

| 2-113 and 2-114 | 2-113 and 2-114 |

| 2-117 through 2-120 | 2-117 through 2-120 |

| 2-125 and 2-126 | 2-125 and 2-126 |

| 2-155 and 2-156 | 2-155 and 2-156 |

| 2-173 and 2-174 | 2-173 and 2-174 |

| A-1 and A-2 | A-1 and A-2 |

| Index 1 through Index 4 | Index 1 through Index 4 |

| DA Form 2028 | DA Form 2028 |

| Cover | Cover |

- File this change sheet in front of the publication for reference purposes.

Approved for public release; distribution is limited.

By Order of the Secretary of the Army: Peter J. Schoomaker General, United States Army Chief of Staff Official: JOEL B. HUDSON Administrative Assistant to the Secretary of the Army 0223410 By Order of the Secretary of the Air Force: RONALD R. FOGLEMAN General, United States Air Force Chief of Staff Official: HENRY VICCELLIO, JR.

General, United States Air Force Commander, Air Force Materiel Command By Order of the Marine Corps: R. P. SHOCKEY Director, Program Support Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 380623, requirements for TM 9-2815-237-34.

CHANGE NO. 1 ARMY TM 9-2815-237-34 AIR FORCE TO 38V1-6-2 MARINE CORPS TM 2815-34/3 A HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS Washington, D.C., 31 May 1999 TECHNICAL MANUAL DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE ENGINE, DIESEL: 8 CYLINDER, NAT U R A L LY ASPIRAT E D , FUEL-INJECTED, WATER COOLED, DDA MODEL 6.2 LITER (SERIAL NUMBER 1-99,999) (NSN 2815-01-231-3672), (SERIAL NUMBER 100,000 AND ABOVE) (NSN 2815-01-314-7940) (1990); DDA MODEL 6.5 LITER (NSN 2815-01-410-9710) (1995,1996), (NSN 2815-01-439-6665) (1997), (NSN 2815-01-453-7403) (1998); ENGINE, DIESEL: 8 CYLINDER,N AT U R A L LY ASPIRATED, DETUNED, FUEL-INJECTED, WATER COOLED, DDA MODEL 6.5 LITER (NSN 2815-01-406-6675) (1996), (NSN 2815-01-439-6664) (1997), (NSN 2815-01-453-7404) (1998); ENGINE, DIESEL: 8 CYLINDER, TURBOCHARGED, FUEL-INJECTED, WATER COOLED, (NSN 2815-01-420-4180) (1996), (NSN 2815-01-439-8164) (1997), (NSN 2815-01-453-7402) (1998).

TM 9-2815-237-34, 31 January 1996, is changed as follows:

-

New engine models have been added to the front cover. The new cover, located at the end of the change package, replaces the front cover.

-

Remove old pages and insert new pages as indicated below. 3. New or changed material is indicated by a vertical bar in the margin of the page. 4. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert pages | Remove pages | Insert pages |

|---|---|---|---|

| Warning a and b | Warning a and b | 2-153 through 2-156 | 2-153 through 2-156 |

| N o n e | A (After Warning b) | 2-169 and 2-170 | 2-169 and 2-170 |

| i and ii | i and ii | 2-183 through 2-186 | 2-183 through 2-186 |

| 1-3 and 1-4 | 1-3 and 1-4 | 2-189 and 2-190 | 2-189 and 2-190 |

| N o n e | 2-6.1 and 2-6.2 | None | 2-193/(2-194 blank) |

| 2-7 through 2-18 | 2-7 through 2-18 | D-1 through D-3/(D-4 blank) | D-1 through D-3/(D-4 blank) |

| 2-23 through 2-26 | 2-23 through 2-26 | E-3/(E-4 blank) | E-3 and E-4 |

| 2-31 through 2-34 | 2-31 through 2-34 | F-3/(F-4 blank) | F-3/(F-4 blank) |

| 2-37 through 2-48 | 2-37 through 2-48 | Index 1 through Index 4 | Index 1 through Index 4 |

| 2-53 through 2-56 | 2-53 through 2-56 | Cover | Cover |

| 2-83 and 2-84 | 2-83 and 2-84 | ||

| N o n e | 2-140.1 through | ||

| 2-140.25/(2-140.26 blank) |

Approved for public release; distribution is limited.

By Order of the Secretary of the Army: O f f i c i a l :

JOEL B. HUDSON Administrative Assistant to the Secretary of the Army 05694 By Order of the Secretary of the Air Force: ERIC K. SHINSEKI General, United States Army Chief of Staff RONALD R. FOGLEMAN General, United States Air Force Chief of Staff O f f i c i a l : H E N RY VICCELLIO, JR.

General, United States Air Force C o m m a n d e r, Air Force Materiel Command By Order of the Marine Corps: D.R. BLOOMER Colonel, USMC Director, Program Support Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 380623, requirements for TM 9-2815-237-34.

TM 9-2815-237-34

List Of Effective Pages

INSERT LATEST CHANGED PAGES. DESTROY SUPERSEDED PAGES.

NOTE: The portion of the text affected by the changes is indicated by a vertical line in the outer margins of the page.

Dates of issue for original and changed pages are: Original . . . . . 0 . . . . . . . 31 January 1996 Change . . . . . . 1 . . . . . . . . . . 31 May 1999 Change . . . . . . 2 . . . . . . . . . . 15 July 2004 TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS 232, CONSISTING OF THE FOLLOWING:

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

|---|---|---|

| Warning a and b 1 | 2-40 - 2-41 0 | 2-173 2 |

| A 2 | 2-42 - 2-47 1 | 2-174 - 2-182 0 |

| B Blank 1 | 2-48 - 2-53 0 | 2-183 - 2-184 1 |

| i - ii 2 | 2-54 - 2-56 1 | 2-184.1 - 2-184.2 Added 1 |

| iii 0 | 2-57 - 2-82 0 | 2-185 0 |

| iv Blank 0 | 2-83 - 2-84 1 | 2-186 1 |

| 1-1 2 | 2-85 0 | 2-187 - 2-188 0 |

| 1-2 - 1-3 0 | 2-86 2 | 2-189 1 |

| 1-4 1 | 2-86.1 - 2-86.2 Added 2 | 2-190 - 2-192 0 |

| 1-5 2 | 2-87 - 2-90 2 | 2-193 Added 1 |

| 1-6 Blank 0 | 2-91 - 2-101 0 | 2-194 Blank 1 |

| 2-1 - 2-6 0 | 2-102 2 | A-1 0 |

| 2-6.1 - 2-6.2 Added 1 | 2-103 - 2-112 0 | A-2 2 |

| 2-7 - 2-8 1 | 2-113 2 | B-1 - B-3 0 |

| 2-9 0 | 2-114 - 2-117 0 | B-4 Blank 0 |

| 2-10 - 2-11 1 | 2-118 - 2-120 2 | C-1 - C-3 0 |

| 2-12 0 | 2-121 - 2-124 0 | C-4 Blank 0 |

| 2-12.1 - 2-12.2 Added 1 | 2-125 2 | D-1 0 |

| 2-13 - 2-15 1 | 2-126-2-140 0 | D-2 - D-3 1 |

| 2-16 - 2-17 0 | 2-140.1 - 2-140.25 Added 1 | D-4 Blank 0 |

| 2-18 1 | 2-140.26 Blank 1 | E-1 - E-2 0 |

| 2-19 - 2-22 0 | 2-141 - 2-152 0 | E-3 1 |

| 2-23 2 | 2-153 1 | E4 Added 1 |

| 2-24 0 | 2-154 0 | F1 - F2 0 |

| 2-25 - 2-26 1 | 2-155 1 | F3 1 |

| 2-27 - 2-31 0 | 2-156 2 | F4 Blank 0 |

| 2-32 - 2-33 1 | 2-157 - 2-168 0 | Index 1 1 |

| 2-34 - 2-37 0 | 2-169 1 | Index 2 - Index 4 2 |

| 2-38 - 2-39 1 | 2-170 - 2-172 0 |

*Zero in this column indicates original page.

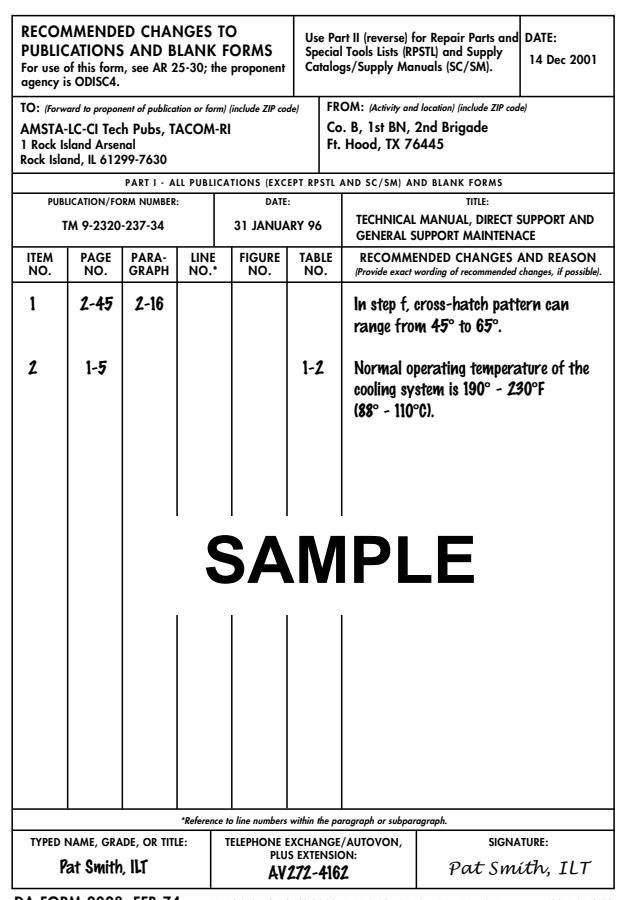

*ARMY TM 9-2815-237-34 AIR FORCE TO 38V1-6-2 MARINE CORPS TM 2815-34/3 A HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS Washington, D.C., 31 January 1996 TECHNICAL MANUAL DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE ENGINE, DIESEL: 8 CYLINDER, NATURALLY ASPIRATED, FUEL-INJECTED, WATER COOLED, DDA MODEL 6.2 LITER (PRE-1990) (NSN 2815-01-231-3672), (POST-1990) (NSN 2815-01-314-7940); DDA MODEL 6.5 LITER (NSN 2815-01-410-9710) (1995,1996), (NSN 2815-01-439-6665) (1997), (NSN 2815-01-453-7403) (1998); ENGINE, DIESEL: 8 CYLINDER, NATURALLY ASPIRATED, DETUNED, FUEL-INJECTED, WATER COOLED, DDA MODEL 6.5 LITER (NSN 2815-01-406-6675) (1996), (NSN 2815-01-439-6664) (1997), (NSN 2815-01-453-7404) (1998); ENGINE, DIESEL: 8 CYLINDER, TURBOCHARGED, FUEL-INJECTED, WATER COOLED, (NSN 2815-01-420-4180) (1996), (NSN 2815-01-439-8164) (1997), (NSN 2815-01-453-7402) (1998) REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS You can help improve this publication. If you find any mistakes or if you know of a way to improve the procedures, please let us know. Submit your DA Form 2028 (Recommended Changes to Publications and Blank Forms), through the Internet, on the Army Electronic Product Support (AEPS) website. The Internet address is http://aeps.ria.army.mil. If you need a password, scroll down and click on "ACCESS REQUEST FORM." The DA Form 2028 is located in the ONLINE FORMS PROCESSING section of the AEPS. Fill out the form and click on SUBMIT. Using this form on the AEPS will enable us to respond quicker to your comments and better manage the DA Form 2028 program. You may also mail, fax or E-mail your letter or DA Form 2028 direct to: AMSTA-LC-CI Tech Pubs, TACOM-RI, 1 Rock Island Arsenal, Rock Island, IL 61299-7630. The E-mail address is TACOM-TECH-PUBS@ria.army.mil. The fax number is DSN 793-0726 or Commercial (309) 782-0726. (Marine Corps) Submit NAVMC 10722 to Commander Code 835-2, Marine Corps Logistic Base, 814 Radford Boulevard, Albany, GA 31704-1128.

Approved for public release; distribution is unlimited.

TECHNICAL MANUAL NO. 9-2815-237-34 NO. 2815-34/3 A TECHNICAL ORDER NO. 38V1-6-2

- This publication supersedes TM 9-2815-237-34 dated 25 June 1985 and all changes.

| Page | ||

|---|---|---|

| HOW TO USE THIS MANUAL | iii | |

| CHAPTER 1 | INTRODUCTION | 1-1 |

| Section I. | General Information | 1-1 |

| II. | Equipment Description and Data | 1-2 |

| CHAPTER 2. | ENGINE MAINTENANCE | 2 -1 |

| Section I. | Repair Parts, Special Tools, Test, Measurement, and Diagnostic | |

| Equipment(TMDE), and Support Equipment | 2 -1 | |

| II. | Service Upon receipt | 2 -1 |

| III. | Troubleshooting | 2 -2 |

| IV. | General Maintenance Instructions | 2 -3 |

| V. | Engine Disassembly, Repair, and Assembly | 2 -7 |

| VI. | Final Inspection | 2-188 |

| VII. | Repair and Replacement Standards | 2-190 |

| APPENDIX A | REFERENCES | A-1 |

| APPENDIX B | EXPENDABLE/DURABLE SUPPLIES AND MATERIALS LIST | B-1 |

| APPENDIX C | ILLUSTRATED LIST OF MANUFACTURED ITEMS | C-1 |

| APPENDIX D | MANDATORY REPLACEMENT PARTS | D-1 |

| APPENDIX E | TOOL IDENTIFICATION LIST | E-1 |

| APPENDIX F | TORQUE LIMITS | F-1 |

| INDEX | Index 1 |

Chapter 1 Introduction

Section I. General Information 1-1. Scope

This technical manual contains instructions for direct support and general support maintenance of the 6.2 liter naturally aspirated, 6.5 liter naturally aspirated detuned, and 6.5 liter turbo V-8 diesel engines.

1-2. Maintenance Forms, Records, And Reports

(Army) Department of the Army forms and procedures used for equipment maintenance will be those prescribed by DA Pam 738-750, The Army Maintenance Management System (TAMMS). (Marine Corps) Refer to MCO 4855-10.

1-3. Destruction Of Army Equipment To Prevent Enemy Use

Procedures for destruction of Army tank-automotive equipment to prevent enemy use are found in TM 750-244-6.

1-4. Preparation For Shipment

(Army) Refer to TM 746-10, Marking, Packaging, and Shipment of Supplies and Equipment: General Packaging Instructions for Field Use. (Marine Corps) Refer to MCO 4450-7.

1-5. Equipment Requiring Calibration

Calibration requirements in this manual cover the fuel injection pump and can be found in paras. 2-33, 2-34, and 2-35 of this manual.

1-6. Reporting Equipment Improvement Recommendations (Eirs)

If your vehicle needs improvement, let us know. Send us an EIR. You, the user, are the only one who can tell us what you don't like about your equipment. Let us know why you don't like the design or performance. The preferred method for submitting QDRs is through the Army Electronic Product Support (AEPS) website under the Electronic Deficiency Reporting System (EDRS). The web address is: https://aeps.ria.army.mil. This is a secured site requiring a password that can be applied for on the front page of the website. If the above method is not available to you, put it on an SF 368, Product Quality Deficiency Report (PQDR), and mail it to us at: Department of the Army, U.S. Army Tank-automotive and Armaments Command, ATTN: AMSTA-TR-E/PQDR MS 267, 6501 E. 11 Mile Road, Warren, MI 48397-500. We'll send you a reply. (Marine Corps) Submit QDR's in accordance with MCO 4855-10.

1.7. Equipment Improvement Report And Maintenance Digest (Eir Md)

The quarterly Equipment Improvement Report and Maintenance Digest, TB 43-0001-62 series, contains valuable field information on the equipment covered in this manual. The information in the TB 43-0001-62 series is compiled from some of the Equipment Improvement Reports that you prepared on the vehicles covered in this manual. Many of these articles result from comments, suggestions, and improvement recommendations that you submitted to the EIR program. The TB 43-0001-62 series contains information on equipment improvements, minor alterations, proposed Modification Work Orders (MWOs), warranties (if applicable), actions taken on some of your DA Form 2028s (Recommended Changes to Publications and Blank Forms), and advance information on proposed changes that may affect this manual. The information will help you in doing your job better and will help in keeping you advised of the latest changes to this manual. Also refer to DA Pam 25-30, Consolidated Index of Army Publications and Blank Forms, and appendix A, References, of this manual. (Marine Corps) Submit QDR's in accordance with MCO 4855-10. For those with access to the World Wide Web (WWW), the EIR MD can be viewed through the Army Electronic Product Support. The site is http://aeps.ria.army.mil.

1-8. Metric System

The engines described herein contain metric components and require metric common and special tools; therefore, metric units in addition to standard units will be used throughout this publication. In addition, a metric conversion table is located on the inside back cover of this publication.

1-9. Mandatory Replacement Parts

The maintenance instructions contained herein make reference to removing and discarding piece parts such as: gaskets, lockwashers, cotter pins, O-rings, seals, etc.; these items should be considered mandatory replacement items and replaced with new parts during assembly/installation.

Section Ii. Equipment Description And Data 1-10. Description

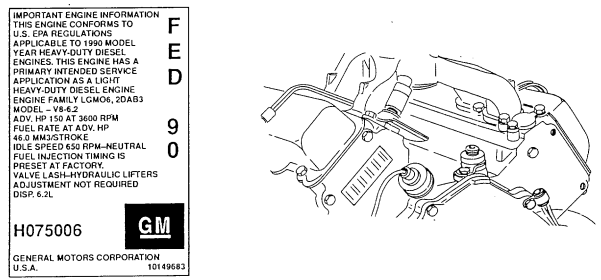

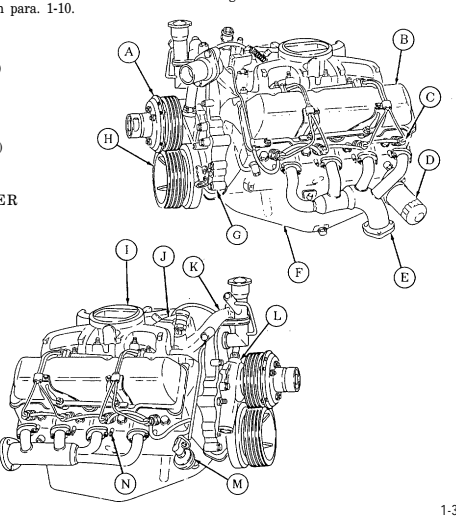

The engine used in the M998 series vehicles is an eight-cylinder, four-cycle, liquid-cooled, naturally aspirated diesel engine. The 6.2L engine has a compression ratio of 21.5:1 and develops approximately 150 horsepower (112 kW) at 3600 rpm. The 6.5L engine has a compression ratio of 21.5:1 and develops approximately 160 horsepower (119 kW) at 3400 rpm. For proper orientation, the left and right sides of the engine are as viewed from the rear.

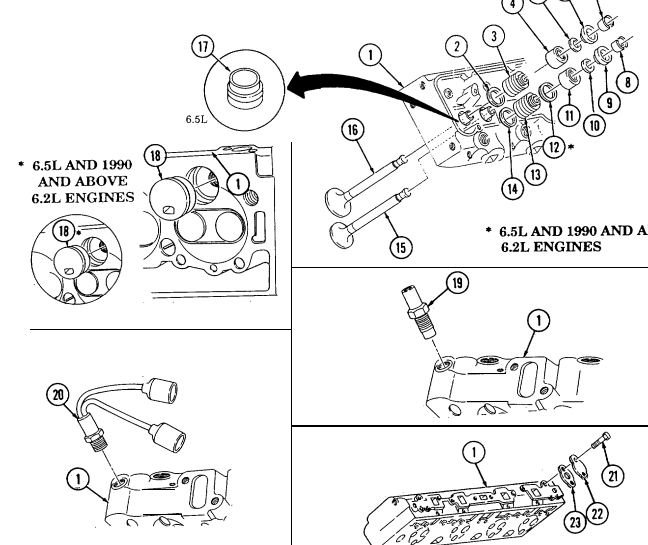

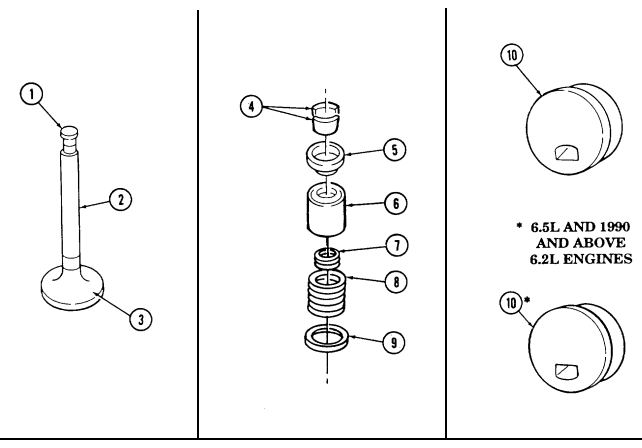

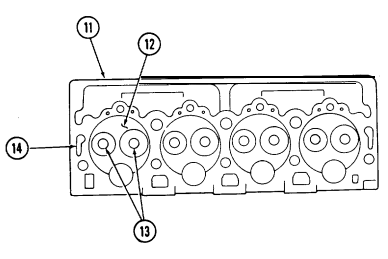

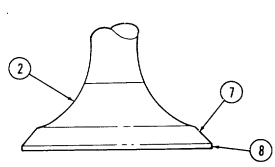

1990 and above 6.2L and 1994 6.5L engines have the following new and revised parts: *Cylinder Heads. The 1990 cylinder heads have been revised to meet 1990 emissions standards. Precombustion Valves. The 1990 engine is equipped with reverse throat precombustion chambers. Exhaust Valves. The 1990 exhaust valves are coated with chrome to prevent burning and to increase durability.

*Exhaust Valve Stem Seal. The 1990 engine is equipped with a new exhaust valve stem seal that is not available for previous model engines.

Cylinder Head Gaskets. The 1990 cylinder head gaskets have new circular combustion seals and are made of a non-asbestos material. Fuel Injection Pump. The 1994 fuel injection pump has a TP sensor and a revised calibration procedure.

Fuel Injection Pump. The 1990 fuel injection pump has a new governor and a revised calibration procedure.

*Fuel Injection Nozzles. The 1990 fuel injection nozzles are shorter and are orientated ten degrees from the vertical. *Fuel Injection Lines. The 1990 engine is equipped with high pressure fuel injection lines. Fuel Injection Line Brackets. The 1990 fuel injection line brackets have been revised to provide clearance for the injection nozzles.

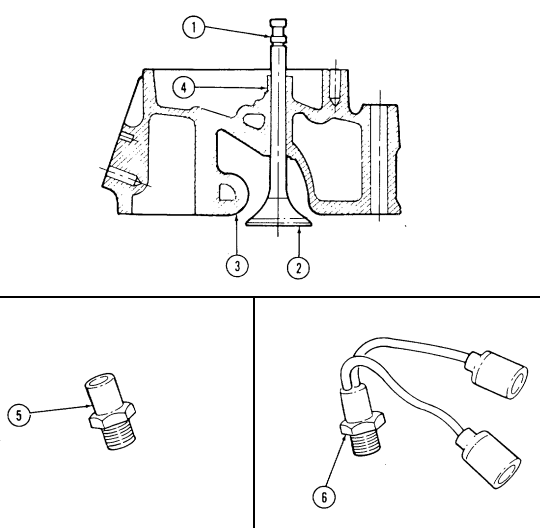

*RPM Sensors. The 1994 engine is equipped with two rpm sensors. One is for STE-ICE-R and one is for the engine. *Fan Cut-Off Switch. The 1994 engine is equipped with a fan cut-off switch which replaced the kick-down switch.

*These 1990 parts are not interchangeable with parts for previous model engines. Differences in maintenance procedures are identified where applicable. Refer to engine decal number on left rocker arm cover before ordering replacement parts.

The 1990 6.2L engine is identified by a decal which is adhered to the left rocker arm cover. The 6.5L engine is identified by a serial number bar code decal.

1-11. Component Location

The locations of components described below are common to all engines in the M998 series vehicles.

Special differences are described in para. 1-10.

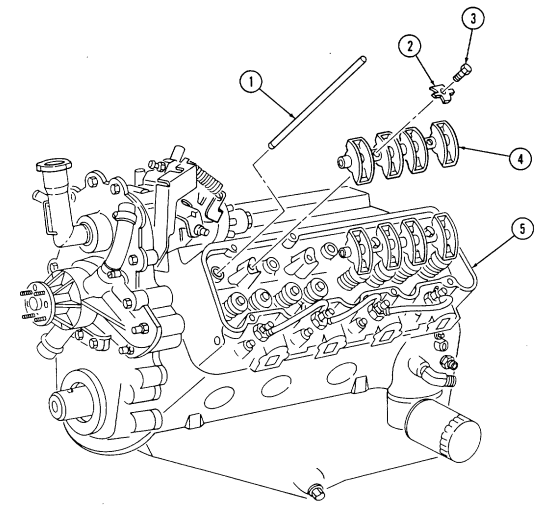

(A) FAN CLUTCH (B) ROCKER ARM COVERS (2) (C) FUEL INJECTORS (8) (D) OIL FILTER (E) EXHAUST MANIFOLDS (2) (F) OIL PAN (G) TIMING GEAR COVER (H) CRANKSHAFT PULLEY (1) INTAKE MANIFOLD (1) FUEL INJECTION PUMP (K) WATER CROSSOVER (L) WATER PUMP (M) FUEL PUMP (N) GLOW BLUGS (8)

1 - 1 2 . Ta B U L Ated Data

Engine tabulated data is listed in tables 1-1 and 1-2. This information includes only those data applicable to direct support and general support maintenance. Information not covered can be found in TM 9-2320-280-20 and TM 9-2320-280-10.

| MEASUREMENT ABBREVIATION | MEASUREMENT | ABBREVIATION | ||

|---|---|---|---|---|

| Quart | qt | Celsius | C | |

| Kilogram | kg | Liter | L | |

| Inch | in. | Centimeter | cm | |

| Pound | lb | Millimeter | mm | |

| Pounds Per Square Inch | psi | Kilopascal | kPa | |

| Revolutions Per Minute | rpm | Newton Meter | N•m | |

| Pound-Feet | lb-ft | Horsepower | hp | |

| Cubic Inch | cu-in. | Kilowatt | kW | |

| Fahrenheit | F |

Ta B U L Ated Data Abbreviat I O N S

Table 1-1. Tabulated Data (6.2 L)

| Manufacturer | Detroit Diesel Allison |

|---|---|

| Model | 6.2 L |

| Type | Four-cycle, liquid-cooled, naturally aspirated |

| STANDARD METRIC | |

| Dimensions: | |

| Length | 35 in. 89 cm |

| Width | 28 in. 71 cm |

| Height | 28 in. 71 cm |

| New weight, dry | 650 lbs 295 kg |

| Cylinders: | |

| Number | Eight |

| Arrangement | 90° V |

| Firing order | 1-8-7-2-6-5-4-3 (clockwise) |

| Bore | 3.98 in. 10.1 cm |

| Stroke (nominal) | 3.82 in. 9.7 cm |

| Displacement | 392 cu-in. 6.2 L |

| Compression ratio | 21.5:1 |

| Maximum Torque (gross) | 260 lb-ft @ 2000 rpm 353 N•m @ |

| 2000 rpm | |

| Governed Speed: | |

| Full load | 3600 rpm |

| No load | 4000 rpm |

| Idle speed | 650±25 rpm |

| Lubrication System: | |

| Type | Pressure feed |

| Operating pressure (normal) | 40-50 psi 276-345 kPa |

| Operating pressure (at idle) | 10 psi 69 kPa |

| System capacity (including filter) | 8 qts 7.6 L |

| Operating temperature (normal) | 180°-260°F 82°-126°C |

| Oil pump | Gear-driven |

| Cooling system: | |

| Type | Liquid with fan and radiator |

| Operating temperature (normal) | 190°-230°F 88°-110°C |

Standard and metric measurements will be used in this table. A list of their abbreviations is provided above.

Chapter 2 Engine Maintenance

Section I. REPAIR PARTS, SPECIAL TOOLS, TEST, MEASUREMENT, AND DIAGNOSTIC EQUIPMENT (TMDE), AND SUPPORT EQUIPMENT

2-1. Common Tools And Equipment

Refer to Modified Table of Organization and Equipment (MTOE) for authorized common tools and equipment applicable to your unit.

2-2. Special Tools And Support Equipment

Special tools and support equipment are listed in Appendix E of this manual and illustrated in TM 9-2815237-34P.

2-3. TEST, MEASUREMENT, AND DIAGNOSTIC EQUIPMENT (TMDE) Calibrate all measuring and test equipment used to determine equipment conformance in accordance with TB 43-180.

2-4. REPAIR PARTS Repair parts are listed and illustrated in TM 9-2815-237-34P.

Section Il. Service Upon Receipt 2-5. Engine Inspection

a. Inspect for any damage done to engine during its removal from the vehicle. Refer to TM 9-2320-280-34 for engine removal procedure.

b. Upon receipt of engine, ensure that all components are present and that no engine subassemblies have been removed. Refer to TM 9-2320-280-34 for engine dress after removal.

c. If the engine has been transferred to you from another DS/GS maintenance facility, check the equipment against the packing slip to see if the shipment is complete. Report all discrepancies in accordance with the instructions of DA Pam 738-750.

Section Iii. Troubleshooting

2-6. General

Information in this section is for use of support maintenance personnel in conjunction with, and as a supplement to, troubleshooting procedures in TM 9-2320-280-20 and TM 9-2320-280-34.

2-7. Engine Troubleshooting

Operation of a deadlined engine without preliminary inspection will cause further damage.

Information to be used for troubleshooting the engine is contained in TM 9-2320-280-20 and TM 9-2320-280-34.

a. Excessive oil consumption is generally caused by leaky gaskets or loose line connections.

b. Always check the easiest and most obvious things first. This simple rule saves time and trouble. c. Double check before disassembly. The source of most engine problems can be traced to more than one part in a system. For example: (1) Excessive fuel consumption may not be caused by the fuel pump alone. Instead, the trouble could be a clogged air cleaner, or a restricted exhaust passage causing severe back pressure.

(2) Engines very often are disassembled in search of a complaint and the real evidence of the problem is destroyed. Check again to be sure an easier solution to the problem has not been overlooked.

d. Before correcting a problem, diagnose the cause of the problem. Do not allow the same failure to occur again.

Section Iv. General Maintenance Instructions

2-8. General Maintenance Instructions Task Summary

| TASK | PROCEDURES | PAGE |

|---|---|---|

| PARA, | NO. | |

| 2-9. | Cleaning | 2-3 |

| 2-10. | Inspection | 2-4 |

| 2-11. | Repair | 2-5 |

| 2-12. | Assembly | 2-6 |

2-9. Cleaning

a. General Instructions. Cleaning procedures will be the same for the majority of parts and components which make up engine subassemblies. General cleaning procedures are detailed in "b" through "i".

b. The Importance of Cleaning. Great care and effort are required in all cleaning operations. The presence of dirt and foreign material is a constant threat to satisfactory engine operation and maintenance.

The following will apply to all cleaning operations: (1) Hands must be kept free of any accumulation of grease which can collect dust and grit. (2) Clean all parts before inspection, after repair, and before assembly. (3) After cleaning, all parts must be covered or wrapped in plastic or paper to protect them from dust and/or dirt.

Warning

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personal protective equipment (goggles/shield, gloves, etc.).

c. External Engine Cleaning. All electrical equipment and other parts that could be damaged by steam cleaning or moisture must be removed, and all openings covered before cleaning. Dry with compressed air.

d. Disassembled Parts Cleaning. Place all disassembled parts in wire baskets for cleaning.

(1) Dry and cover all cleaned parts. (2) Place on or in "racks" and hold for inspection or repair. (3) All parts subject to rusting must be lightly oiled and wrapped.

(4) Keep all related parts and components together. Do not mix parts.

Warning

Improper cleaning methods and use of unauthorized cleaning solutions will injure personnel and damage equipment. See TM 9-247 for correct information.

E. Castings.

(1) Clean inner and outer surfaces of castings and all areas subject to grease and oil with cleaning solvents. Refer to TM 9-247.

(2) Use a stiff brush to remove sludge and gum deposits. (3) Use compressed air to blow out all tapped capscrew holes and dry castings after cleaning.

f. Oil Passages. Particular attention must be given to all oil passages in castings and machined parts.

Oil passages must be clean and free of any obstructions.

(1) Clean passages with wire probes to breakup any sludge or gum deposits. (2) Wash passages by flushing with solvents. See TM 9-247, (3) Dry passages with compressed air.

Do not allow drycleaning solvents to come in contact with seals, cables, or flexible hoses. These cleaners cause leather, rubber, and synthetic materials to dry out, rot, and lose pliability making them unserviceable.

g. Nonmetallic Parts. Clean hoses and other nonmetallic parts with soap and water. h. Bearings.

Warning

Do not use compressed air to dry bearings. Spinning a dry bearing with compressed air may cause injury to personnel or damage to equipment.

(1) Bearings require special cleaning. After removing surface oil and gum deposits, place bearings in hot oil, 140°F (60•C), to loosen congealed oil and grease. Wipe bearings dry with a Iint-free cloth; do not use compressed air.

(2) See TM 9-214 for information and care of bearings.

I. Electrical Components.

(1) Clean electrical components with clean cloth dampened with drycleaning solvent. Care must be taken not to damage protective insulation.

Warning

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personaI protective equipment (goggles/shield, gloves, etc.).

(2) Use compressed air oa dry electrical components.

2-10. Inspection

a. General Instructions. Procedures for inspections will be the same for many parts and components which make up the engine subassemblies. General procedures are detailed in "b" through "k", Dimensional standards for parts have been fixed at extremely close tolerances, so use specification tables. Use specified inspection equipment for inspection where cracks and other damage cannot be spotted visually. Exercise extreme care in all phases of inspection. Repair or replace all unserviceable components; refer to para. 2-11.

B. Castings.

(1) Inspect all ferrous and nonferrous castings for cracks. See MIL-I-6866, Inspection, Penetrant Methods, and MIL-I-6868, Inspection Process, Magnetic Particles. Particularly check areas around studs, pipe plugs, threaded inserts, and sharp comers. Replace cracked castings.

(2) Inspect machined surfaces for nicks, burrs, and raised metal. Mark damaged areas for repair or replacement.

(3) Inspect all pipe plugs, pipe plug openings, capscrews, and capscrew openings for damaged and stripped threads. Replace if damaged or threads are stripped.

(4) Check all gasket mating surfaces, flanges on housings, and supports for warpage with a straight edge or surface plate. Inspect mating flanges for discolorations which may indicate leakage. Replace if warped.

(5) Check all castings for conformance to applicable repair standards.

All engine connecting rod and main bearings will be replaced if one or more bearings fail.

Check all bearings for conformance to applicable repair standards .

d. Bushings and Bushing-Type Bearings.

(1) Check all bushings and bushing-type bearings for secure fit, evidence of heating, wear, burrs, nicks, and out-of-round conditions.

from (2) Check for dirt in lubrication holes or grooves. Holes and grooves must be clean and free damage.

e.

Machined Parts.

(1) Check machined parts for cracks, distortion, and damage. (2) Check all surfaces for nicks, burrs, and raised metal.

Studs, Bolts, and Capscrews. Replace if bent, loose, stretched, or threads are damaged.

Gears.

f.

g.

When gear teeth wear limits are not established, good judgment is required to determine if gear replacement is necessary.

(1) Inspect all gears for cracks and missing teeth. Replace if cracked or teeth are missing. (2) Inspect gear teeth for wear, sharp fins, burrs, and galled or pitted surfaces. (3) Inspect splines for wear, burrs, and galled or pitted surfaces. (4) Check keyway slots for wear and/or damage. Oil Seals. Oil seals are mandatory replacement items. Casting Plugs. Inspect for leakage. Replace plugs when leakage is present. Springs. Inspect for damaged, distorted, and collapsed coils.

k. Snaprings, Retaining Rings, and Washers. Many of these parts are mandatory replacement items. Inspect all others for obvious damage.

h.

i.

j.

2-11. Repair

a. General Instructions. Repair of most parts and components is limited to general procedures outlined in applicable maintenance instructions and the following detailed procedures "b" through "h".

CAUTION Repaired items must be thoroughly cleaned to remove metal chips and abrasives to prevent them from entering working parts of the engine.

B. Castings.

(1) All cracked castings will be replaced. (2) Only minor repairs to machined surfaces, flanges, and gasket mating surfaces are permitted.

Remove minor nicks, burrs, and/or scratches with: (a) Fine mill file. (b) Abrasive crocus cloth dipped in cleaning solvent. (c) Lapping across a surface plate. (d) Remachining of machined surfaces to repair damage, warpage, or uneven surfaces is not permitted. Replace castings.

(3) Repair damaged threaded pipe plug and/or capscrew holes with a thread tap or repair oversize holes with threaded inserts.

C. Bearings. See Tm 9-214.

d. Studs. Replace all bent and stretched studs. Repair minor thread damage with a thread restorer file.

Replace studs having stripped or damaged threads as outlined below: (1) Remove, using a stud remover. Back studs out slowly to avoid heat buildup and seizure which can cause stud to break off.

(2) If studs break off too short to use with a stud remover, use extractor to remove. (3) Replacement studs have a special coating and must have a small amount of antiseize compound (Appendix B, Item 3) applied on threads before stud is installed. Install replacement stud slowly to prevent heat buildup and snapping off.

e. Gears.

(1) Remove gears using pullers, as required. (2) Use the same methods described in paragraph 2-11.b.(2) for castings tO remove minor nicks, burrs, or scratches on gear teeth.

(3) If keyways are worn or enlarged, replace gear.

f. Bushings and BushingType Bearings. When bushings and bushing-type bearings seize to a shaft and spin in the bore, the associated part must also be inspected and replaced, as required.

g. Oil Seals.

(1) Remove oil seals, being careful not to damage casting or adapter bore.

(2) Always install new seal in bore using proper seal replacing tool.

h. Cylinder Block or Cylinder Head. Repair of cylinder block and cylinder head is limited to procedures outlined in paragraphs 2-16 and 2-21. Cylinder block or cylinder head must be replaced if measurements are outside tolerance limits listed in table 2-2 or table 2-3.

2-12. Assembly

a. Cleanliness is essential in all component assembly operations. Dirt and dust, even in minute quantities, are abrasive. Parts must be cleaned as specified, and kept clean. Wrap or cover parts and components when assembly procedures are not immediately completed.

b. Coat all bearings and contact surfaces with engine oil (MIL-L-2104) to ensure lubrication of parts during initial operation after repair.

c. Use new gaskets and preformed packings during assembly of all components.

Section V. Engine Disassembly, Repair, And Assembly 2 - 1 3 . Engine Disassembly, Repair, And Assembly Task Summary

| T A S K | P R O C E D U R E S | P A G E |

|---|---|---|

| P A R A . | N O . | |

| 2-13.1. | Engine Replacement in Shipping/Storage Container | 2-6.2 |

| 2-14. | Mounting Engine on Repair Stand | 2-8 |

| 2-15. | Engine Disassembly into Subassemblies | 2-10 |

| 2-16. | Cylinder Block Repair | 2-40 |

| 2-17. | Crankshaft Repair | 2-52 |

| 2-18. | Connecting Rod and Piston Repair | 2-54 |

| 2-19. | Camshaft, Timing Chain, and Drive Gears Repair | 2-58 |

| 2-20. | Timing Gear Cover Repair | 2-60 |

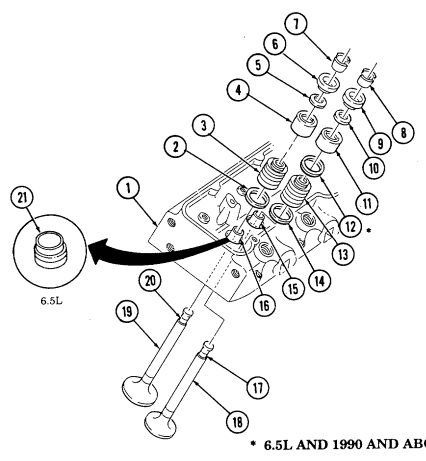

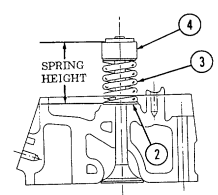

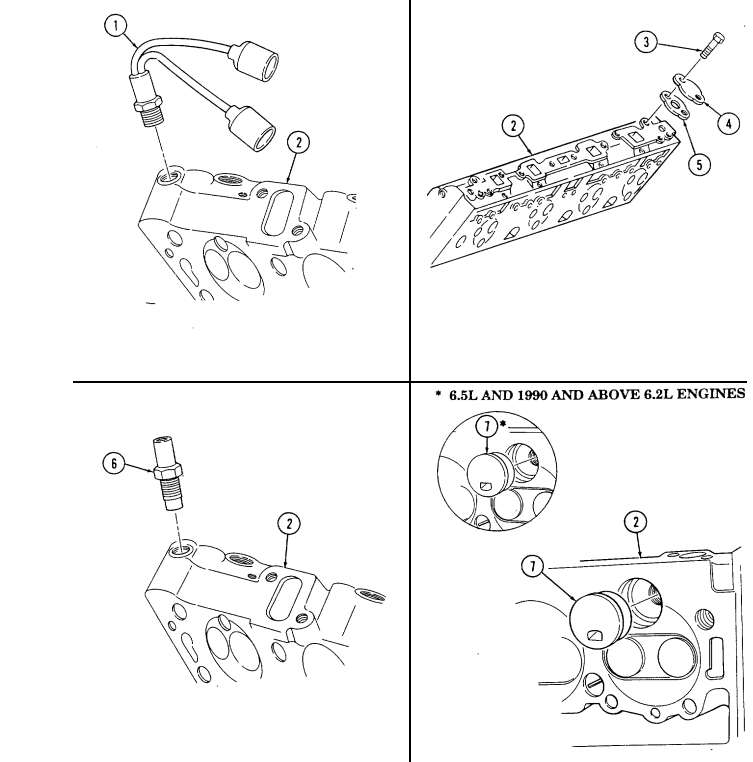

| 2-21. | Cylinder Head and Valve Repair | 2-62 |

| 2-22. | Valve Train Repair | 2-72 |

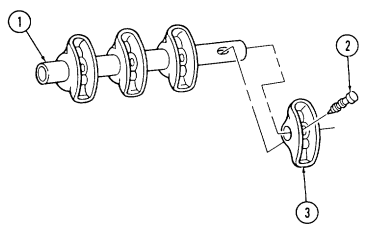

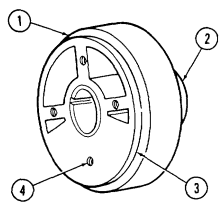

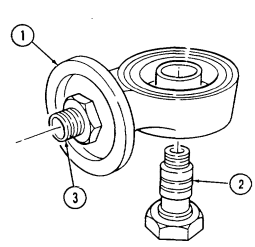

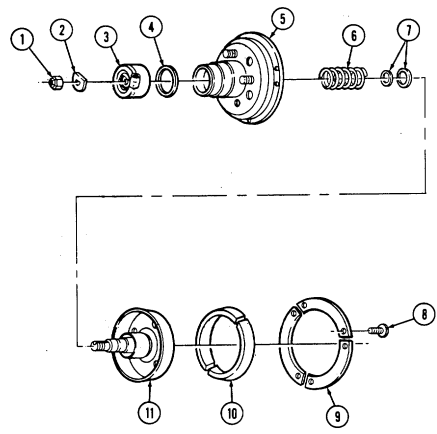

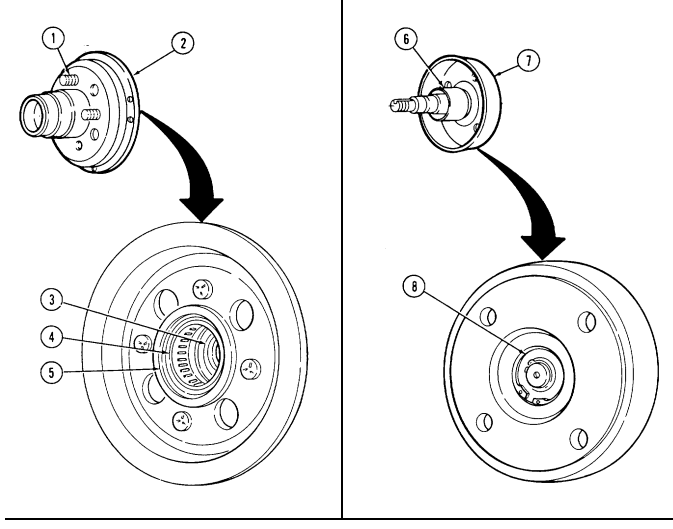

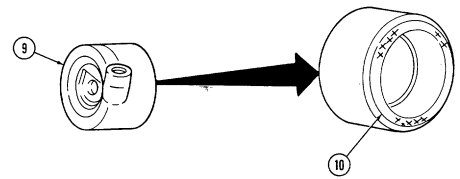

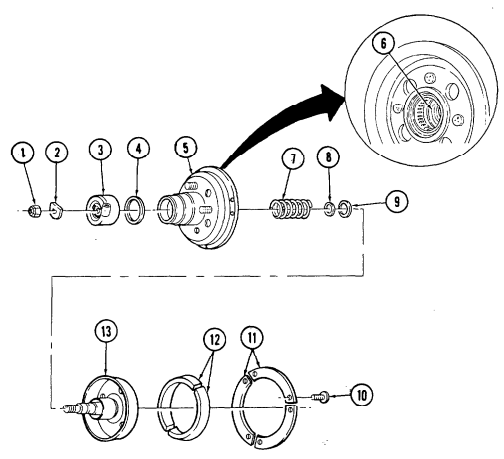

| 2-23. | Torsional Damper Repair | 2-74 |

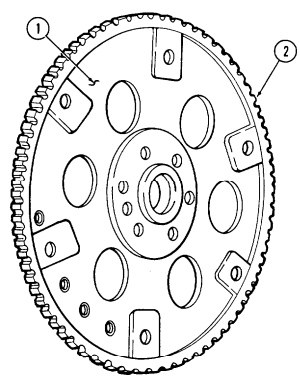

| 2-24. | Flywheel Repair | 2-75 |

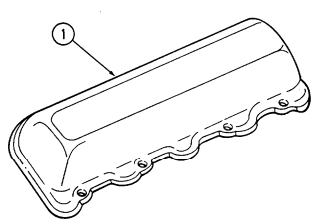

| 2-25. | Rocker Arm Cover Repair | 2-76 |

| 2-26. | Oil Pan Repair | 2-77 |

| 2-27. | Oil Pump Repair | 2-78 |

| 2-28. | Oil Filter Adapter and Oil Pressure Sending Unit Repair | 2-82 |

| 2-29. | Exhaust Manifold Repair | 2-83 |

| 2-30. | Intake Manifold Repair | 2-84 |

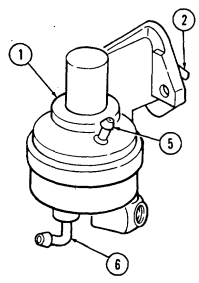

| 2-31. | Fuel Pump Repair | 2-85 |

| 2-32. | Fuel Injection Pump Repair (All Models) | 2-86 |

| 2-33. | Pre-1990 (6.2L) Fuel Injection Pump (DB2829-4523) Calibration | 2-126 |

| 2-34. | 1990 (6.2L) Fuel Injection Pump (DB2829-4879) Calibration | 2-131 |

| 2-35. | (6.5L) Fuel Injection Pump (DB2831-5149) Calibration | 2-136 |

| 2-35.1. | (6.5L) Fuel Injection Pump (DB2831-5209) Calibration | 2-140.1 |

| 2-35.2. | (6.5L) Fuel Injection Pumps (DB2831-5485 or DB2831-5079) | |

| Calibration | 2-140.6 | |

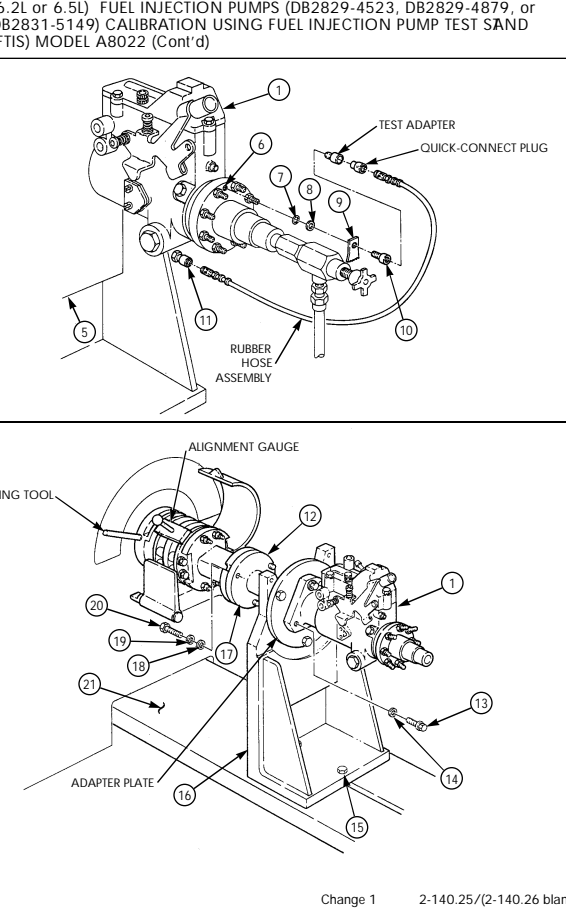

| 2-35.3. | (6.2L or 6.5L) Fuel Injection Pumps (DB2829-4523, DB2829-4879, | |

| or DB2831-5149) Calibration Using Fuel Injection Pump Test | ||

| Stand (FTIS) Model A8022 | 2 - 1 4 0 . 1 2 | |

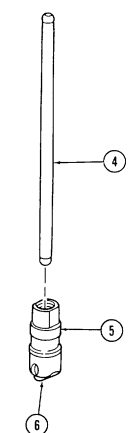

| 2-36. | Glow Plug Repair | 2-141 |

| 2-37. | Fuel Injection Nozzle Repair | 2-142 |

| 2-38. | Water Pump Repair | 2-144 |

| 2-39. | Water Crossover Repair | 2-146 |

| 2-40. | Fan Drive Repair | 2-148 |

| 2-41. | Engine Assembly from Subassemblies | 2-153 |

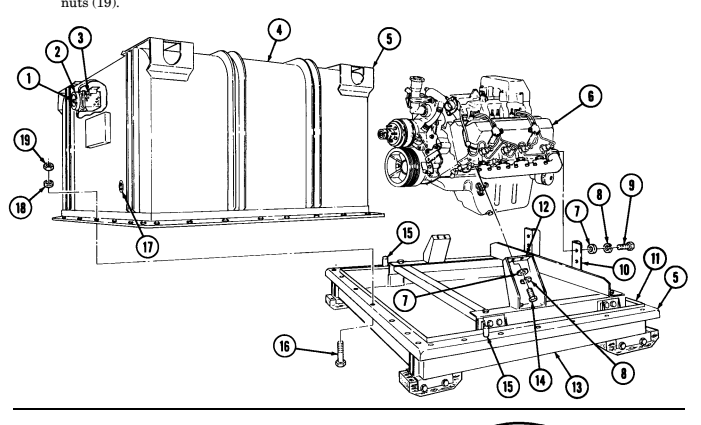

2 - 1 3 . 1 . Engine Replacement In Shipping/Storage Conta I N E R

This task covers:

| a. Removal | b. Installation |

|---|---|

| INITIAL SETUP: | |

| Tools | Manual References |

| General mechanic's tool kit: | TM 9-2815-237-34P |

| automotive (Appendix E, Item 1) | Personnel Required |

| Special Tools | One mechanic |

| Engine lifting sling (Appendix E, Item 3) | One assistant |

| Materials/Parts | General Safety Instructions |

| Eight lockwashers (Appendix D, Item 26.1) | Direct personnel to stand clear during hoisting |

| operation. |

a. Removal

Warning

Direct personnel to stand clear during hoisting operation. Failure to do this may cause injury to personnel.

- Attach hoist to engine lifting sling and remove engine assembly (6) from lower container (13). 8. Position engine on repair stand (para. 2-14).

b. Installation 6. Remove two capscrews (23) and sling bracket (21) from left cylinder head (20). 7. Visually check humidity indicator (17) for discolorization. If indicator (17) is dark purple, replace desiccant (3).

-

If engine container (5) is closed and sealed, press air-release button (1) located at center of breather valve (2) before opening engine container (5).

-

Remove twenty-six nuts (19), washers (18), capscrews (16), and upper container (4) from lower container (13).

-

Position engine lifting sling on engine assembly (6) and install sling on right cylinder head (25) with two capscrews (24).

-

Install sling bracket (21) to engine lifting sling with pin (22) and on left cylinder head (20) with two capscrews (23). Tighten capscrews (23).

-

Remove four capscrews (14), lockwashers (8), and washers (7) from two engine mounts (12). Discard lockwashers (8).

-

Remove four capscrews (9), lockwashers (8), and washers (7) from two rear engine mounts (10).

Discard lockwashers (8).

-

Install engine assembly (6) in lower container (13). 2. Install engine assembly (6) on two rear engine mounts (10) with four washers (7), lockwashers (8), and capscrews (9).

-

Install engine assembly (6) on two engine mounts (12) with four washers (7), lockwashers (8), and capscrews (14).

-

Remove pin (22) from sling bracket (21). 5. Remove two capscrews (24) and lifting sling from right cylinder head (25).

2-13.1. Engine Replacement In Shipping/Storage Container (Cont'D)

Ensure gasket is seated properly.

Using alignment pins (15), position upper container (4) on gasket (11) and lower container (13).

Install upper container (4) on lower container (13) with twenty-six capscrews (16), washers (18), and

nuts (19).

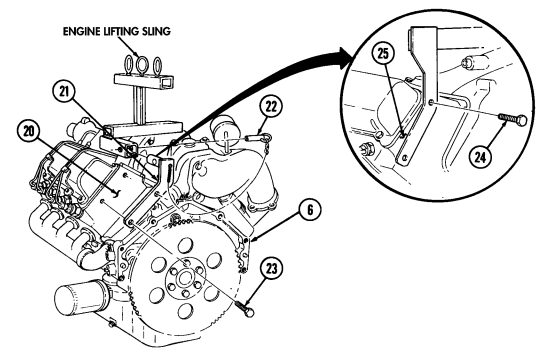

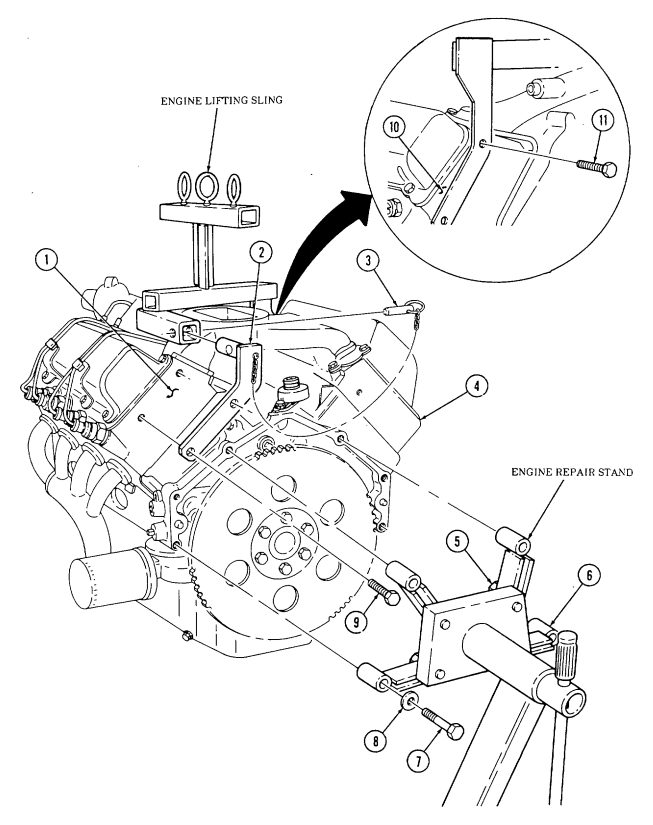

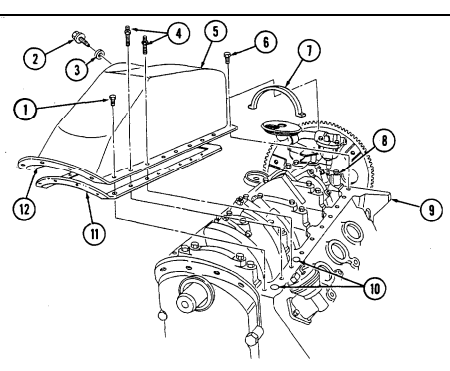

2 - 1 4 . Mounting Engine On Repair Sta N D

This task covers: a. Installation b. Removal INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix E, Item 1) Special Tools Engine repair stand (Appendix E, Item 2) Engine lifting sling (Appendix E, Item 3) a. Installation

Do not perform step 1 if engine lifting sling has been previously installed.

- Position engine lifting sling on engine (4) and secure to right cylinder head (10) with two bolts (11).

Finger tighten bolts (11).

- Install sling bracket (2) to engine lifting sling with pin (3) and on left cylinder head (1) with two bolts (9). Tighten bolts (9) and (11).

Warning

Direct personnel to stand clear during hoisting operation. Failure to do this may cause injury to personnel.

-

Attach hoist to engine lifting sling and hoist engine (4) into position over engine repair stand. 4. Loosen four capscrews (5) securing repair stand arms (6) on engine repair stand and align arms (6) with holes in rear of engine (4).

-

Install repair stand arms (6) to engine (4) with four washers (8) and capscrews (7). 6. Tighten capscrews (5) and (7). 7. Disconnect hoist and remove two bolts (11) and (9), engine lifting sling, and bracket (2) from engine (4).

B. Removal

- Attach hoist to engine lifting sling and hoist engine (4) to relieve pressure on engine repair stand. 4. Remove four capscrews (7) and washers (8) from repair stand arms (6) and hoist engine away from engine repair stand.

General Safety Instructions Direct personnel to stand clear during hoisting operation.

- Position engine lifting sling on engine (4) and secure to right cylinder head (10) with two bolts (11).

Finger tighten bolts (11).

- Install sling bracket (2) to engine lifting sling with pin (3) and on left cylinder head (1) with two bolts (9). Tighten bolts (9) and (11).

2-14. Mounting Engine On Repair Stand (Cont'D)

2 - 1 5 . Engine Disassembly Into Subassemblies

This task covers: a. Fan Drive and Water Pump Pulley b. Crankshaft Pulley c. Torsional Damper c.1. Wastegate Actuator c.2. Wastegate Housing c.3. Manifold-to-Turbocharger Exhaust Pipe c.4. Turbocharger d. Exhaust Manifolds e. Intake Manifold f. Water Crossover g. Fuel Injection Lines h. Fuel Supply and Return Lines i. Modulator Link j. Rocker Arm Covers k. Rocker Arm Shafts and Pushrods l. Fuel Injection Nozzles INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix E, Item 1) Puller (Appendix E, Item 19) Cylinder ridge reamer (Appendix E, Item 11) Dial indicator (Appendix E, Item 10)

Special Tools

Hydraulic valve lifter remover (Appendix E, Item 4) Injection nozzle socket (Appendix E, Item 5) Glow plug socket (Appendix E, Item 6) Hex-head driver, 6 mm (Appendix E, Item 7) Hex-head driver, 8 mm (Appendix E, Item 8) Hex-head driver, 5/16-in.

(Appendix E, Item 9) m. Glow Plugs n. Cylinder Heads o. Valve Lifters p. Water Pump and Adapter Plate q. Fuel Injection Pump r. Timing Gear Cover s. Timing Chain and Drive Sprockets t. Oil Filter, Adapter, and Oil Pressure Sending Unit u. Oil Pan v. Oil Pump w. Fuel Pump x. Oil Pump Drive y. Camshaft z. Pistons and Connecting Rods aa. Flywheel bb. Crankshaft and Main Bearings

Personnel Required

One mechanic One assistant Equipment Condition Engine mounted on repair stand (para. 2-14).

General Safety Instructions

-

Do not perform this procedure near fire, flame, or sparks.

-

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be disposed of IAW current directives.

Not E

-

Work area should be clean, well-ventilated, and free from blowing dirt and dust. - In some cases, flanged head fasteners may be present instead of standard fasteners and washers. In all cases, washers should be used when replacing a flanged head fastener with a standard fastener.

-

Disassembly procedures for pre-1990, 1990 and above 6.2L and 6.5L engines are basically the same. Any differences in procedures are noted. Refer to para. 1-10 to determine engine model before ordering replacement parts.

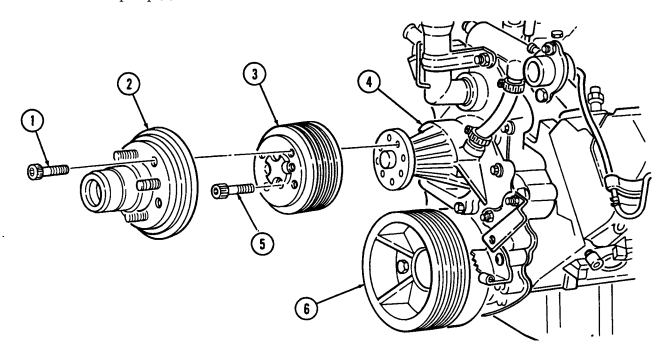

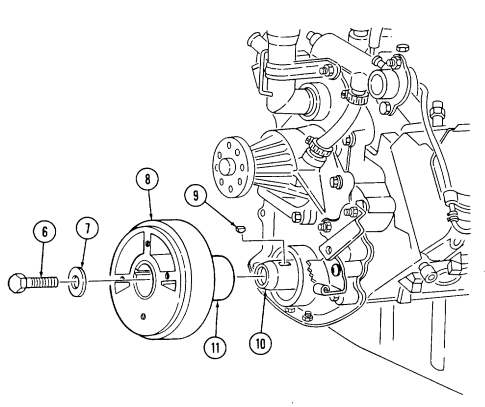

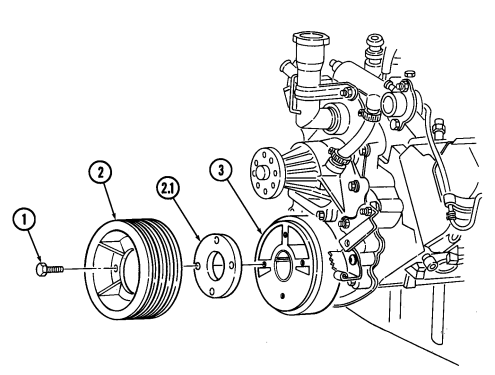

A. Fan Drive And Water Pump Pulley Not E

It may be necessary to apply compressed air to fan drive fitting. This disengages fan drive and allows access to socket head capscrews.

- Position pry bar between water pump pulley (3) and crankshaft pulley (6) and apply pressure.

2 - 1 5 . Engine Disassembly Into Subassemblies (Cont'D)

- Using a 5/16-in. hex-head driver, remove four socket-head screws (1) and fan drive (2) from water

pump pulley (3).

- Using a 6-mm hex-head driver, remove four socket-head screws (5) and water pump pulley (3) from water pump (4).

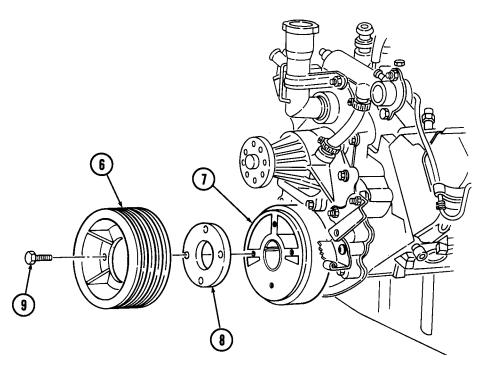

B. Crankshaft Pulley

Remove four capscrews (9), crankshaft pulley (6), and spacer (8) (if installed) from torsional damper (7).

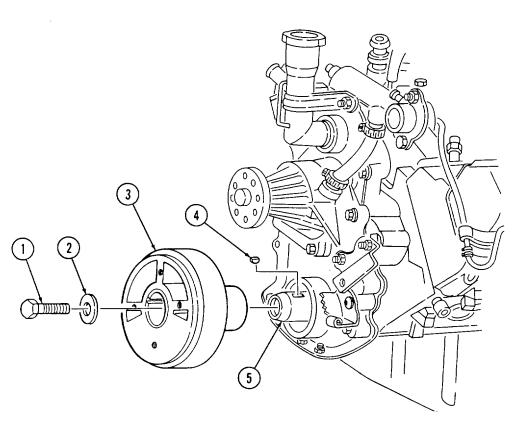

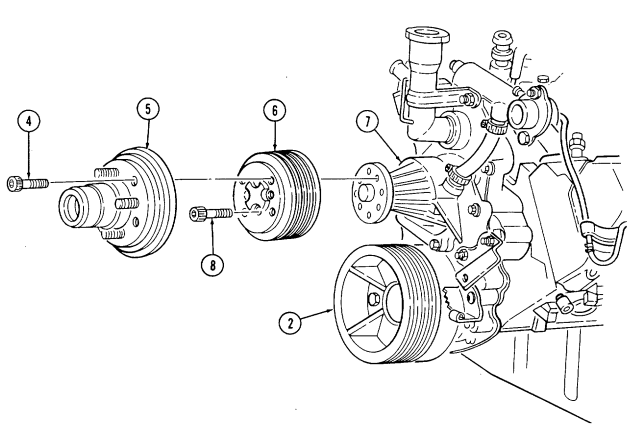

2-15. Engine Disassembly Into Subassemblies (Cont'D) C. Torsional Damper

-

Hold flywheel stationary with pry bar.

-

Remove capscrew (1) and washer (2) from torsional damper (3) and crankshaft (5). 3. Reinstall capscrew (1) and remove torsional damper (3) with puller. 4. Remove capscrew (1) and woodruff key (4) from crankshaft (5). Discard woodruff key (4).

2 - 1 5 . Engine Disassembly Into Subassemblies (Cont'D)

Not E

Perform tasks c.1 through c.4 for 6.5L turbo engines only.

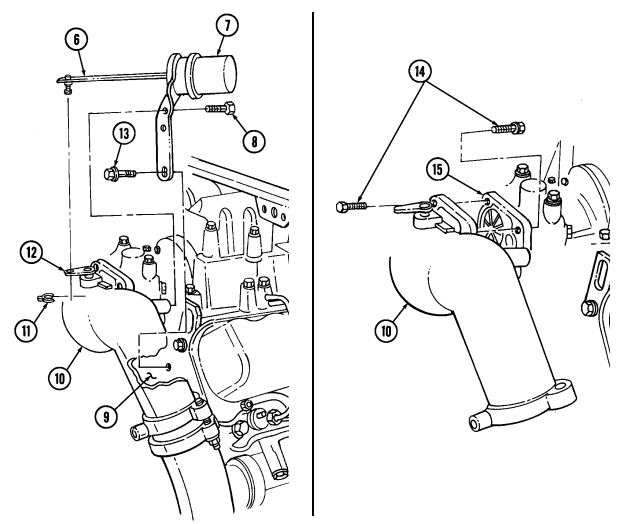

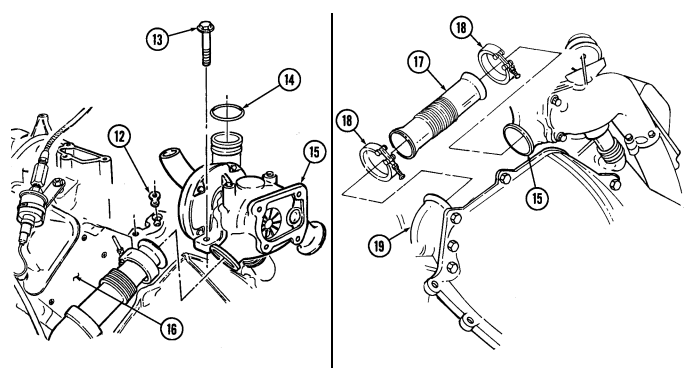

C.1. Wastegate Actuator

- Remove clip (11) and actuator rod (6) from wastegate bellcrank (12). 2. Remove two capscrews (8) from wastegate actuator (7) and wastegate housing (10). 3. Remove capscrew (13) and wastegate actuator (7) from cylinder head (9).

c.2. Wastegate Housing Remove four capscrews (14) and wastegate housing (10) from turbocharger (15).

2 - 1 5 . ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd)

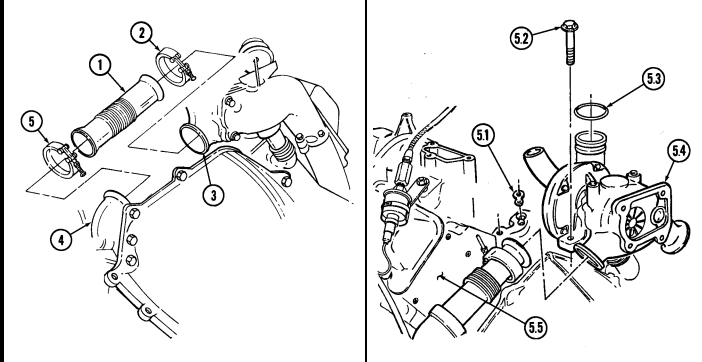

C.3. Manifold-To-Turbocharger Exhaust Pipe

-

Loosen clamp (5) and remove exhaust pipe (1) from exhaust manifold (4). Slide clamp (5) onto exhaust pipe (1).

-

Loosen clamp (2) and remove exhaust pipe (1) from turbocharger (3). Slide clamp (2) onto exhaust pipe (1).

-

Remove clamps (2) and (5) from exhaust pipe (1). 4. Repeat steps 1 through 3 for opposite side of engine.

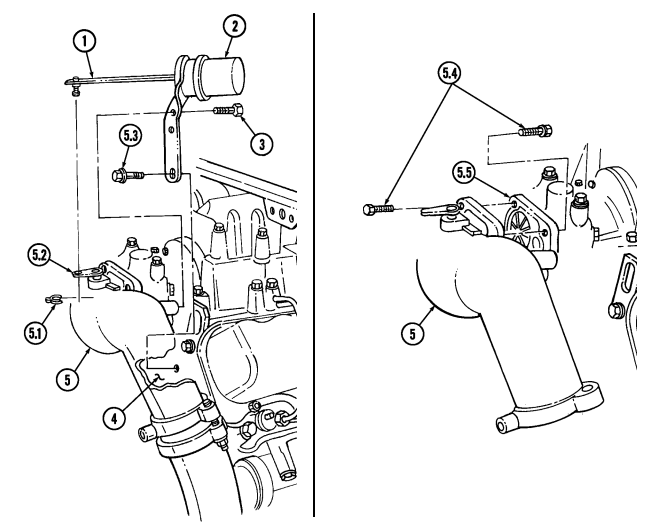

c.4. Turbocharger

Center inlet manifold must be removed before removing turbocharger.

- Remove two capscrews (5.2) and turbocharger (5.4) from engine block (5.5). 2. Remove turbocharger oil gasket (5.1) from engine block (5.5). Discard gasket (5.1). 3. Remove O-ring (5.3) from turbocharger (5.4) outlet. Discard O-ring (5.3).

2 - 1 5 . Engine Disassembly Into Subassemblies (Cont'D)

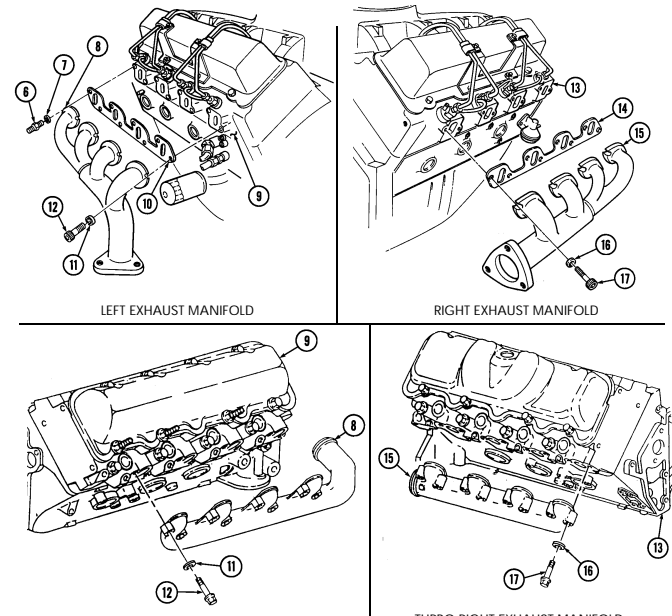

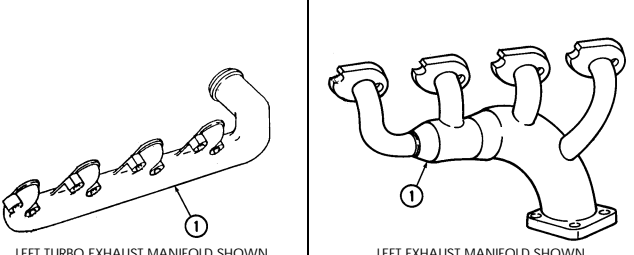

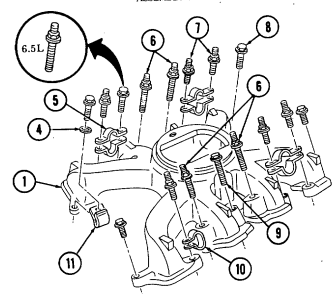

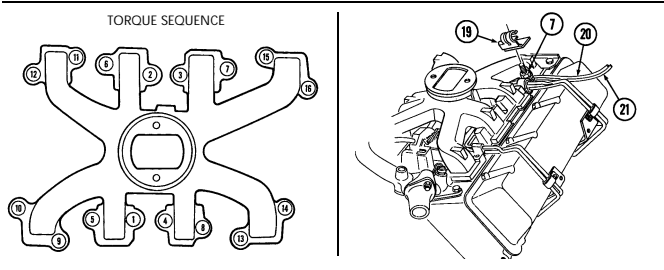

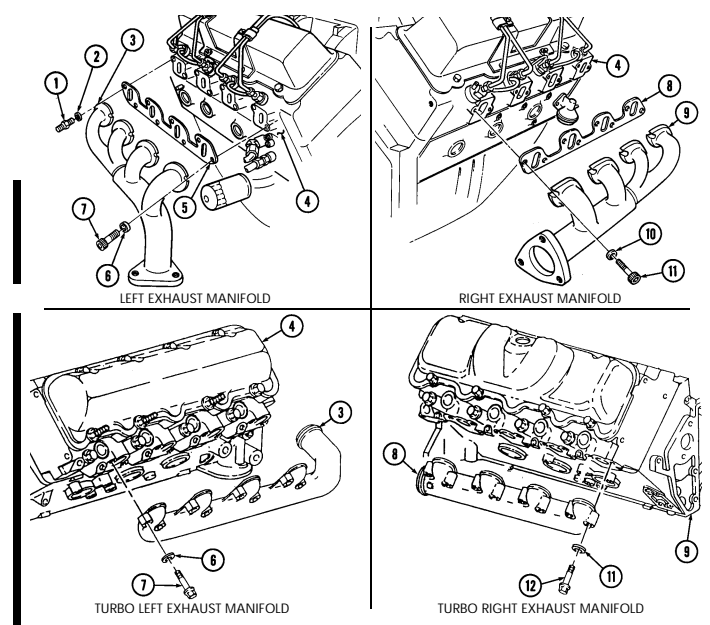

d. Exhaust Manifolds

Not E

Early production vehicles may have a socket-head screw in place of stud.

- Remove stud (6) and washer (7) securing left exhaust manifold (8) to cylinder head (9).

Not E

Turbo exhaust manifolds use hex-head capscrews and do not have gaskets as indicated in steps 2 and 3.

-

Using 8-mm hex-head driver, remove seven socket-head screws (12), washers (11), left exhaust manifold (8), and gasket (10) from cylinder head (9). Discard gasket (10).

-

Using 8-mm hex-head driver, remove eight socket-head screws (17), washers (16), right exhaust manifold (15), and gasket (14) from cylinder head (13). Discard gasket (14).

TURBO LEFT EXHAUST MANIFOLD TURBO RIGHT EXHAUST MANIFOLD

2 - 1 5 . Engine Disassembly Into Subassemblies (Cont'D)

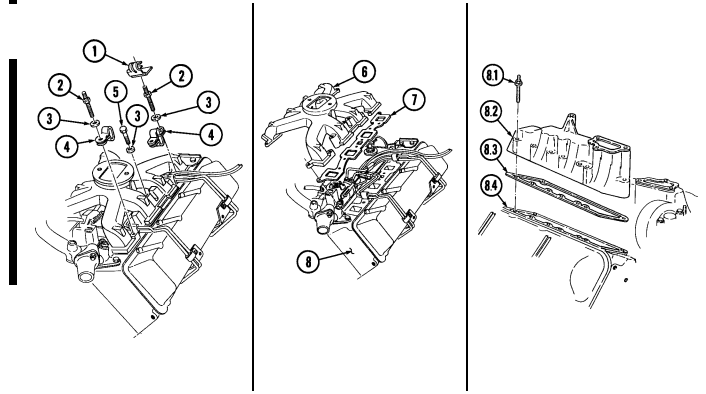

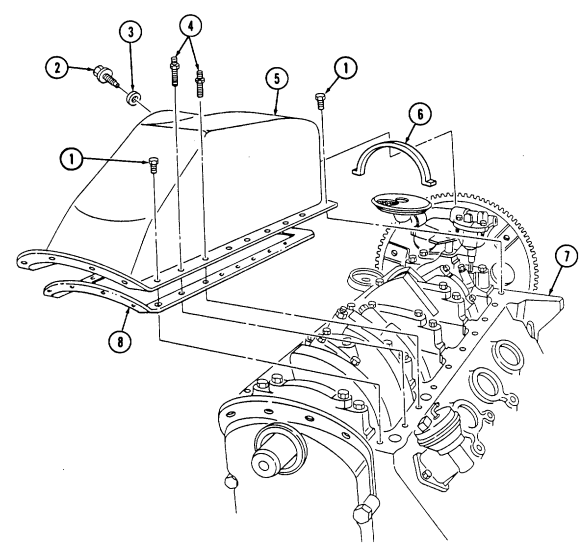

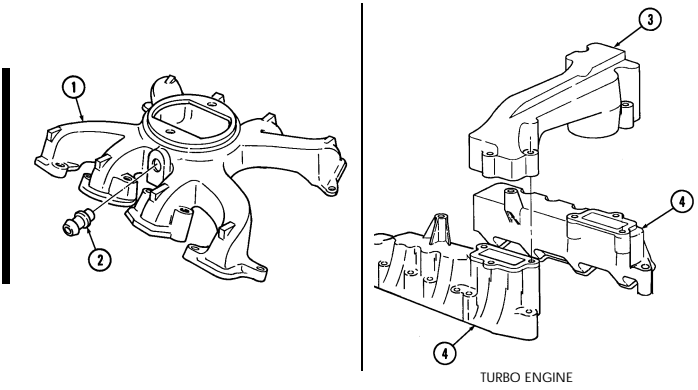

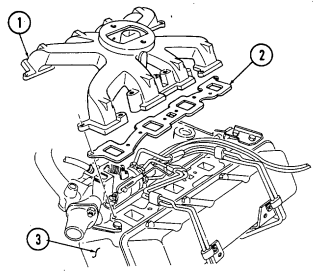

e. Intake Manifold 1. Remove fuel filter line clamp (1) from stud (2).

- Note location of studs for installation. - Perform step 2 for 6.2L engines. Perform step 3 for 6.5L engines.

- Remove six intake manifold capscrews (5), ten studs (2), and sixteen washers (3). 3. Remove four intake manifold capscrews (5), twelve studs (2), and sixteen washers (3). 4. Remove four injection line clips (4). 5. Remove intake manifold (6) and two gaskets (7) from cylinder heads (8). Discard gaskets (7).

- Perform steps 6 through 8 for turbo engines. - Outer intake manifold is removed before engine is removed from vehicle.

- Remove eight intake manifold studs (8.1) from intake manifold (8.2).

.Warning.

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be removed with a scraper or putty knife and then be disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

- Remove intake manifold (8.2) and gasket (8.3) from cylinder head (8.4). Discard gasket (8.3).

8. Repeat steps 6 and 7 for opposite side.

8. Repeat steps 6 and 7 for opposite side.

2 - 1 5 . Engine Disassembly Into Subassemblies (Cont'D)

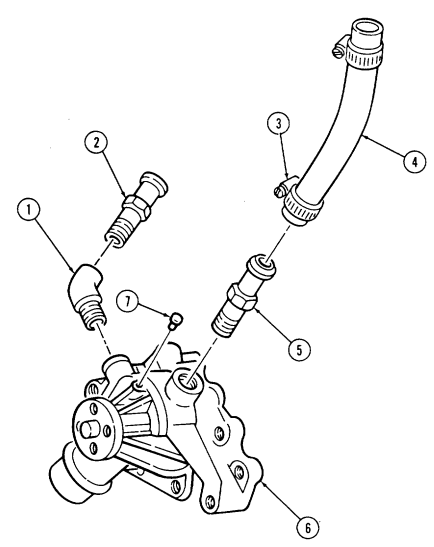

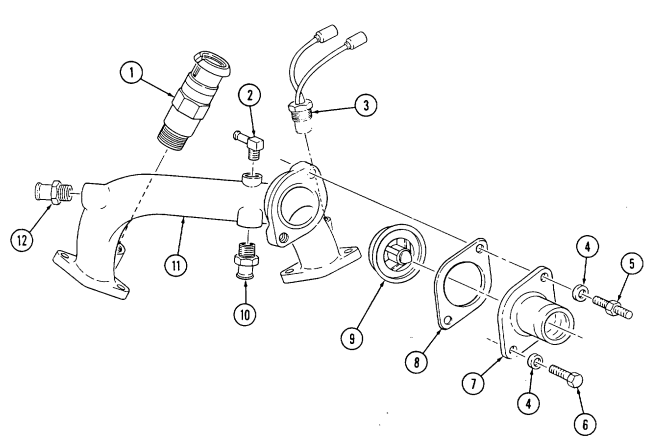

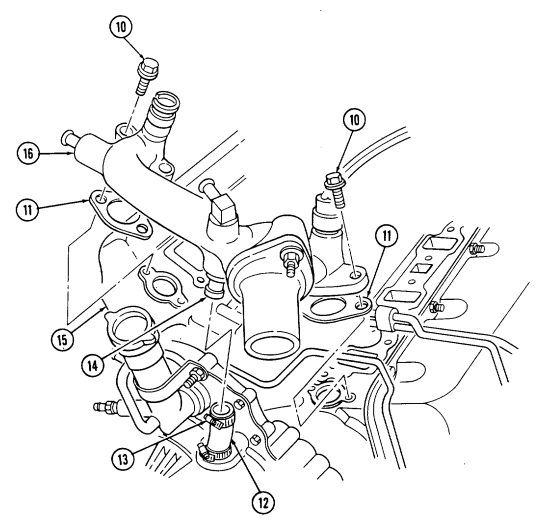

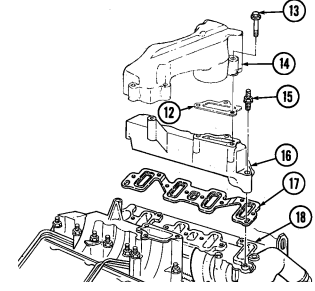

F. Water Crossover

- Remove four capscrews (9) securing water crossover (14) to cylinder heads (8). 2. Loosen hose clamp (12) and disconnect thermostat bypass hose (11) from water crossover nipple (13).

.Warning.

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be removed with a scraper or putty knife and then be disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

- Remove water crossover (14) and two gaskets (10). Discard gaskets (10).

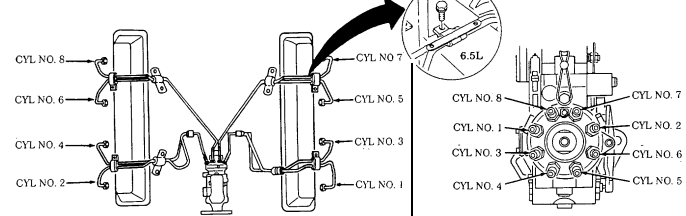

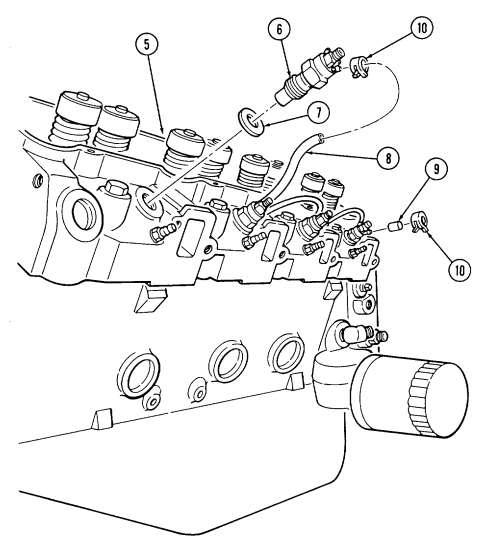

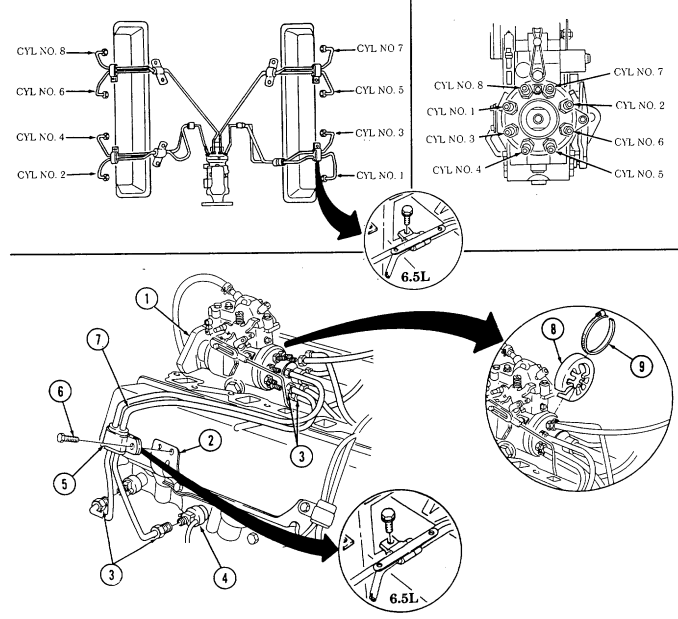

2-15. ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd) g. Fuel Injection Lines

Warning

Diesel fuel is highly flammable. Do not perform this procedure near fire, flame, or sparks. Severe injury or death by result.

-

Loosen and disconnect eight fuel injection line nuts (4) at injection nozzles (3).

-

Remove four screw-assembled washers (5) and clamps (6) from support brackets (2).

Plug fuel injection pump openings to prevent contamination.

Tag lines by cylinder number for assembly.

- Remove clamp (8) and boot (9) from fuel injection pump (1). Disconnect and remove eight fuel injection lines (7) at fuel injection pump (1).

2-15. Engine Disassembly Into Subassemblies (Cont'D) H. Fuel Supply And Return Lines

-

Loosen clamp (11) and remove fuel filter inlet hose (12) from fuel supplY line (10). 2. Disconnect fuel supply line (10) at fuel pump (27).

-

Remove stud (24), washer (25), two clamps (28) and fuel supply line (10) from fuel return line (18) and cylinder block (29).

-

Remove nut (19), washer (20), and clamp (21) from fuel return line (18) and rocker arm cover stud (22).

-

Remove capscrew (13), washer (14), and clamp (15) from fuel return line (18) and timing gear cover (26).

-

Loosen three clamps (16) and disconnect three hoses (17) at fuel injection pump (1) and front fuel injection nozzles (23).

-

Remove fuel return line (18).

2 - 1 5 . ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd) i. Modulator Link

Not E

Removal of the modulator link is applicable only to 6.2L engines.

- Remove two capscrews (2) securing modulator link bracket (3) to cylinder head (6).

.Warning.

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be removed with a scraper or putty knife and then be disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

- Slide modulator link (1) forward and disconnect from fuel injection pump (7) and remove bracket (3),

modulator link (1), water jacket cover (4), and gasket (5). Discard gasket (5).

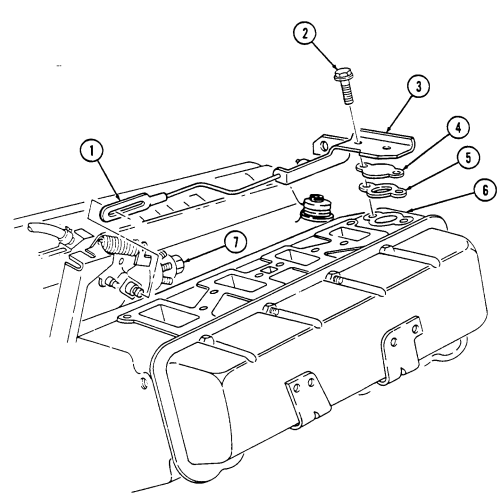

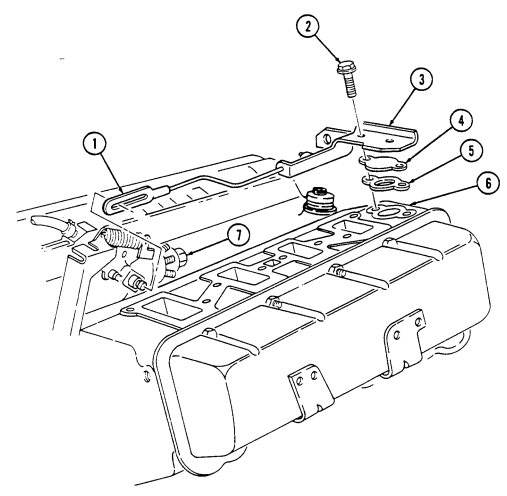

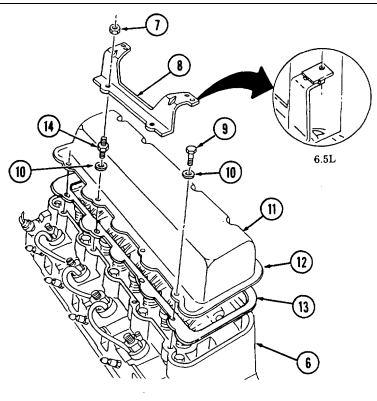

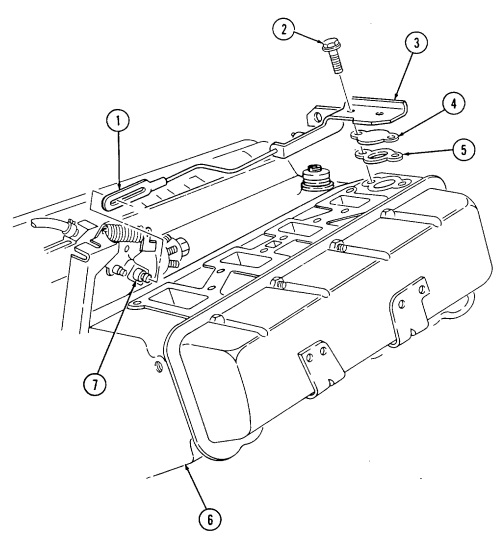

2-15. Engine Disassembly Into Subassemblies (Cont'D) J. Rocker Arm Covers

-

Remove two nuts (8) and injection line support bracket (9) from rocker arm cover studs (14),

-

Remove a combination of three capscrews (10), five studs (14), eight washers (11), rocker arm cover (12), and gasket (13) (if applicable) from cylinder head (6).

-

Repeat steps 1 and 2 for opposite side.

2-15. ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd)

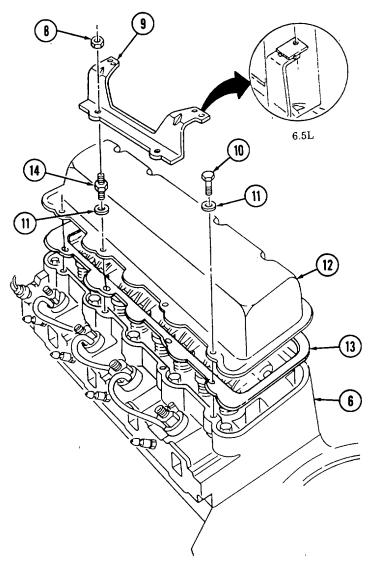

K. Rocker Arm Shafts And Pushrods

- Remove four capscrews (3) and four retainers (2) from rocker arm and shaft assembly (4) and cylinder head (5).

Tag rocker arm and shaft assembly for assembly.

- Remove two rocker arm and shaft assemblies (4).

Tops of pushrods are hardened and must be tagged for assembly.

- Remove eight pushrods (1).

- Repeat steps 1 through 3 for opposite side.

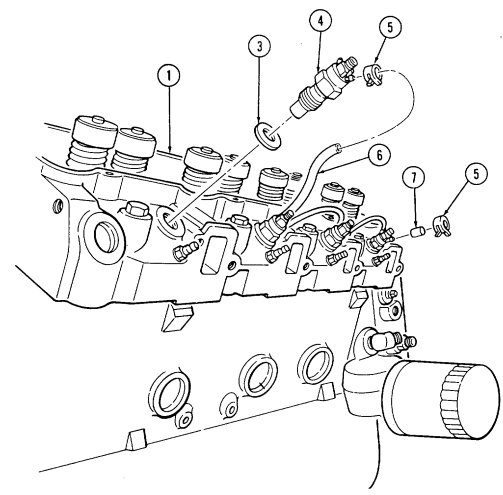

2-15. Engine Disassembly Into Subassemblies (Cont'D) L. Fuel Injection Nozzles

-

Remove seven clamps (10), one cap (9), and three hoses (8) from fuel injection nozzles (6).

-

Using injection nozzle socket, remove four fuel injection nozzles (6) and gaskets (7) from cylinder head (5). Discard gaskets (7).

-

Repeat steps 1 and 2 for opposite side.

2-15. ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd)

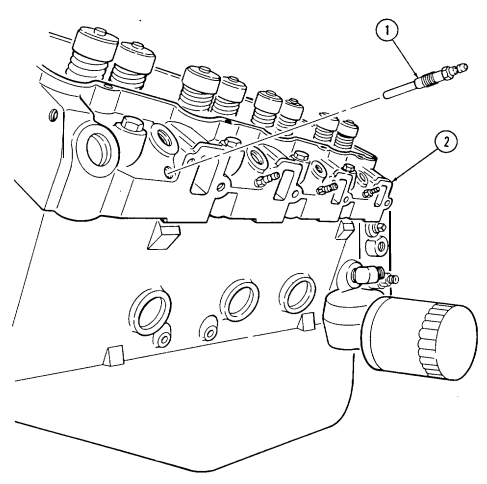

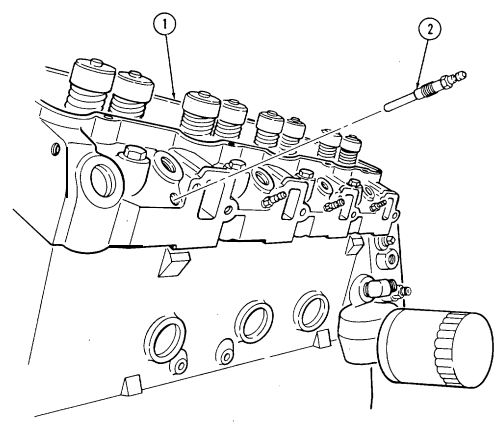

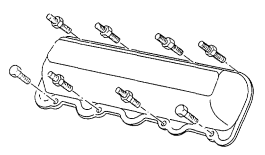

M. Glow Plugs

-

Using glow plug socket, remove four glow plugs (1) from cylinder head (2).

-

Repeat step 1 for opposite side.

2-15. Engine Disassembly Into Subassemblies (Cont'D)

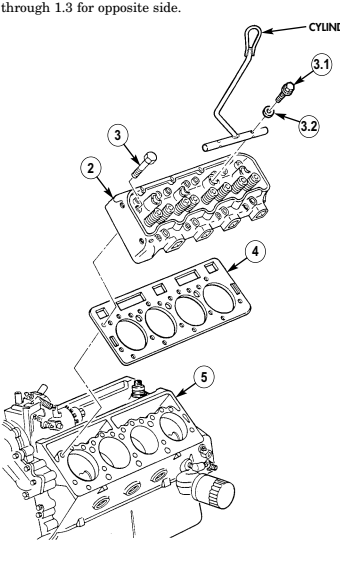

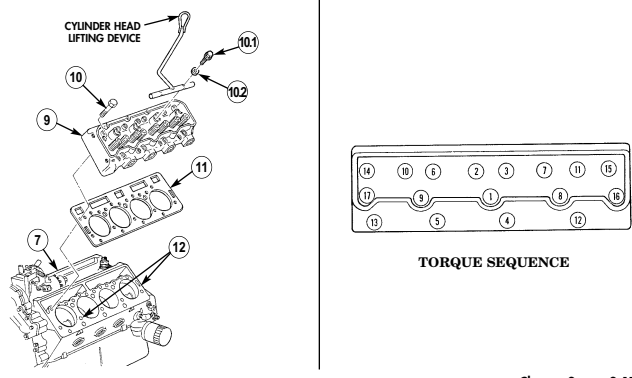

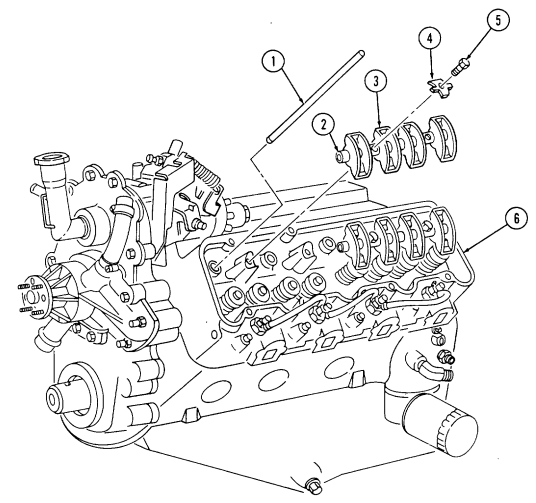

n. Cylinder Heads

.Warning.

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be removed with a scraper or putty knife and then be disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

- Remove seventeen capscrews (3) from cylinder head (2) and cylinder block (5).

Use of cylinder head lifting device is optional.

1.1. Install cylinder head lifting device on center of cylinder head (2) with two washers (3.2) and capscrews (3.1).

1.2. Using a hoist or other lifting device, remove cylinder head (2) and cylinder head gasket (4) from cylinder block (5).

1.3. Remove two capscrews (3.1), washers (3.2), and cylinder head lifting device from cylinder head (2).

- Repeat steps 1 through 1.3 for opposite side.

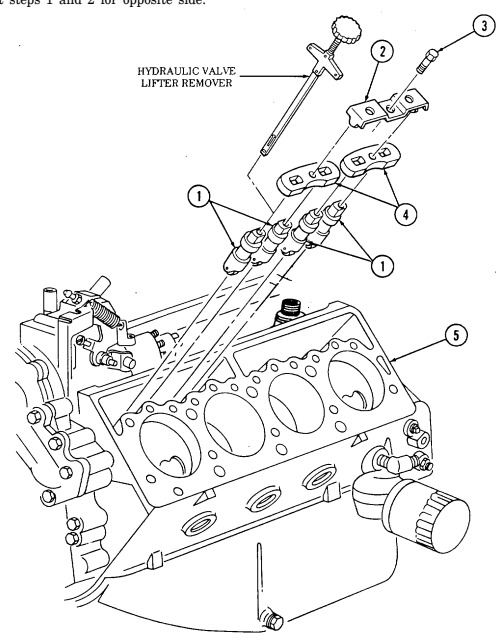

CYLINDER HEAD LIFTING DEVICE 2-15. ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd) o. Valve Lifters 1. Remove two capscrews (3), guide plate clamps (2), and four guide plates (4) from cylinder block (5).

NOTE Tag lifters for assembly.

-

Remove eight valve lifters (1) from cylinder block (5) with hydraulic valve lifter remover.

-

Repeat steps 1 and 2 for opposite side.

2 - 1 5 . Engine Disassembly Into Subassemblies (Cont'D)

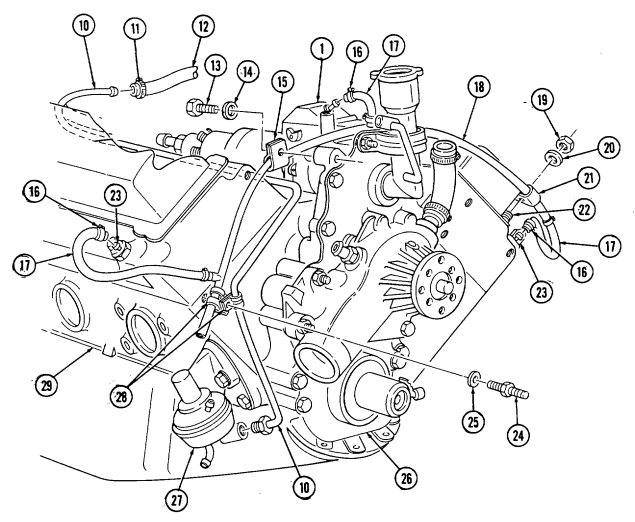

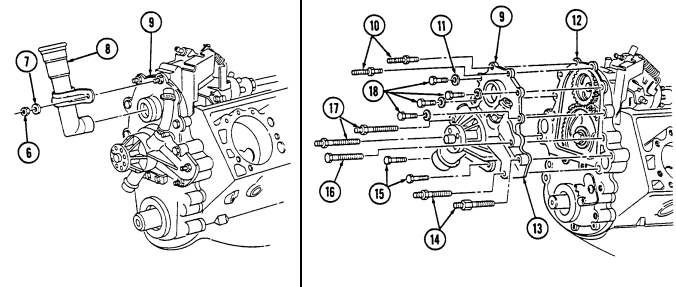

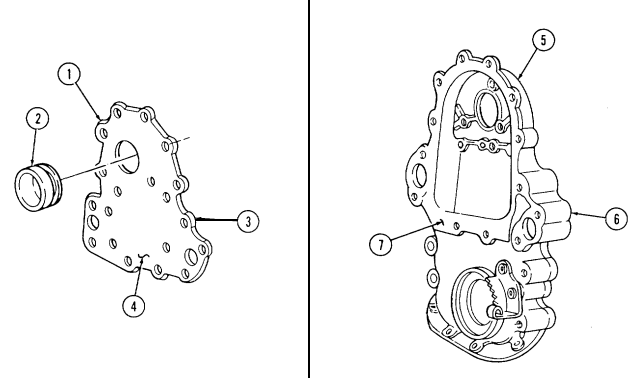

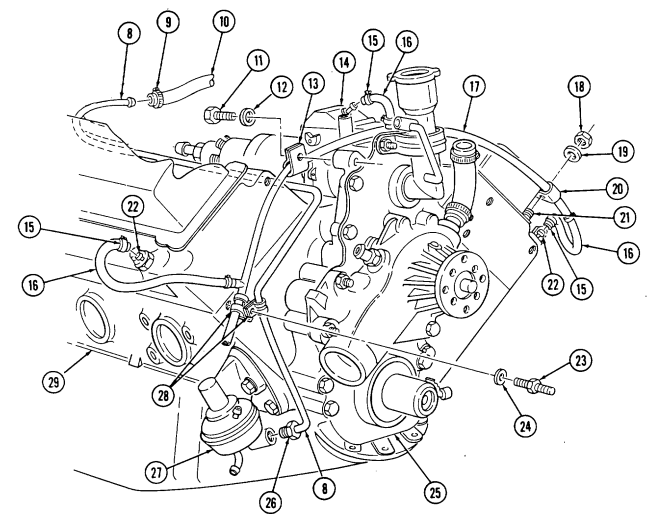

P. Water Pump And Adapter Plate

- Remove two nuts (6), washers (7), and oil fill tube (8) from adapter plate (9). 2. Remove two studs (10), (14), and (17), four capscrews (18), washers (11), two capscrews (15), capscrew (16), water pump (13), and adapter plate (9) from timing gear cover (12).

.Warning.

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be removed with a scraper or putty knife and then be disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

- Remove seven capscrews (20) from water pump (13) and separate water pump (13) and gasket (19)

from adapter plate (9). Discard gasket (19).

2 - 1 5 . ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd)

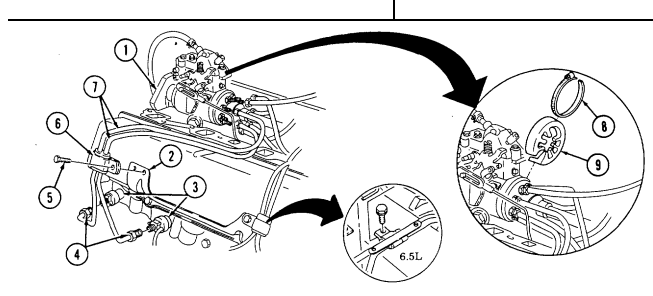

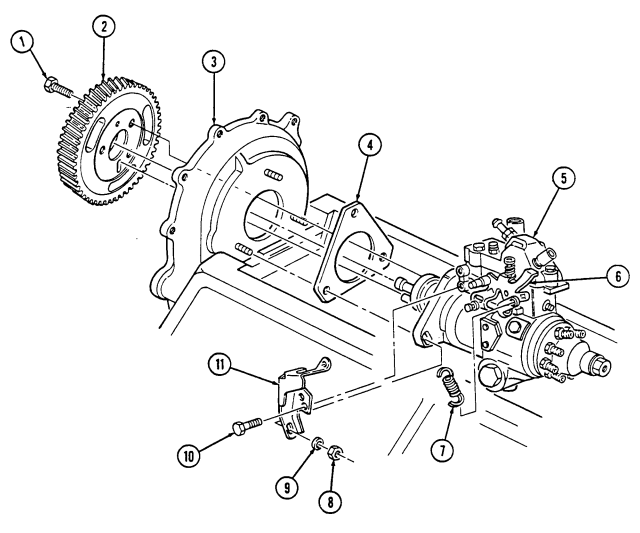

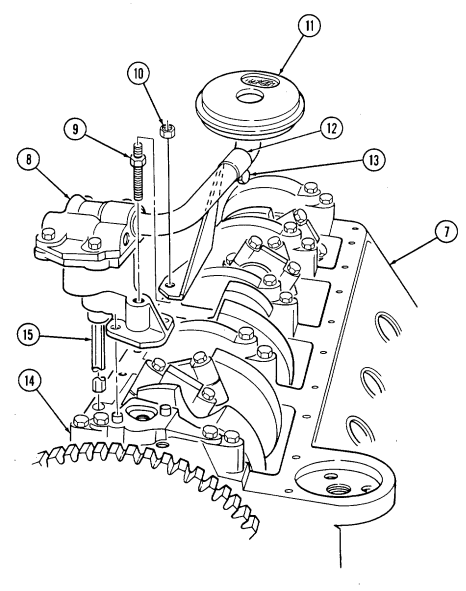

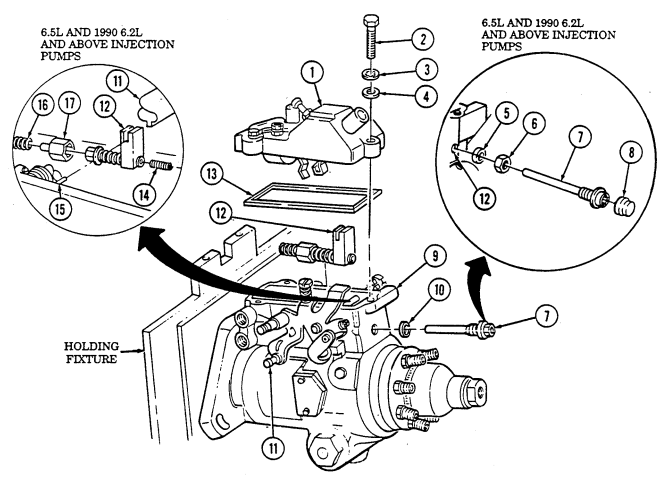

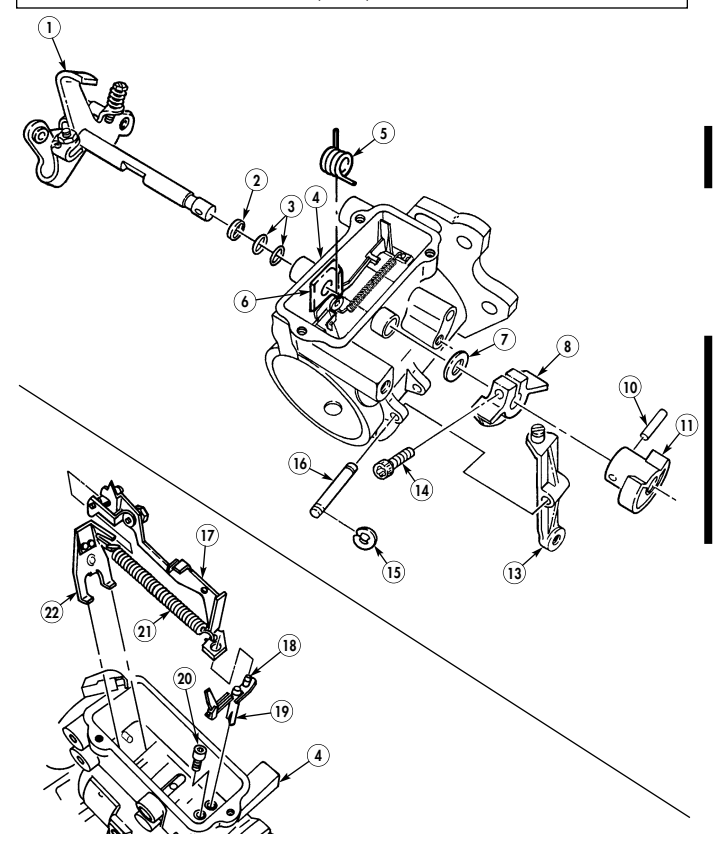

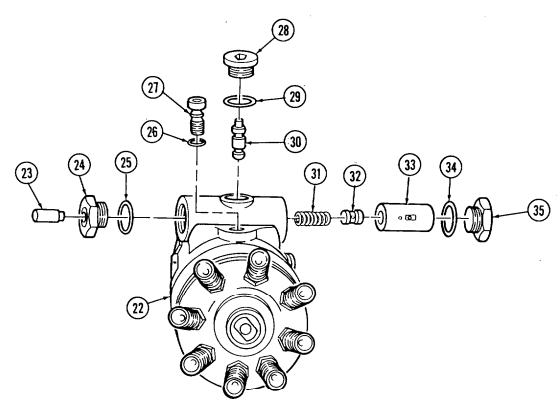

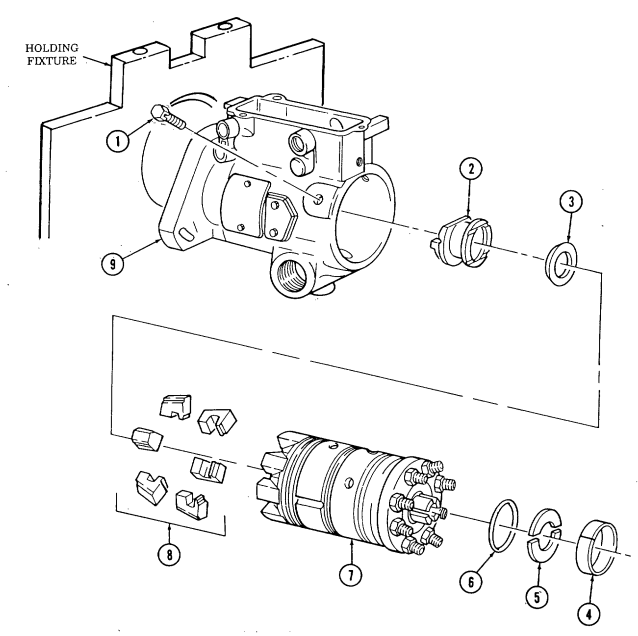

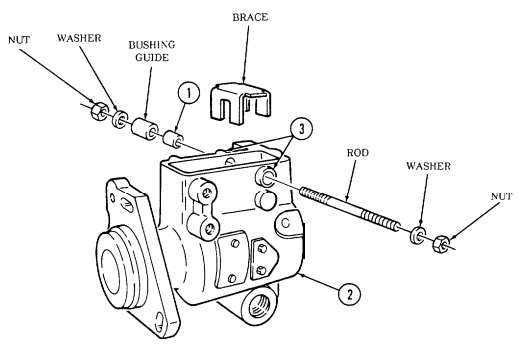

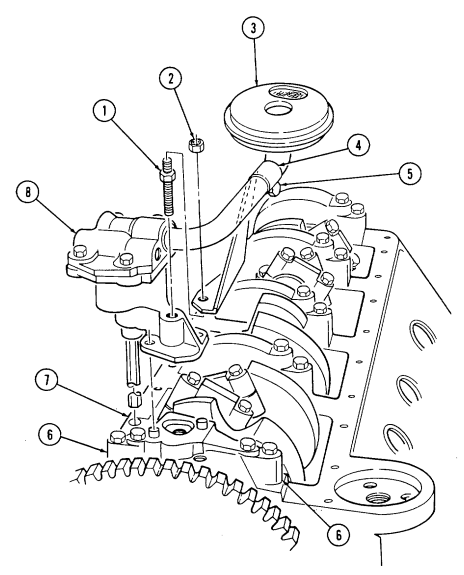

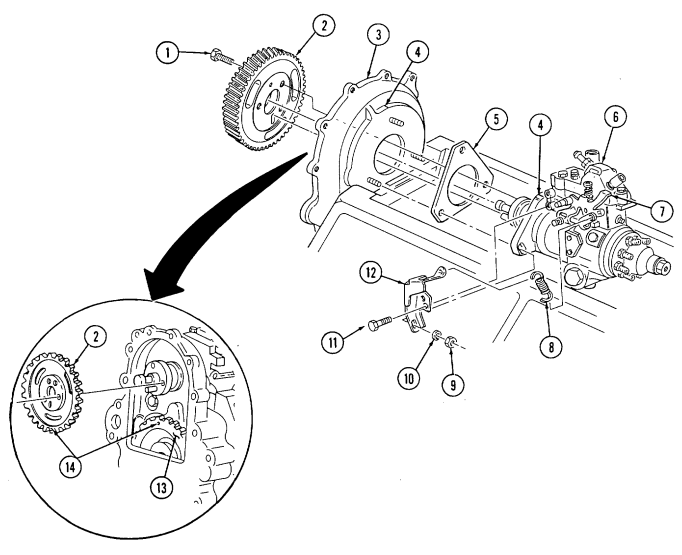

Q. Fuel Injection Pump

- Remove three capscrews (1) and pump driven gear (2) from fuel injection pump (5). 2. Remove idle return spring (7) from throttle lever (6). 3. Remove three nuts (8) and washers (9) from fuel injection pump (5) and timing gear cover (3). 4. Remove two capscrews (10) and accelerator cable bracket (11) from fuel injection pump (5).

.Warning.

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be removed with a scraper or putty knife and then be disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

- Remove the fuel injection pump (5) and gasket (4) from cover (3). Discard gasket (4).

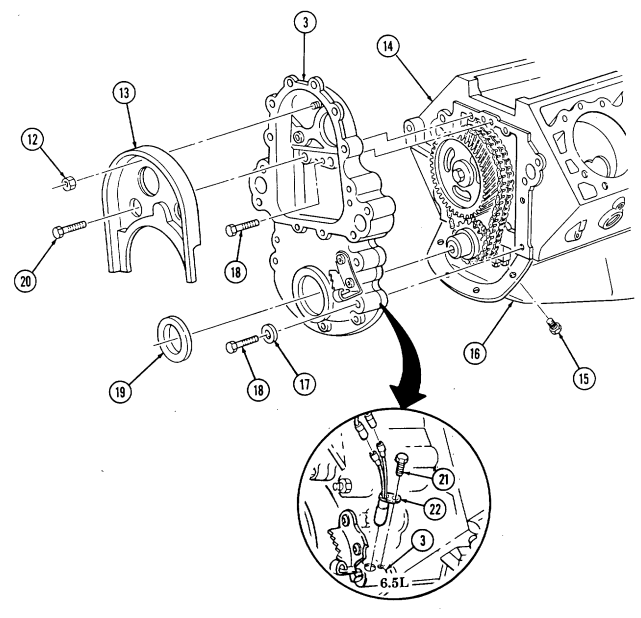

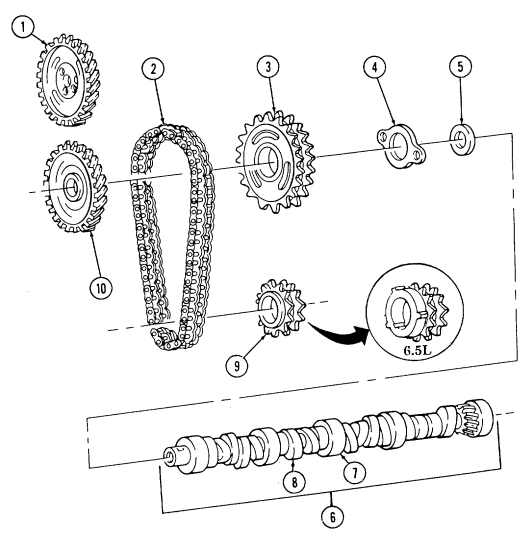

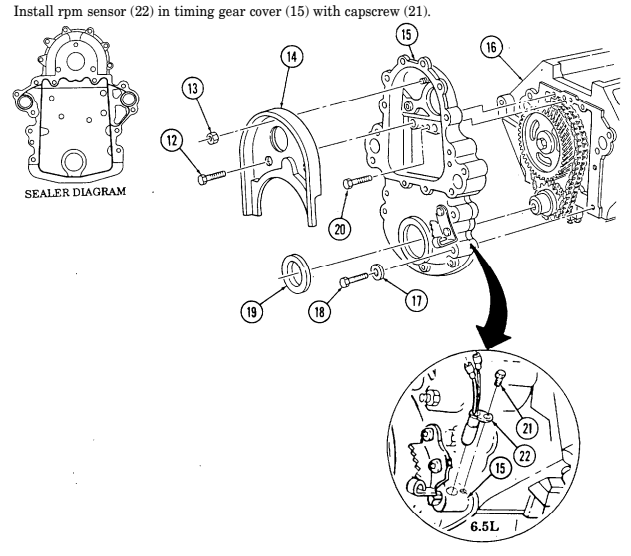

2-15. ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd) r. Timing Gear Cover

Perform step 1 for 6.5L engines.

-

Remove capscrew (21) and rpm sensor (22) from timing gear cover (3).

-

Remove two capscrews (20), nut (12), and baffle (13) from timing gear cover (3). 3. Remove four capscrews (15) from oil pan (16) and timing gear cover (3).

-

Remove five capscrews (18), four washers (17), and timing gear cover (3) from cylinder block (14). 5. Remove front cover seal (19) from timing gear cover (3). Discard seal (19).

2-15. Engine Disassembly Into Subassemblies (Cont'D)

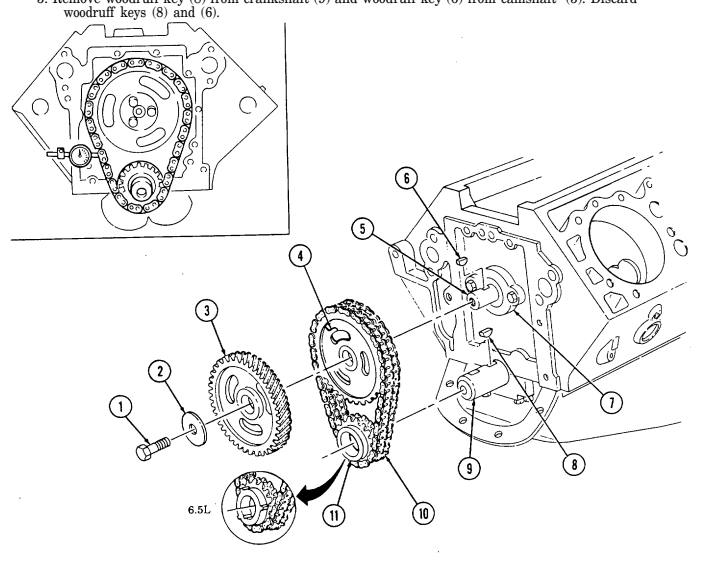

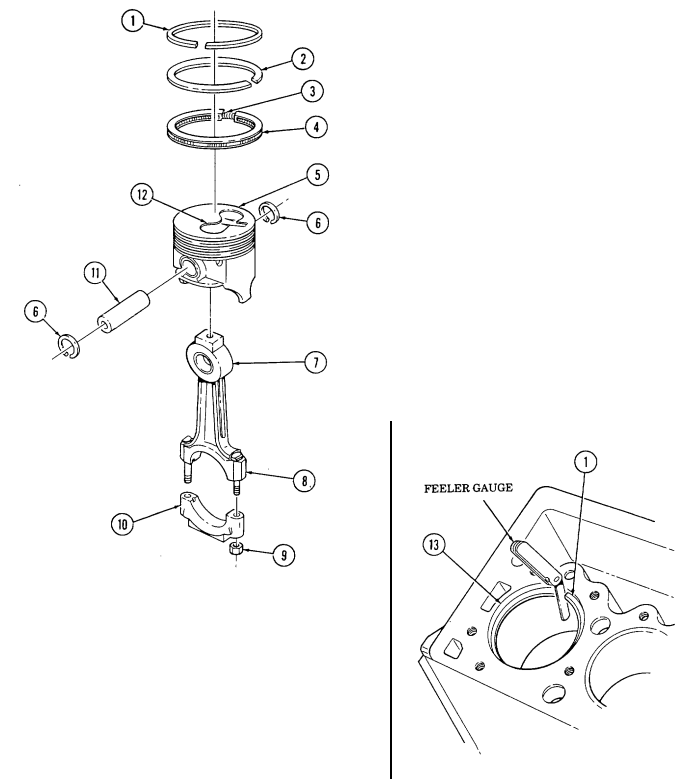

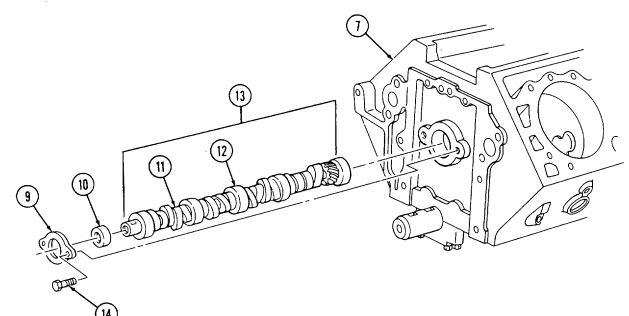

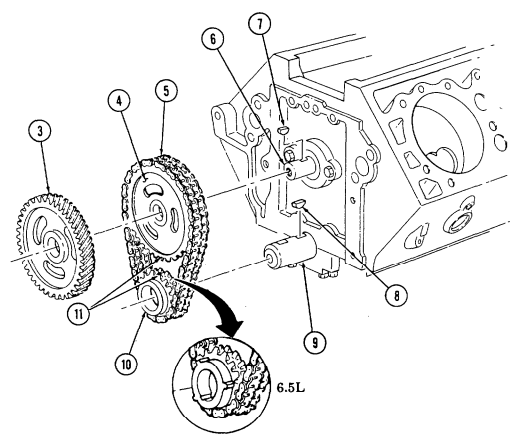

s. Timing Chain and Drive Sprockets

When measuring timing chain deflection, slack should be removed from one side before measurement is taken on opposite side.

-

Using dial indicator, check timing chain (10) deflection midway between camshaft sprocket (4) and crankshaft sprocket (11). Total deflection must not exceed 0.810-in. (20.6 mm). If deflection exceeds specification, timing chain (10) must be replaced.

-

Using dial indicator, check camshaft end play. Camshaft end play must not be more than 0.012-in.

(0.3 mm). If end play exceeds specification, camshaft sprocket (4), thrust plate (7), and spacer must be inspected for wear after removal.

- Remove capscrew (1), washer (2), and pump drive gear (3) from camshaft (5). 4. Remove crankshaft sprocket (11), camshaft sprocket (4), and timing chain (10) as an assembly.

NOTE Cover oil pan opening to prevent woodruff key from falling into oil pan.

- Remove woodruff key (8) from crankshaft (9) and woodruff key (6) from camshaft (5). Discard

2-15. Engine Disassembly Into Subassemblies (Cont'D)

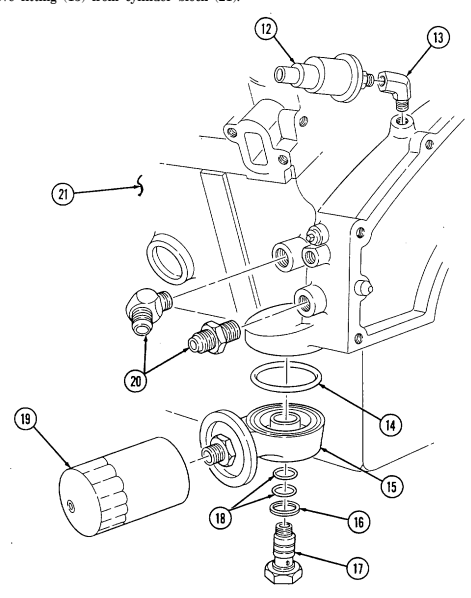

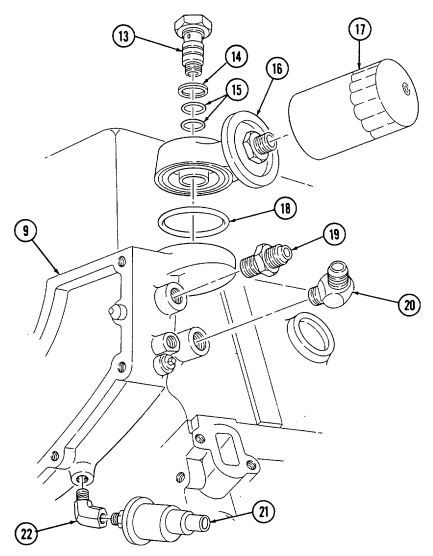

T. Oil Filter, Adaptter, And Oil Pressure Sending Unit Note

Have drainage container ready to catch oil.

Remove oil filter (19) from adapter (15). Discard oil filter (19).

Remove adapter bolt (17), gasket (16), and adapter (15) from cylinder block (21). Discard Remove two O-rings (18) from adapter bolt (17). Discard o-rings (18). Remove O-ring (14) from adapter (15). Discard O-ring (14).

gasket (16).

Remove two oil cooler line fittings (20) from cylinder block (21).

Remove oil pressure sending unit (12) from fitting (13).

Remove fitting (13) from cylinder block (21).

Remove fitting (13) from cylinder block (21).

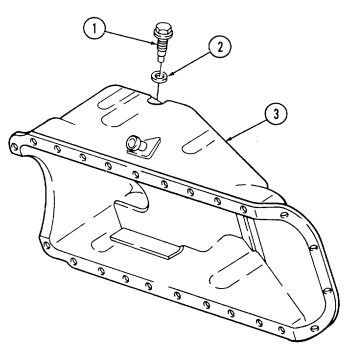

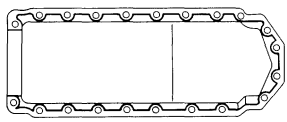

2-15. ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd) u. Oil Pan

Have drainage container ready to catch oil.

-

Remove oil drainplug (2) and gasket (3) from oil pan (5) and drain oil. Inspect gasket (3) and discard if damaged.

-

Rotate cylinder block (7) 180°. 3. Remove eighteen capscrews (i) and two studs (4) from oil pan (5) and cylinder block (7).

4. Remove oil pan (5), gasket (8) (if installed), and oil pan rear seal (6) from cylinder block (7). Discard gasket (8) and seal (6).

4. Remove oil pan (5), gasket (8) (if installed), and oil pan rear seal (6) from cylinder block (7). Discard gasket (8) and seal (6).

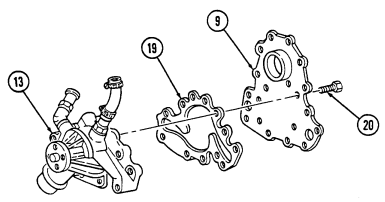

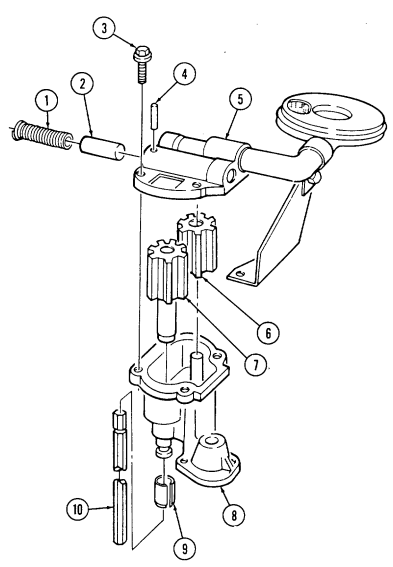

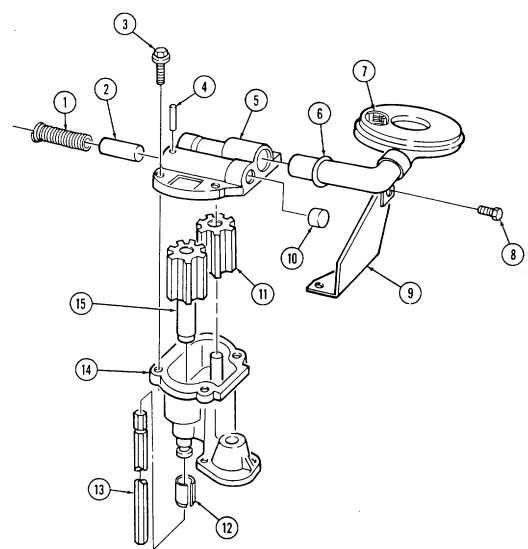

2-15. Engine Disassembly Into Subassemblies (Cont'D) V. Oil Pump

-

Remove nut (10) securing bracket (12) to stud (9).

-

Loossencapscrew (13) from bracket (12) and oil screen (11) and slide bracket (12) off stud (9).

-

Remove stud (9) from oil pump (8) and rear main bearing cap (14). 4. Remove oil pump (8) and shaft (15) from cylinder block (7).

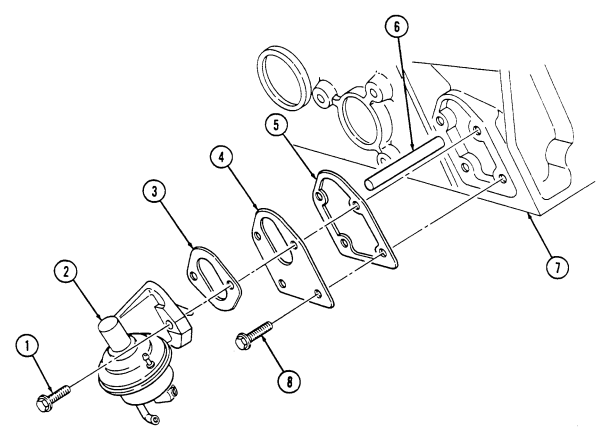

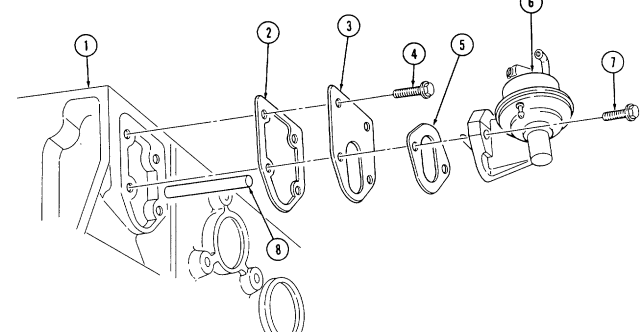

2 - 1 5 . ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd) w. Fuel Pump 1. Rotate cylinder block (7) 180°.

Warning.

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets in steps 2 and 3 should be removed with a scraper or putty knife and then be disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

- Remove two capscrews (1), fuel pump (2), and gasket (3) from cylinder block (7). Discard gasket (3).

3. Remove two capscrews (8), adapter plate (4), gasket (5), and pushrod (6) from cylinder block (7).

3. Remove two capscrews (8), adapter plate (4), gasket (5), and pushrod (6) from cylinder block (7).

Discard gasket (5).

2-15. Engine Disassembly Into Subassemblies (Cont'D)

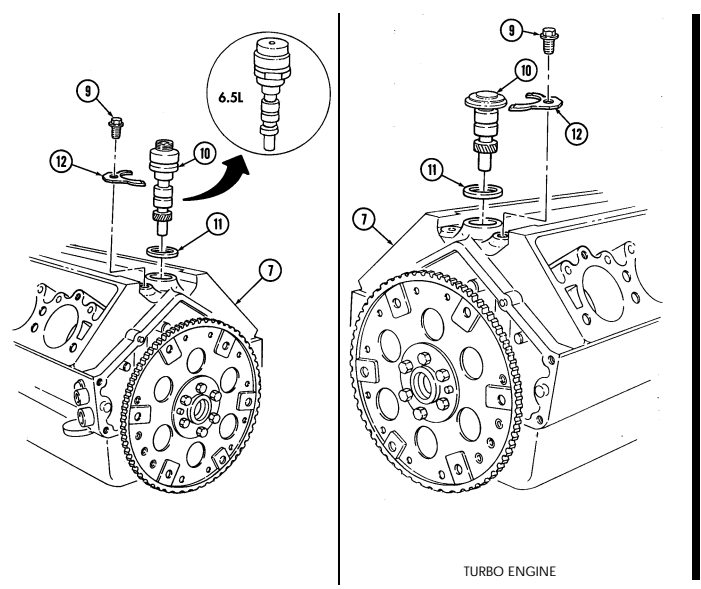

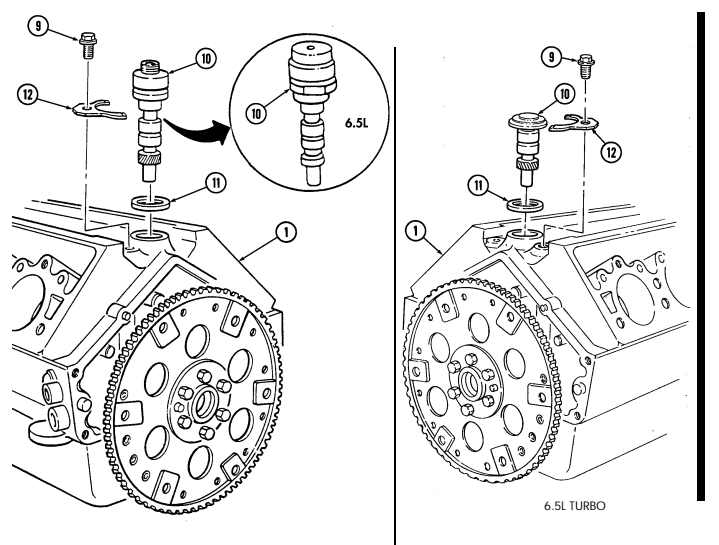

X. Oil Pump Drive

Remove capscrew (9) and clamp (12) from cylinder block (7).

Remove oil pump drive (10) and gasket (11) from cylinder block (7). Discard gasket (11).

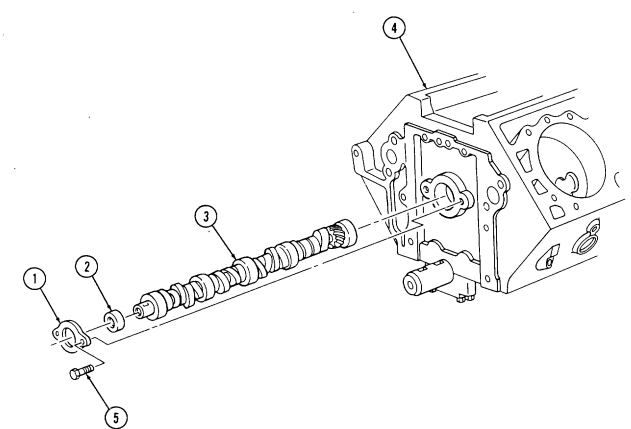

2-15. ENGINE DISASSEMBLY INTO SUBASSEMBLIES (Cont'd) y. Camshaft 1. Remove two capscrews (5), camshaft thrust plate (1), and spacer (2) from cylinder block (4).

Support camshaft during removal to prevent damage to camshaft bearings.

- Remove camshaft (3) from cylinder block (4).

2-15. Engine Disassembly Into Subassemblies (Cont'D)

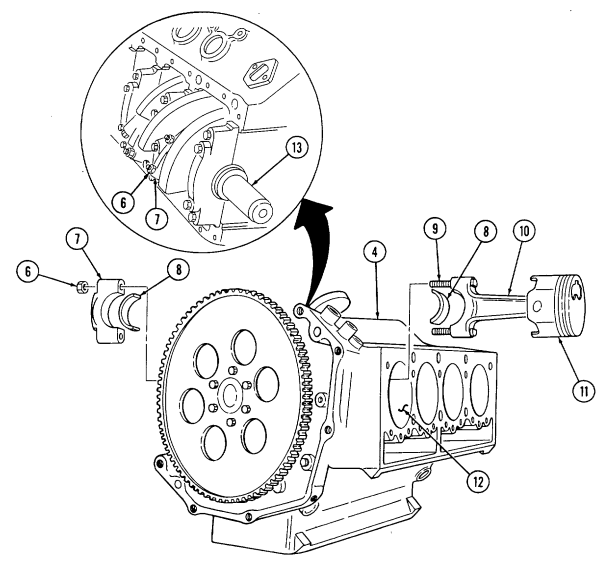

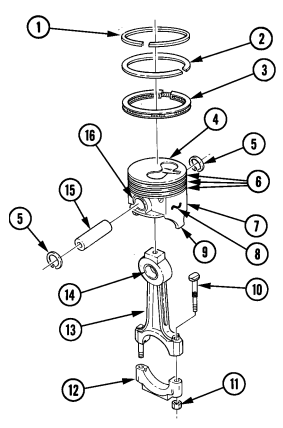

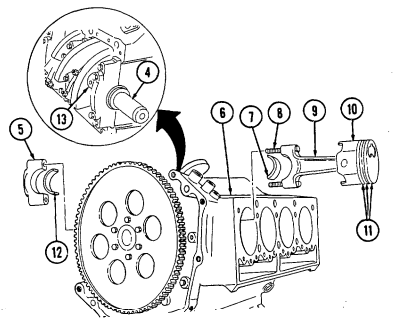

Z. Pistons And Connecting Rods

Remove ridge from upper inside wall of each cylinder (12) with ridge reamer. Rotate cylinder block (4) approximately 90°.

6, 7.

Rotate crankshaft (13) to gain access to two nuts (6).

Check sides of connecting rod (10) and rod cap (7) for matching identification numbers. If no numbers are present, stamp connecting rod (10) and rod cap (7) with cylinder number for assembly. Remove two nuts (6) securing rod cap (7) to connecting rod (10) and remove rod cap (7) and two bearings (8). Discard bearings (8). Cover connecting rod bolts (9) with 3/8-in. rubber hose.

Push connecting rod (10) and piston (11) out from the inside and remove from cylinder block (4).

Remove rubber hose from connecting rod bolts (9) and install rod cap (7) on connecting rod (10) and secure with nuts (6).

Repeat steps 3 through 8 for remaining pistons and connecting rods.

2-15. Engine Disassembly Into Subassemblies (Cont'D)

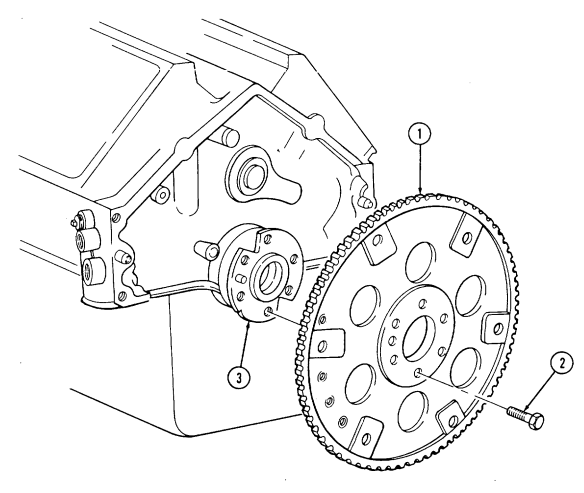

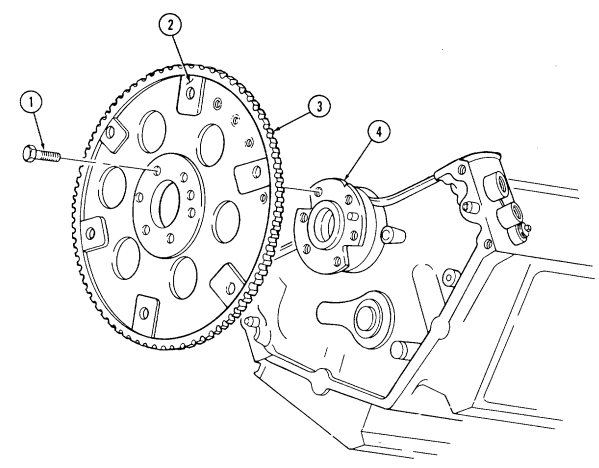

aa. Flywheel Keep crankshaft (3) from rotating and remove six capscrews (2) and flywheel (1) from crankshaft (3).

2-15. Engine Disassembly Into Subassemblies (Cont'D)

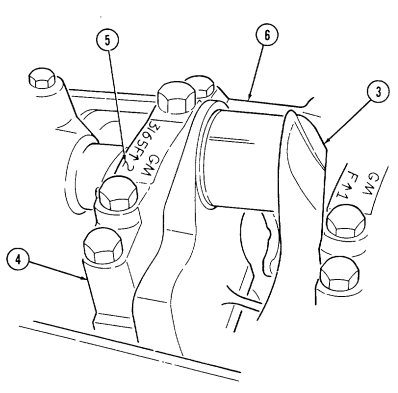

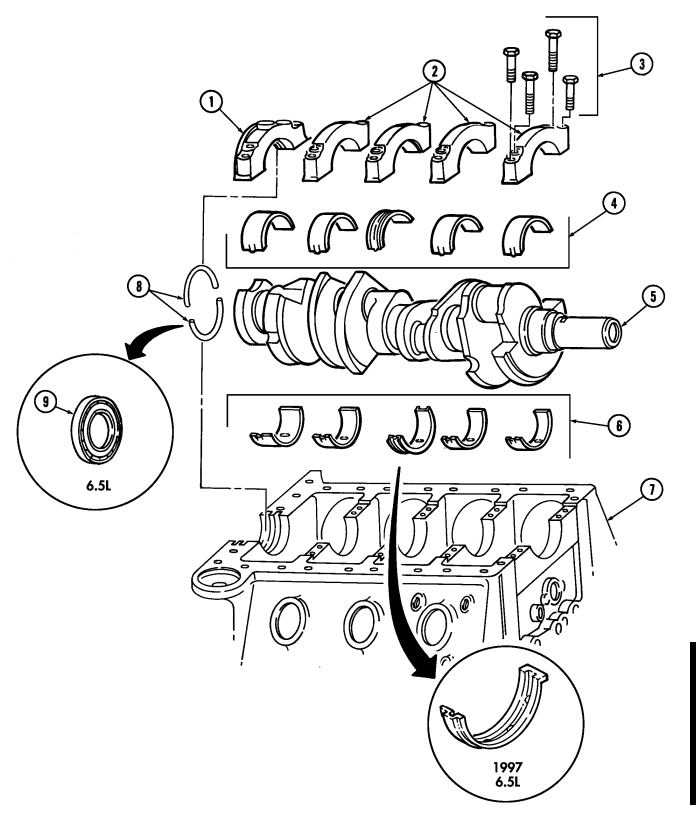

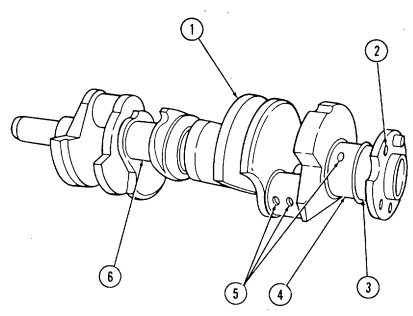

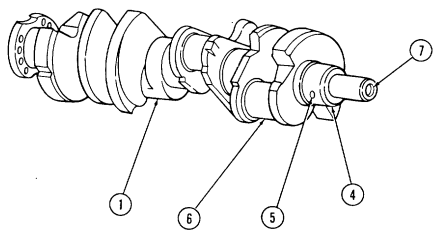

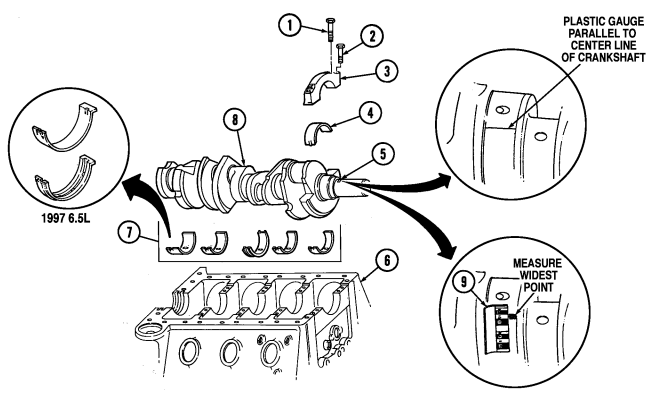

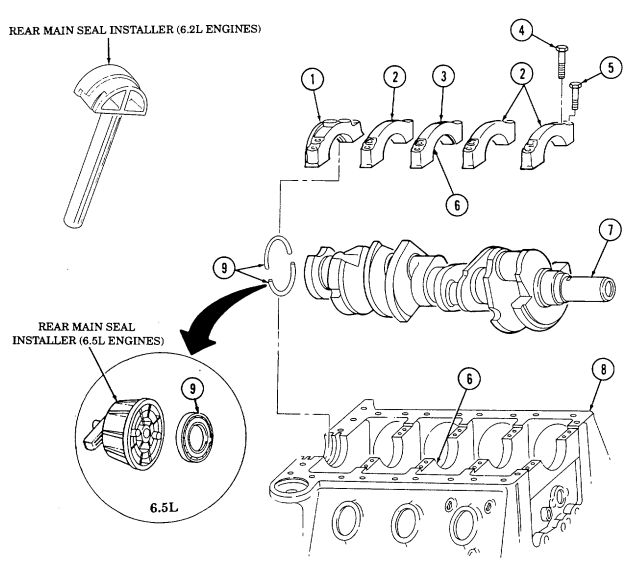

Bb. Crankshaft And Main Bearings

- Rotate cylinder block (6) so crankshaft (3) faces upward.

- Check location numbers (5) on main bearing caps (4). If location numbers (5) are not clear, stamp main bearing caps (4) for assembly.

2 - 1 5 . Engine Disassembly Into Subassemblies (Cont'D)

Perform step 3 for 6.5L engines only.

- Remove one-piece crankshaft rear oil seal (9) from rear main bearing cap (1) and cylinder block (7).

Discard one-piece crankshaft rear oil seal (9).

-

Remove four capscrews (3) securing main bearing cap (2) to cylinder block (7) and remove cap (2) and bearing (4). Discard bearing (4).

-

Repeat step (4) for remaining main bearing caps (2), rear main bearing cap (1), and bearings (4).

Warning.

Crankshaft must be supported during removal and installation. Failure to support crankshaft may cause injury to personnel or damage to equipment.

- Remove crankshaft (5) and bearings (6) from cylinder block (7). Discard bearings (6).

Warning.

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be removed with a scraper or putty knife and then be disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

Perform step 7 for 6.2L engines only.

- Remove two-piece crankshaft rear oil seal (8) from rear main bearing cap (1) and cylinder block (7).

Discard two-piece crankshaft rear oil seal (8).

- Install bearing caps (1) and (2) on cylinder block (7) and secure with twenty capscrews (3).

2-15. Engine Disassembly Into Subassemblies (Cont'D)

2-16. Cylinder Block Repair

This task covers:

a. Preinspection c. Inspection

b. Cleaning d. Repair

lNITIAL SETUP:

| General mechanic's tool kit: |

|---|

Tools automotive (Appendix E, Item 1) Straightedge (Appendix E, Item 15) Feeler gauge (Appendix E, Item 13) Cylinder bore gauge (Appendix E, Item 14) Micrometer (Appendix E, Item 16) Cylinder boring machine (Appendix E, Item 17) Cylinder honing unit (Appendix E, Item 18)

Special Tools

Camshaft bearing remover and installer (Appendix E, Item 12)

General Safety Instructions

| Manual References |

|---|

| TM 9-2815-237-34P |

| Equipment Condition |

| Engine disassembled into subassemblies |

| (para. 2-15). |

-

Compressed air for cleaning purposes will not exceed 30 psi (207 kPa).

-

Protective clothing must be used with steam cleaning.

-

Wear eyeshields when using compressed air.

Materials/Parts

Six protective dust caps (Appendix D, Item 5) Lubricating oil OE/HDO (Appendix B, Item 13) Pipe sealing compound (Appendix B, Item 17) Sealing compound, anaerobic (Appendix B, Item 18) Sealing compound, high temperature (Appendix B, Item 21)

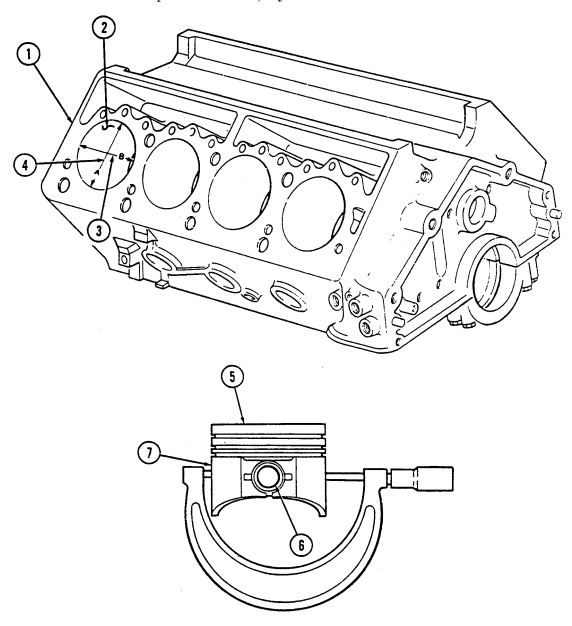

A. Preinspection

-

Inspect camshaft bearings (2) for chips, cracks, or scoring. If any bearing (2) is chipped, cracked, or scored, remove all camshaft bearings (2) (para. 2-16.d.3) and hot tank clean cylinder block (1) (para. 2-16.b.1).

-

Measure inside diameter of all camshaft bearings (2). Number one through number four camshaft bearings must be 2.167-2.170 in. (55.041-55.118 mm) and number five camshaft bearing (rear) must be 2.009-2.012-in. (51.028-51.104 mm). If any camshaft bearings (2) do not meet specifications, replace all camshaft bearings (2) (para. 2-16.d.3) and hot tank clean cylinder block (1) (para. 2-16.b.1).

-

If all bearings (2) are to be reused, steam clean cylinder block (1) (para. 2-16.b.2).

B. Cleaning

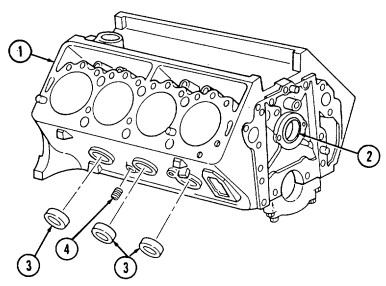

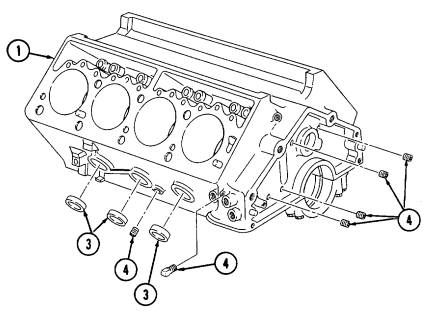

- Hot tank cleaning.

a. Remove six protective dust caps (3) and all plugs (4) from cylinder block (1). b. Clean cylinder block (1) by submerging in tank of heated cleaning solution.

c. Run rods with brushes through all oil passages and repeat step 1.b.

2-16. Cylinder Block Repair (Cont'D)

Warning

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personal protective equipment (goggles/shield, gloves, etc.).

d. Blow all dirt and cleaning solution from capscrew holes and oil passages with compressed air.

e. Refer to para. 2-9 for additional cleaning instructions. f. Coat all cylinder bores, lifter bores, and machined surfaces with OE/HDO. g. Apply pipe sealing compound to six protective dust caps (3) and all plugs (4) and install in cylinder block (1).

2 - 1 6 . Cylinder Block Repair (Cont'D)

- Steam cleaning.

a. Remove six protective dust caps (9) and all plugs (10) from cylinder block (1).

Warning

When steam cleaning, protective clothing must be used. Failure to use protective clothing may result in serious injury.

b. Thoroughly steam clean cylinder block (1). c. Run rods with brushes through all oil passages and repeat step b.

Warning

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personnel protective equipment (goggles/shield, gloves, etc.).

f. Coat all cylinder bores, lifter bores, and machined surfaces with OE/HDO. g. Apply pipe sealing compound to six protective dust caps (9) and all plugs (10) and install in cylinder block (1).

c. Inspection

- For general inspection instructions, refer to para. 2-10. - If cylinder block inspection indicates that cylinder block is suitable for continued use, except for out-of-round, taper, or minor nicks or scratches, it can be conditioned by honing or boring. The cylinder block can then be fitted with a Hi-Limit or oversized piston (refer to para. 2-45, table 2-4 or 2-5). The 6.5L engines do not have Hi-Limit pistons.

-

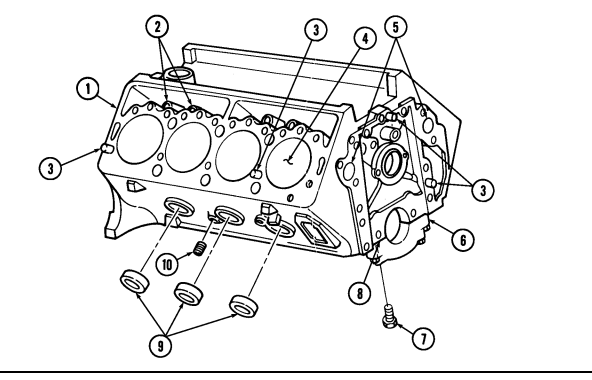

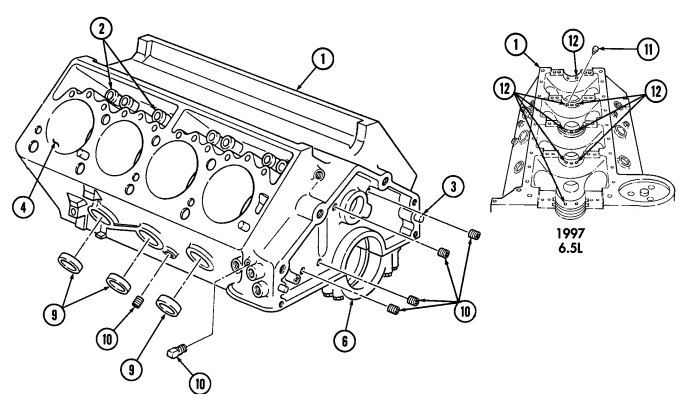

Inspect main bearing caps (6) for cracks, scoring, or damage. Replace engine if any are cracked, scored, or damaged.

-

Inspect main bearing cap bolts (7) for damage. Replace if damaged. 6. Inspect dowel pins (3) for damage. Replace if damaged. 7. Using a straightedge and feeler gauge, check flatness of cylinder head sealing surfaces on cylinder block (1). Flatness on cylinder block (1) must not vary more than 0.002 in. (0.051 mm) in a distance of 6 in. (15.2 mm) or more than 0.006 in. (0.152 mm) overall. Repair cylinder or replace engine if flatness does not meet above specifications.

Perform step 7.1 for 1997 6.5L engines only.

7.1. Inspect piston oil nozzles (11) and bores (12) for damage. Replace piston oil nozzles (11) if damaged.

d. Blow all dirt and cleaning solution from capscrew holes and oil passages with compressed air. e. Refer to para. 2-9 for additional cleaning instructions.

-

Inspect all surfaces and general overall condition of the cylinder block (1). 2. Visually check the cylinder block (1) for pitting in cylinder walls (4) and lifter bores (2). Replace engine if pitted or distorted.

-

Inspect the cylinder block (1) for cracks in cylinder walls (4), water jacket (5), lifter bores (2), and main bearing webs (8). Replace engine if cracked.

2-16. Cylinder Block Repair (Cont'D)

2 - 1 6 . Cylinder Block Repair (Cont'D)

Not E

If cylinder bores are found to have less than 0.005 in. (0.127 mm) wear, taper, or out-of-round, they may be honed oversize (refer to para. 2-16.d.1) and fitted with "Hi-Limit" standard size pistons.

-

Using cylinder bore gauge, measure all cylinder bores (2) for taper. Measurements must be taken at point "A" (4) at top and bottom of cylinder bore (2). If any cylinder exceeds specifications (table 2-2 or 2-3) by 0.005 in. (0.127 mm) or more, repair cylinder or replace engine.

-

Using cylinder bore gauge, measure all cylinder bores (2) for out-of-round. Measurement must be taken at point "A" (4) and point "B" (3) at top and bottom of cylinder bore (2). If any cylinder exceeds specifications (table 2-2 or 2-3) by 0.005 in. (0.127 mm) or more, repair cylinder or replace engine.

-

Using cylinder bore gauge, measure all cylinder bores (2) for bore diameter. Measurement must be taken at point "A" (4) 2-1/2 in. (64 mm) from top of cylinder bore (2). If any cylinder exceeds specifications (table 2-2 or 2-3) by 0.005 in. (0.127 mm) or more, repair cylinder or replace engine.

d. Repair

Not E

If cylinder block inspection indicated that the cylinder block was suitable for continued use except for out-of-round, taper, or minor nicks or scratches, it can be conditioned by honing or boring.

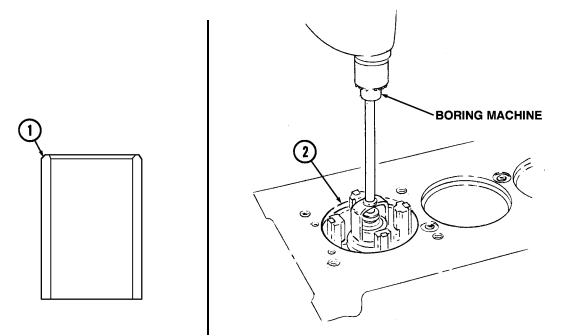

1. Boring.

a. Before using any type of boring bar, the top of the cylinder block should be filed off to remove any dirt or burrs. This is very important. If not checked, the boring bar may be tilted, which would result in the rebored cylinder wall not being at right angles to the crankshaft.

b. Measure piston diameter of the piston to be used at the skirt across the center line of the piston pin. c. Using a boring bar, bore the cylinder to the same diameter as the piston. Hone the cylinder to get proper piston-to-bore clearance.

d. Repeat steps b. and c. for remaining cylinders.

- Honing.

a. Using cylinder bore gauge, measure cylinder bore (2) for cylinder bore diameter. Measurement must be taken at point "A" (4) 2-1/2 in. (64 mm) from top of cylinder bore (2).

b. Measure "piston diameter" of piston (5) removed from corresponding cylinder using a micrometer at piston skirt (7) across center line of piston pin (6).

c. Subtract "piston diameter" from "cylinder bore diameter" to determine "piston-to-bore clearance".

d. Repeat steps a. through c. for remaining cylinder bores and pistons.

Not E

-

Cylinders can be conditioned with a hone or boring bar and fitted with a standard "Hi-Limit" piston or oversized piston, if necessary.

-

If a cylinder is pitted or worn such that it cannot be honed and fitted with a "Hi-Limit" piston or oversized piston, a cylinder sleeve may be used to repair the engine block.

-

6.5L engines do not have "Hi-Limit" pistons.

e. If all cylinder bores (2) have proper "piston-to-bore clearance" of 0.004-0.005 in. (0.102-0.127 mm) or if proper "piston-to-bore clearance" may be obtained using a standard "Hi-Limit" piston or oversized piston, go to step f. If not, engine may be repaired using a cylinder sleeve (para. 2-16.d.2).

2 - 1 6 . Cylinder Block Repair (Cont'D)

Not E

Occasionally during the honing operation, cylinder bore should be thoroughly cleaned, and the piston-to-bore clearance checked for correct fit.

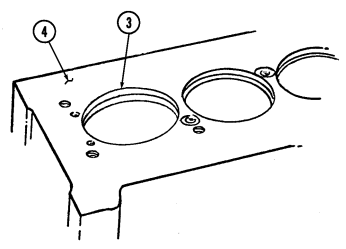

f. Using cylinder hone, refinish cylinder bore (2). Hone should be moved up and down at sufficient speed to obtain very fine uniform surface finish marks, in a cross-hatch pattern of approximately 45° to 65° included angle. The finish marks should be clean, not sharp, and free from imbedded particles and torn or folded material.

g. If a "Hi-Limit" piston or oversized piston (5) was fitted to a cylinder bore (2), permanently mark the piston (5) for the cylinder bore (2) to which it has been fitted.

h. Repeat steps f. and g. for remaining cylinder bores. i. Thoroughly clean the cylinder block (1) with hot water and detergent. Scrub cylinder bores (2)

with a stiff brush and rinse thoroughly with hot water. The cylinder bores (2) should be coated with OE/HDO and wiped with a clean, dry cloth.

2 - 1 6 . Cylinder Block Repair (Cont'D)

- Installation of cylinder sleeves.

Do not use cylinder sleeves to repair a cracked engine block.

Cylinders that still show damage or wear after being honed to a maximum oversize of 0.030 in. (0.762 mm) will require sleeves.

a. Identify cylinders that require sleeves. b. Using micrometer, measure outside diameter of cylinder sleeve (1).

-

Before using any type of boring bar, the top of the cylinder block should be filed off to remove any dirt or burrs. This is very important. If not checked, the boring bar may be tilted, which would result in the rebored cylinder wall not being at right angle to crankshaft.

-

The cylinder must be bored to within 0.125 in. (3.18 mm) of the rod relief in the bottom of the cylinder. Ensure the depth of the bore does not exceed the length of the sleeve. Ensure to cut the bottom of the bore square. This will provide a stop, or ledge, for the sleeve to bottom out on.

c. Using cylinder boring machine, bore cylinder (2) to diameter of sleeve (1) less 0.002 to 0.003 in.

(0.051 to 0.076 mm) to create an interference fit between sleeve (1) and cylinder (2).

Store the sleeve in a freezer at a temperature of 28 to 30°F (-2.2 to -1.1°C) for several hours before installing it into the engine block.

d. Apply bead of high temperature sealing compound to top and bottom of cylinder (2) bore. Press frozen sleeve (1) into cylinder (2) until it bottoms out on ledge at bottom of cylinder (2) bore.

e. Remove any excess sleeve material protruding above the head deck surface (4). Finish the sleeve (1) flush with deck of block (3), taking care not to damage deck surface (4).

f. Using cylinder boring machine, bore the sleeved cylinder (1) to appropriate piston size. g. Finish cylinder surface (refer to para. 2-16.d.1).

2-16. CYLINDER BLOCK REPAIR (Cont'd)

2-16. Cylinder Block Repair (Cont'D)

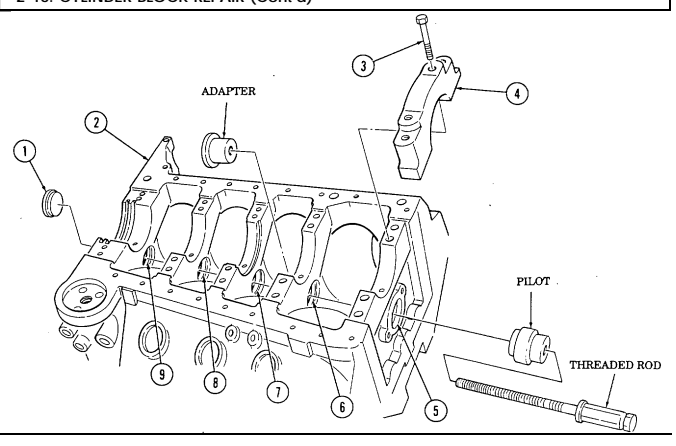

- Camshaft bearing replacement.

Warning

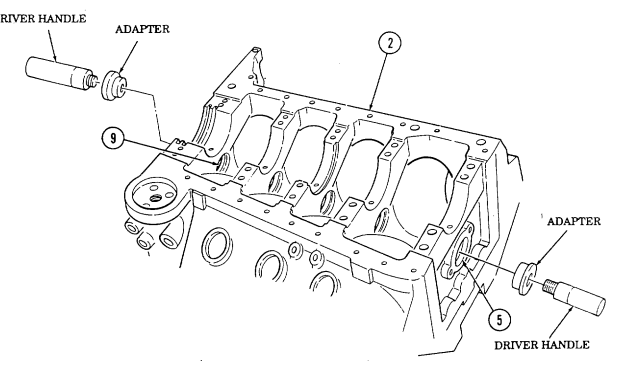

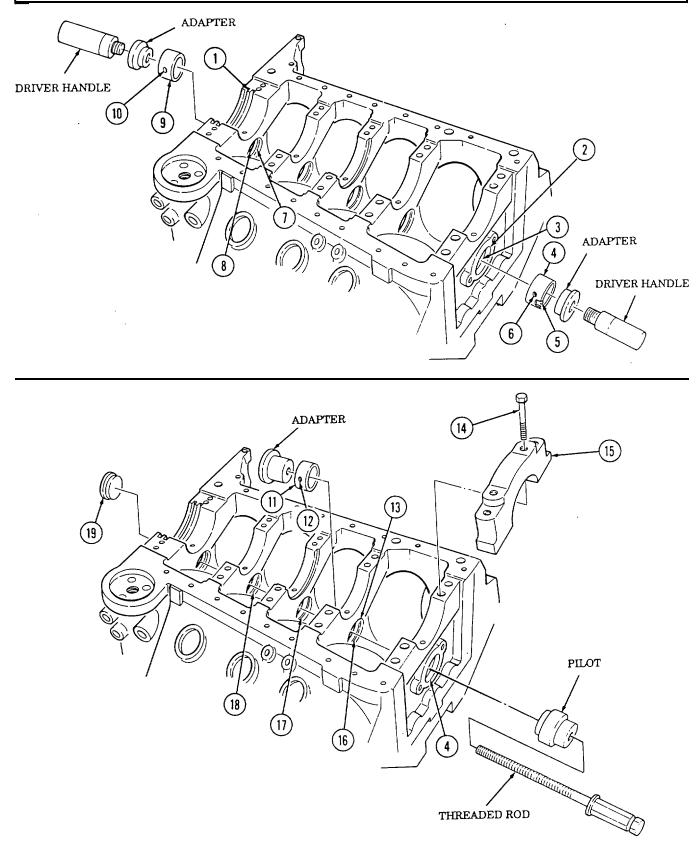

Cylinder block must be supported during removal and installation from engine stand. Failure to support cylinder block may cause injury to personnel or damage to equipment.

The following steps are to be performed only if camshaft bearings are to be replaced.

a.

Remove cylinder block (2) from engine stand.

b.

twenty capscrews (3) and five main bearing caps (4) from cylinder block (2).

Remove c. d.

e.

f.

g. h.

Drive camshaft rear plug (1) from cylinder block (2). Discard plug (1). Install adapter J 6098-11 in camshaft bearing number two (6).

Install pilot in number one camshaft bearing (5). Insert threaded rod through pilot and into adapter.

thread Hold threaded rod stationary and tighten long hex nut to remove camshaft bearing (6) from cylinder block (2). When camshaft bearing (6) has been completely removed from cylinder block (2), remove threaded rod, pilot, and adapter. Discard bearing (6). Repeat steps d. through f. for number three camshaft bearing (7). Repeat steps d. through f., working from rear of cylinder block (2), for number four camshaft bearing (8).

Using driver handle and adapter J6098-11, remove number one camshaft bearing (5) from cylinder block (2). Discard bearing (5).

Using driver handle and adapter J 6098-12, remove number five camshaft bearing (9) from cylinder block (2). Discard bearing (9).

i.

j.

2-16. Cylinder Block Repair (Cont'D)

2-16. Cylinder Block Repair (Cont'D)

All five bearings must have an oil hole at the approximate ten o'clock position, when viewed from the front with the block in an upside down position, or engine damage will result. The seam in the bearing must always be located in the lower half of the block face, when viewed with the block in an upside down position, or engine damage will result. The front bearing has an additional oil hole which will be located between the six and seven o'clock positions. This bearing also has a notch which must be positioned toward the front of the block, or engine damage will result.

● ● ● ● All oil holes in camshaft bearings must be aligned with grooves in camshaft bearing bores after installation, or engine damage will result.