hmmwv-manuals

DECEMBER 1997

PCN 184 110332 00

Army Tm 9-2320-387-24-2 Volume No. 2 Air Force To 36A12-1A-3052-2 Marine Corps Tm 11033-In Vol 2

TECHNICAL MANUAL UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038) (EIC: BEG); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007) (EIC: BEH); TRUCK, UTILITY: COMMAND AND CONTROL/ GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993) (EIC: BEK); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017) (EIC: BEJ); TRUCK, UTILITY: EXPANDED CAPACITY, TOW ITAS CARRIER, M1167 (2320-01-544-9638).

Approved for public release; distribution is unlimited.

| BODY AND ACCESSORIES (UNIT) MAINTENANCE | 10-1 |

|---|---|

| SPECIAL PURPOSE BODIES (UNIT) MAINTENANCE 11-1 | |

| SPECIAL PURPOSE KITS (UNIT) MAINTENANCE | 12-1 |

| PREPARATION FOR STORAGE OR SHIPMENT | 13-1 |

| TROUBLESHOOTING (DS)/(GS) | 14-1 |

| ENGINE (DS) MAINTENANCE | 15-1 |

| FUEL SYSTEM (DS) MAINTENANCE | 16-1 |

| COOLING SYSTEM (DS) MAINTENANCE | 17-1 |

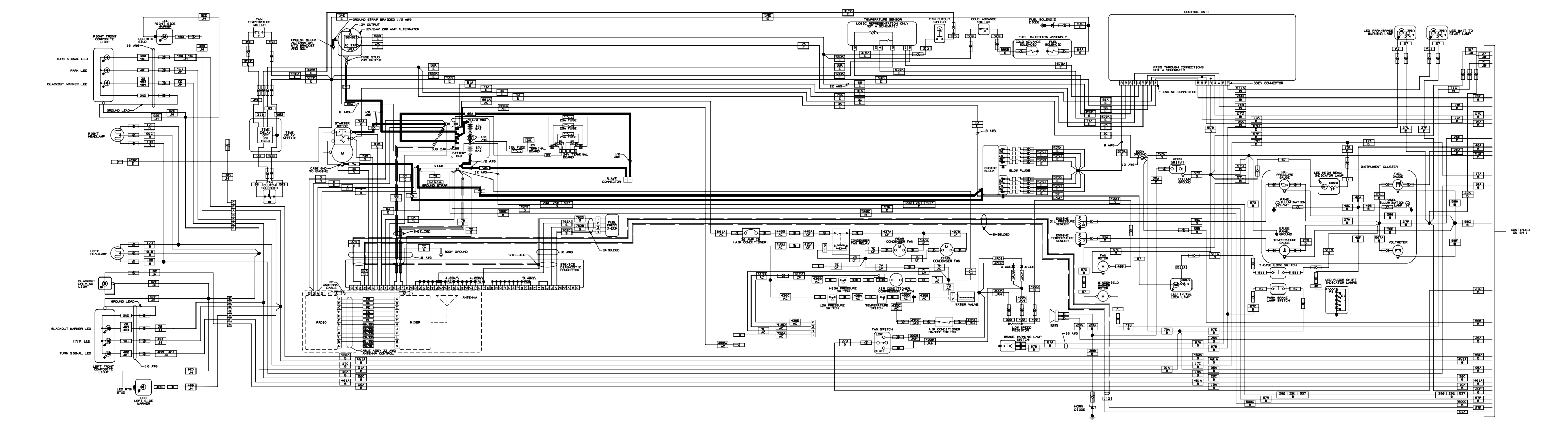

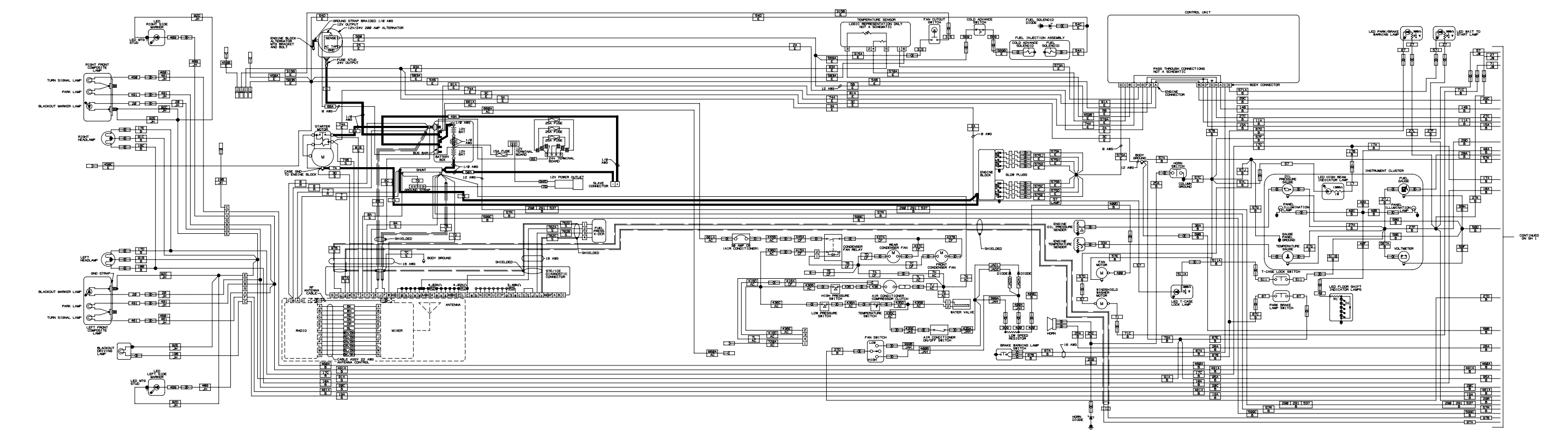

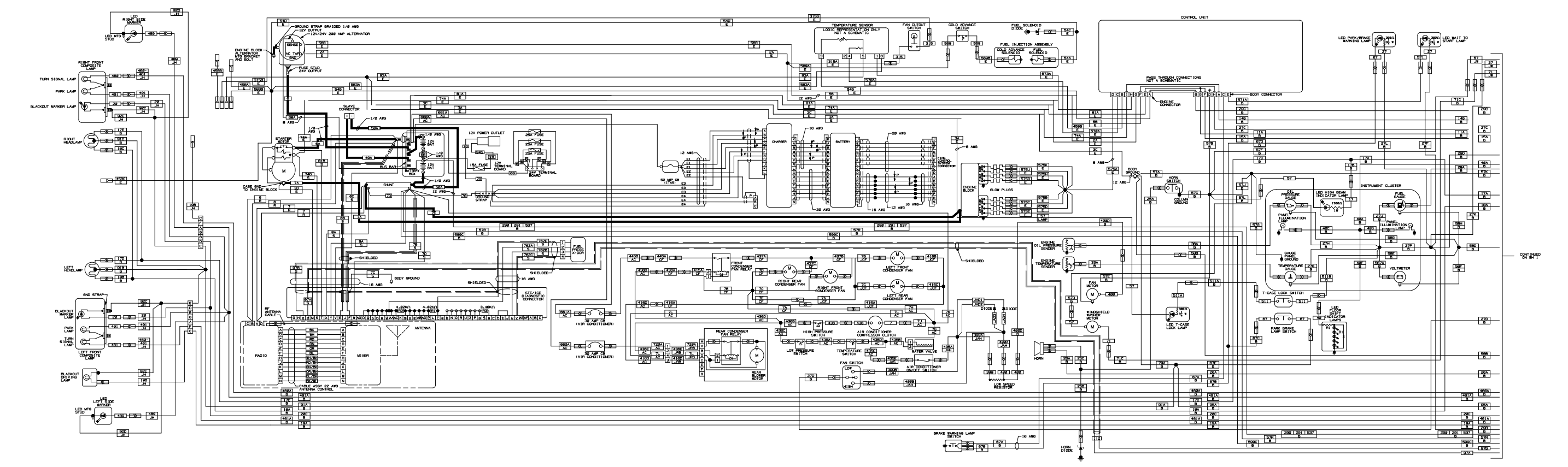

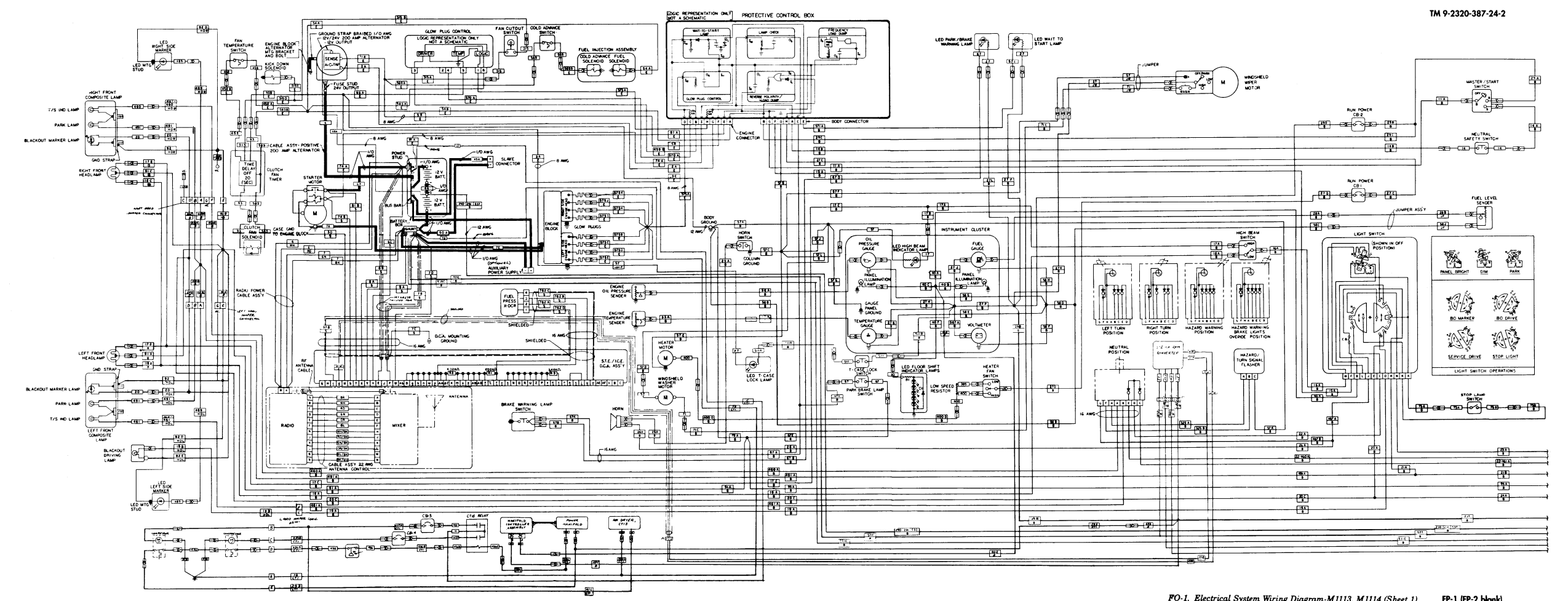

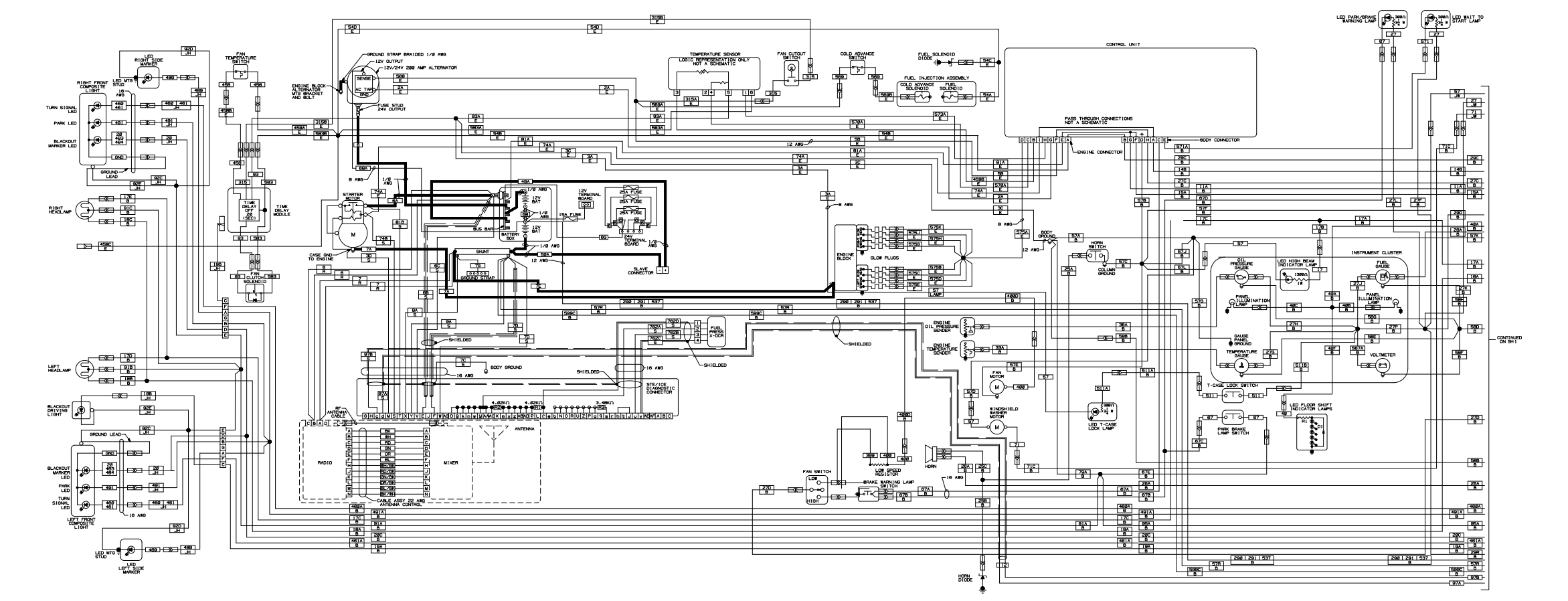

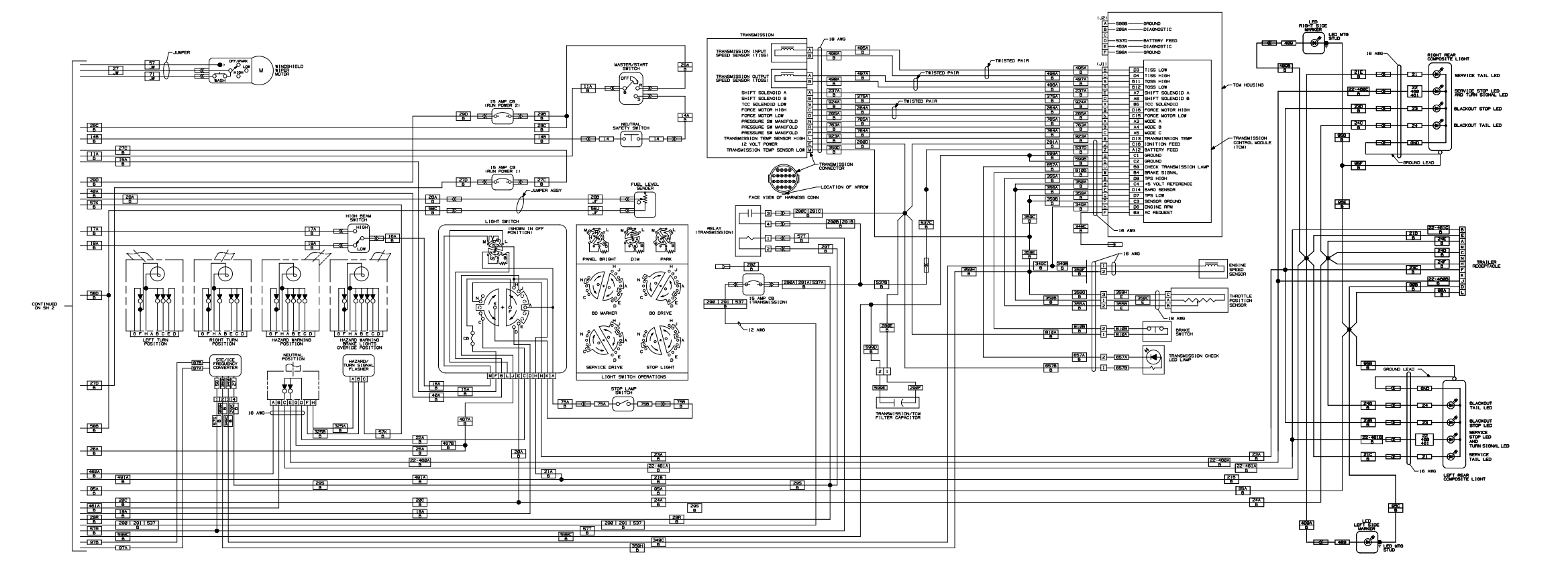

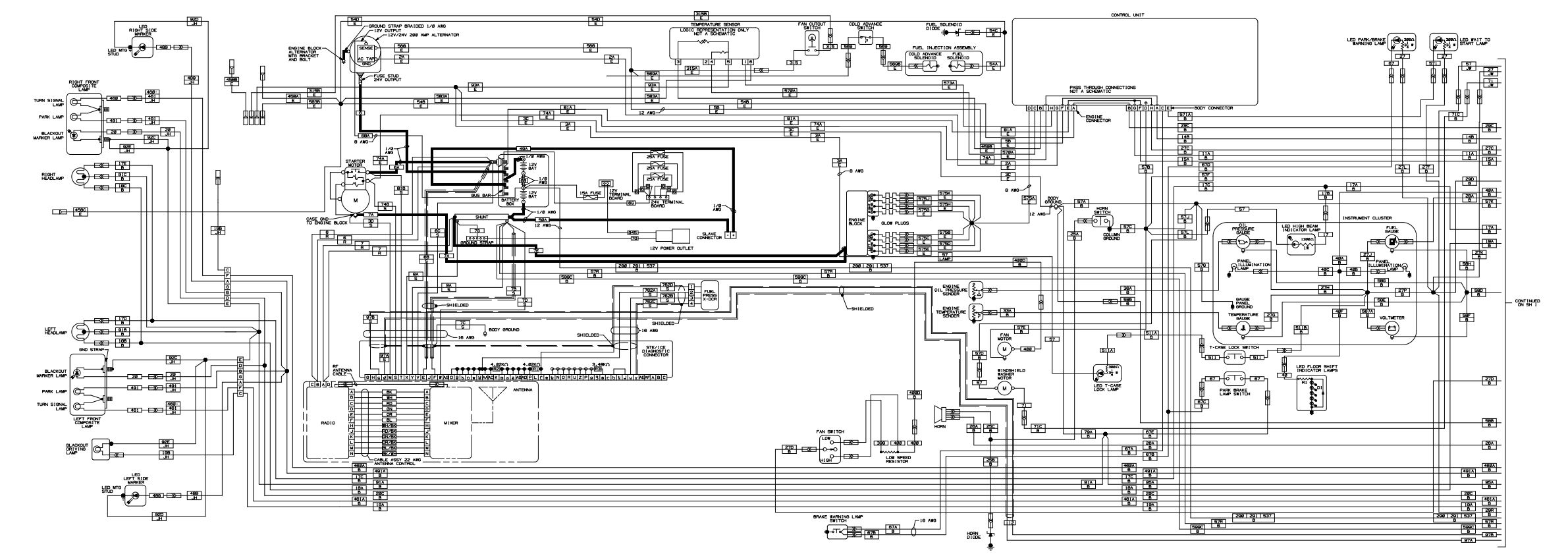

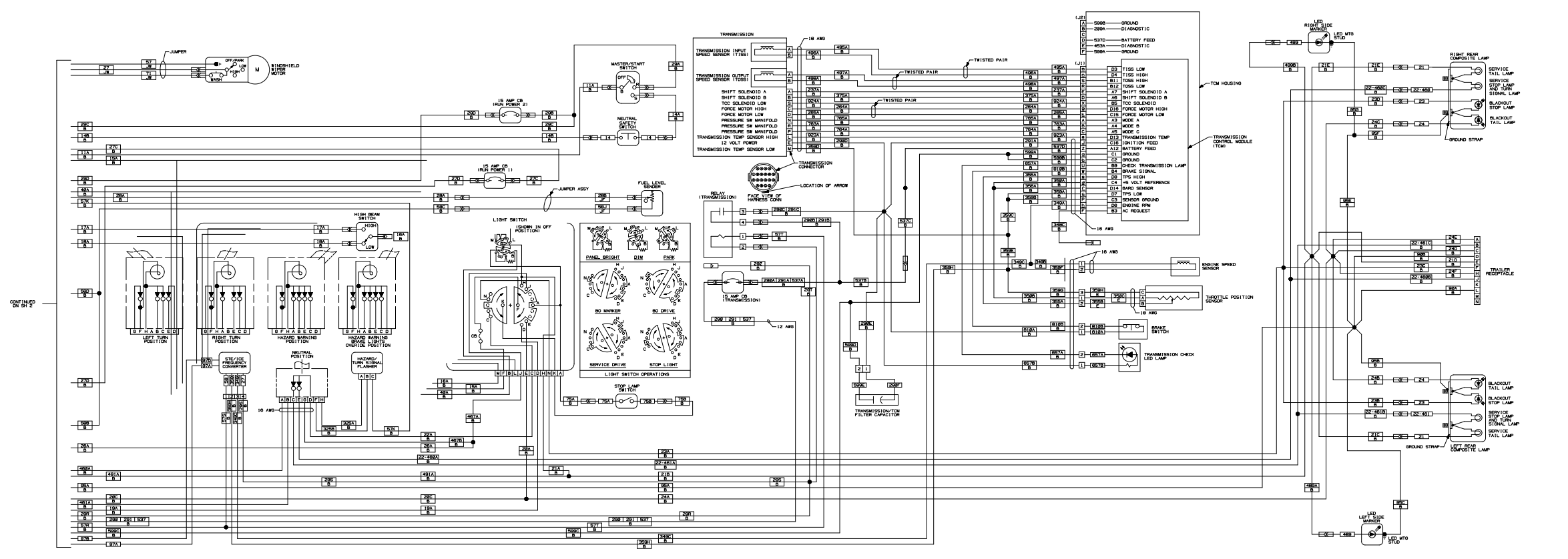

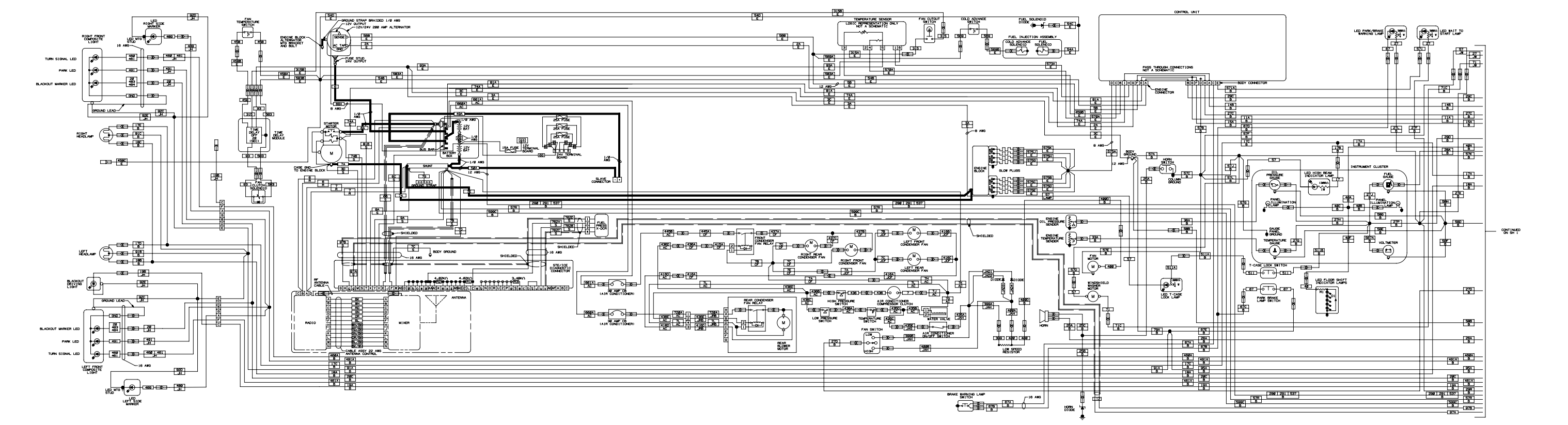

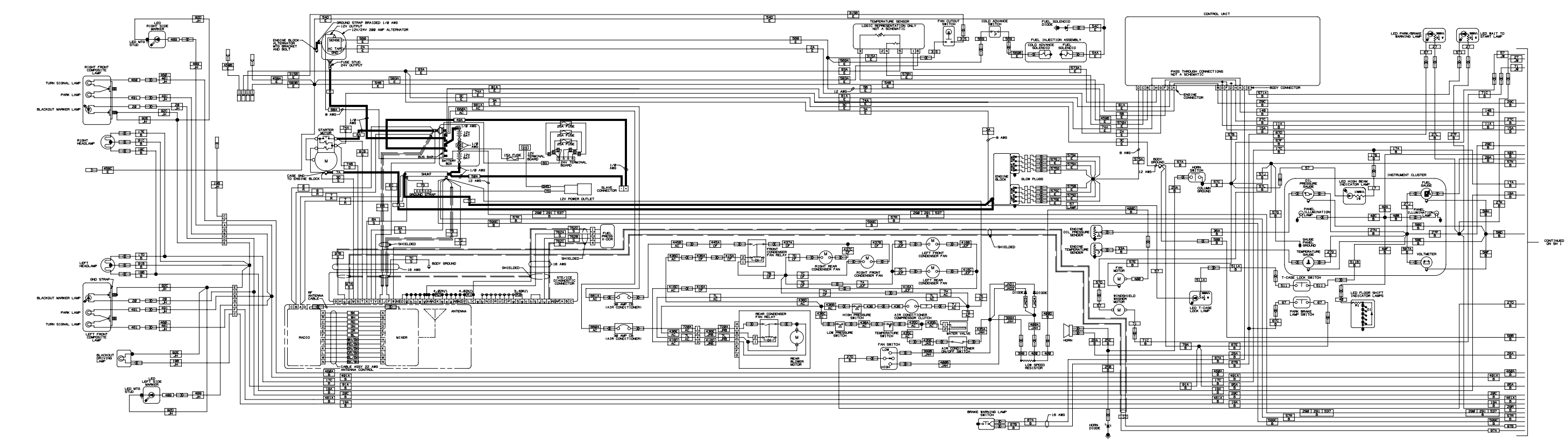

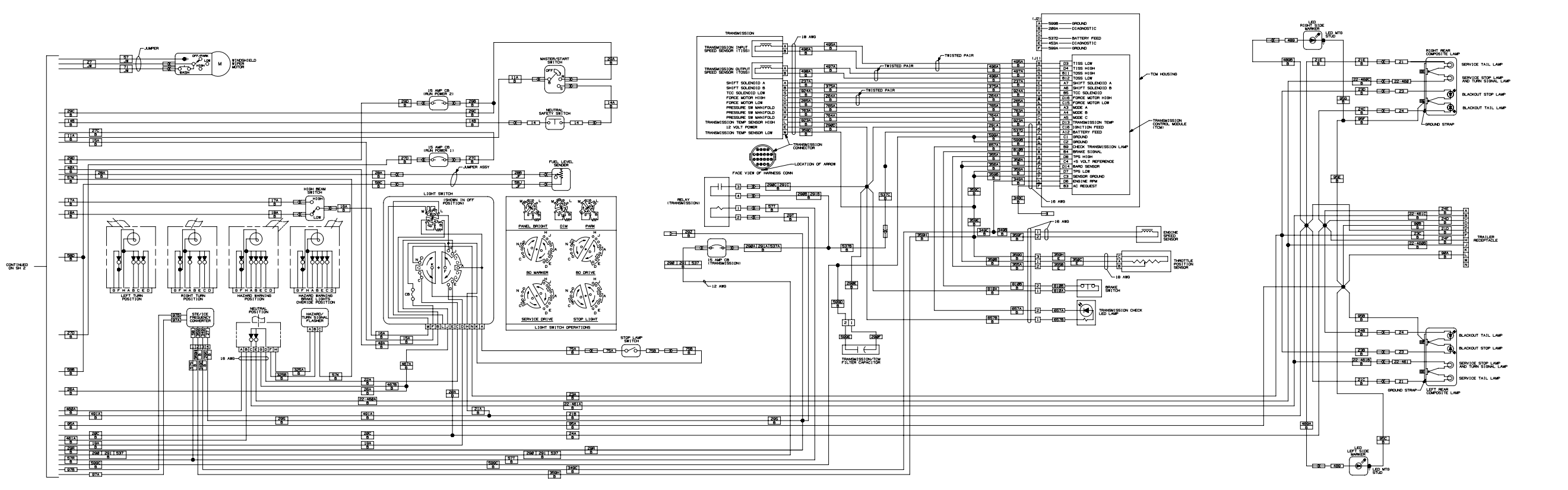

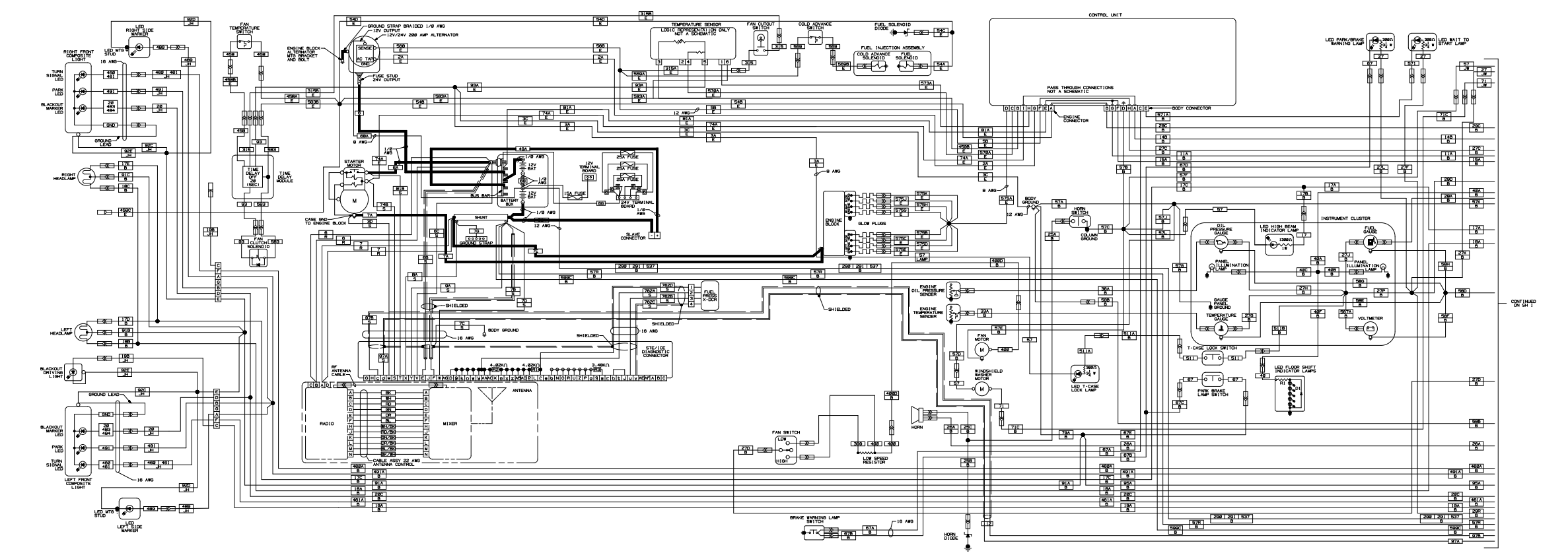

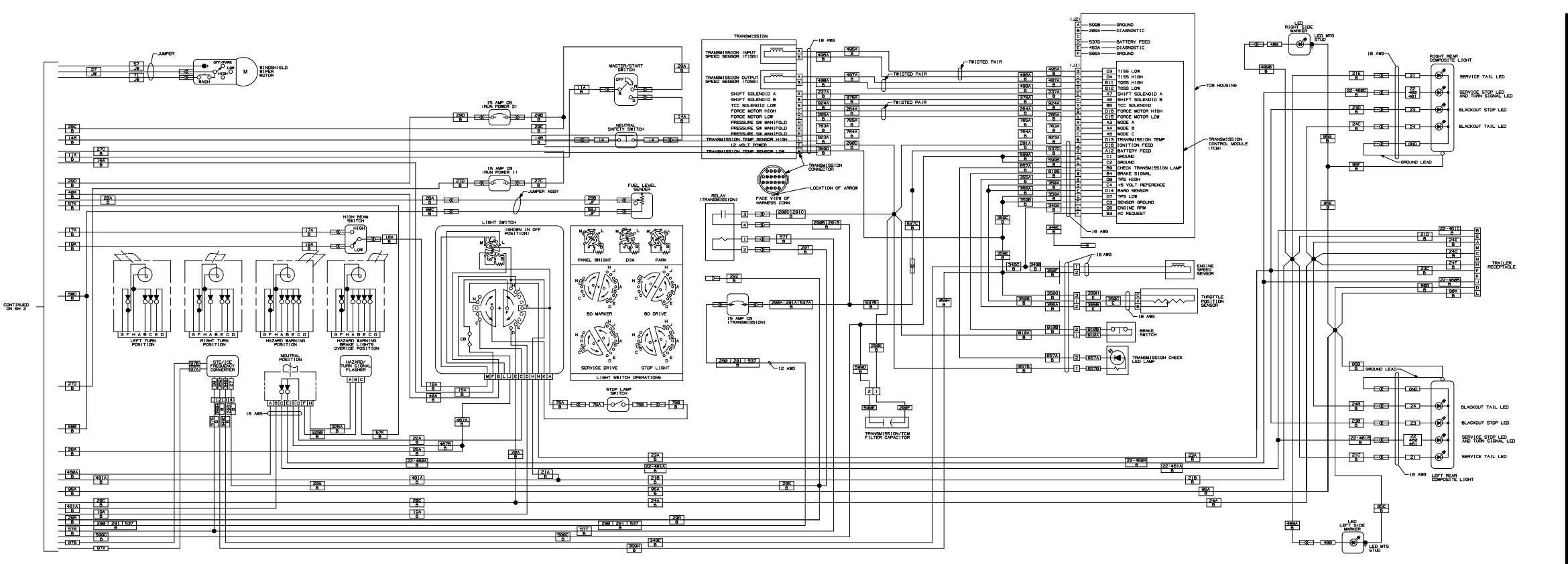

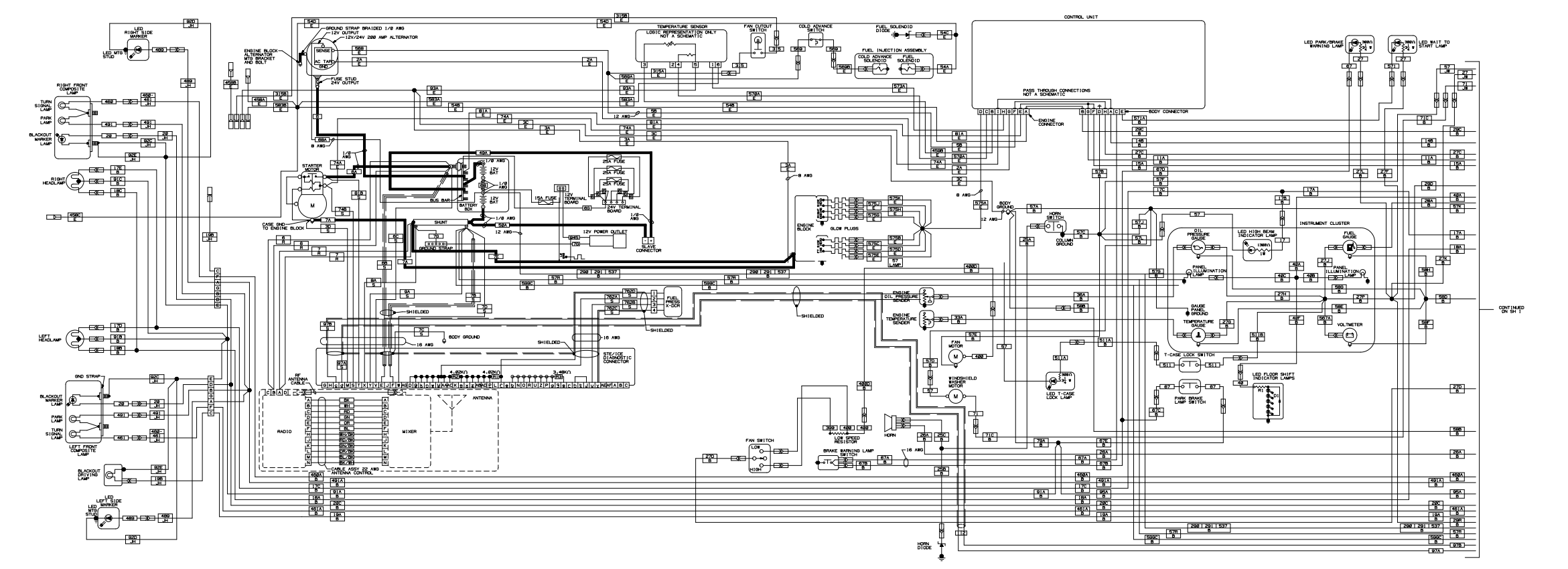

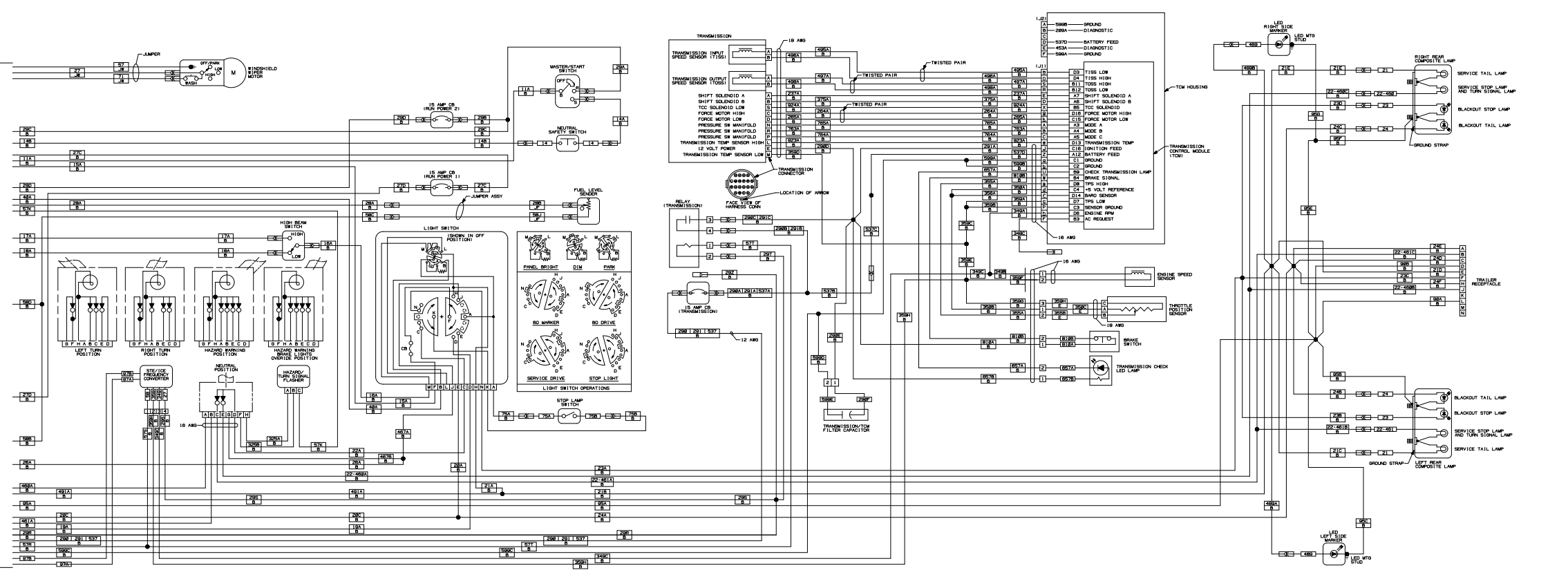

| ELECTRICAL SYSTEM (DS) MAINTENANCE | 18-1 |

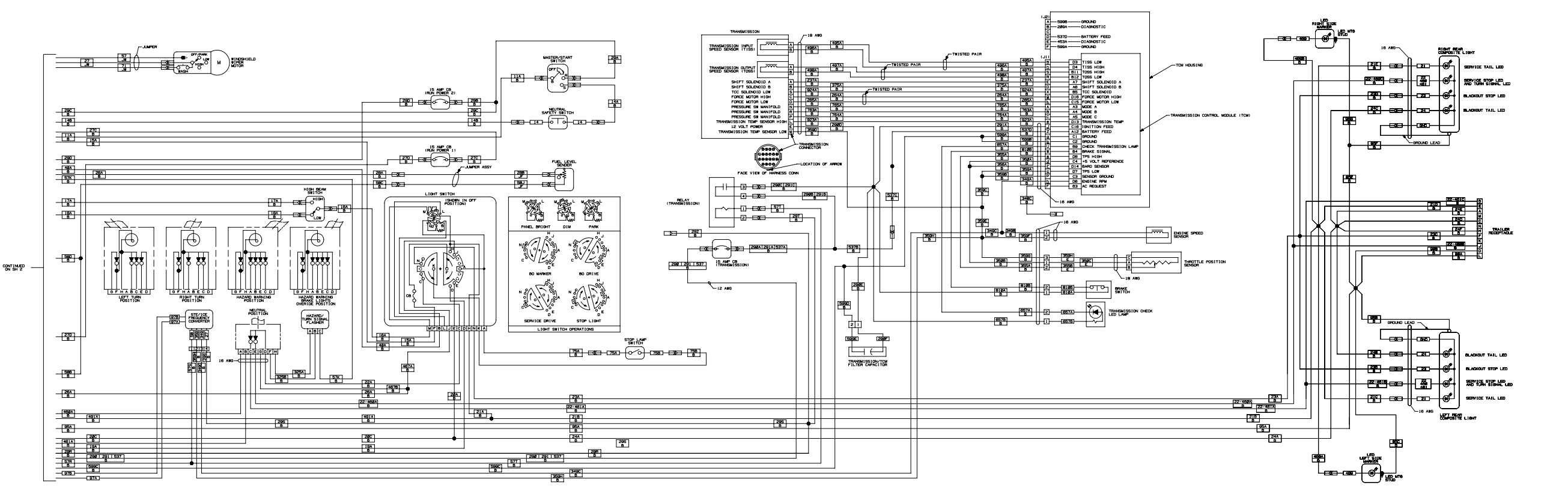

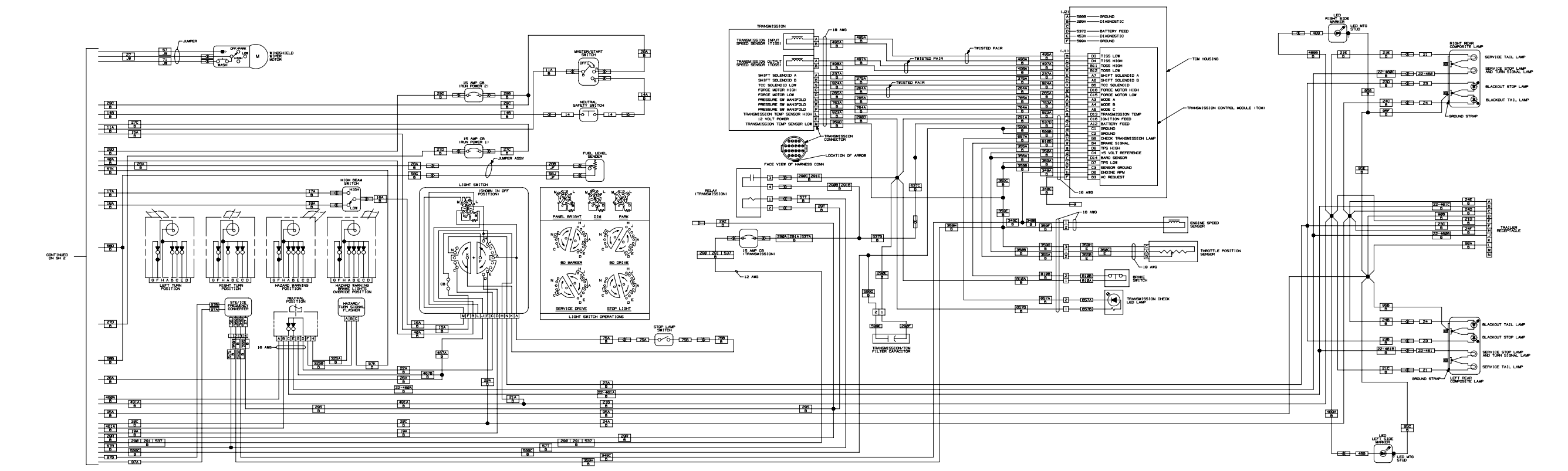

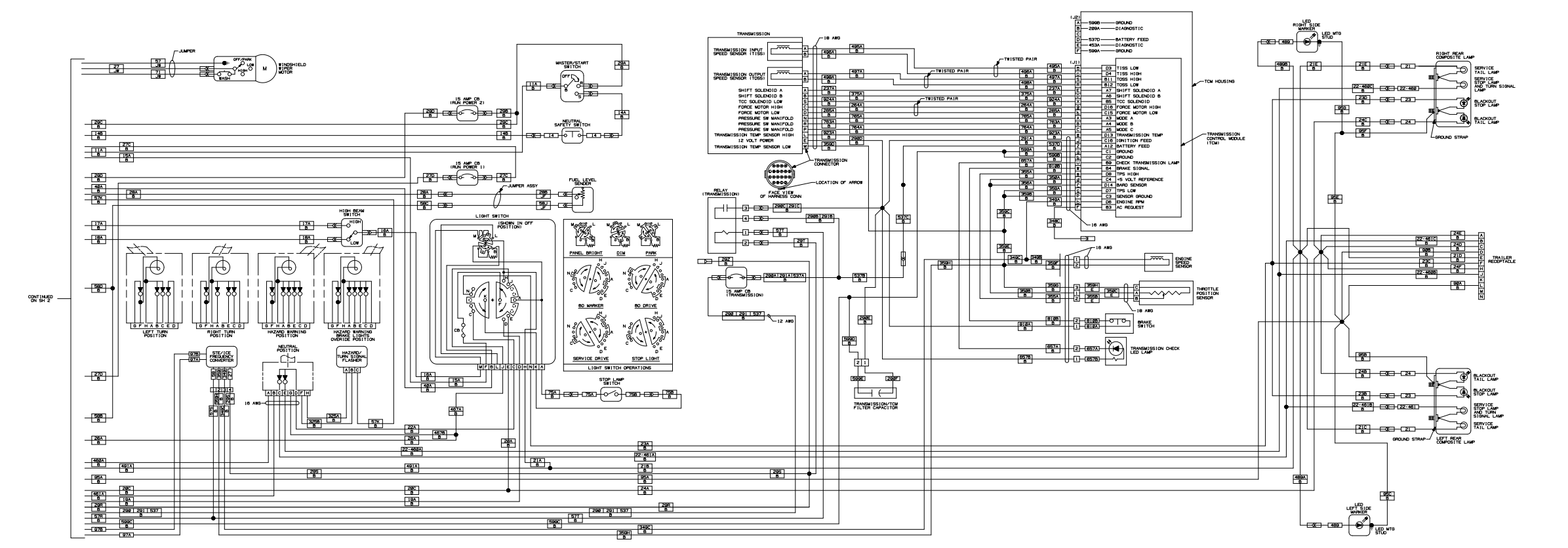

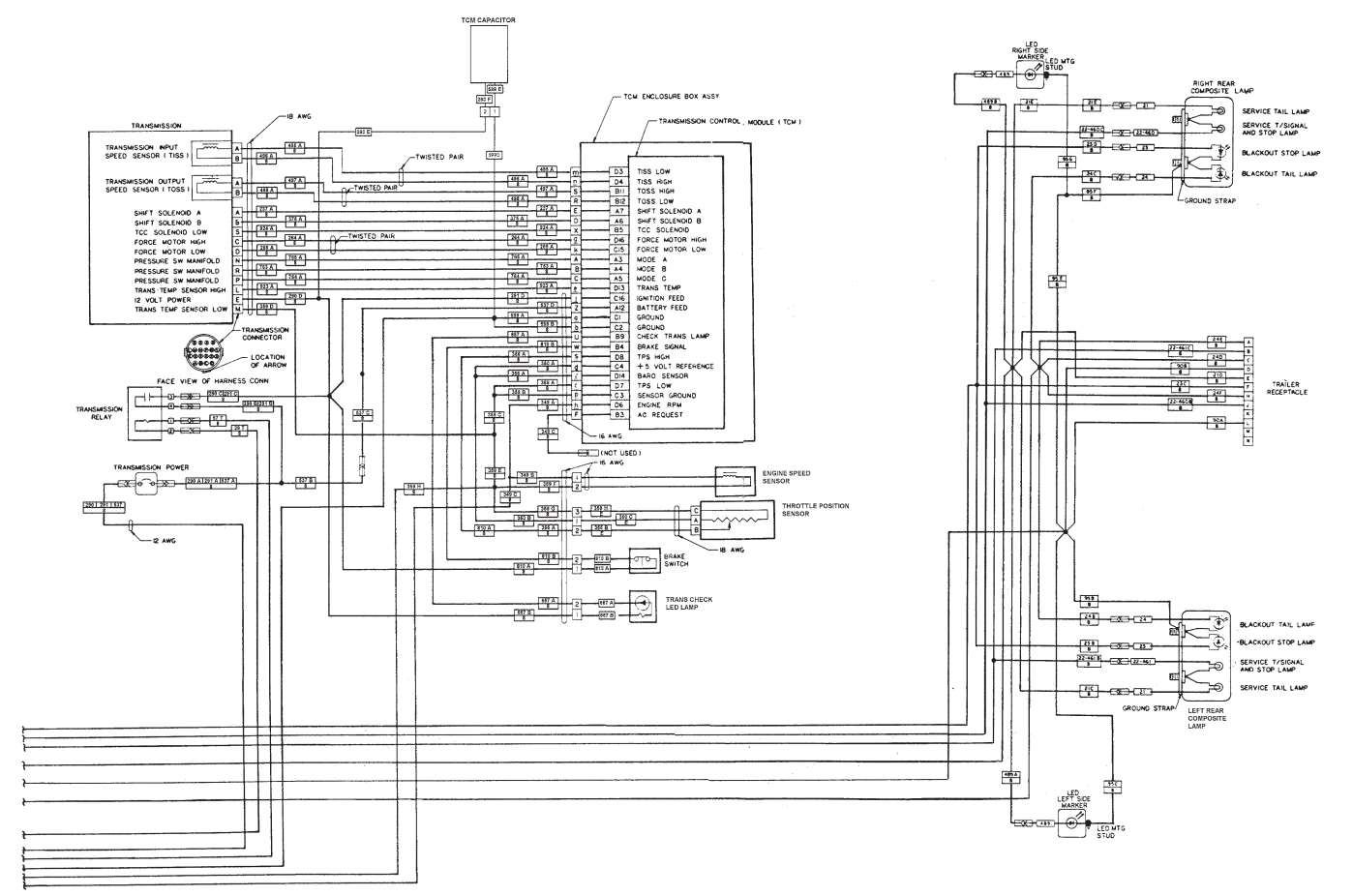

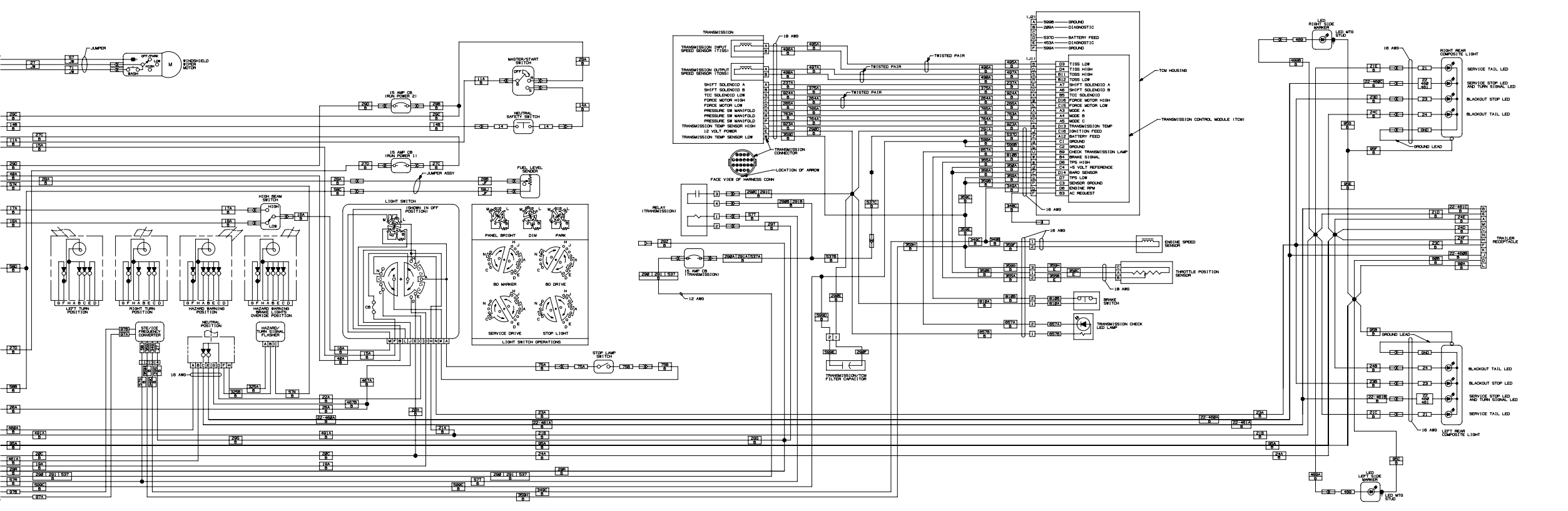

| TRANSMISSION (DS) MAINTENANCE | 19-1 |

| TRANSFER CASE (DS) MAINTENANCE | 20-1 |

| PROPELLER SHAFTS, AXLES, AND | 21-1 |

| SUSPENSION (DS) MAINTENANCE | |

| SERVICE BRAKE SYSTEM (DS) MAINTENANCE | 22-1 |

| STEERING SYSTEM (DS) MAINTENANCE | 23-1 |

| FRAME (DS) MAINTENANCE | 24-1 |

| SPECIAL PURPOSE BODIES (DS) MAINTENANCE | 25-1 |

| SPECIAL PURPOSE KITS (DS) MAINTENANCE | 26-1 |

| ELECTRICAL SYSTEM (GS) REPAIR | 27-1 |

| TRANSMISSION (GS) REPAIR | 28-1 |

| TRANSFER CASE (GS) REPAIR | 29-1 |

| DIFFERENTIAL (GS) REPAIR | 30-1 |

| STEERING SYSTEM (GS) REPAIR | 31-1 |

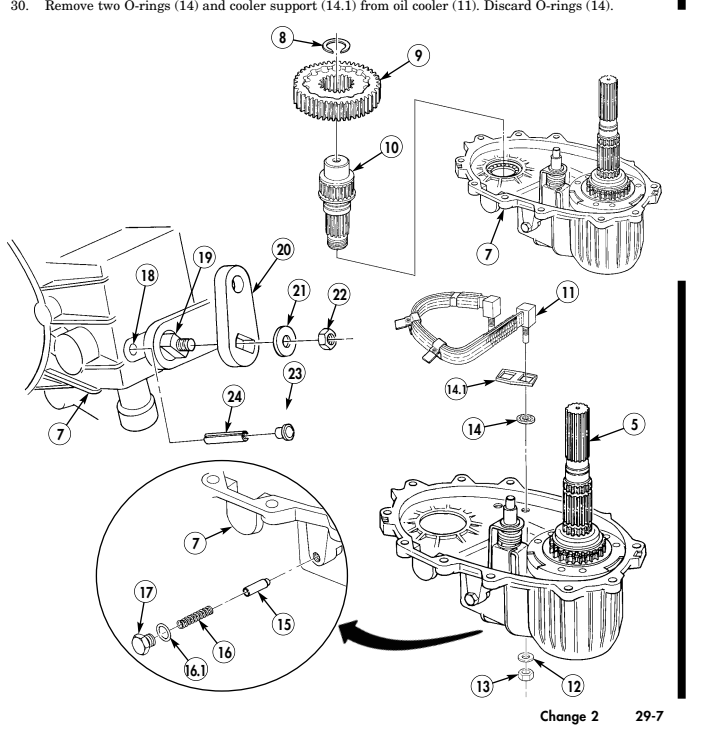

| FRAME (GS) REPAIR | 32-1 |

| BODY (GS) REPAIR | 33-1 |

| SUSPENSION (GS) MAINTENANCE | 34-1 |

HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS

Exhaust Gases Can Kill

Brain damage or death can result from heavy exposure. Precautions must be followed to ensure personnel safety when the personnel heater or engine of any vehicle is operated for any purpose.

- Do not operate your vehicle engine in enclosed areas. 2. Do not idle vehicle engine with vehicle windows closed. 3. Be alert at all times for exhaust odors. 4. Be alert for exhaust poisoning symptoms. They are:

- Headache - Dizziness - Sleepiness - Loss of muscular control 5. If you see another person with exhaust poisoning symptoms:

- Remove person from area - Expose to open air - Keep person warm - Do not permit physical exercise - Administer artificial respiration, if necessary* - Notify a medic

- For artificial respiration, refer to FM 21-11.

- BE AWARE, the field protective mask for nuclear, biological, or chemical (NBC) protection will not protect you from exhaust poisoning. THE BEST DEFENSE AGAINST EXHAUST POISONING IS ADEQUATE VENTILATION.

Warning Summary

-

Improper cleaning methods and use of unauthorized cleaning solutions may cause injury to personnel or damage to equipment. See TM 9-247 for correct information.

-

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personal protective equipment (goggles/shield, gloves, etc.).

-

Do not touch hot exhaust system components with bare hands. Severe injury will result. - Gloves must be worn whenever handling winch cable. Severe injury may result. - Seatbelts are to be replaced as a set. Failure to do this may cause injury to personnel or damage to equipment.

-

Direct all personnel to stand clear during any hoisting operations. A heavy, swinging load can be extremely dangerous. Failure to do so may cause injury to personnel or damage to equipment.

-

Diesel fuel is highly flammable. Do not perform any procedure near fires, flames, or sparks. Severe injury or death may result.

-

Ensure engine compartment is free of all tools and working material before starting engine. Failure to do this may cause injury to personnel or damage to equipment.

-

Do not remove surge tank filler cap before depressurizing system when engine temperature is above 190°F (88°C). Steam or hot coolant under pressure will cause severe burns.

-

Do not drain oil when engine is hot. Severe injury to personnel will result. - Allow transmission/transfer case to cool before performing maintenance. Failure to do this may cause injury.

-

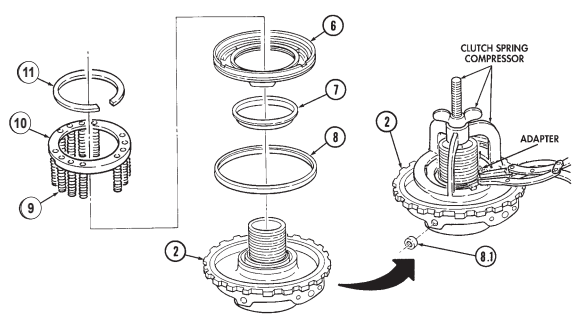

When steam cleaning, protective clothing must be used. Failure to do this may cause injury. - Air pressure must not exceed 50 psi (345 kPa) when air checking forward and direct clutch piston or injury to personnel or damage to equipment may result.

-

Direct all personnel to stand clear of vehicle before starting engine. Transmission slipping into gear may cause injury to personnel or damage to equipment.

-

When sanding fiberglass, personal protective equipment (respirator, goggles/shield, gloves, coveralls, etc.) must be used. Failure to do this may cause injury.

-

Do not operate heater in enclosed areas. Exhaust gases can kill. Make sure work area is well ventilated and exhaust fumes are routed away from test area.

-

Drycleaning solvent is flammable and will not be used near an open flame. A fire extinguisher will be kept nearby when solvent is used. Use only in well-ventilated places. Failure to do this may result in injury to personnel or damage to equipment.

-

Always wear eye protection around R-134a or when servicing the air-conditioning system. Exercise extreme care when handling R-134a; direct contact between R-134a and skin may cause frostbite. Never smoke in areas where R-134a is used or stored. Ensure adequate ventilation whenever R-134a is being discharged. Personnel with a history of cardiac rhythm abnormalities should be made aware of potential aggravation as a result of exposure to R-134a. Failure to do so may result in injury to personnel.

-

Air-conditioning system must be discharged prior to replacing components. Failure to do this may result in injury to personnel or damage to equipment.

-

Protective eye equipment (goggles/shield) must be worn when removing snaprings or springs. Failure to comply may result in injury to personnel.

-

Ensure all slack from the three-point seatbelt or Improved Personal Restraint System is removed. The three-point seatbelt and Improved Personal Restraint System will lock only during sudden stops or impact. Injury and/or death to personnel may result if an accident occurs and seatbelts or lap and shoulder straps are not in use or adjusted properly.

-

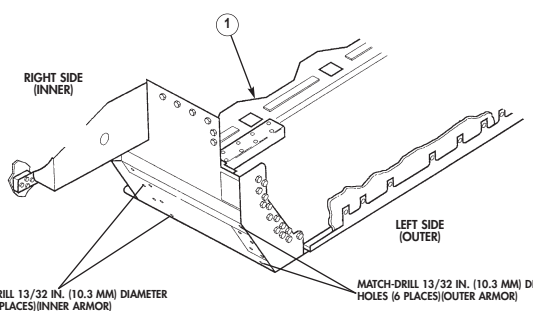

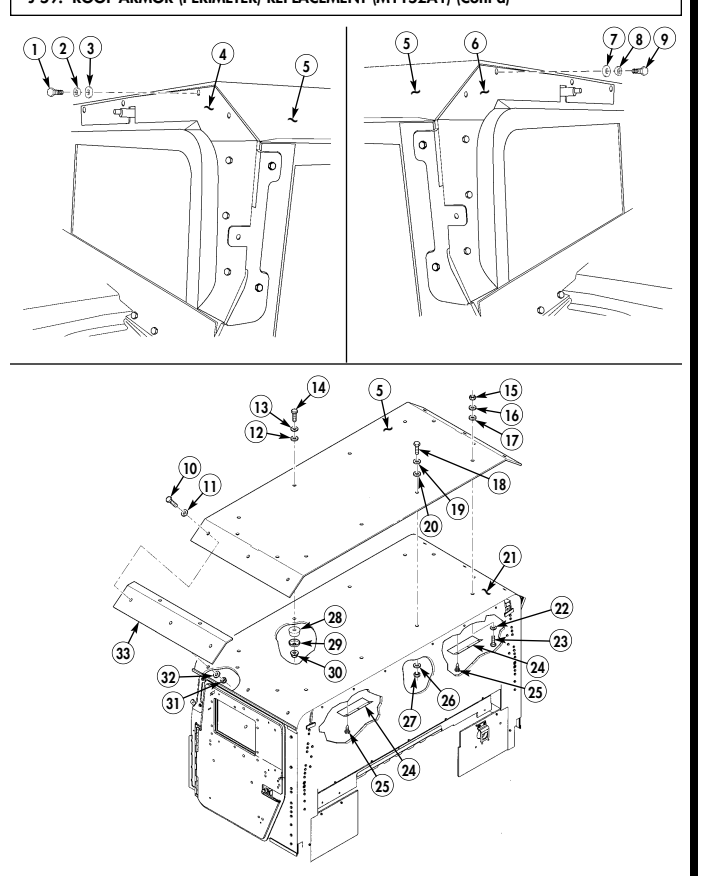

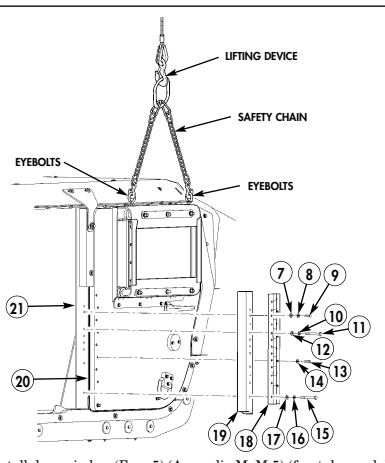

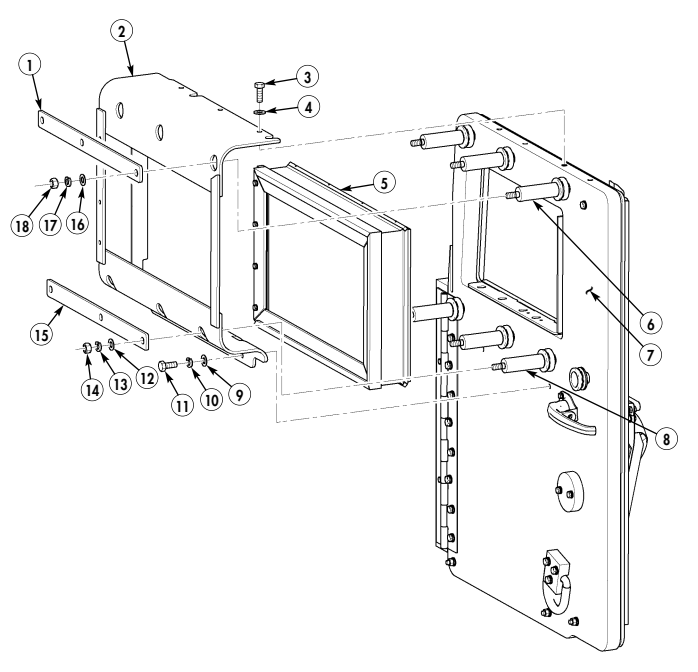

Vehicle armor is extremely heavy and must be supported during removal and installation. Failure to do so may result in injury to personnel or damage to equipment.

CHANGE NO. 6 ARMY TM 9-2320-387-24-2 AIR FORCE TO 36A12-1A-3052-2 MARINE CORPS TM 11033-IN VOL 2 HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS WASHINGTON, D.C., 31 AUGUST 2009 TECHNICAL MANUAL VOLUME 2 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038) (EIC: BEG); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007) (EIC: BEH); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993) (EIC: BEK); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017) (EIC: BEJ); TRUCK, UTILITY: EXPANDED CAPACITY, TOW ITAS, CARRIER, M1167 (2320-01-544-9638).

TM 9-2320-387-24-2, 31 December 1997, is changed as follows:

-

One new model has been added to the front cover. The new cover, located at the end of the change package, replaces the existing cover.

-

Remove old pages and insert new pages as indicated below. 3. New or changed material is indicated by a vertical bar in the margin of the page. 4. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert pages |

|---|---|

| A through I/(J blank) | A through I/(J blank) |

| i through iv | i through iv |

| 10-1 and 10-2 | 10-1 and 10-2 |

| 10-37 through 10-46 | 10-37 through 10-46 |

| 10-75 and 10-76 | 10-75 and 10-76 |

Approved for public release; distribution is unlimited.

| Remove pages | Insert pages |

|---|---|

| 10-81 through 10-82.2 | 10-81 through 10-82.2 |

| 10-82.7 through 10-82.14 | 10-82.7 through 10-82.14 |

| 10-95 and 10-96 | 10-94.1 through 10-95/(10-96 blank) |

| 10-98.3 and 10-98.4 | 10-98.3 and 10-98.4 |

| 10-98.19 through 10-100 | 10-98.19 through 10-100 |

| 10-128.13 and 10-128.14 | 10-128.13 through 10-128.17/(10-128.18 blank) |

| 10-159 and 10-160 | 10-159 through 10-165/(10-166 blank) |

| 11-2.1 and 11-2.2/(11-3 blank) | 11-2.1 and 11-2.2/(11-3 blank) |

| 11-31 through 11-42 | 11-31 through 11-42 |

| 11-45 through 11-52.2 | 11-45 through 11-52.2 |

| 11-90.1 and 11-90.2/(11-91 blank) | 11-90.1 and 11-90.2/(11-91 blank) |

| 11-123 through 11-126 | 11-123 through 11-126 |

| (11-130.1 blank) through | (11-130.1 blank) through |

| 11-130.6/(11-131 blank) | 11-130.6/(11-131 blank) |

| 11-132.7/(11-132.8 blank) | 11-132.7 through 11-132.13/(11-132.14 blank) |

| 11-163 and 11-164 | 11-163 and 11-164 |

| 11-191 through 11-194 | 11-191 through 11-194 |

| 11-202.1 and 11-202.2 | 11-202.1 through 11-202.5/(11-202.6 blank) |

| 11-208.1 and 11-208.2 | 11-208.1 and 11-208.2 |

| 11-209 through 11-212 | 11-209 through 11-212 |

| 11-214.1 and 11-214.2 | 11-214.1 and 11-214.2 |

| 11-216.1 through 11-218 | 11-216.1 through 11-218 |

| 11-220.1 and 11-220.2 | 11-220.1 and 11-220.2 |

| 11-222.1 and 11-222.2 | 11-222.1 and 11-222.2 |

| 11-224.1 and 11-224.2 | 11-224.1 and 11-224.2 |

| 11-226.1 and 11-226.2 | 11-226.1 and 11-226.2 |

| 11-228.1 through 11-234.2 | 11-228.1 through 11-234.2 |

| 11-236.1 through 11-238 | 11-236.1 through 11-238 |

| None | 11-345 through 11-463/(11-464 blank) |

| 12-35 through 12-38 | 12-35 through 12-38 |

| 12-51 and 12-52 | 12-51 and 12-52 |

| 12-54.1 and 12-54.2 | 12-54.1 and 12-54.2 |

| 12-55 and 12-56 | 12-55 and 12-56 |

| None | 12-62.9 through12-62.17/(12-62.18 blank) |

| 12-79 and 12-80 | 12-79 and 12-80 |

| 12-225 through 12-234 | 12-225 through 12-234 |

| 12-239 through 12-264 | 12-239 through 12-264 |

| None | 12-351 through 12-379/(12-380 blank) |

| 13-1 and 13-2 | 13-1 and 13-2 |

| 14-15 and 14-16 | 14-15 and 14-16 |

| 14-25 through 14-28 | 14-25 through 14-28 |

| 15-1 and 15-2 | 15-1 and 15-2 |

| 15-7 and 15-8 | 15-7 and 15-8 |

| 15-11 through 15-14 | 15-11 through 15-14 |

| 15-39 through 15-42 | 15-39 through 15-42 |

| 15-47 through 15-126 | 15-47 through 15-126 |

| 17-1/(17-2 blank) | 17-1 through 17-13/(17-14 blank) |

| 19-1 through 19-15/(19-16 blank) | 19-1 through 19-17/(19-18 blank) |

| 20-1 through 20-9/(20-10 blank) | 20-1 through 20-11/(20-12 blank) |

| 21-1 through 21-8.2 | 21-1 through 21-8.2 |

| Remove pages | Insert pages |

|---|---|

| 24-1 through 24-14 | 24-1 through 24-14 |

| 24-17 through 24-36 | 24-17 through 24-36 |

| 24-39 and 24-40 | 24-38.1 through 24-40 |

| 25-1 and 25-2 | 25-1 and 25-2 |

| 25-23 and 25-24 | 25-22.1 through 25-24 |

| 25-41 through 25-44 | 25-41 through 25-44 |

| 25-71 through 25-74 | 25-71 through 25-74 |

| 25-119 through 25-122 | 25-119 through 25-122 |

| 25-125 through 25-130 | 25-125 through 25-130 |

| 25-133 and 25-134 | 25-133 and 25-134 |

| 25-137 and 25-138 | 25-137 and 25-138 |

| 25-141 and 25-142 | 25-141 and 25-142 |

| 25-151 and 25-152 | 25-151 and 25-152 |

| 25-165 through 25-168 | 25-165 through 25-168 |

| 32-1 and 32-2 | 32-1 and 32-2 |

| 32-9 and 32-10 | 32-9 and 32-10 |

| A-1 and A-2 | A-1 and A-2 |

| B-17 and B-18 | B-17 and B-18 |

| G-1 through G-12 | G-1 through G-12 |

| H-1 and H-2 | H-1 and H-2 |

| H-7/(H-8 blank) | H-7/(H-8 blank) |

| J-1 and J-2 | J-1 and J-2 |

| J-7 and J-8 | J-7 and J-8 |

| J-22 | J-22 |

| J-25 through J-42 | J-25 through J-42 |

| J-45 through J-104 | J-45 through J-104 |

| J-113/(J-114 blank) | J-113 through J-145/(J-146 blank) |

| K-1 through K-26 | K-1 through K-26 |

| L-1 through L-4 | L-1 through L-4 |

| M-1 through M-16 | M-1 through M-16 |

| M-21 through M-30 | M-21 through M-30 |

| INDEX 1 through INDEX 75/ | INDEX 1 through INDEX 83/ |

| (INDEX 76 blank) | (INDEX 84 blank) |

| FP-7/(FP-8 blank) | FP-7/(FP-8 blank) |

| and FP-9/(FP-10 blank) | through FP-41/(FP-42 blank) |

| Cover | Cover |

By Order of the Secretary of the Army: GEORGE W. CASEY, JR.

General, United States Army Chief of Staff Official:

JOYCE E. MORROW Administrative Assistant to the Secretary of the Army 0830506 By Order of the Secretary of the Air Force: JOHN P. JUMPER General, United States Air Force Chief of Staff Official: GREGORY S. MARTIN General, United States Air Force Commander, Air Force Materiel Command By Order of the Marine Corps: MICHAEL W. EVERLY Program Manager, Motor Transportation (PMM151) Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-2.

Marine Corps Distribution: PCN 184 110332 00 ARMY TM 9-2320-387-24-2 AIR FORCE TO 36A12-1A-3052-2 MARINE CORPS TM 11033-IN VOL 2 CHANGE NO. 5 HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS WASHINGTON, D.C., 30 NOVEMBER, 2007 TECHNICAL MANUAL VOLUME 2 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017).

TM 9-2320-387-24-2, December 1997, is changed as follows:

- Remove old pages and insert new pages as indicated below. 2. New or changed material is indicated by a vertical bar in the margin of the page. 3. File this change sheet in front of the publication for reference purposes.

Remove pages Insert pages

| a and b | a and b |

|---|---|

| A through F | A through I/(J blank) |

| i through iv | i through iv |

| 10-1 through 10-4 | 10-1 through 10-4 |

| 10-32.1 and 10-32.2/(10-33 blank) | 10-32.1 and 10-32.2/(10-33 blank) |

| 10-37 and 10-38 | 10-37 and 10-38 |

| 10-39 though 10-42 | 10-39 though 10-42 |

| 10-43 and 10-44 | 10-43 and 10-44 |

| 10-47 through 10-48.3/(10-48.4 blank) | 10-47 through 10-48.3/(10-48.4 blank) |

| 10-51 through 10-56.2 | 10-51 through 10-56.2 |

| 10-57 through 10-62 | 10-56.7 through 10-62 |

Approved for public release; distribution is unlimited.

| Remove pages | Insert pages |

|---|---|

| 10-65 and 10-66/(10-67 blank) | 10-65 and 10-66/(10-67 blank) |

| 10-69 through 10-86 | 10-69 through 10-86 |

| 10-89 and 10-90 | 10-88.1 through 10-90 |

| 10-91 through 10-98.2 | 10-91 through 10-98.2 |

| 10-103 and 10-104 | 10-103 and 10-104 |

| 10-107 through 10-120 | 10-107 through 10-120 |

| 10-125 and 10-126 | 10-125 and 10-126 |

| 10-129 through 10-132 | 10-129 through 10-132 |

| 10-137 through 10-150/(10-150.1 blank) | 10-137 through 10-150/(10-150.1 blank) |

| 10-151 through 10-154.2 | 10-151 through 10-154.2 |

| 10-155 and 10-156 | 10-155 and 10-156 |

| 10-157 and 10-158 | 10-157 and 10-158 |

| 10-159 and 10-160 | 10-159 and 10-160 |

| 11-1 and 11-2 | 11-1 and 11-2 |

| 11-5 and 11-6 | 11-5 and 11-6 |

| 11-9 and 11-10 | 11-9 and 11-10 |

| 11-31 through 11-40 | 11-31 through 11-40 |

| 11-41 and 11-42 | 11-41 and 11-42 |

| 11-45 through 11-66 | 11-45 through 11-66 |

| 11-68.1 and 11-68.2 | 11-68.1 and 11-68.2 |

| 11-89 through 11-100 | 11-89 through 11-100 |

| 11-103 through 11-106 | 11-103 through 11-106 |

| 11-123 through 11-126 | 11-123 through 11-126 |

| 11-130.1 blank through 11-130.6/11-131 blank) | 11-130.1 blank through 11-130.6/11-131 blank) |

| 11-163 through 11-170 | 11-163 through 11-170 |

| 11-183 through 11-239/(11-240 blank) | 11-183 through 11-343/(11-344 blank) |

| 12-30.3 and 12-30.4 | 12-30.3 and 12-30.4 |

| 12-35 through 12-38 | 12-35 through 12-38 |

| 12-54.1 and 12-54.2 | 12-54.1 and 12-54.2 |

| 12-56.1 through 12-60.4 | 12-56.1 through 12-60.4 |

| 12-61 and 12-62 | 12-61 and 12-62 |

| 12-68.7 and 12-68.8 | 12-68.7 and 12-68.8 |

| 12-68.19 and 12-68.20 | 12-68.19 and 12-68.20 |

| 12-131 through 12-162 | 12-131 through 12-162 |

| 12-165 through 12-188 | 12-165 through 12-188 |

| 12-191 and 12-192 | 12-191 and 12-192 |

| 12-195 and 12-196 | 12-195 and 12-196 |

| 12-201 and 12-202 | 12-201 and 12-202 |

| 12-205 and 12-206 | 12-205 and 12-206 |

| 12-209 through 12-216 | 12-209 through 12-216 |

| none | 12-217 through 12-349/(12-350 blank) |

| 13-1 through 13-3/13-4 blank) | 13-1 through 13-3/13-4 blank) |

| 14-7 and 14-8 | 14-7 and 14-8 |

| 14-19 and 14-20 | 14-19 and 14-20 |

| 14-23 through 14-28 | 14-23 through 14-28 |

| 15-7 and 15-8 | 15-7 and 15-8 |

| 15-11 and 15-12 | 15-11 and 15-12 |

| 15-61 and 15-62 | 15-61 and 15-62 |

| 15-67 and 15-68 | 15-67 and 15-68 |

| 15-97 and 15-98 | 15-97 and 15-98 |

| 15-105 and 15-106 | 15-105 and 15-106 |

| Remove pages | Insert pages |

|---|---|

| 15-115 and 15-116 | 15-115 and 15-116 |

| 15-121 and 15-122 | 15-121 and 15-122 |

| 18-13 and 18-14 | 18-13 and 18-14 |

| 18-21 and 18-22 | 18-21 and 18-22 |

| 18-39 and 18-40 | 18-39 and 18-40 |

| 24-3 through 24-6 | 24-3 through 24-6 |

| 25-36.1 through 25-36.6 | 25-36.1 through 25-36.6 |

| 25-36.17 through 25-36.20 | 25-36.17 through 25-36.20 |

| 25-36.33 and 25-36.34 | 25-36.33 and 25-36.34 |

| 25-36.37 and 25-36.38 | 25-36.37 and 25-36.38 |

| 25-119 through 25-122 | 25-119 through 25-122 |

| 25-125 through 25-130 | 25-125 through 25-130 |

| 25-133 through 25-138 | 25-133 through 25-138 |

| 25-141 and 25-142 | 25-141 and 25-142 |

| 25-151 and 25-152 | 25-151 and 25-152 |

| 25-159 through 25-162 | 25-159 through 25-162 |

| 25-165 through 25-179/(25-180 blank) | 25-165 through 25-181/(25-182 blank) |

| 27-1 and 27-2 | 27-1 and 27-2 |

| 27-9 and 27-10 | 27-9 and 27-10 |

| 27-29 and 27-30 | 27-29 and 27-30 |

| 28-29 through 28-30.2 | 28-29 through 28-30.2 |

| 28-35 and 28-36 | 28-35 and 28-36 |

| 28-39 and 28-40 | 28-39 and 28-40 |

| 28-43 through 28-46 | 28-43 through 28-46 |

| 28-49 and 28-50 | 28-49 and 28-50 |

| 28-53 and 28-54 | 28-53 and 28-54 |

| 28-57 through 28-58.2 | 28-57 through 28-58.2 |

| 28-69 through 28-72 | 28-69 through 28-72 |

| 28-77 and 28-78 | 28-77 and 28-78 |

| A-1 and A-2 | A-1 and A-2 |

| B-21 and B-22 | B-21 and B-22 |

| C-1 and C-2 | C-1 and C-2 |

| C-5 and C-6 | C-5 and C-6 |

| D-13 and D-14 | D-13 and D-14 |

| D-65 and D-66 | D-65 and D-66 |

| G-1 through G-8 | G-1 through G-8 |

| G-11 and G-12 | G-11 and G-12 |

| H-1 through H-3/(H-4 blank) | H-1 through H-7/(H-8 blank) |

| J-1 through J-99/(J-100 blank) | J-1 through J-113/(J-114 blank) |

| none | K-1 through K-27/(K-28 blank) |

| none | L-1 through L-5/(L-6 blank) |

| none | M-1 through M-33/(M-34 blank) |

| INDEX 1 through INDEX 67/(INDEX 68 blank) | INDEX 1 through INDEX 75/(INDEX 76 blank) |

By Order of the Secretary of the Army: GEORGE W. CASEY, JR.

General, United States Army Chief of Staff Official:

JOYCE E. MORROW Administrative Assistant to the Secretary of the Army 0721903 By Order of the Secretary of the Air Force: JOHN P. JUMPER General, United States Air Force Chief of Staff Official: GREGORY S. MARTIN General, United States Air Force Commander, Air Force Materiel Command By Order of the Marine Corps: S. I. SCHULER Colonel, USMC Program Manager Motor Transportation (PMM151) Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-2.

ARMY TM 9-2320-387-24-2 AIR FORCE TO 36A12-1A-3052-2 MARINE CORPS TM 11033-IN VOL 2 CHANGE NO. 4 HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS Washington, D.C., 28 February, 2007 TECHNICAL MANUAL VOLUME 2 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017).

TM 9-2320-387-24-2, December 1997, is changed as follows:

-

Four new models have been added to the front cover. The new cover, located at the end of the change package, replaces the existing cover.

-

Remove old pages and insert new pages as indicated below. 3. New or changed material is indicated by a vertical bar in the margin of the page. 4. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert pages |

|---|---|

| A and B | A and B |

| i and ii | i and ii |

| Cover | Cover |

By Order of the Secretary of the Army: GEORGE W. CASEY, JR.

General, United States Army Chief of Staff Official:

JOYCE E. MORROW Administrative Assistant to the Secretary of the Army 0703803 By Order of the Secretary of the Air Force: JOHN P. JUMPER General, United States Air Force Chief of Staff GREGORY S. MARTIN General, United States Air Force Commander, Air Force Materiel Command By Order of the Marine Corps: S. I. SCHULER Colonel, USMC Program Manager Motor Transportation (PMM151) Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-2.

ARMY TM 9-2320-387-24-2 AIR FORCE TO 36A12-1A-3052-2 MARINE CORPS TM 11033-IN VOL 2 HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS Washington, D.C., 31 May, 2006 TECHNICAL MANUAL VOLUME 2 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332).

TM 9-2320-387-24-2, December 1997, is changed as follows:

-

Two new models have been added to the front cover. The new cover, located at the end of the change package, replaces the existing cover.

-

This change implements Army Maintenance Transformation and changes the Maintenance Allocation Chart (MAC) to support Field and Sustainment Maintenance.

-

Remove old pages and insert new pages as indicated below. 4. New or changed material is indicated by a vertical bar in the margin of the page. 5. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert pages |

|---|---|

| A through F | A through F |

| i through iv | i through iv |

| 10-1 and 10-2 | 10-1 and 10-2 |

| 10-29 through 10-34 | 10-29 through 10-34 |

| 10-37 through 10-44 | 10-37 through 10-44 |

| 10-47 and 10-48 | 10-47 through 10-48.3/(10-48.4 blank) |

| 10-51 through 10-62 | 10-51 through 10-62 |

| 10-65 through 10-86 | 10-65 through 10-86 |

| 10-89 and 10-90 | 10-89 and 10-90 |

| 10-97 through 10-98.2 | 10-96.1 through 10-98.2 |

| 10-98.5 and 10-98.6 | 10-98.5 and 10-98.6 |

| 10-98.15 and 10-98.16 | 10-98.15 and 10-98.16 |

| 10-98.19 through 10-100 | 10-98.19 through 10-100 |

| 10-103 and 10-104 | 10-103 and 10-104 |

| 10-107 through 10-120 | 10-107 through 10-120 |

| 10-125 and 10-126 | 10-125 and 10-126 |

| 10-129 through 10-132 | 10-129 through 10-132 |

| 10-137 through 10-150/(10-150.1 blank) | 10-137 through 10-150/(10-150.1 blank) |

CHANGE NO. 3 Approved for public release; distribution is unlimited.

| Remove pages | Insert pages |

|---|---|

| 10-151 through 10-160 | 10-151 through 10-160 |

| 11-1 through 11-4 | 11-1 through 11-4 |

| None | 11-24.3 through 11-24.23/(11-24.24 blank) |

| 11-31 through 11-40 | 11-31 through 11-40 |

| 11-41 and 11-42 | 11-41 and 11-42 |

| 11-45 through 11-54 | 11-45 through 11-54 |

| 11-91 and 11-92 | 11-90.1 through 11-92 |

| 11-95 and 11-96 | 11-95 and 11-96 |

| 11-123 through 11-126 | 11-123 through 11-126 |

| 11-129 through 11-132 | 11-129 through 11-132 |

| 11-133 through 11-146 | 11-133 through 11-146 |

| None | 11-163 through 11-239/(11-240 blank) |

| 12-27 and 12-28 | 12-27 and 12-28 |

| 12-31 and 12-32 | 12-30.3 through 12-32 |

| 12-35 through 12-38 | 12-35 through 12-38 |

| 12-54.1 and 12-54.2 | 12-54.1 and 12-54.2 |

| 12-56.1 through 12-60.2 | 12-56.1 through 12-60.2 |

| 12-61 and 12-62 | 12-61 and 12-62 |

| 12-69 through 12-76 | 12-69 through 12-76 |

| 12-79 through 12-84 | 12-79 through 216 |

| 14-17 through 14-22 | 14-17 through 14-28 |

| 15-53 and 15-54 | 15-53 and 15-54 |

| 15-61 and 15-62 | 15-61 and 15-62 |

| 15-67 and 15-68 | 15-67 and 15-68 |

| 15-73 and 15-74 | 15-73 and 15-74 |

| 15-97 and 15-98 | 15-97 and 15-98 |

| 15-105 and 15-106 | 15-105 and 15-106 |

| 15-115 and 15-116 | 15-115 and 15-116 |

| 15-121 and 15-122 | 15-121 and 15-122 |

| 18-33 and 18-34 | 18-33 and 18-34 |

| 18-37 through 18-40 | 18-37 through 18-40 |

| 24-3 through 24-6 | 24-3 through 24-6 |

| 25-36.1 through 25-36.6 | 25-36.1 through 25-36.6 |

| 25-36.17 and 25-36.18/(25-36.19 blank) | 25-36.17 and 25-36.18/(25-36.19 blank) |

| 25-37 and 25-38 | 25-37 and 25-38 |

| None | 25-119 through 25-179/(25-180 blank) |

| 26-1 and 26-2 | 26-1 and 26-2 |

| 27-1 and 27-2 | 27-1 and 27-2 |

| 27-9 and 27-10 | 27-9 and 27-10 |

| 27-29 and 27-30 | 27-29 and 27-30 |

| 33-19 and 33-20 | 33-19 and 33-20 |

| 33-39 and 33-40 | 33-39 and 33-40 |

| 33-67 and 33-68 | 33-67 and 33-68 |

| 33-87 and 33-88 | 33-87 and 33-88 |

| 34-1 and 34-2 | 34-1 and 34-2 |

| B-1 through B-18 | B-1 through B-18 |

| C-3 and C-4 | C-3 and C-4 |

| C-7 through C-10 | C-7 through C-10 |

| D-1 and D-2 | D-1 and D-2 |

| D-89/(D-90 blank) | D-89 through D-97/(D-98 blank) |

| G-1 through G-11/(G-12 blank) | G-1 through G-12 |

| None | J-1 through J-99/(J-100 blank) |

| INDEX 1 through INDEX 54 | INDEX 1 through INDEX 67/(INDEX 68 blank) |

| FP-5/(FP-6 blank) | FP-5/(FP-6 blank) and FP-7/(FP-8 blank) |

| Cover | Cover |

By Order of the Secretary of the Army: Official:

JOYCE E. MORROW Administrative Assistant to the Secretary of the Army 0602406 By Order of the Secretary of the Air Force: PETER J. SCHOOMAKER General, United States Army Chief of Staff JOHN P. JUMPER General, United States Air Force Chief of Staff GREGORY S. MARTIN General, United States Air Force Commander, Air Force Materiel Command By Order of the Marine Corps: S. I. SCHULER Colonel, USMC Program Manager Motor Transportation (PMM151) Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-2.

AIR FORCE TO 36A12-1A-3052-2 CHANGE NO. 2 HEADQUARTERS, DEPARTMENTS OF THE ARMY, AND THE AIR FORCE Washington, D.C., 30 July 2004 TECHNICAL MANUAL VOLUME 2 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B) TRUCK, UTILITY: UP - ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C) TM 9-2320-387-24-2, December 1997, is changed as follows:

- Remove old pages and insert new pages as indicated below. 2. New or changed material is indicated by a vertical bar in the margin of the page. 3. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert page |

|---|---|

| A through D | A through F |

| i and ii | i and ii |

| 10-1 and 10-2 | 10-1 and 10-2 |

| 10-5 through 10-14 | 10-5 through 10-14 |

| 10-18.1 through 10-20 | 10-18.1 through 10-20 |

| 10-23 through 10-30 | 10-23 through 10-30 |

| 10-33 through 10-38 | 10-33 through 10-38 |

| 10-41 through 10-46 | 10-41 through 10-46 |

| 10-49 and 10-50 | 10-49 and 10-50 |

| 10-53 through 10-58 | 10-53 through 10-58 |

| 10-61 through 10-78 | 10-61 through 10-78 |

| 10-83 and 10-84 | 10-83 and 10-84 |

| 10-87 and 10-88 | 10-87 and 10-88 |

| 10-97 through 10-100 | 10-97 through 10-100 |

| 10-103 through 10-108 | 10-103 through 10-108 |

| 10-113 through 10-116 | 10-113 through 10-116 |

| 10-121 and 10-122 | 10-121 and 10-122 |

| 10-127 through 10-132 | 10-127 through 10-132 |

| 10-137 through 10-140 | 10-137 through 10-140 |

| 10-143 and 10-144 | 10-143 and 10-144 |

| 10-149 and 10-150 | 10-149 through 10-150.7/(10-150.8 |

| blank) |

Approved for public release; distribution is unlimited.

| Remove pages | Insert pages |

|---|---|

| 10-159 and 10-160 | 10-159 and 10-160 |

| 11-1 through 11-6 | 11-1 through 11-6 |

| 11-9 through 11-16 | 11-9 through 11-16 |

| 11-19 through 11-26 | 11-19 through 11-26 |

| 11-29 through 11-40 | 11-29 through 11-40 |

| 11-41 and 11-42 | 11-41 and 11-42 |

| 11-45 through 11-52 | 11-45 through 11-52 |

| 11-55 through 11-68.2 | 11-55 through 11-68.2 |

| 11-68.5 through 11-68.8 | 11-68.5 through 11-68.8 |

| 11-69 through 11-86 | 11-69 through 11-86 |

| 11-89 through 11-92 | 11-89 through 11-92 |

| 11-95 through 11-98 | 11-95 through 11-98 |

| 11-101 through 11-104 | 11-101 through 11-104 |

| 11-107 through 11-116 | 11-107 through 11-116 |

| 11-121 through 11-128 | 11-120.1 through 11-128 |

| 11-131 through 11-142 | 11-131 through 11-142 |

| 11-145 and 11-146 | 11-145 and 11-146 |

| 11-151 and 11-152 | 11-151 and 11-152 |

| 12-1 through 12-2.2 | 12-1 through 12-2.2 |

| 12-9 through 12-12 | 12-9 through 12-12 |

| 12-17 and 12-18 | 12-17 and 12-18 |

| 12-21 through 12-28 | 12-21 through 12-28 |

| 12-31 through 12-40 | 12-30.1 through 12-40 |

| 12-47 and 12-48 | 12-47 and 12-48 |

| 12-51 through 12-62 | 12-51 through 12-62 |

| 12-63 through 12-68.8 | 12-63 through 12-68.8 |

| 12-68.19 and 12-68.20 | 12-68.19 and 12-68.20 |

| 12-68.23 through 12-68.26 | 12-68.23 through 12-68.26 |

| 12-68.29/(12-68.30 blank) | 12-68.29 through |

| 12-68.31/(12-68.32 blank) | |

| 12-69 and 12-70 | 12-69 and 12-70 |

| 12-75 through 12-84 | 12-75 through 12-84 |

| 14-7 and 14-8 | 14-7 and 14-8 |

| 15-1 and 15-2 | 15-1 and 15-2 |

| 15-5 through 15-14 | 15-5 through 15-14 |

| 15-19 and 15-20 | 15-19 and 15-20 |

| 15-23 through 15-40 | 15-23 through 15-40 |

| 15-47 through 15-50 | 15-47 through 15-50 |

| 15-53 through 15-56 | 15-53 through 15-56 |

| 15-63 and 15-64 | 15-63 and 15-64 |

| 15-67 and 15-68 | 15-67 and 15-68 |

| 15-73 and 15-74 | 15-73 and 15-74 |

| 15-77 and 15-78 | 15-77 and 15-78 |

| 15-81 through 15-86 | 15-81 through 15-86 |

| 15-91 through 15-102 | 15-91 through 15-102 |

| 15-105 and 15-106 | 15-105 and 15-106 |

| 15-111 through 15-114 | 15-111 through 15-114 |

| 15-119 through 15-126 | 15-119 through 15-126 |

| 16-1 through 16-8 | 16-1 through 16-8 |

| Remove pages | Insert pages |

|---|---|

| 16-11 and 16-12 | 16-11 and 16-12 |

| 16-15 through 16-18 | 16-15 through 16-18 |

| 18-1 and 18-2 | 18-1 and 18-2 |

| 18-5 and 18-6 | 18-5 and 18-6 |

| 18-9 through 18-10.2 | 18-9 through 18-10.2 |

| 18-10.7 and 18-10.8 | 18-10.7 and 18-10.8 |

| 18-10.11 through 18-16 | 18-10.11 through 18-16 |

| 18-19 through 18-22 | 18-19 through 18-22 |

| 18-27 through 18-30 | 18-27 through 18-30 |

| 18-33 through 18-36 | 18-33 through 18-36 |

| 18-39 and 18-40 | 18-39 and 18-40 |

| 18-43 and 18-44 | 18-43 and 18-44 |

| 19-3 through 19-8 | 19-3 through 19-8 |

| 19-11 through 19-14 | 19-11 through 19-14 |

| 20-1 and 20-2 | 20-1 and 20-2 |

| 20-7 and 20-8 | 20-7 and 20-8 |

| 21-1 through 21-12 | 21-1 through 21-12 |

| 21-19 and 21-20 | 21-19 and 21-20 |

| 22-3 and 22-4 | 22-3 and 22-4 |

| 22-7 and 22-8 | 22-7 and 22-8 |

| 23-1 and 23-2 | 23-1 and 23-2 |

| 23-5 and 23-6 | 23-5 through |

| 23-25/(23-26 blank) | |

| 24-1 through 24-26 | 24-1 through 24-26 |

| 24-29 and 24-30 | 24-29 and 24-30 |

| 24-33 through 24-40 | 24-33 through 24-40 |

| 25-1 through 25-4 | 25-1 through 25-4 |

| 25-9 and 25-10 | 25-9 and 25-10 |

| 25-15 and 25-16 | 25-15 and 25-16 |

| 25-23 and 25-24 | 25-23 and 25-24 |

| 25-27 through 25-32 | 25-27 through 25-32 |

| 25-35 through 25-36.20 | 25-35 through 25-36.20 |

| 25-36.33/(25-36.34 blank) | 25-36.33 through 25-36.43/ |

| (25-36.44 blank) | |

| 25-47 through 25-52 | 25-47 through 25-52 |

| 25-55 through 25-58 | 25-55 through 25-58 |

| 25-61 through 25-64 | 25-61 through 25-64 |

| 25-67 and 25-68 | 25-67 and 25-68 |

| 25-75 through 25-78 | 25-75 through 25-78 |

| 25-79 and 25-80 | 25-79 and 25-80 |

| 25-87 through 25-90 | 25-87 through 25-90 |

| 25-93 and 25-94 | 25-93 and 25-94 |

| 26-1 through 26-4 | 26-1 through 26-4 |

| 26-9 and 26-10 | 26-9 and 26-10 |

| 27-1 through 27-6 | 27-1 through 27-6 |

| 27-9 and 27-10 | 27-9 and 27-10 |

| 27-13 through 27-38 | 27-13 through 27-38 |

| Remove pages | Insert pages |

|---|---|

| 28-3 through 28-6 | 28-3 through 28-6 |

| 28-9 through 28-14 | 28-9 through 28-14 |

| 28-31 and 28-32 | 28-31 and 28-32 |

| 28-35 through 28-48 | 28-35 through 28-48 |

| 28-57 through 28-66 | 28-57 through 28-66 |

| 28-69 through 28-74 | 28-69 through 28-74 |

| 28-83 and 28-84 | 28-83 and 28-84 |

| 28-89 and 28-90 | 28-89 and 28-90 |

| 29-1 and 29-2 | 29-1 and 29-2 |

| 29-7 through 29-12 | 29-7 through 29-12 |

| 29-17 through 29-27/(29-28 blank) | 29-17 through 29-27/(29-28 blank) |

| 30-1 through 30-4 | 30-1 through 30-4 |

| 30-25/(30-26 blank) | 30-25 through 30-29/(30-30 blank) |

| 31-1 through 31-19/(31-20 blank) | 31-1/(31-2 blank) (31-3 through |

| 31-19/(31-20 blank) deleted) | |

| 32-1 through 32-4 | 32-1 through 32-4 |

| 32-7 through 32-13/(32-14 blank) | 32-6.1 through 32-13/(32-14 blank) |

| 33-1 and 33-2 | 33-1 and 33-2 |

| 33-19 and 33-20 | 33-19 and 33-20 |

| 33-39 and 33-40 | 33-39 and 33-40 |

| 33-67 and 33-68 | 33-67 and 33-68 |

| 33-87 and 33-88 | 33-87 and 33-88 |

| 34-1 and 34-2 | 34-1 and 34-2 |

| A-1 and A-2 | A-1 and A-2 |

| B-3 through B-18 | B-3 through B-18 |

| B-23 and B-24 | B-23 and B-24 |

| C-1 through C-4 | C-1 through C-4 |

| D-1 and D-2 | D-1 and D-2 |

| D-85/(D-86 blank) | D-85 through D-89/(D-90 blank) |

| G-1 through G-15/(G-16 blank) | G-1 through G-11/(G-12 blank) |

| INDEX 1 through INDEX 53/ | INDEX 1 through INDEX 54 |

| (INDEX 54 blank) |

By Order of the Secretary of the Army: PETER J. SCHOOMAKER General, United States Army Chief of Staff Official: JOEL B. HUDSON Administrative Assistant to the Secretary of the Army 0412007 By Order of the Secretary of the Air Force: JOHN P. JUMPER General, United States Air Force Chief of Staff Official: GREGORY S. MARTIN General, United States Air Force Commander, Air Force Materiel Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-2.

ARMY TM 9-2320-387-24-2 AIR FORCE TO 36A12-1A-3052-2 CHANGE NO. 1 HEADQUARTERS, DEPARTMENTS OF THE ARMY, AND THE AIR FORCE Washington, D.C., 31 October 2001 TECHNICAL MANUAL VOLUME 2 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B) TRUCK, UTILITY: UP - ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C) TM 9-2320-387-24-2, December 1997, is changed as follows:

- Remove old pages and insert new pages as indicated below. 2. New or changed material is indicated by a vertical bar in the margin of the page. 3. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert page |

|---|---|

| Warning a and b | Warning a and b |

| None | A through C/(D blank) (after warning b) |

| i and ii | i and ii |

| 10-1 through 10-8 | 10-1 through 10-8 |

| 10-11 through 10-14 | 10-11 through 10-14 |

| 10-17 and 10-18 | 10-17 and 10-18 |

| None | 10-18.1/(10-18.2 blank) |

| 10-19 through 10-26 | 10-19 through 10-26 |

| 10-49 through 10-52 | 10-49 through 10-52 |

| 10-55 and 10-56 | 10-55 and 10-56 |

| 10-59 and 10-60 | 10-59 and 10-60 |

| 10-63 and 10-64 | 10-63 and 10-64 |

| 10-69 and 10-70 | 10-69 and 10-70 |

| 10-75 and 10-76 | 10-75 and 10-76 |

| None | 10-76.1/(10-76.2 blank) |

| 10-77 through 10-80 | 10-77 through 10-80 |

| 10-87 and 10-88 | 10-87 and 10-88 |

| 10-91 and 10-92 | 10-91 and 10-92 |

| 10-95 and 10-96 | 10-95 and 10-96 |

| None | 10-98.1 through 10-98.16 |

| 10-99 and 10-100 | 10-99 and 10-100 |

| 10-103 and 10-104 | 10-103 and 10-104 |

Approved for public release; distribution is unlimited.

| Remove pages | Insert pages |

|---|---|

| 10-107 through 10-110 | 10-107 through 10-110 |

| 10-113 through 10-120 | 10-113 through 10-120 |

| 10-129 through 10-132 | 10-129 through 10-132 |

| 10-157 and 10-158 | 10-157 through 10-160 |

| 11-1 through 11-4 | 11-1 through 11-4 |

| None | 11-4.1 and 11-4.2 |

| 11-5 through 11-30 | 11-5 through 11-30 |

| 11-39 and 11-40 | 11-39 and 11-40 |

| None | 11-40.1/(11-40.2 blank) |

| 11-41 through 11-46 | 11-41 through 11-46 |

| 11-49 through 11-68 | 11-49 through 11-68 |

| None | 11-68.1 through 11-68.10 |

| 11-69 through 11-82 | 11-69 through 11-82 |

| None | 11-82.1 and 11-82.2 |

| 11-83 and 11-84 | 11-83 and 11-84 |

| None | 11-84.1 through 11-84.6/(11-85 blank) |

| 11-85 through 11-100 | 11-86 through 11-100 |

| 11-103 and 11-104 | 11-103 and 11-104 |

| 11-107 through 11-116 | 11-107 through 11-116 |

| 11-123 through 11-132 | 11-123 through 11-132 |

| 11-145 through 11-148 | 11-145 through 11-148 |

| 11-151 through 11-158 | 11-151 through 11-158 |

| 12-1 and 12-2 | 12-1 and 12-2 |

| None | 12-2.1 and 12-2.2 |

| 12-3 through 12-32 | 12-3 through 12-32 |

| 12-47 through 12-52 | 12-47 through 12-52 |

| None | 12-54.1 through 12-54.6 |

| 12-55 and 12-56 | 12-55 and 12-56 |

| None | 12-56.1 and 12-56.2 |

| 12-57 and 12-58 | 12-57 and 12-58 |

| None | 12-60.1 through 12-60.6 |

| 12-61 and 12-62 | 12-61 and 12-62 |

| None | 12-62.1 through 12-62.8 |

| None | 12-68.1 through 12-68.29/(12-68.30 blank) |

| 12-71 through 12-74 | 12-71 through 12-74 |

| 14-1 through 14-8 | 14-1 through 14-8 |

| 15-9 through 15-14 | 15-9 through 15-14 |

| 15-27 and 15-28 | 15-27 and 15-28 |

| 15-37 and 15-38 | 15-37 and 15-38 |

| 15-43 and 15-44 | 15-43 and 15-44 |

| 15-47 and 15-48 | 15-47 and 15-48 |

| 15-59 through 15-62 | 15-59 through 15-62 |

| 15-73 and 15-74 | 15-73 and 15-74 |

| 15-83 and 15-84 | 15-83 and 15-84 |

| 15-93 and 15-94 | 15-93 and 15-94 |

| 15-97 and 15-98 | 15-97 and 15-98 |

| 15-101 and 15-102 | 15-101 and 15-102 |

| 15-111 through 15-116 | 15-111 through 15-116 |

| Remove pages | Insert pages |

|---|---|

| 16-11 and 16-12 | 16-11 and 16-12 |

| 18-1 and 18-2 | 18-1 and 18-2 |

| None | 18-10.1 through 18-10.12 |

| 18-11 and 18-12 | 18-11 and 18-12 |

| 18-29 and 18-30 | 18-29 and 18-30 |

| 18-33 and 18-34 | 18-33 and 18-34 |

| 18-37 and 18-38 | 18-37 and 18-38 |

| 18-41 and 18-42 | 18-41 and 18-42 |

| 21-1 and 21-2 | 21-1 and 21-2 |

| 21-5 through 21-8 | 21-5 through 21-8 |

| 22-1 through 22-6 | 22-1 through 22-6 |

| None | 22-7 through 22-11/(22-12 blank) |

| 24-5 through 24-10 | 24-5 through 24-10 |

| 24-19 through 24-22 | 24-19 through 24-22 |

| 25-1 through 25-36 | 25-1 through 25-36 |

| None | 25-36.1 through 25-36.33/(25-36.34 blank) |

| 25-37 and 25-38 | 25-37 and 25-38 |

| 25-45 through 25-50 | 25-45 through 25-50 |

| None | 25-50.1 and 25-50.2 |

| 25-51 through 25-56 | 25-51 through 25-56 |

| None | 25-56.1 and 25-56.2 |

| 25-57 through 25-66 | 25-57 through 25-66 |

| 25-73 through 25-78 | 25-73 through 25-78 |

| None | 25-78.1 and 25-78.2 |

| 25-79 and 25-80 | 25-79 and 25-80 |

| 25-81/(25-82 blank) | 25-81 through 25-117/(25-118 blank) |

| 27-1 through 27-4 | 27-1 through 27-4 |

| 27-37 and 27-38 | 27-37 and 27-38 |

| 28-1 through 28-8 | 28-1 through 28-8 |

| 28-11 and 28-12 | 28-11 and 28-12 |

| 28-17 and 28-18 | 28-17 and 28-18 |

| 28-25 and 28-26 | 28-25 and 28-26 |

| None | 28-26.1 and 28-26.2 |

| 28-27 through 28-30 | 28-27 through 28-30 |

| None | 28-30.1 and 28-30.2 |

| 28-31 through 28-46 | 28-31 through 28-46 |

| 28-55 through 28-58 | 28-55 through 28-58 |

| None | 28-58.1 and 28-58.2 |

| 28-59 and 28-60 | 28-59 and 28-60 |

| 28-63 and 28-64 | 28-63 and 28-64 |

| 28-71 through 28-80 | 28-71 through 28-80 |

| 28-85 and 28-86 | 28-85 and 28-86 |

| None | 28-86.1 and 28-86.2 |

| 28-87 through 28-90 | 28-87 through 28-90 |

| 29-1 and 29-2 | 29-1 and 29-2 |

| 29-11 and 29-12 | 29-11 and 29-12 |

| 29-25 through 29-27/(29-28 blank) | 29-25 through 29-27/(29-28 blank) |

| Remove pages | Insert pages |

|---|---|

| 30-1 and 30-2 | 30-1 and 30-2 |

| 30-9 and 30-10 | 30-9 and 30-10 |

| 30-17 through 30-22 | 30-17 through 30-22 |

| 33-1 through 33-4 | 33-1 through 33-4 |

| 33-17/(33-18 blank) | 33-17 through 33-109/(33-110 blank) |

| 34-1 through 34-3/(34-4 blank) | 34-1 through 34-3/(34-4 blank) |

| B-9 through B-12 | B-9 through B-12 |

| B-15 through B-24 | B-15 through B-24 |

| C-1 through C-10 | C-1 through C-10 |

| D-1 and D-2 | D-1 and D-2 |

| None | D-84.1 through D-84.6 |

| D-85/(D-86 blank) | D-85/(D-86 blank) |

| G-1 through G-14 | G-1 through G-15/(G-16 blank) |

| H-1 through H-3/(H-4 blank) | H-1 through H-3/(H-4 blank) |

| INDEX 1 through INDEX 45/ | INDEX 1 through INDEX 53/ |

| (INDEX 46 blank) | (INDEX 54 blank) |

| FP-3/(FP-4 blank) | FP-3/(FP-4 blank) |

| None | FP-5/(FP-6 blank) |

By Order of the Secretary of the Army: TBD ERIC K. SHINSEKI General, United States Army Chief of Staff Official: JOEL B. HUDSON Administrative Assistant to the Secretary of the Army 0119704 By Order of the Secretary of the Air Force: RONALD R. FOGLEMAN General, United States Air Force Chief of Staff Official: HENRY VICCELLIO, JR.

General, United States Air Force Commander, Air Force Materiel Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-2.

List Of Effective Pages

NOTE: The portion of the text affected by the changes is indicated by a vertical line in the outer margins of the page. Dates of issue for original and changed pages of volume 2 are:

| Original 0 . |

|---|

| Change 1 31 October 2001 |

| Change 2 30 July 2004 |

| Change 3 31 May 2006 |

| Change 4 28 February 2007 |

| Change 5 30 November 2007 |

| Change . |

| Page No *Change No. | ГО ПРЕДАННЕГ АГ ГУРЕФ И ПЛАТ АВЕЛАНИАТ ТА ДА ААТАРАНИЯ АГ. ШЕТ ФЕРАНИА Page No *Change No. | Page No *Change No. |

|---|---|---|

| 10-40.1 - 10-40.6 Added | 10-76.1 | |

| VOLUME 2 а. | 10-41 - 10-42 | 10-76.2 |

| b | 10-42.1 - 10-42.2 | 10-76.3 Blank Added |

| A - I | 10-43 - 10-44 | 10-76.4 |

| J Blank Added | 10-44.1 - 10-44.6 Added | 10-77 |

| i - iii. | 10-45 | 10-78 - 10-81 |

| İV . | 10-46 | 10-82 |

| 10-1 - 10-2 | 10-47 | 10-82.1 |

| 10-3 - 10-4 | 10-48 | 10-82.2 - 10-82.7 Added |

| 10-5 . | 10-48.1 Blank Added | 10-82.8 - 10-82.9 |

| 10-6 - 10-7 | 10-48.2 - 10-48.3 | 10-82.10 - 10-82.11 Added |

| 10-8 . | 10-48.4 Blank Added | 10-82.12 - 10-82.13 |

| 10-9 . | 10-49 | 10-82.14 - 10-82.18 |

| 10-10 | 10-50 - 10-51 | Added |

| 10-11 | 10-52 | 10-83 - 10-84 |

| 10-12 | 10-53 | 10-85 |

| 10-13 | 10-54 - 10-56 | 10-86 |

| 10-14 | 10-56.1 - 10-56.2 | 10-87 |

| 10-15 - 10-17 | 10-56.3 - 10-56.6 | 10-88 |

| 10-18 | 10-56.7 - 10-56.8 Added | 10-88.1 - 10-88.2 |

| 10-18.1 | 10-57 - 10-58 | 10-89 Blank |

| 10-18.2 Blank | 10-58.1 | 10-90 |

| 10-19 | 10-58.2 Blank Added | 10-91 |

| 10-20 | 10-59 | 10-92 - 10-95 |

| 10-21 - 10-22 | 10-60 | 10-93 - 10-94 |

| 10-23 - 10-25 | 10-61 - 10-62 | 10-94.1 - 10.94.2 |

| 10-26 | 10-63 - 10-64 | 10-95 |

| 10-27 - 10-28 | 10-65 | 10-96 Blank |

| 10-29 | 10-66 | 10-96.1 |

| 10-30 - 10-32 | 10-67 Blank | 10-96.2 |

| 10-32.1 - 10-32.2 | 10-68 | 10-97 |

| 10-33 Blank | 10-68.1 Added | 10-98 |

| 10-34 - 10-35 | 10-68.2 Blank Added | 10-98.1 |

| 10-36 - 10-37 | 10-69 - 10-71 | 10-98.2 |

| 10-38 | 10-72 | 10.98.3. |

| 10-38.1 - 10-38.2 | 10-73 - 10-75 | 10-98.4 |

| 10-39 - 10-40 | 10-76 |

TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS 3,016 CONSISTING OF THE FOLLOWING: *Zero in this column indicates original page.

List Of Effective Pages (Contd)

| Page No. . | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 10-98.5 | 10-146 - 10-150 | 11-24 |

| 10-98.6 | 10-150.1 Blank Added . | 11-24.1 - 11-24.2 Added |

| 10-98.7 | 10-150.2 - 10-150.7 Added | 11-24.3 - 11-24.23 Added . |

| 10-98.8 - 10-98.11 . | 10-150.8 Blank Added . | 11-24.24 Blank Added . |

| 10-98.12 Blank . | 10-151 - 10-154 | 11-25 |

| 10-98.13 - 10-98.14 | 10-154.1 . | 11-26 |

| 10-98.15 - 10-98.16 | 10-154.2 . | 11-27 - 11-29. |

| 10-98.17 - 10 .- 98.18 Added . | 10-154.1 - 10-154.4 Added | 11-30 - 11-31 |

| 10-98.19 - 10-98.20 | 10-155 . | 11-32 - 11-36 |

| 10-98.21 - 10-98.22 Added | 10-156 . | 11-37 |

| 10-99 - 10-100 . | 10-156.1 - 10-156.2 Added | 11-38 |

| 10-101 - 10-102 | 10-157 . | 11-39 |

| 10-103 - 10-104 | 10-158 . | 11-40 |

| 10-105 . | 10-158.1 Added . | 11-40.1 |

| 10-106 . | 10-158.2 Blank Added . | 11-40.2 Blank Added |

| 10-107 . | 10-159 . | 11-41 |

| 10-108 - 10-110 | 10-160 . | 11-42 |

| 10-111 . | 10-161 Blank Added . | 11-43 - 11-44. |

| 10-112 - 10-113 | 10-162 - 10-165 Added | 11-45 |

| 10-114 . | 10-166 Blank Added . | 11-46 |

| 10-115 . | 11-1 . | 11-46.1 |

| 10-116 - 10-119 | 11-2 . | 11-46.2 |

| 10-120 . | 11-2.1 - 11-2.2 Added | 11-46.3 Blank Added |

| 10-121 . | 11-3 Blank . | 11-46.4 |

| 10-122 - 10-125 | 11-4 . | 11-47 |

| 10-126 . | 11-4.1 . | 11-48 - 11-51 |

| 10-127 . | 11-4.2 . | 11-52 |

| 10-128 . | 11-5 . | 11-52.1 |

| 10-128.1 Blank Added . | 11-6 . | 11-52.2 |

| 10-128.2 - 10-128.13 Added . | 11-7 - 11-8. | 11-53 - 11-55 |

| 10-128.14 | 11-9 . | 11-56 |

| 10-128.15 Added Blank | 11-10 | 11-57 |

| 10-128.16 - 10-128.17 Added . | 11-11 | 11-58 - 11-66 |

| 10-128.18 Blank Added | 11-12 | 11-67 - 11-68 |

| 10-129 - 10-132 | 11-12.1 - 11-12.3 Added | 11-68.1 |

| 10-133 - 10-137 . | 11-12.4 Blank Added | 11-68.2 |

| 10-138 . | 11-13 - 11-16 | 11-68.3 - 11.68.5 |

| 10-139 . | 11-17 | 11-68.6 |

| 10-140 . | 11-18 | 11-68.7 |

| 10-141 . | 11-19 | 11-68.8 |

| 10-142 . | 11-20 | 11-68.9 - 11-68.10 |

| 10-143 . | 11-21 | 11-69 |

| 10-144 . | 11-22 | 11-70 - 11-73 |

| 10-145 . | 11-23 | 11-74 - 11-77 Deleted |

*Zero in this column indicates original page.

Change 6 B

List Of Effective Pages (Contd)

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 11-78 - 11-82. | 11-131 Blank | 11-202.2 . |

| 11-82.1 | 11-132 . | 11-202.3 Blank Added . |

| 11-82.2 | 11-132.1 - 11-132.6 Added | 11-202.4 - 11-202.5 Added |

| 11-83 | 11-132.7 - 11-132.13 . | 11-202.6 Blank Added . |

| 11-84 | 11-132.14 Blank Added | 11-203 . |

| 11-84.1 - 11-84.6 Deleted | 11-133 - 11-138 | 11-204 . |

| 11-85 | 11-139 . | 11-205 Blank . |

| 11-86 - 11-89 | 11-140 . | 11-206 - 11-208 |

| 11-90 | 11-141 . | 11-208.1 Added . |

| 11-90.1 | 11-142 - 145 . | 11-208.2 . |

| 11-90.2 | 11-146 . | 11-208.3 - 11-208.4 Added |

| 11-91 Blank | 11-147 . | 11-209 . |

| 11-92 - 11-95 | 11-148 - 11-151 | 11-210 . |

| 11-96 - 11-97 | 11-152 . | 11-210.1 Added . |

| 11-98 - 11-99 | 11-153 - 11-155 | 11-210.2 Added . |

| 11-100 - 11-101 | 11-156 - 11-157 | 11-211 . |

| 11-102 - 11-103 | 11-158 . | 11-212 . |

| 11-104 - 11-105 | 11-159 - 11-161 | 11-213 . |

| 11-106 - 11-107 | 11-162 Blank . | 11-214 . |

| 11-108 . | 11-163 - 11-164 | 11-214.1 Added |

| 11-108.1 - 11-108.7 Added | 11-165 . | 11-214.2 . |

| 11-108.8 Blank Added . | 11-166 . | 11-215 - 11-216 |

| 11-109 . | 11-167 . | 11-216.1 Added . |

| 11-110 . | 11-168 - 11-170 | 11-216.2 . |

| 11-110.1 - 11-110.2 Added | 11-171 - 11-183 | 11-217 . |

| 11-111 - 11-112 | 11-184 . | 11-218 . |

| 11-112.1 - 11-112.2 Added | 11-185 . | 11-219 . |

| 11-113 . | 11-186 . | 11-220 . |

| 11-114 . | 11-187 . | 11-220.1 Added . |

| 11-115 . | 11-188 . | 11-220.2 . |

| 11-116 . | 11-189 . | 11-221 - 11-222. |

| 11-117 - 11-120 | 11-190 . | 11-222.1 Added |

| 11-120.1 - 11-120.2 Added | 11-191 . | 11-222.2 . |

| 11-121 . | 11-192 - 11-193 | 11-223 - 11-224. |

| 11-122 - 11-123 | 11-194 . | 11-224.1 Added |

| 11-124 - 11-125 | 11-195 . | 11-224.2 . |

| 11-126 - 11-127 | 11-196 . | 11-225 - 11-226 |

| 11-128 . | 11-197 . | 11-226.1 Added . |

| 11-129 . | 11-198 . | 11-226.2 . |

| 11-130 . | 11-199 . | 11-227 - 11-228 |

| 11-130.1 Blank Added . | 11-200 . | 11-228.1 Added . |

| 11-130.2 - 11-130.3 | 11-201 . | 11-228.2 . |

| 11-130.4 . | 11-202 . | 11-229 . |

| 11-130.5 - 11-130.6 | 11-202.1 Added | 11-230 . |

*Zero in this column indicates original page.

List Of Effective Pages (Contd)

| Page No. . | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 11-230.1 Added . | 12-30.4 | 12-68.5 |

| 11-230.2 . | 12-31 | 12-68.6 |

| 11-231 . | 12-32 | 12-68.7 |

| 11-232 . | 12-33 | 12-68.8 |

| 11-232.1 Added . | 12-34 | 12-68.9 - 12-68.18 . |

| 11-232.2 . | 12-35 - 12-37 | 12-68.19 . |

| 11-233 . | 12-38 | 12-68.20 . |

| 11-234 . | 12-39 - 12-40 | 12-68.21 - 12-68.22 |

| 11-234.1 Added . | 12-41 - 12-46 | 12-68.23 . |

| 11-234.2 . | 12-47 | 12-68.24 - 12-68.25 |

| 11-235 - 11-236 | 12-48 - 12-49 | 12-68.26 . |

| 11-236.1 Added . | 12-50 Blank. | 12-68.27 - 12-68.28 |

| 11-236.2 . | 12-51 - 12-52 | 12-68.29 - 12-68.30 |

| 11-237 . | 12-53 | 12-68.31 Added . |

| 11-238 . | 12-54 | 12-68.32 Blank Added . |

| 11-238.1 Added | 12-54.1 | 12-69 - 12-70 |

| 11-238.2 Blank Added . | 12-54.2 | 12-71 |

| 11-239 - 11-343 Added | 12-54.3 | 12-72 - 12-73 |

| 11-344 Blank Added . | 12-54.4 | 12-74 |

| 11-345 - 11-413 Added | 12-54.5 - 12-54.6 | 12-75 - 12-77 |

| 11-414 Blank Added . | 12-55 | 12-78 |

| 11-415 - 11-430 Added | 12-56 | 12-79 |

| 11-431 Blank Added . | 12-56.1 | 12-80 |

| 11-432 - 11-463 Added | 12-56.2 | 12-81 |

| 11-464 Blank Added . | 12-57 | 12-82 - 12-83 |

| 12-1 . | 12-58 - 12-59 | 12-84 |

| 12-2 . | 12-60 | 12-85 - 12-131 . |

| 12-2.1 . | 12-60.1 | 12-132 - 12-12-135 . |

| 12-2.2 . | 12-60.2 | 12-136 . |

| 12-3 - 12-9 | 12-60.3 | 12-137 - 12-141 |

| 12-10 | 12-60.4 | 12-142 . |

| 12-11 | 12-60.5 | 12-143 - 12-145 |

| 12-12 | 12-60.6 | 12-146 . |

| 12-13 - 12-17 | 12-61 | 12-147 . |

| 12-18 | 12-62 | 12-148 . |

| 12-19 - 12-21 | 12-62.1 - 12.62.8 | 12-149 . |

| 12-22 - 12-23 | 12-62.9 - 12-62.17 Added . | 12-150 . |

| 12-24 | 12-62.18 Blank Added . | 12-151 - 12-153 |

| 12-25 Deleted | 12-63 | 12-155 . |

| 12-26 Blank Deleted | 12-64 - 12-65 | 12-156 - 12-160 |

| 12-27 | 12-66 - 12-68 | 12-161 . |

| 12-28 - 12-30 | 12-68.1 | 12-162 . |

| 12-30.1 - 12-30.2 Added | 12-68.2 - 12-68.3 | 12-163 - 12-165 |

| 12-30.3 | 12-68.4 | 12-166 - 12-170 |

*Zero in this column indicates original page.

Change 6 D

List Of Effective Pages (Contd)

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 12-171 . | 12-351 - 12-379 Added. | 15-42 - 15-43 |

| 12-172 . | 12-380 Blank Added . | 15-44 |

| 12-173 . | 13-1 . | 15-45 - 15-46 |

| 12-174 . | 13-2 . | 15-47 - 15-76 |

| 12-175 . | 13-3 . | 15-76.1 - 15-76.36 Added . |

| 12-176 - 12-178 | 13-4 Blank . | 15-77 |

| 12-179 . | 14-1 . | 15-78 - 15-96 |

| 12-180 - 12-184 | 14-2 - 14-3 | 15-96.1 - 15-96.20 Added |

| 12-185 . | 14-4 - 14-5 | 15-97 - 15-124 . |

| 12-186 . | 14-6 . | 15-124.1 - 15-124.32 Added . |

| 12-187 . | 14-7 . | 15-125 . |

| 12-188 . | 14-8 . | 15-126 . |

| 12-189 - 12-191 | 14-9 - 14-13 . | 15-127 . |

| 12-192 . | 14-15 - 14-16 | 15-128 Blank . |

| 12-193 - 12-195 | 14-17 | 16-1 . |

| 12-196 . | 14-18 - 14-19 | 16-2 - 16-3 |

| 12-197 - 12-201 | 14-20 | 16-4 - 16-5 |

| 12-202 . | 14-21 | 16-6 . |

| 12-203 - 12-205 | 14-22 | 16-7 . |

| 12-206 . | 14-23 - 14-28 | 16-8 . |

| 12-207 - 12-209 | 14-25 | 16-9 - 16-10 . |

| 12-210 - 12-216 | 14-26 | 16-11 |

| 12-217 - 12-20 Added . | 14-27 - 14-28 | 16-12 |

| 12-221 Blank Added . | 15-1 . | 16-13 - 16-15 |

| 12-222 - 12-223 Added | 15-2 . | 16-16 |

| 12-224 Blank Added . | 15-3 - 15-5 | 16-17 |

| 12-225 - 12-229 | 15-6 . | 16-18 |

| 12-230 - 12-231 | 15-7 - 15-8 | 16-19 - 16-21 |

| 12-232 - 12-233 | 15-9 - 15-10 . | 16-22 Blank |

| 12-236 Added . | 15-11 - 15-14 | 17-1 - 17-2 |

| 12-234 - 12-235 | 15-15 - 15-19 | 17-3 - 17-13 Added |

| 12-236.1 - 12-236.2 Added | 15-20 | 17-14 Blank Added |

| 12-237 - 12-239 Added | 15-21 - 15-23 | 18-1 . |

| 12-240 - 12-241 | 15-24 | 18-2 . |

| 12-242 - 12-243 Added | 15-25 | 18-3 - 18-5 |

| 12-244 - 12-245 . | 15-26 | 18-6 . |

| 12-246 - 12-247 Added. | 15-27 | 18-7 - 18-9 |

| 12-248 - 12-249 | 15-28 - 15-29 | 18-10 |

| 12-250 - 12-251 | 15-30 - 15-31 | 18-10.1 - 18-10.2 |

| 12-252 - 12-263 | 15-32 | 18-10.3 - 18-10.7 |

| 12-264 - 12-70 . | 15-33 | 18-10.8 |

| 12-270.1 - 12-270.9 Added. | 15-34 - 15-35 | 18-10.9 - 18-10.10 . |

| 12-270.10 Blank Added | 15-36 | 18-10.11 - 18-10.12 |

| 12-271 - 12-349 Added. | 15-37 - 15-39 | 18-11 |

| 12-350 Blank Added . | 15-40 - 15-41 |

*Zero in this column indicates original page.

List Of Effective Pages (Contd)

| Page No. . | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 18-12 | 21-2.1 - 21-2.4 Added. | 24-32.1 - 24-32.4 Added. |

| 18-13 | 21-3 - 21-4 | 24-33 - 24-34 |

| 18-14 - 18-15 | 21-4.1 - 21-4.14 Added | 24-34.1 -24-34..2 Added |

| 18-16 | 21-5 - 21-8 | 24-35 |

| 18-17 - 18-19 | 21-8.1 - 21-8.2 Added. | 24-36 |

| 18-20 | 21-9 - 21-11 . | 24-37 |

| 18-21 | 21-12 - 21-19 | 24-38 |

| 18-22 | 21-20 | 24-38.1 - 24-38.2 Added |

| 18-23 - 18-27 | 22-1 - 22-3 | 24-39 Blank |

| 18-28 | 22-4 . | 24-40 |

| 18-29 | 22-5 . | 25-1 . |

| 18-30 | 22-6 - 22-7 | 25-2 . |

| 18-31 - 18-33 | 22-8 . | 25-3 . |

| 18-34 | 22-9 - 22-11 . | 25-4 . |

| 18-35 | 22-12 Blank | 25-5 - 25-8 |

| 18-36 | 23-1 - 23-2 | 25-9 . |

| 18-37 | 23-3 - 23-5 | 25-10 |

| 18-38 | 23-6 . | 25-11 - 25-15 |

| 18-39 - 18-40 | 23-7 - 23-25 Added | 25-16 |

| 18-41 | 23-26 Blank Added | 25-17 - 25-21 |

| 18-42 | 24-1 - 24-2 | 25-22 |

| 18-43 | 24-2.1 - 24-2.2 Added. | 25-22.1 - 25-22.12 Added . |

| 18-44 - 18-45 | 24-2.3 Blank Added . | 25-23 |

| 18-46 Blank | 24-4 - 24-5 | 25-24 |

| 19-1 - 19-6 | 24-6 . | 25-25 - 25-27 |

| 19-6.1 Blank Added . | 24-6.1 - 24-6.2 Added. | 25-28 |

| 19-6.2 - 19-6.8 Added | 24-7 - 24-8 | 25-29 |

| 19-7 - 19-12 . | 24-8.1 - 24-8.2 Added. | 25-30 |

| 19-12.1 - 19-12.6 Added | 24-9 - 24-10 . | 25-31 |

| 19-13 - 19-16 | 24-11 | 25-32 |

| 19-17 Added | 24-12 | 25-33 |

| 19-18 Blank Added | 24-13 | 25-34 |

| 19-9 - 19-10 . | 24-14 | 25-35 |

| 19-11 | 24-15 | 25-36 |

| 19-12 - 19-13 | 24-16 - 24-17 | 25-36.1 |

| 19-14 | 24-18 | 25-36.2 - 25-36.5 |

| 19-15 | 24-19 | 25-36.6 - 25-36.16 . |

| 19-16 Blank | 24-20 - 24-22 | 25-36.17 - 25-36.18 |

| 20-1 - 20-6 | 24-22.1 - 22.4 Added . | 25-36.19 Blank |

| 20-6.1 - 20-6.6 Added | 24-23 - 24-24 | 25-36.20 . |

| 20-7 - 20-10 . | 24-24.1 - 24-24.2 Added | 25-36.21 - 25-36.32 |

| 20-11 Added | 24-25 - 24-28 | 25-36.33 - 25-36.34 |

| 20-12 Added Blank | 24-28.1 - 24-28.4 Added | 25-36.35 - 25-36.36 |

| 21-1 - 21-2 | 24-29 - 24-32 | 25-36.37 . |

*Zero in this column indicates original page.

Change 6 F

List Of Effective Pages (Contd)

| Page No. . | Page No. . | Page No *Change No. |

|---|---|---|

| 25-36.38 - 36.43 Added . | 25-94 | 27-2 . |

| 25-36.44 Blank Added . | 25-95 - 25-117 . | 27-3 . |

| 25-37 | 25-118 Blank . | 27-4 - 27-6 |

| 25-38 - 25-41 | 25-119 . | 27-7 - 27-9 |

| 25-42 | 25-120 - 25-122 | 27-10 |

| 25-42.1 - 25-42.2 Added | 25-123 - 25-124 | 27-11 - 27-13 |

| 25-43 | 25-125 - 25-127 | 27-14 |

| 25-44 - 25-45 | 25-128 . | 25-15 |

| 25-46 | 25-129 . | 27-16 - 27-22 |

| 25-47 | 25-130 . | 27-23 |

| 25-48 | 25-131 - 25-132 | 27-24 - 27-29 |

| 25-49 | 25-133 - 25-134 | 27-30 |

| 25-50 | 25-135 . | 27-31 |

| 25-50.1 | 25-136 . | 27-32 - 27-33 |

| 25-50.2 | 25-137 . | 27-34 |

| 25-51 | 25-138 . | 27-35 |

| 25-52 | 25-139 - 25-140 | 27-36 - 27-37 |

| 25-53 | 25-141 . | 27-38 |

| 25-54 | 25-142 . | 27-39 |

| 25-55 | 25-143 - 25-150 | 27-40 Blank |

| 25-56 | 25-151 . | 28-1 - 28-2 |

| 25-56.1 - 25-56.2 | 25-152 . | 28-3 . |

| 25-57 - 25-58 | 25-153 - 25-158 | 28-4 - 28-5 |

| 25-59 - 25-61 | 25-159 - 25-160 | 28-6 . |

| 25-62 | 25-161 . | 28-7 . |

| 25-63 | 25-162 . | 28-8 . |

| 25-64 | 25-163 - 25-164 | 28-9 . |

| 25-65 | 25-165 . | 28-10 - 28-11 |

| 25-66 - 25-67 | 25-166 - 25-167 | 28-12 - 28-13 |

| 25-68 | 25-168 . | 28-14 |

| 25-69 - 25-71 | 25-169 - 25-172 | 28-15 - 28-16 |

| 25-72 - 25-73 | 25-172.1 - 25-172.4 Added | 28-17 - 28-18 |

| 25-74 - 25-75 | 25-173 - 25-174 | 28-19 - 29-25 |

| 25-76 | 25-174.1 - 25-174.2 Added | 28-26 |

| 25-77 | 25-175 - 25-176 | 28-26.1 - 28-26.2 |

| 25-78 | 25-177 . | 28-27 - 28-29 |

| 25-78.1 - 25-78.2 | 25-178 - 25-180 | 28-30 |

| 25-79 | 25-181 Added . | 28-30.1 |

| 25-80 | 25-182 Blank Added . | 28-30.2 |

| 25-81 - 25-87 | 26-1 . | 28-31 |

| 25-88 | 26-2 - 26-4 | 28-32 |

| 25-89 | 26-5 - 26-9 | 28-33 - 28-34 |

| 25-90 | 26-10 | 28-35 |

| 25-91 - 25-93 | 27-1 . | 28-36 |

*Zero in this column indicates original page.

List Of Effective Pages (Contd)

| Page No. . | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 28-37 - 28-39 | 29-10 | 33-19 |

| 28-40 | 29-11 | 33-20 - 33-38 |

| 28-41 - 28-43 | 29-12 | 33-39 |

| 28-44 | 29-13 - 29-17 | 33-40 - 33-67 |

| 28-45 | 29-18 - 29-21 | 33-68 |

| 28-46 | 29-22 - 29-23 | 33-69 - 33-87 |

| 28-47 | 29-24 | 33-88 |

| 28-48 | 29-24.1 Added | 33-89 - 33-109 . |

| 28-49 | 29-24.2 Blank Added | 33-110 Blank |

| 28-50 | 29-25 | 34-1 . |

| 28-51 - 28-53 | 29-26 | 34-2 - 34-3 |

| 28-54 | 29-27 | 34-4 Blank . |

| 28-55 | 29-28 Blank. | A-1 |

| 28-56 | 30-1 - 30-3 | A-2 |

| 28-57 - 28-58 | 30-4 - 30-9 | B-1 - B-3 |

| 28-58.1 | 30-10 | B-4 - B-17 . |

| 28-58.2 | 30-11 - 30-17 | B-18 - B-21 |

| 28-59 | 30-18 | B-22 . |

| 28-60 | 30-19 | B-23 . |

| 28-61 | 30-20 | B-24 . |

| 28-62 - 28-64 | 30-21 | C-1 |

| 28-65 | 30-22 | C-2. |

| 28-66 | 30-23 - 30-24 | C-3 |

| 28-67 - 28-69 | 30-25 | C-4. |

| 28-70 | 30-26 - 30-29 Added | C-5 |

| 28-71 | 30-30 Blank Added | C-6 - C-10 . |

| 28-72 | 31-1 . | D-1 |

| 28-73 | 31-2 Blank Added . | D-2 |

| 28-74 | 31-3 - 31-19 Deleted . | D-3 - D-12 |

| 28-75 - 28-77 | 31-20 Blank Deleted | D-13 . |

| 28-78 | 32-1 - 32-2 | D-14 - D-65 |

| 28-80 - 28-82 | 32-3 . | D-66 . |

| 28-83 | 32-4 . | D-67 - D-84 |

| 28-84 - 28-85 | 32-5 - 32-6 | D-84.1 - D-84.6 |

| 28-86 | 32-6.1 - 32-6.2 Added | D-85 . |

| 28-86.1 - 28-86.2 | 32-7 - 32-8 | D-86 - D-89 Added |

| 28-87 - 28-88 | 32-9 - 32-10 . | D-90 Blank Added . |

| 28-89 - 28-90 | 32-11 - 32-13 | E-1 - E-5 |

| 28-91 | 32-14 Blank | E-6 Blank |

| 28-92 Blank | 33-1 . | F-1 - F-2 |

| 29-1 . | 33-2 . | G-1 |

| 29-2 . | 33-3 - 33-4 | G-2 - G-12 |

| 29-3 - 29-6 | 33-5 - 33-16 . | G-13 - G-15 Deleted |

| 29-7 . | 33-17 - 33-18 | G-16 Blank Deleted . |

| 29-8 - 29-9 |

*Zero in this column indicates original page.

Change 6 H

List Of Effective Pages (Contd)

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

|---|---|---|

| H-1 | J-77 - J-78 Deleted | M-28 . |

| H-2 | J-79 - J100 Deleted | M-29 Added . |

| H-3 - H-4 | J-100.1 - J-100.2 Deleted | M-30 . |

| H-5 - H-7 Added | J-100.1 - J-100.2 Added | M-30 - M-33 Added |

| H-8 Blank Added | J-101 Deleted | M-34 Blank Added . |

| J-1 - J-2 | J-102.1 Added | Index 1 - Index 68 . |

| J-3 Blank Added | J-102.2. | Index 69 - Index 75 Added |

| J-4 - J-7 | J-103 | Index 76 Blank Added . |

| J-8 | J-104 - J-112 | FP-1 . |

| J-9 - J-12 . | J-113 - J-114 | FP-2 Blank . |

| J-13 . | J-115 - J-145 Added | FP-3 . |

| J-14 . | J-146 Blank Added | FP-4 Blank . |

| J-15 . | K-1 - K-2. | FP-5 Added . |

| J-16 . | K-3 | FP-6 Blank Added |

| J-17 . | K-4 | FP-7 . |

| J-18 - J-20 | K-5 | FP-8 Blank . |

| J-21 Blank . | K-6 - K-12 | FP-9 . |

| J-22 . | K-13 Added . | FP-10 Blank |

| J-23 - J-24 | K-14 - K-16 | FP-11 Added |

| J-25 . | K-17 Added . | FP-12 Blank Added. |

| J-26 - J-27 | K-18 - K-24 | FP-13 Added |

| J-28 . | K- 25 Added | FP-14 Blank Added. |

| J-29 . | K-26 . | FP-15 Added |

| J-30 - J-33 Deleted | K-27 Added . | FP-16 Blank Added. |

| J-34 - J-38 | L-1 | FP-17 Added |

| J-39 . | L-2 | FP-18 Blank Added. |

| J-40 - J-41 | L-3 Added | FP-19 Added |

| J-42 - J-45 | L-4 | FP-20 Blank Added. |

| J-46 - J-49 | L-5 | FP-21 Added |

| J-50 . | L-6 Blank Added | FP-22 Blank Added. |

| J-50.1 Added . | M-1 Added | FP-23 Added |

| J-50.2 . | M-2 | FP-24 Blank Added. |

| J-51 . | M-3 Added | FP-25 Added |

| J-52 - J-53 | M-4 | FP-26 Blank Added. |

| J-54 - J-56 | M-5 Added | FP-27 Added |

| J-56.1 - J-56.4 | M-6 - M-8 | FP-28 Blank Added. |

| J-57 . | M-9 Added | FP-29 Added |

| J-58 . | M-10 . | FP-30 Blank Added. |

| J-59 . | M-11 Added . | FP-31 Added |

| J-60 . | M-12 | FP-32 Blank Added. |

| J-60.1 . | M-13 Added . | FP-33 Added |

| J-60.2 . | M-14 . | FP-34 Blank Added. |

| J-61 - J-63 | M-15 Added . | FP-35 Added |

| J-64 - J-65 | M-16 . | FP-36 Blank Added. |

| J-66 - J-68 | M-17 - M-21 Added | FP-37 Added |

| J-68.1 . | M-22 . | FP-38 Blank Added. |

| J-68.2 - J-68.4 Added | M-23 Added . | FP-39 Added |

| J-69 . | M-24 . | FP-40 Blank Added. |

| J-70 . | M-25 Added . | FP-41 Added |

| J-71 . | M-26 . | FP-42 Blank Added. |

| J-72 - J-75 | M-27 Added . |

*Zero in this column indicates original page.

NO. 36A12-1A-3052-1 ARMY TM 9-2320-387-24-2 AIR FORCE TO 36A12-1A-3052-1 MARINE CORPS TM 11033-IN VOL 2 TECHNICAL MANUAL HEADQUARTERS NO. 9-2320-387-24-2 DEPARTMENTS OF THE ARMY, THE AIR FORCE, NO. 11033-IN VOL 2 AND MARINE CORPS TECHNICAL ORDER WASHINGTON, D.C., 31 DECEMBER 1997

Technical Manual Volume 2 Of 2

UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038) (EIC: BEG); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007) (EIC: BEH); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993) (EIC: BEK); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017) (EIC: BEJ); TRUCK, UTILITY: EXPANDED CAPACITY, TOW ITAS CARRIER, M1167 (2320-01-544-9638).

Approved for public release; distribution is unlimited.

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS (Army) You can help improve this publication. If you find any errors, or if you would like to recommend any improvements to the procedures in this publication, please let us know. The preferred method is to submit your DA Form 2028 (Recommended Changes to Publications and Blank Forms) through the Internet, on the Army Electronic Product Support (AEPS) website. The Internet address is https://aeps.ria.army.mil. The DA Form 2028 is located under the Public Applications section in the AEPS Public Home Page. Fill out the form and click on SUBMIT. Using this form on the AEPS will enable us to respond quicker to your comments and better manage the DA Form 2028 program. You may also mail, email, or fax your comments or DA Form 2028 directly to the U.S. Army TACOM Life Cycle Management Command. The postal mail address is U.S. Army TACOM Life Cycle Management Command, ATTN: AMSTA-LC-LMPP / TECH PUBS, 1 Rock Island Arsenal, Rock Island, IL 61299-7630. The e-mail address is tacomlcmc.daform2028@us.army.mil. The fax number is DSN 793-0726 or Commercial (309) 782-0726. (Marine Corps) Submit notice of discrepancies or suggest changes on a NAVMC 10772. Users without CAC/PKI certificates may submit the NAVMC via the Internet using website http://www.ala.usmc.mil/navmc/part1.htm, You can then fill in and submit the automated NAVMC 10772 Form. NAVMC forms may also be submitted by electronic mail to mbatcommarlogbases@logcom.usmc.mil mailto:mbmatcommarlogbases@logcom.usmc.mil, or by mailing a paper copy of the NAVMC 10772 in an envelope addressed to Commander, Marine Corps Systems Command, Attn: Assistant Commander Acquisition and Logistics (LOG/TP), 814 Radford Blvd., Room 316E, Albany, Georgia 31704-0343. Problems or questions regarding the NAVMC 10772 program should be reported by calling DSN 567-5017 or DSN 567-6439. In addition to electronic submittal of the NAVMC form via the above web links, forward an information copy (cc:) or mail a paper copy to the Logistics Management Specialist at the following address: Logistics Management Specialist, Code PMM151, 814 Radford Blvd., STE 310W, Albany, Georgia 31704-0343.

This manual is published in two parts. TM 9-2320-387-24-1 contains chapters 1 through 9. TM 9-2320-387-24-2 contains chapters 10 through 33 and appendices A through M. This manual contains a table of contents and alphabetical index for both volumes 1 and 2.

Volume 2 Of 2

| LIST OF EFFECTIVE PAGES | ||

|---|---|---|

| NOTE: The portion of the text affected by the changes is indicated by a vertical line in the outer margins of the page. | ||

| Dates of issue for original and changed pages of | ||

| volume 2 are: | ||

| Original 0 31 December 1997 | ||

| Change 1 31 October 2001 | ||

| Change 2 30 July 2004 | ||

| Change 3 31 May 2006 | ||

| Change 4 28 February 2007 | ||

| Change 5 30 November 2007 | ||

| Change 6 31 August 2009 | ||

| TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS 3,016 CONSISTING OF THE FOLLOWING: | ||

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

| 10-40.1 - 10-40.6 Added 6 | 10-76.1 5 | |

| VOLUME 2 a 0 | 10-41 - 10-42 6 | 10-76.2 3 |

| b 5 | 10-42.1 - 10-42.2 6 | 10-76.3 Blank Added 3 |

| A - I 6 | 10-43 - 10-44 6 | 10-76.4 5 |

| J Blank Added 5 | 10-44.1 - 10-44.6 Added 6 | 10-77 3 |

| i - iii 6 | 10-45 6 | 10-78 - 10-81 5 |

| iv 5 | 10-46 0 | 10-82 6 |

| 10-1 - 10-2 6 | 10-47 5 | 10-82.1 6 |

| 10-3 - 10-4 5 | 10-48 3 | 10-82.2 - 10-82.7 Added 5 |

| 10-5 1 | 10-48.1 Blank Added 3 | 10-82.8 - 10-82.9 6 |

| 10-6 - 10-7 2 | 10-48.2 - 10-48.3 5 | 10-82.10 - 10-82.11 Added 5 |

| 10-8 1 | 10-48.4 Blank Added 3 | 10-82.12 - 10-82.13 6 |

| 10-9 2 | 10-49 2 | 10-82.14 - 10-82.18 |

| 10-10 0 | 10-50 - 10-51 1 | Added 5 |

| 10-52 5 | 10-83 - 10-84 5 | |

| 10-11 1 10-12 2 | 10-53 3 | 10-85 0 |

| 10-13 0 | 10-54 - 10-56 5 | 10-86 5 |

| 10-14 2 | 10-56.1 - 10-56.2 5 | 10-87 2 |

| 10-15 - 10-17 0 | 10-56.3 - 10-56.6 3 | 10-88 1 |

| 10-18 1 | 10-56.7 - 10-56.8 Added 5 | 10-88.1 - 10-88.2 5 |

| 10-18.1 2 | 10-57 - 10-58 5 | 10-89 Blank 5 |

| 10-18.2 Blank 1 | 10-58.1 5 | 10-90 0 |

| 10-19 1 | 10-58.2 Blank Added 3 | 10-91 5 |

| 10-20 2 | 10-59 5 | 10-92 - 10-95 0 |

| 10-21 - 10-22 1 | 10-60 0 | 10-93 - 10-94 5 |

| 10-23 - 10-25 2 | 10-61 - 10-62 5 | 10-94.1 - 10.94.2 6 |

| 10-26 1 | 10-63 - 10-64 2 10-65 5 | 10-95 6 |

| 10-27 - 10-28 2 | 10-66 3 | 10-96 Blank 6 |

| 10-29 0 | 10-67 Blank 3 | 10-96.1 5 |

| 10-30 - 10-32 2 | 10-96.2 3 | |

| 10-32.1 - 10-32.2 5 | 10-68 3 | 10-97 3 |

| 10-33 Blank 3 | 10-68.1 Added 3 | 10-98 3 |

| 10-34 - 10-35 2 | 10-68.2 Blank Added 3 | 10-98.1 5 |

| 10-36 - 10-37 0 | 10-69 - 10-71 5 | 10-98.2 2 |

| 10-38 6 | 10-72 2 | 10.98.3 1 |

| 10-38.1 - 10-38.2 6 | 10-73 - 10-75 5 | 10-98.4 6 |

| 10-39 - 10-40 6 | 10-76 6 |

| LIST OF EFFECTIVE PAGES (Contd) | |||||

|---|---|---|---|---|---|

| Page No *Change No. | Page No *Change No. | Page No *Change No. | 10-98.5 1 | 10-146 - 10-150 5 | 11-24 2 |

| 10-98.6 3 | 10-150.1 Blank Added 2 | 11-24.1 - 11-24.2 Added 2 | 10-98.7 1 | 10-150.2 - 10-150.7 Added 2 | 11-24.3 - 11-24.23 Added 3 |

| 10-98.8 - 10-98.11 2 | 10-150.8 Blank Added 2 | 11-24.24 Blank Added 3 | 10-98.12 Blank 2 | 10-151 - 10-154 5 | 11-25 1 |

| 10-98.13 - 10-98.14 2 | 10-154.1 3 | 11-26 2 | 10-98.15 - 10-98.16 3 | 10-154.2 5 | 11-27 - 11-29 1 |

| 10-98.17 - 10.-98.18 Added 2 | 10-154.1 - 10-154.4 Added 3 | 11-30 - 11-31 2 | 10-98.19 - 10-98.20 6 | 10-155 3 | 11-32 - 11-36 6 |

| 10-98.21 - 10-98.22 Added 6 | 10-156 5 | 11-37 0 | 10-99 - 10-100 6 | 10-156.1 - 10-156.2 Added 3 | 11-38 6 |

| 10-101 - 10-102 0 | 10-157 3 | 11-39 0 | 10-103 - 10-104 5 | 10-158 5 | 11-40 6 |

| 10-105 0 | 10-158.1 Added 3 | 11-40.1 6 | 10-106 2 | 10-158.2 Blank Added 3 | 11-40.2 Blank Added 1 |

| 10-107 0 | 10-159 5 | 11-41 6 | 10-108 - 10-110 5 | 10-160 6 | 11-42 3 |

| 10-111 0 | 10-161 Blank Added 6 | 11-43 - 11-44 1 | 10-112 - 10-113 5 | 10-162 - 10-165 Added 6 | 11-45 3 |

| 10-114 2 | 10-166 Blank Added 6 | 11-46 6 | 10-115 1 | 11-1 3 | 11-46.1 6 |

| 10-116 - 10-119 5 | 11-2 5 | 11-46.2 5 | 10-120 1 | 11-2.1 - 11-2.2 Added 6 | 11-46.3 Blank Added 5 |

| 10-121 2 | 11-3 Blank 3 | 11-46.4 6 | 10-122 - 10-125 0 | 11-4 2 | 11-47 5 |

| 10-126 5 | 11-4.1 1 | 11-48 - 11-51 6 | 10-127 0 | 11-4.2 2 | 11-52 2 |

| 10-128 2 | 11-5 1 | 11-52.1 3 | 10-128.1 Blank Added 2 | 11-6 5 | 11-52.2 6 |

| 10-128.2 - 10-128.13 Added 2 | 11-7 - 11-8 1 | 11-53 - 11-55 5 | 10-128.14 6 | 11-9 5 | 11-56 2 |

| 10-128.15 Added Blank 6 | 11-10 2 | 11-57 0 | 10-128.16 - 10-128.17 Added 6 | 11-11 1 | 11-58 - 11-66 5 |

| 10-128.18 Blank Added 6 | 11-12 2 | 11-67 - 11-68 2 | 10-129 - 10-132 5 | 11-12.1 - 11-12.3 Added 2 | 11-68.1 5 |

| 10-133 - 10-137 0 | 11-12.4 Blank Added 2 | 11-68.2 2 | 10-138 5 | 11-13 - 11-16 2 | 11-68.3 - 11.68.5 1 |

| 10-139 0 | 11-17 1 | 11-68.6 2 | 10-140 5 | 11-18 0 | 11-68.7 1 |

| 10-141 0 | 11-19 1 | 11-68.8 2 | 10-142 5 | 11-20 2 | 11-68.9 - 11-68.10 1 |

| 10-143 3 | 11-21 0 | 11-69 1 | 10-144 5 | 11-22 2 | 11-70 - 11-73 2 |

| 10-145 0 | 11-23 1 | 11-74 - 11-77 Deleted 2 | |||

| *Zero in this column indicates original page. | B | Change 6 |

| LIST OF EFFECTIVE PAGES (Contd) | ||

|---|---|---|

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

| 11-78 - 11-82 2 | 11-131 Blank 3 | 11-202.2 6 |

| 11-82.1 1 | 11-132 2 | 11-202.3 Blank Added 6 |

| 11-82.2 2 | 11-132.1 - 11-132.6 Added 2 | 11-202.4 - 11-202.5 Added 6 |

| 11-83 1 | 11-132.7 - 11-132.13 6 | 11-202.6 Blank Added 6 |

| 11-84 2 | 11-132.14 Blank Added 6 | 11-203 5 |

| 11-84.1 - 11-84.6 Deleted 2 | 11-133 - 11-138 3 | 11-204 5 |

| 11-85 2 | 11-139 0 | 11-205 Blank 5 |

| 11-86 - 11-89 1 | 11-140 3 | 11-206 - 11-208 5 |

| 11-90 5 | 11-141 0 | 11-208.1 Added 5 |

| 11-90.1 5 | 11-142 - 145 3 | 11-208.2 6 |

| 11-90.2 6 | 11-146 2 | 11-208.3 - 11-208.4 Added 5 |

| 11-91 Blank 3 | 11-147 1 | 11-209 6 |

| 11-92 - 11-95 5 | 11-148 - 11-151 0 | 11-210 5 |

| 11-96 - 11-97 1 | 11-152 2 | 11-210.1 Added 5 |

| 11-98 - 11-99 5 | 11-153 - 11-155 1 | 11-210.2 Added 6 |

| 11-100 - 11-101 0 | 11-156 - 11-157 0 | 11-211 5 |

| 11-102 - 11-103 2 | 11-158 1 | 11-212 6 |

| 11-104 - 11-105 5 | 11-159 - 11-161 0 | 11-213 3 |

| 11-106 - 11-107 0 | 11-162 Blank 0 | 11-214 5 |

| 11-108 2 | 11-163 - 11-164 6 | 11-214.1 Added 5 |

| 11-108.1 - 11-108.7 Added 2 | 11-165 3 | 11-214.2 6 |

| 11-108.8 Blank Added 2 | 11-166 5 | 11-215 - 11-216 5 |

| 11-109 1 | 11-167 3 | 11-216.1 Added 5 |

| 11-110 2 | 11-168 - 11-170 5 | 11-216.2 6 |

| 11-110.1 - 11-110.2 Added 2 | 11-171 - 11-183 3 | 11-217 5 |

| 11-111 - 11-112 2 | 11-184 5 | 11-218 6 |

| 11-112.1 - 11-112.2 Added 2 | 11-185 3 | 11-219 3 |

| 11-113 2 | 11-186 5 | 11-220 5 |

| 11-114 1 | 11-187 3 | 11-220.1 Added 5 |

| 11-115 0 | 11-188 5 | 11-220.2 6 |

| 11-116 2 | 11-189 3 | 11-221 - 11-222 5 |