hmmwv-manuals

Army Tm 9-2320-387-24-1 Volume No. 1 Air Force To 36A12-1A-3052-1 Marine Corps Tm 11033-In Vol 1

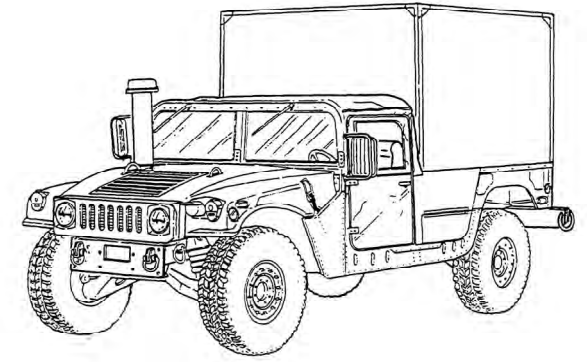

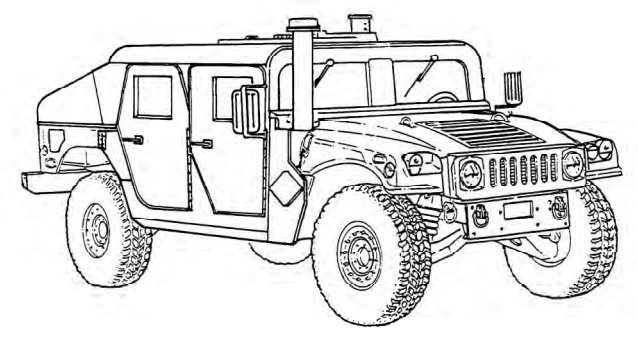

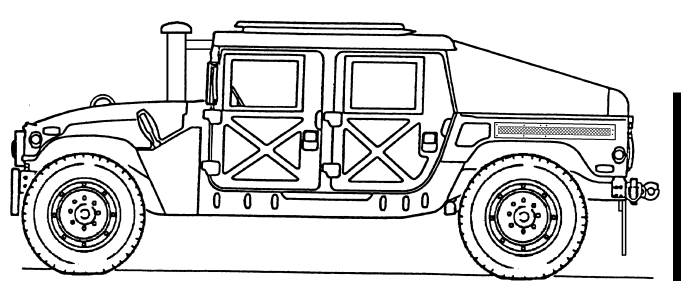

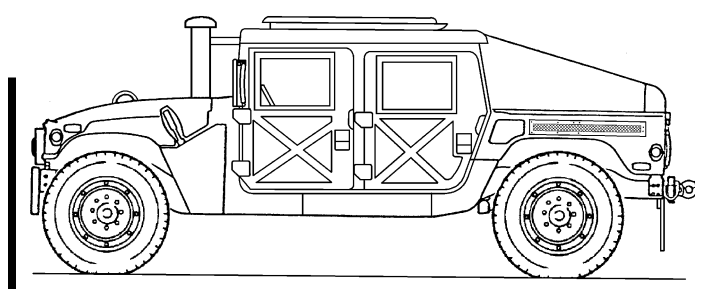

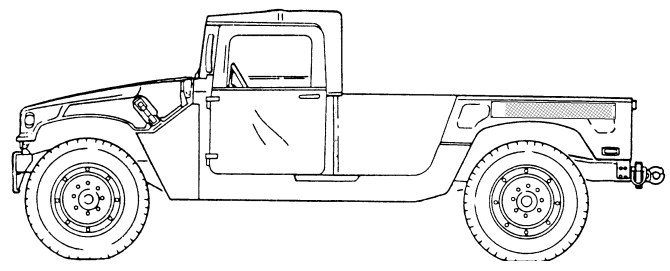

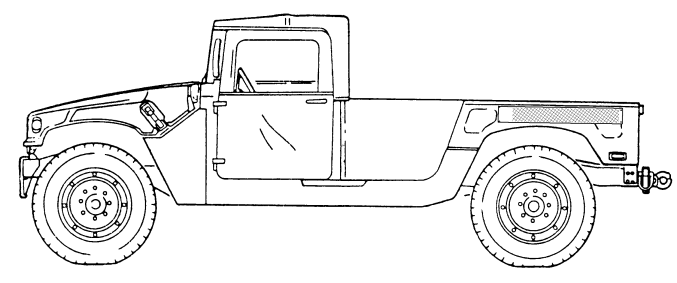

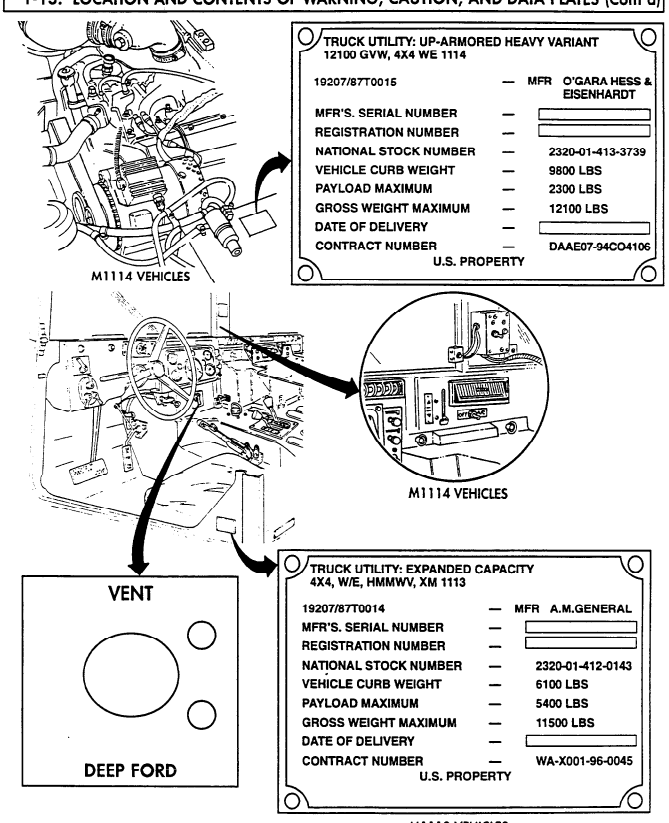

TECHNICAL MANUAL UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038) (EIC: BEG); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007) (EIC: BEH); TRUCK, UTILITY: COMMAND AND CONTROL/ GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993) (EIC: BEK); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017) (EIC: BEJ); TRUCK, UTILITY: EXPANDED CAPACITY, TOW ITAS CARRIER, M1167 (2320-01-544-9638).

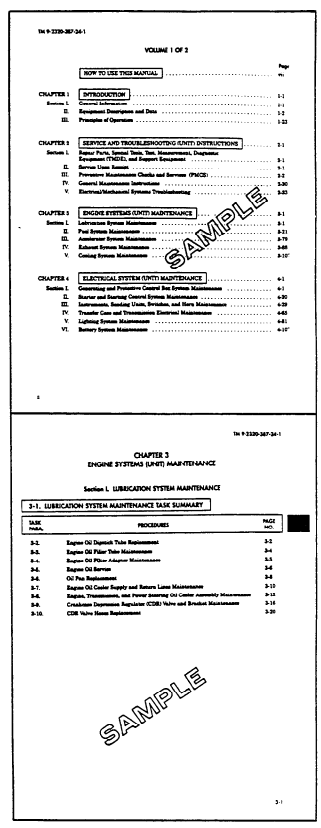

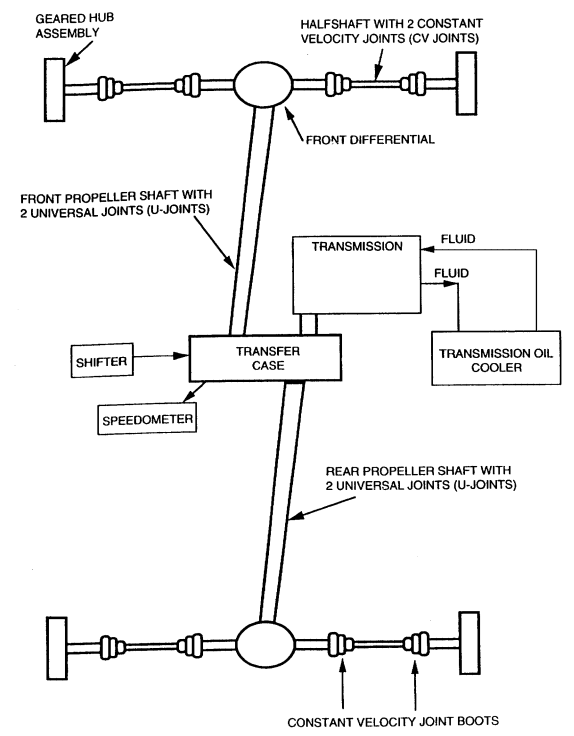

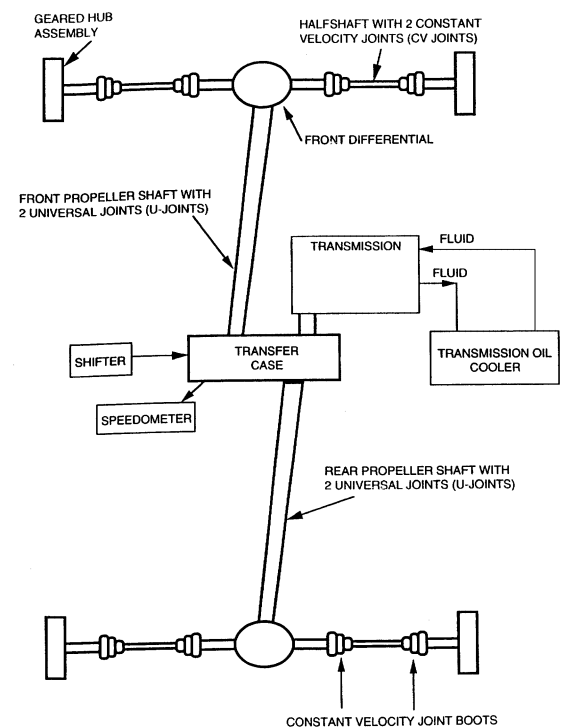

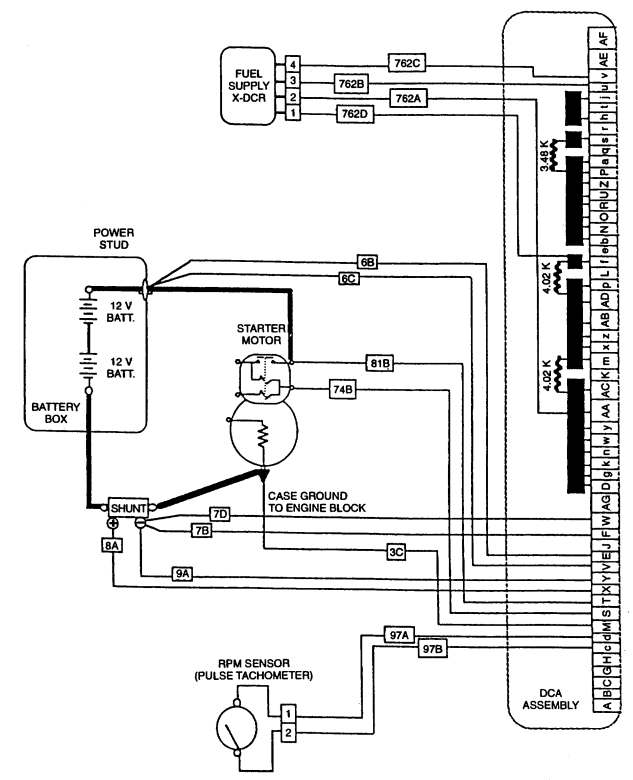

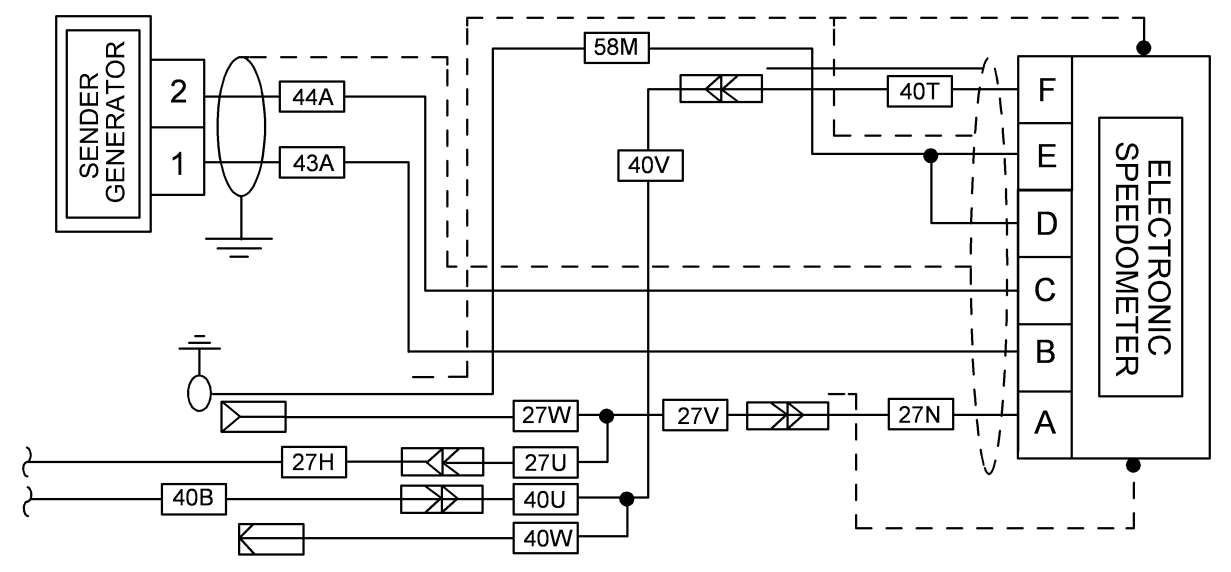

HOW TO USE THIS MANUAL vii INTRODUCTION 1-1 SERVICE AND TROUBLESHOOTING 2-1 (UNIT) INSTRUCTIONS ENGINE SYSTEMS (UNIT) MAINTENANCE 3-1 ELECTRICAL SYSTEMS (UNIT) MAINTENANCE 4-1 TRANSMISSION AND TRANSFER CASE 5-1 (UNIT) MAINTENANCE PROPELLER SHAFTS, AXLES, AND SUSPENSION 6-1 (UNIT) MAINTENANCE BRAKE SYSTEM (UNIT) MAINTENANCE 7-1 WHEELS AND STEERING (UNIT) MAINTENANCE 8-1 FRAME (UNIT) MAINTENANCE 9-1 INDEX INDEX-1 DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited.

HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS DECEMBER 1997 PCN 184 110331 00

Warning Exhaust Gases Can Kill

Brain damage or death can result from heavy exposure. Precautions must be followed to ensure crew safety when the personnel heater, main, or auxiliary engine of any vehicle is operated for any purpose.

- Do not operate your vehicle engine in enclosed areas. 2. Do not idle vehicle engine with vehicle windows closed. 3. Be alert at all times for exhaust odors. 4. Be alert for exhaust poisoning symptoms:

- Headache - Dizziness - Sleepiness - Loss of muscular control 5. If you see another person with exhaust poisoning symptoms:

- Remove person from area - Expose to open air - Keep person warm - Do not permit physical exercise - Administer artificial respiration, if necessary* - Notify a medic *For artificial respiration, refer to FM 21-11.

- BE AWARE, the field protective mask for Nuclear, Biological, or Chemical (NBC) protection will not protect you from carbon monoxide poisoning. THE BEST DEFENSE AGAINST EXHAUST POISONING IS ADEQUATE VENTILATION.

Warning Summary

-

Drycleaning solvent is flammable and will not be used near an open flame. A fire extinguisher will be kept nearby when the solvent is used. Use only in well-ventilated places. Failure to do this may result in injury to personnel and/or damage to equipment.

-

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personal protective equipment (goggles/shield, gloves, etc.).

-

Diesel fuel is highly flammable. Do not perform any procedure near fire, flames, or sparks. Severe injury or death will result.

-

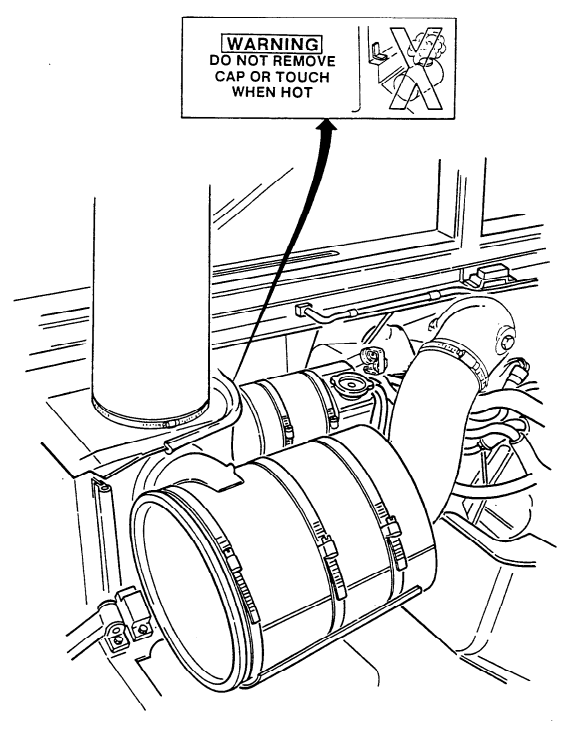

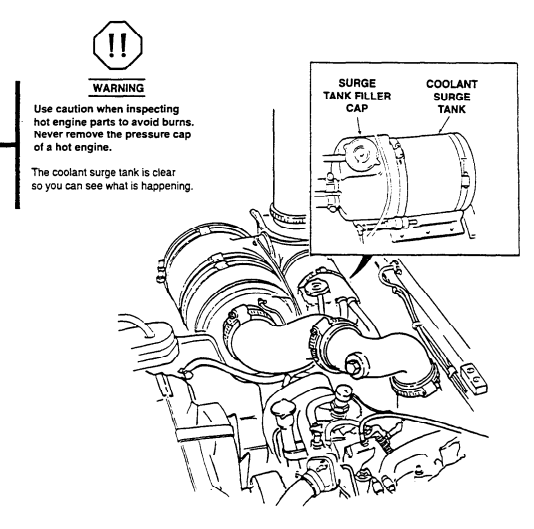

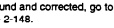

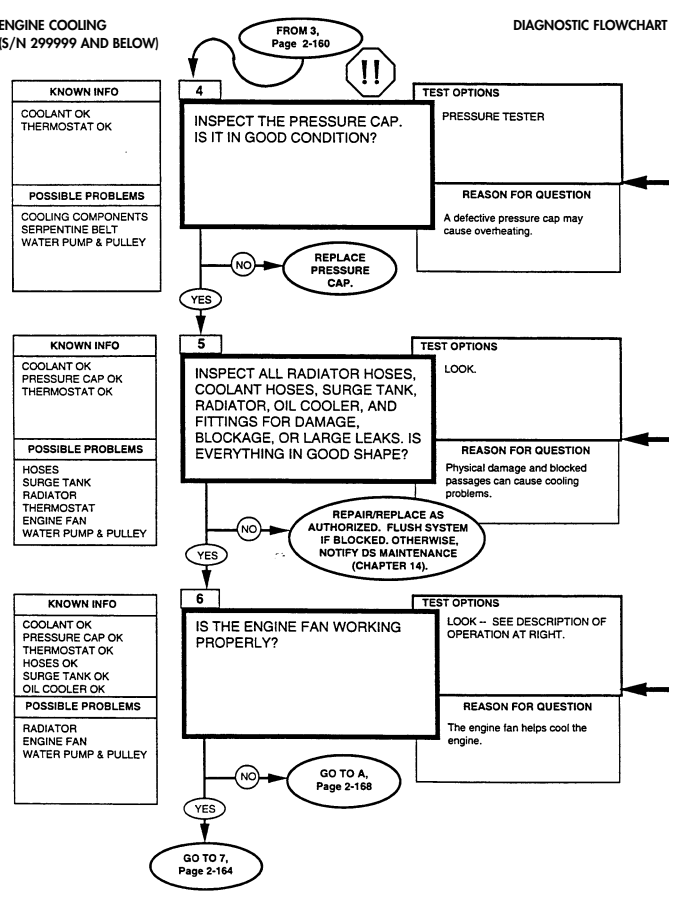

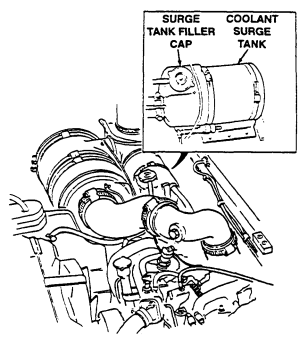

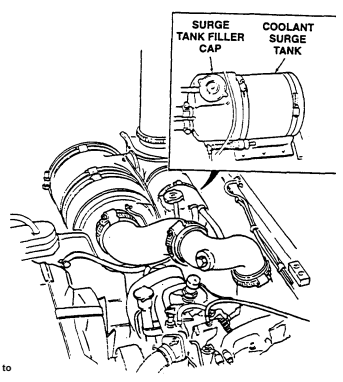

Do not touch hot exhaust system components with bare hands. Severe injury will result. - Do not remove surge tank filler cap before releasing internal pressure when engine temperature is above 185°F (85°C). Steam or hot coolant under pressure will cause injury.

-

Do not drain oil when engine is hot. Severe injury to personnel will result. - Always wear eye protection when bleeding brakes. Failure to do this may cause injury if brake fluid comes in contact with eyes.

-

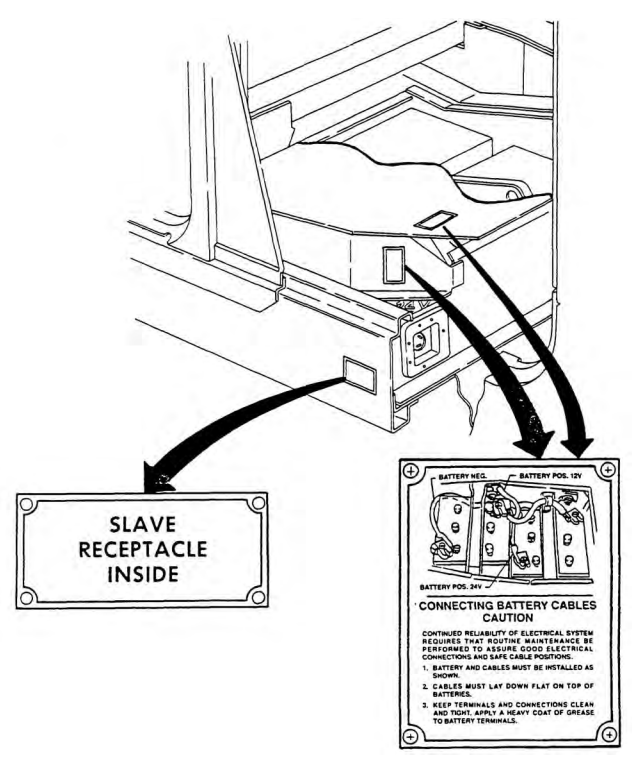

Do not perform battery system checks or inspections while smoking or near fire, flames, or sparks.

Batteries may explode, causing damage to vehicle, injury, or death to personnel.

-

Remove all jewelry such as rings, dog tags, bracelets, etc. If jewelry or disconnected battery ground cable contacts battery terminal, a direct short will result, causing injury to personnel or damage to equipment.

-

Use caution when testing thermostat. Hot water will cause burns. - Negative battery cable must be disconnected before disconnecting any harness from protective control box or serious injury to personnel or damage to equipment will result.

-

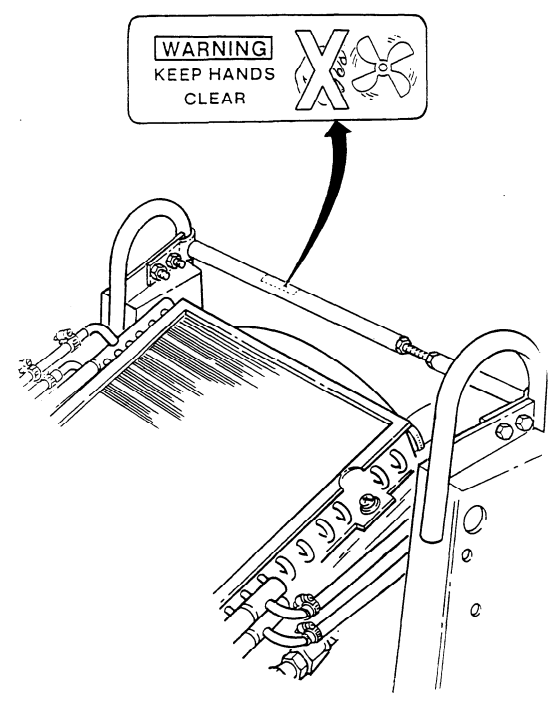

Keep hands and arms away from fan blade and drivebelts while engine is running or serious injury may result.

-

Battery acid (electrolyte) is extremely harmful. Always wear safety goggles and rubber gloves, and do not smoke when performing maintenance on batteries. Injury will result if acid contacts eyes or skin.

-

When removing battery cable clamps, disconnect ground cable first. Ensure all switches are in OFF position before disconnecting ground cable. Do not allow tools to come in contact with vehicle when disconnecting cable clamps. A direct short can result, causing instant heating of tools, tool damage, battery damage, or battery explosion.

-

Allow transmission/transfer case to cool before performing maintenance. Failure to do this may cause injury.

-

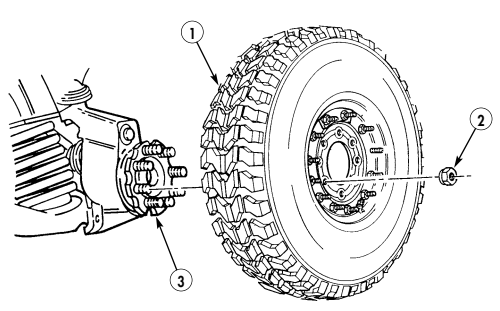

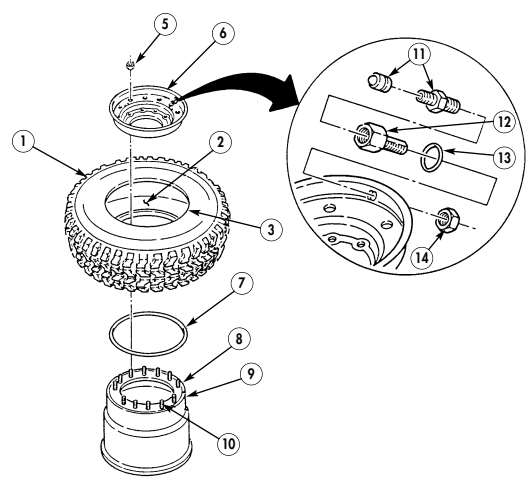

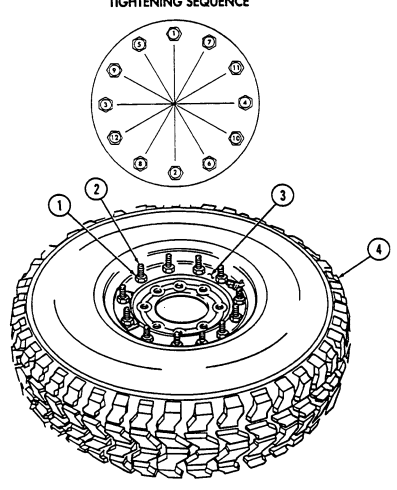

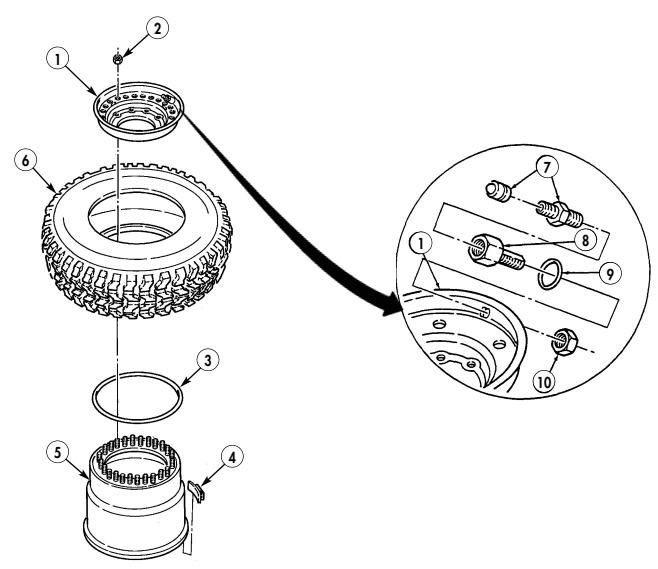

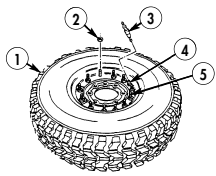

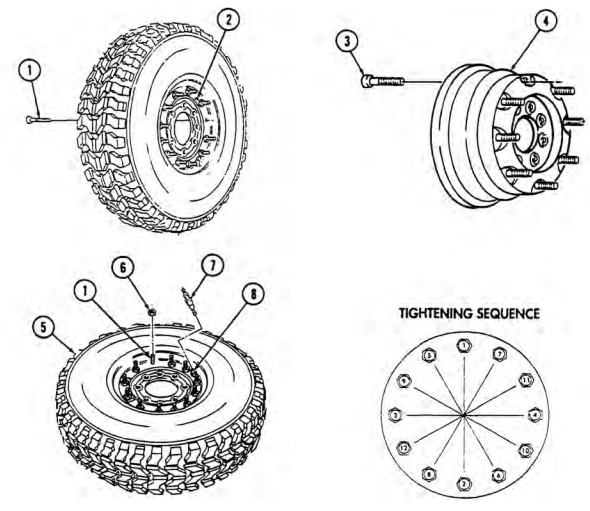

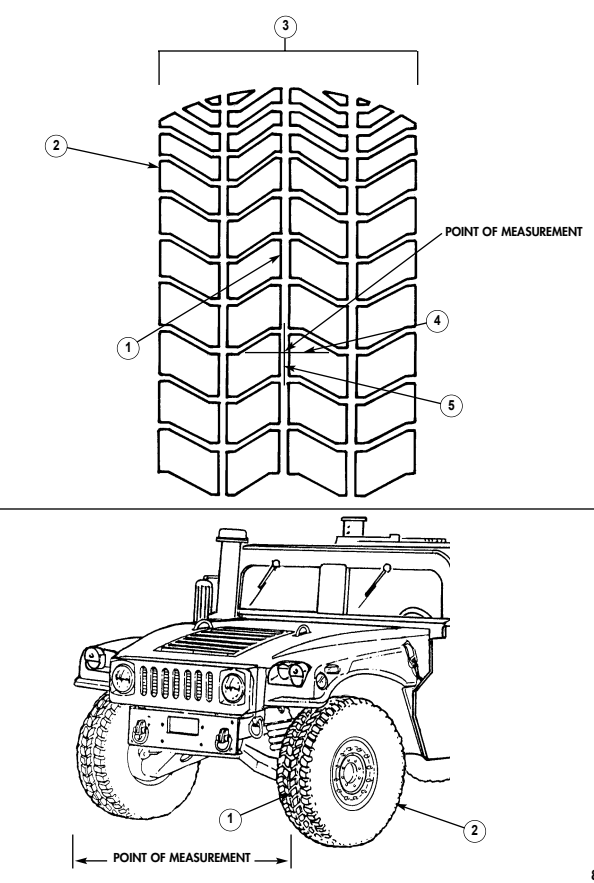

Always apply parking brake and chock opposite wheel before removing wheel. Avoid removing wheel when vehicle is on sloping terrain. Injury to personnel or damage to equipment may result.

-

Gloves must be worn whenever handling winch cable. Severe injury may result. - Hydraulic jacks are used for raising and lowering, and are not used to support vehicle. Never work under vehicle unless wheels are blocked and it is properly supported. Injury or damage to equipment may result if vehicle suddenly shifts or moves.

-

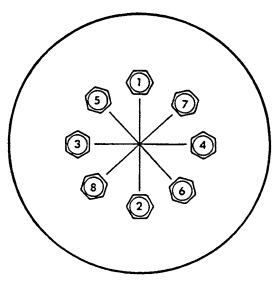

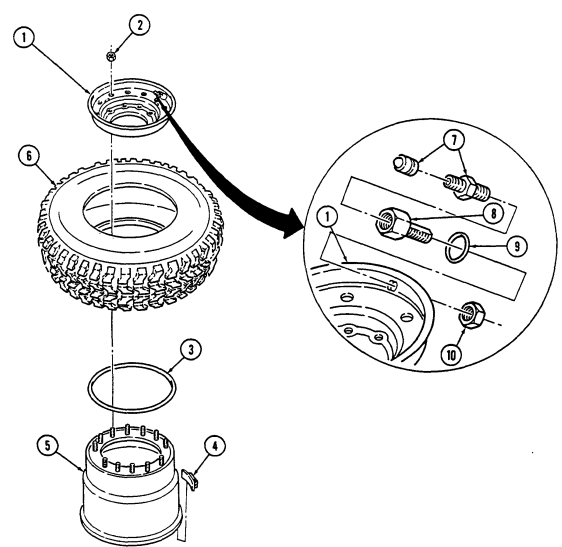

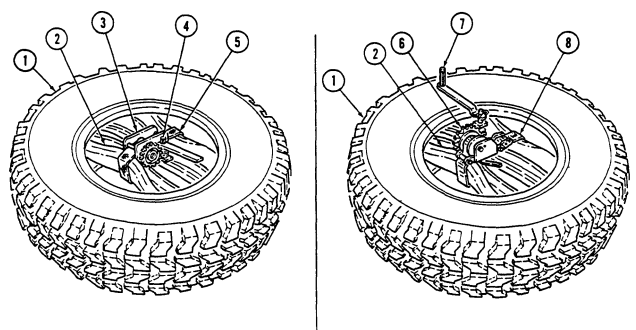

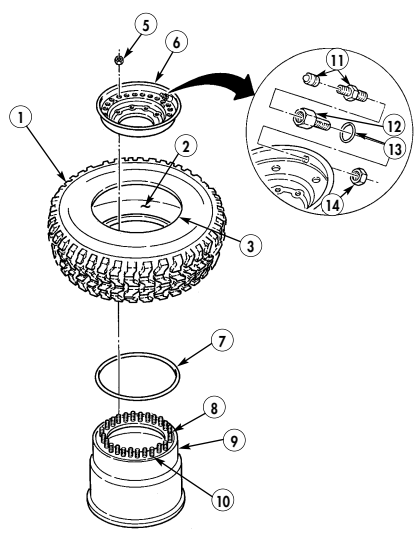

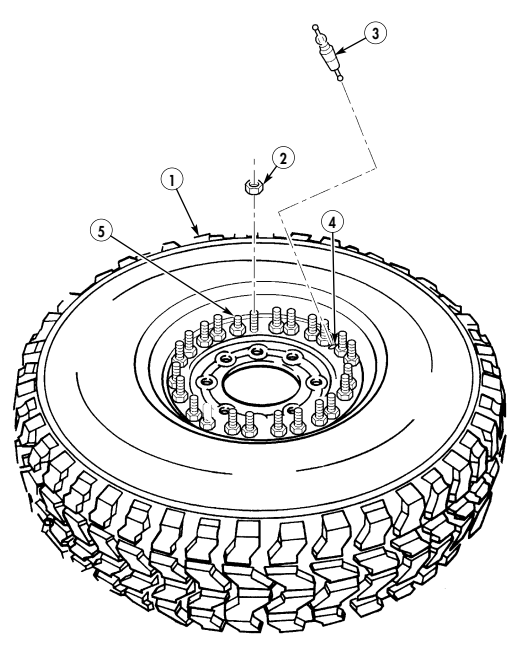

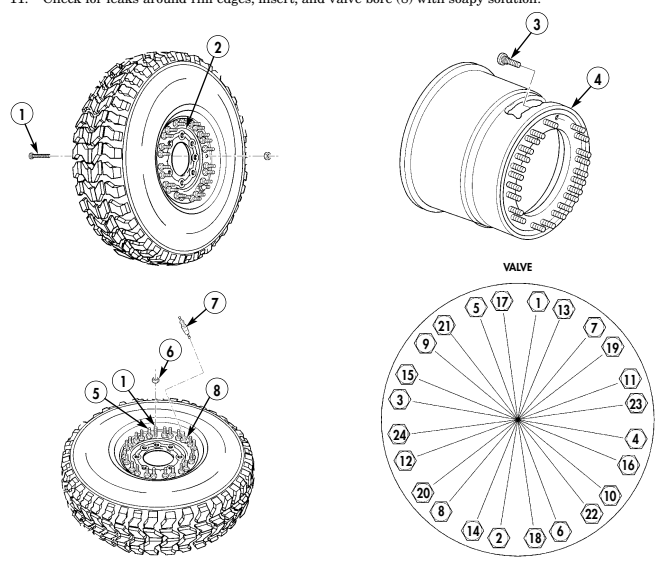

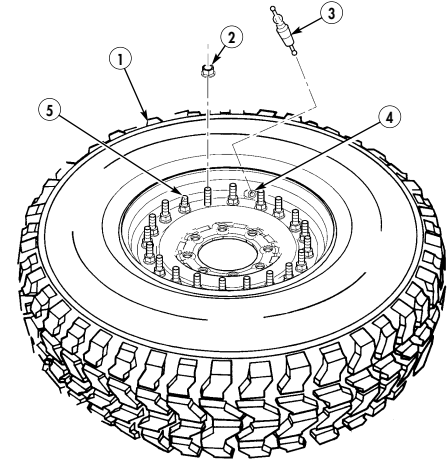

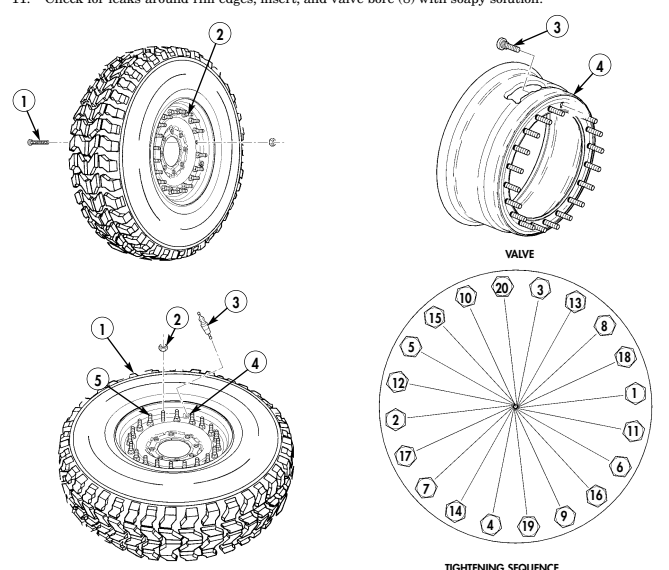

Remove only the inner group of nuts when removing a wheel from the vehicle. Removing the outer nuts which hold the rim together while the assembly is inflated could result in serious injury or death.

-

In all disassembly of the wheel assembly operations, ensure the tire is totally deflated before removing wheel nuts. Failure to follow proper safety precautions could cause serious injury or death.

-

Never inflate a wheel assembly with the wheel locknuts removed in an attempt to separate inner and outer rim halves. The assembly will separate under pressure, resulting in serious injury or death.

Warning Summary (Cont'D)

-

Never use wheel assemblies with studs which are damaged, loose, or have damaged threads. Damaged studs can cause improper assembly, which could cause individual fasteners to fail. Any of these situations could cause serious injury or death.

-

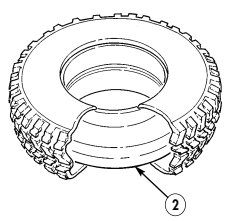

Never use tubes in wheel assemblies. Use of a tube defeats built-in safety features, and could allow the wheel to come apart under pressure, resulting in serious injury or death.

-

Use only replacement parts specified in TM 9-2320-387-24P. Wheels assembled with components which do not meet specifications could cause the assembly to separate under pressure, resulting in serious injury or death.

-

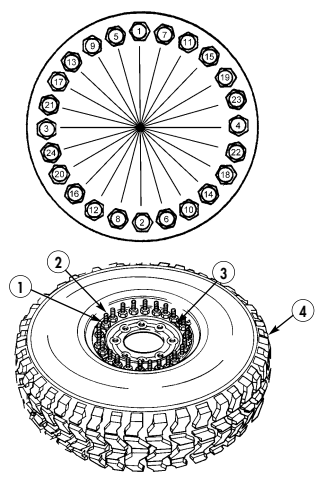

Never inflate a wheel assembly without having checked wheel locknut torques that ensure that wheel locknuts are tightened to specifications. An assembly with improperly tightened locknuts could separate under pressure, resulting in serious injury or death.

-

Always use an OSHA approved tire inflation cage for inflation purposes. Stand on one side of cage during inflation; never directly in front. Keep hands out of the cage during inflation. Inflate assembly to recommended pressure using a clip-on air chuck. Do not exceed 30 psi (207 kPa) cold bias tire inflation pressure or 50 psi (344 kPa) cold radial tire inflation pressure. Failure to follow these instructions may result in serious injury or death.

-

NBC contaminated filters must be handled and disposed of only by authorized and trained personnel.

The unit commander or senior officer in charge of maintenance personnel must ensure that prescribed protective clothing (FM 3-4) is used, and prescribed safety measures and decontamination procedures (FM 3-5) are followed. The local unit SOP is responsible for final disposal of contaminated air filters. Failure to do this may cause severe injury to personnel.

-

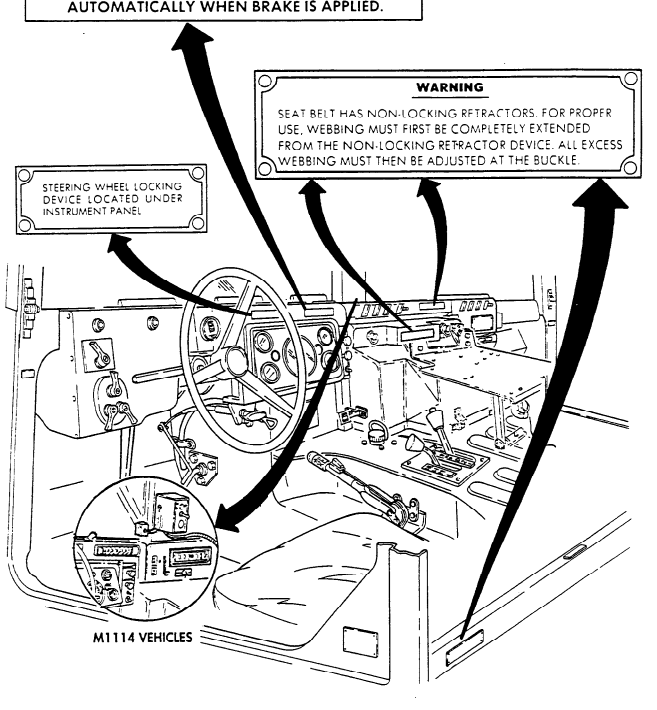

Seatbelts are to be replaced as a set. Failure to do this may cause injury to personnel or damage to equipment.

-

The Department of Transportation requires 105 mm cannon ammunition to be in wooden boxes when transporting ammunition on public highways, by fixed wing aircraft, rail, or ship. Movement of cannon ammunition in fiber containers (inner pack) in the HMMWV ammunition rack is restricted to other than public highways.

-

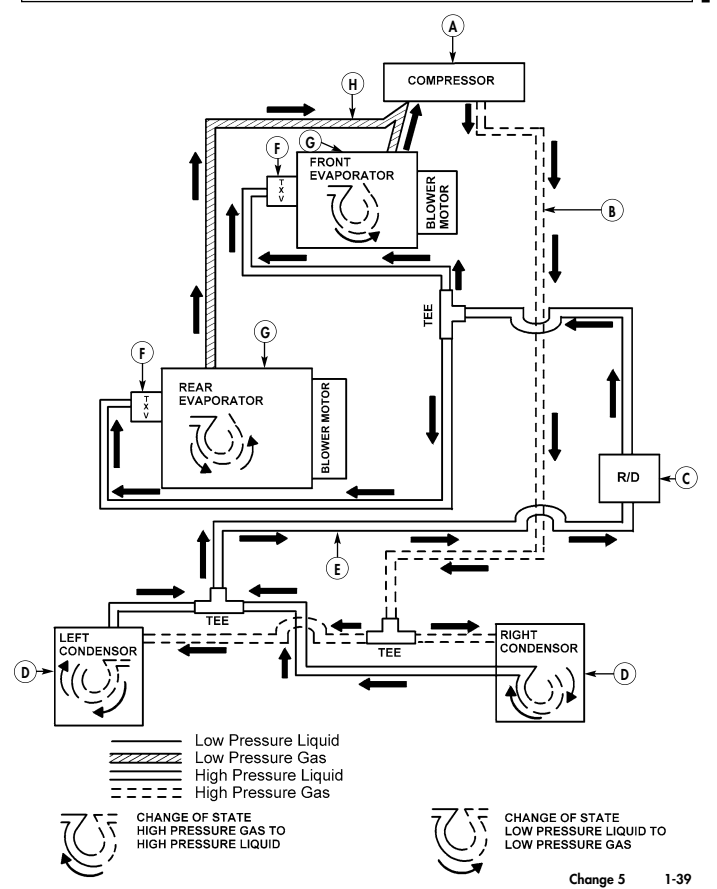

Air-conditioning system must be discharged prior to replacing components. Failure to do this may result in injury to personnel or damage to equipment.

-

Ensure all slack from the three-point seatbelt or Improved Personal Restraint System is removed. The three-point seatbelt and Improved Personal Restraint System will lock only during sudden stops or impact. Injury and/or death to personnel may result if an accident occurs and seatbelts or lap and shoulder straps are not in use or adjusted properly.

-

Protective eye equipment (goggles/shield) must be worn when removing snaprings or springs. Failure to comply may result in injury to personnel.

-

Ensure automatic fire extinguishing system (AFES) anti-recoil device is installed in place of deflector valve.

Failure to do so can result in discharge of liquid and powder agents can cause injury to personnel.

- Vehicle armor is extremely heavy and must be supported during removal and installation. Failure to do so may result in injury to personnel or damage to equipment.

ARMY TM 9-2320-387-24-1 AIR FORCE TO 36A12-1A-3052-2 MARINE CORPS TM 11033-IN VOL 1 CHANGE NO. 6 HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS WASHINGTON, D.C., 30 JUNE 2009 TECHNICAL MANUAL VOLUME 1 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038) (EIC: BEG); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007) (EIC: BEH); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993) (EIC: BEK); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017) (EIC: BEJ); TRUCK, UTILITY: EXPANDED CAPACITY, TOW ITAS, CARRIER, M1167 (2320-01-544-9638).

TM 9-2320-387-24-1, 31 December 1997, is changed as follows:

-

One new model has been added to the front cover. The new cover, located at the end of the change package, replaces the existing cover.

-

Remove old pages and insert new pages as indicated below. 3. New or changed material is indicated by a vertical bar in the margin of the page. 4. File this change sheet in front of the publication for reference purposes.

Remove pages Insert pages A through M/(N blank) A through N i through vi i through vi 1-1 and 1-2/(1-2.1 through 1-2.10 1-1 and 1-2/(1-2.1 through 1-2.10

blank deleted) blank deleted)

DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited.

Marine Corps PCN 184 110331 00

| Remove pages | Insert pages |

|---|---|

| None | 1-4.9/(1-4.10 blank) |

| 1-17 through 1-28 | 1-16.1 through 1-28 |

| 1-33 through 1-36 | 1-33 through 1-36.2 |

| 2-11 through 2-14 | 2-11 through 2-14 |

| 2-17 through 2-20 | 2-17 through 2-20 |

| 2-23 through 2-32 | 2-23 through 2-32 |

| 2-35 through 2-38 | 2-35 through 2-38 |

| 2-159 through 2-189/(2-190 blank) | 2-159 through 2-190.11/(2-190 blank) |

| 2-419 and 2-420 | 2-419 and 2-420 |

| 2-425 through 2-430 | 2-425 through 2-430 |

| 2-433 through 2-452 | 2-433 through 2-452.22 |

| None | 2-488.1 through 2-488.5/(2-488.6 blank) |

| 3-1 and 3-2 | 3-1 and 3-2 |

| 3-5 and 3-6 | 3-4.1 through 3-6 |

| 3-9 through 3-16 | 3-9 through 3-16 |

| 3-21 through 3-24 | 3-21 through 3-24 |

| 3-41 and 3-42 | 3-41 and 3-42 |

| 3-51 through 3-54 | 3-51 through 3-54 |

| 3-63 through 3-66 | 3-63 through 3-66 |

| 3-109 and 3-110 | 3-108.1 through 3-110 |

| 3-112 through 3-120 | 3-112 through 3-120 |

| 3-123 and 3-124 | 3-122.1 through 3-124 |

| 3-127 and 3-128 | 3-126.1 through 3-128 |

| 3-131 through 3-134 | 3-131 through 3-134 |

| 3-137 through 3-142 | 3-137 through 3-142 |

| 3-142.3 through 3-142.8 | 3-142.3 through 3-142.12 |

| 3-169 through 3-191/(3-192 blank) | 3-169 through 3-193/(3-194 blank) |

| 4-29 through 4-34 | 4-29 through 4-34 |

| 4-37 through 4-46 | 4-36.1 through 4-46 |

| 4-50.3/(4-50.4 blank) | 4-50.3 and 4-50.4 |

| 4-69 through 4-72.2 | 4-69 through 4-72.2 |

| 4-107 and 4-108 | 4-107 and 4-108 |

| 4-121 through 4-122 | 4-120.1 through 4-122 |

| 4-133 and 4-134 | 4-132.1 through 4-134 |

| 5-1 and 5-2 | 5-1 and 5-2 |

| 5-5 through 5-12 | 5-5 through 5-12 |

| 5-23 through 5-26 | 5-23 through 5-26 |

| 5-31 and 5-32 | 5-31 and 5-32 |

| 5-35 through 5-40 | 5-34.1 through 5-40 |

| 6-1 through 6-4 | 6-1 through 6-4 |

| 6-11 through 6-14 | 6-11 through 6-14 |

| 6-17 through 6-20 | 6-17 through 6-20 |

| 6-29 through 6-36 | 6-29 through 6-36 |

| 6-39 and 6-40 | 6-38.1 through 6-40 |

| 6-45 through 6-50 | 6-45 through 6-50 |

| 6-61 through 6-64 | 6-61 through 6-64 |

| 7-1 through 7-36 | 7-1 through 7-36.3/(7-36.4 blank) |

| None | 7-59 through7-67/(7-68 blank) |

| 8-1 through 8-16 | 8-1 through 8-16 |

| 8-19 through 8-22/(8-23 blank) | 8-19 through 8-22/(8-23 blank) |

| 8-33 through 8-36 | 8-33 through 8-36 |

| 8-39 through 8-44 | 8-39 through 8-44 |

| Remove pages | Insert pages |

|---|---|

| 8-55 through 8-60 | 8-55 through 8-60 |

| 8-63 through 8-68 | 8-63 through 8-68 |

| 9-1 and 9-2 | 9-1 and 9-2 |

| 9-5 through 9-16 | 9-4.1/(9-4.2 blank) through 9-16 |

| INDEX 1 through | INDEX 1 through |

| INDEX 75/(INDEX 76 blank) | INDEX 83/(INDEX 84 blank) |

| FP-7/(FP-8 blank) | FP-6.1/(FP 6.2 blank) and |

| FP-7/(FP-8 blank) | |

| FP-23/(FP-24 blank) | FP 22.1/(FP-22.2 blank) and |

| FP-23/(FP-24 blank) | |

| FP-25/(FP-26 blank) | FP 24.1/(FP 24.2 blank) and |

| FP-25/(FP-26 blank) | |

| FP-27 (FP-28 blank) | FP-26.1/(FP-26.2 blank) and |

| FP-27/(FP-28 blank) | |

| None | FP-31/(FP-28 blank) |

| Cover | Cover |

By Order of the Secretary of the Army: Official:

JOYCE E. MORROW Administrative Assistant to the Secretary of the Army 0830505 By Order of the Secretary of the Air Force: GEORGE W. CASEY, JR.

General, United States Army Chief of Staff JOHN P. JUMPER General, United States Air Force Chief of Staff Official: GREGORY S. MARTIN General, United States Air Force Commander, Air Force Materiel Command By Order of the Marine Corps: MICHAEL W. EVERLY Program Manager, Motor Transportation (PMM151) Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-1.

Marine Corps PCN 184 110331 00 ARMY TM 9-2320-387-24-1 AIR FORCE TO 36A12-1A-3052-2 MARINE CORPS TM 11033-IN VOL 1 CHANGE NO. 5 HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS WASHINGTON, D.C., 30 NOVEMBER 2007 TECHNICAL MANUAL VOLUME 1 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017).

TM 9-2320-387-24-1, 31 December 1997, is changed as follows:

- Remove old pages and insert new pages as indicated below. 2. New or changed material is indicated by a vertical bar in the margin of the page. 3. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert pages |

|---|---|

| c/(d blank) | c/(d blank) |

| A through I/(J blank) | A through M/(N blank) |

| i and ii | i and ii |

| 1-1 through 1-6 | 1-1 through 1-6 |

| 1-9 through 1-12 | 1-9 through 1-12 |

| 1-19 through 1-24 | 1-19 through 1-24 |

| 1-38.1 through 2-6 | 1-38.1 through 2-6 |

| 2-21 through 2-24 | 2-21 through 2-24 |

| 2-26.1 and 2-26.2 | 2-26.1 and 2-26.2 |

| 2-29 and 2-30 | 2-29 and 2-30 |

| 2-159 and 2-160 | 2-159 and 2-160 |

| 2-447 and 2-448 | 2-447 and 2-448 |

Distribution Statement A: Approved for public release; distribution is unlimited.

| Remove pages | Insert pages |

|---|---|

| 2-455 and 2-456 | 2-455 and 2-456 |

| 3-23 through 3-28 | 3-23 through 3-28 |

| 3-31 through 3-34 | 3-31 through 3-34 |

| 3-49 and 3-50 | 3-49 and 3-50 |

| 3-67 through 3-70 | 3-67 through 3-70 |

| 3-110.1 and 3-110.2/(3-111 blank) | 3-110.1 and 3-110.2/(3-111 blank) |

| 3-119 through 3-122 | 3-119 through 3-122 |

| 3-143 and 3-144 | 3-143 and 3-144 |

| 3-171 and 3-172 | 3-171 and 3-172 |

| 3-189 and 3-190 | 3-189 and 3-190 |

| 4-5 blank through 4-8 | 4-5 blank through 4-8 |

| 4-13 and 4-14 | 4-13 and 4-14 |

| 4-31 through 4-34 | 4-31 through 4-34 |

| 4-47 through 4-50 | 4-47 through 4-50.4 blank |

| 4-65 and 4-66 | 4-65 and 4-66 |

| 4-69 through 4-74 | 4-69 through 4-74 |

| 4-81 and 4-82 | 4-81 and 4-82 |

| 4-101 and 4-102 | 4-101 and 4-102 |

| 4-129 and 4-130 | 4-129 and 4-130 |

| 5-29 and 5-30 | 5-29 and 5-30 |

| 6-19 and 6-20 | 6-19 and 6-20 |

| 6-31 through 6-34 | 6-31 through 6-34 |

| 6-49 through 6-62 | 6-49 through 6-62 |

| 6-65 and 6-66 | 6-65 and 6-66 |

| 8-1 and 8-2 | 8-1 and 8-2 |

| 8-21 through 8-26 | 8-21 through 8-26 |

| 8-29 through 8-32 | 8-29 through 8-32 |

| INDEX 1 through INDEX 67/ | INDEX 1 through INDEX 75/ |

| (INDEX 68 blank) | (INDEX 76 blank) |

By Order of the Secretary of the Army: GEORGE W. CASEY, JR.

General, United States Army Chief of Staff Official:

JOYCE E. MORROW Administrative Assistant to the Secretary of the Army 0721902 By Order of the Secretary of the Air Force: JOHN P. JUMPER General, United States Air Force Chief of Staff Official: GREGORY S. MARTIN General, United States Air Force Commander, Air Force Materiel Command By Order of the Marine Corps: S. I. SCHULER Colonel, USMC Program Manager Motor Transportation (PMM151) Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-1.

PCN 184 110331 00 CHANGE NO. 4 ARMY TM 9-2320-387-24-1 AIR FORCE TO 36A12-1A-3052-2 MARINE CORPS TM 11033-IN VOL 1 HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS Washington, D.C., 28 February 2007 TECHNICAL MANUAL VOLUME 1 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017).

TM 9-2320-387-24-1, December 1997, is changed as follows:

-

Four new models have been added to the front cover. The new cover, located at the end of the change package, replaces the existing cover.

-

Remove old pages and insert new pages as indicated below. 3. New or changed material is indicated by a vertical bar in the margin of the page. 4. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert pages |

|---|---|

| A through I/(J blank) | A through I/(J blank) |

| i and ii | i and ii |

| 1-1 and 1-2 | 1-1 through 1-2.9/(1-2.10 blank) |

| Index 5 and Index 6 | Index 5 and Index 6 |

| Index 11 and Index 12 | Index 11 and Index 12 |

| Index 17 and Index 18 | Index 17 and Index 18 |

| Index 23 and Index 24 | Index 23 and Index 24 |

| Index 29 and Index 30 | Index 29 and Index 30 |

| Index 39 through Index 48 | Index 39 through Index 48 |

| Index 51 through Index 54 | Index 51 through Index 54 |

| Cover | Cover |

Approved for public release; distribution is unlimited.

By Order of the Secretary of the Army: Official:

JOYCE E. MORROW Administrative Assistant to the Secretary of the Army 0703802 By Order of the Secretary of the Air Force: PETER J. SCHOOMAKER General, United States Army Chief of Staff JOHN P. JUMPER General, United States Air Force Chief of Staff Official: GREGORY S. MARTIN General, United States Air Force Commander, Air Force Materiel Command By Order of the Marine Corps: S. I. SCHULER Colonel, USMC Program Manager Motor Transportation (PMM151) Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-1.

PCN 184 110331 00 ARMY TM 9-2320-387-24-1 AIR FORCE TO 36A12-1A-3052-2 MARINE CORPS TM 11033-IN Vol 1 CHANGE NO. 3 HEADQUARTERS, DEPARTMENTS OF THE ARMY, THE AIR FORCE, AND MARINE CORPS Washington, D.C., 31 May 2006 TECHNICAL MANUAL VOLUME 1 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332).

TM 9-2320-387-24-1, December 1997, is changed as follows:

-

Two new models have been added to the front cover. The new cover, located at the end of the change package, replaces the existing cover.

-

Remove old pages and insert new pages as indicated below. 3. New or changed material is indicated by a vertical bar in the margin of the page. 4. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert pages |

|---|---|

| warning a and warning b | warning a and warning b |

| A through I/(J blank) | A through I/(J blank) |

| i and ii | i and ii |

| 1-1 through 1-6 | 1-1 through 1-6 |

| 1-9 and 1-10 | 1-9 and 1-10 |

| 1-17 through 1-24 | 1-17 through 1-24 |

| 1-39 and 1-40 | 1-38.1 through 1-40 |

| 2-7 through 2-26 | 2-7 through 2-26.2 |

| 2-63 through 2-66 | 2-63 through 2-66 |

| 2-159 through 2-162 | 2-159 through 2-162 |

| 2-311 and 2-312 | 2-311 and 2-312 |

| 2-347 and 2-348 | 2-347 and 2-348 |

| 2-443 and 2-444 | 2-443 and 2-444 |

| 2-449 through 2-451/(2-452 blank) | 2-449 through 2-452 |

| 3-31 through 3-36 | 3-31 through 3-36 |

| 3-67 through 3-70 | 3-67 through 3-70 |

| 3-109 through 3-112 | 3-109 through 3-112 |

Approved for public release; distribution is unlimited.

| Remove pages | Insert pages |

|---|---|

| 3-142.7 through 3-144 | 3-142.7 through 3-144 |

| 3-144.3 through 3-146 | 3-144.3 through 3-146 |

| 3-171 and 3-172 | 3-171 and 3-172 |

| 3-189 and 3-190 | 3-189 and 3-190 |

| (4-5 blank) through 4-8 | (4-5 blank) through 4-8 |

| 4-13 and 4-14 | 4-13 and 4-14 |

| 4-31 through 4-34 | 4-31 through 4-34 |

| 4-49 and 4-50 | 4-49 and 4-50 |

| 4-65 and 4-66 | 4-65 and 4-66 |

| 4-69 through 4-76 | 4-69 through 4-76 |

| 4-79 and 4-80 | 4-79 through 4-80.3/(4-80.4 blank) |

| 4-89 and 4-90 | 4-89 and 4-90 |

| 4-101 and 4-102 | 4-101 and 4-102 |

| 4-129 and 4-130 | 4-129 and 4-130 |

| 5-13 through 5-16 | 5-13 through 5-16 |

| 6-11 and 6-12 | 6-11 and 6-12 |

| 6-47 and 6-48 | 6-46.1 through 6-48 |

| 6-59 through 6-62 | 6-59 through 6-62 |

| 6-65 and 6-66 | 6-65 and 6-66 |

| 7-33 through 7-36 | 7-33 through 7-36 |

| 8-25 and 8-26 | 8-25 and 8-26 |

| 8-31 and 8-32 | 8-31 and 8-32 |

| 8-35 and 8-36 | 8-35 and 8-36 |

| 8-55 through 8-58 | 8-55 through 8-58 |

| 9-7 through 9-10 | 9-7 through 9-10 |

| 9-15 and 9-16 | 9-15 and 9-16 |

| INDEX 1 through INDEX 54 | INDEX 1 through INDEX 67/(INDEX 68 blank) |

| Cover | Cover |

By Order of the Secretary of the Army: Official:

JOYCE E. MORROW Administrative Assistant to the Secretary of the Army 0602405 By Order of the Secretary of the Air Force: PETER J. SCHOOMAKER General, United States Army Chief of Staff JOHN P. JUMPER General, United States Air Force Chief of Staff Official: GREGORY S. MARTIN General, United States Air Force Commander, Air Force Materiel Command By Order of the Marine Corps: S. I. SCHULER Colonel, USMC Program Manager Motor Transportation (PMM151) Marine Corps Systems Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-1.

ARMY TM 9-2320-387-24-1 AIR FORCE TO 36A12-1A-3052-1 CHANGE HEADQUARTERS, DEPARTMENTS OF THE ARMY, AND THE AIR FORCE Washington, D.C., 30 July 2004 NO. 2 TECHNICAL MANUAL VOLUME 1 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B) TRUCK, UTILITY: UP - ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C) TM 9-2320-387-24-1, December 1997, is changed as follows:

- Remove old pages and insert new pages as indicated below. 2. New or changed material is indicated by a vertical bar in the margin of the page. 3. File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert page |

|---|---|

| A through D | A through I/(J blank) |

| i and ii | i and ii |

| 1-1 and 1-2 | 1-1 and 1-2 |

| 1-35 and 1-36 | 1-35 and 1-36 |

| 2-1 through 2-6 | 2-1 through 2-6 |

| 2-9 and 2-10 | 2-9 and 2-10 |

| 2-27 and 2-28 | 2-27 and 2-28 |

| 2-47 through 2-49/(2-50 blank) | 2-47 through 2-49/(2-50 blank) |

| 2-111 through 2-114 | 2-111 through 2-114 |

| 2-207 through 2-210 | 2-207 through 2-210 |

| 2-441 through 2-444 | 2-441 through 2-444 |

| 2-451/(2-452 blank) | 2-451/(2-452 blank) |

| 2-455 through 2-460 | 2-455 through 2-460 |

| 2-471 through 2-476 | 2-471 through 2-478.7/(2-478.8 blank) |

| 3-1 through 3-10 | 3-1 through 3-10 |

| 3-21 through 3-24 | 3-21 through 3-24 |

| 3-27 and 3-28 | 3-27 and 3-28 |

| 3-31 through 3-34 | 3-31 through 3-34 |

| 3-39 through 3-70 | 3-39 through 3-70 |

| 3-75 and 3-76 | 3-75 and 3-76 |

Approved for public release; distribution is unlimited.

| Remove pages | Insert pages |

|---|---|

| 3-79 through 3-94 | 3-79 through 3-94 |

| 3-97 through 3-112 | 3-97 through 3-112 |

| 3-117 through 3-120 | 3-117 through 3-120 |

| 3-127 and 3-128 | 3-127 and 3-128 |

| 3-131 through 3-134 | 3-131 through 3-134 |

| 3-137 through 3-146 | 3-137 through 3-191/(3-192 blank) |

| 4-1 through 4-8 | 4-1 through 4-8 |

| 4-11 through 4-14 | 4-11 through 4-14 |

| 4-17 through 4-18.4 | 4-17 through 4-18.4 |

| 4-18.11 through 4-26 | 4-18.11 through 4-26 |

| 4-29 and 4-30 | 4-29 and 4-30 |

| 4-33 and 4-34 | 4-33 and 4-34 |

| 4-37 and 4-38 | 4-37 and 4-38 |

| 4-45 and 4-46 | 4-45 and 4-46 |

| 4-49 and 4-50 | 4-49 and 4-50 |

| 4-55 and 4-56 | 4-55 and 4-56 |

| 4-61 through 4-64 | 4-61 through 4-64 |

| 4-69 through 4-78 | 4-69 through 4-78 |

| 4-83 through 4-100 | 4-83 through 4-100 |

| 4-109 and 4-110 | 4-109 and 4-110 |

| 4-115 through 4-124 | 4-115 through 4-124 |

| 4-129 through 4-134 | 4-129 through 4-134 |

| 4-137 through 4-144 | 4-137 through 4-144 |

| 5-1 through 5-6 | 5-1 through 5-6 |

| 5-11 through 5-18 | 5-11 through 5-18 |

| 5-21 through 5-36 | 5-21 through 5-36 |

| 6-1 and 6-2 | 6-1 and 6-2 |

| 6-5 through 6-10 | 6-5 through 6-10 |

| 6-13 through 6-18 | 6-13 through 6-18 |

| 6-21 and 6-22 | 6-21 and 6-22 |

| 6-27 through 6-30 | 6-27 through 6-30 |

| 6-35 through 6-38 | 6-35 through 6-38 |

| 6-45 through 6-62 | 6-45 through 6-62 |

| 7-3 through 7-6 | 7-3 through 7-6 |

| 7-9 through 7-20 | 7-9 through 7-20 |

| 7-27 through 7-38 | 7-27 through 7-38 |

| 7-41 and 7-42 | 7-41 and 7-42 |

| 7-45 through 7-56 | 7-45 through 7-56 |

| 8-7 and 8-8 | 8-7 and 8-8 |

| 8-13 and 8-14 | 8-13 and 8-14 |

| 8-17 and 8-18 | 8-17 and 8-18 |

| Remove pages | Insert pages |

|---|---|

| 8-21 and 8-22 | 8-21 and 8-22 |

| 8-33 through 8-56 | 8-33 through 8-56 |

| 8-59 through 8-76 | 8-59 through 8-83/(8-84 blank) |

| 9-1 through 9-12 | 9-1 through 9-12 |

| 9-15 and 9-16 | 9-15 and 9-16 |

| INDEX 1 through INDEX 53/ (INDEX 54 Blank) | INDEX 1 through INDEX 54 |

By Order of the Secretary of the Army: PETER J. SCHOOMAKER General, United States Army Chief of Staff Official: JOEL B. HUDSON Administrative Assistant to the Secretary of the Army By Order of the Secretary of the Air Force: RONALD R. FOGLEMAN General, United States Air Force Chief of Staff Official: HENRY VICCELLIO, JR.

General, United States Air Force Commander, Air Force Materiel Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-1.

CHANGE NO. 1 HEADQUARTERS, DEPARTMENTS OF THE ARMY, AND THE AIR FORCE Washington, D.C., 31 OCTOBER 2001 TECHNICAL MANUAL VOLUME 1 OF 2 UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B) TRUCK, UTILITY: UP - ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C) TM 9-2320-387-24-1, December 1997, is changed as follows:

-

Remove old pages and insert new pages as indicated below. 2. New or changed material is indicated by a vertical bar in the margin of the page.

-

File this change sheet in front of the publication for reference purposes.

| Remove pages | Insert page |

|---|---|

| Warning c/(d blank) | Warning c/(d blank) |

| None | A through D (after warning d blank) |

| i through iv | i through iv |

| 1-1 and 1-2 | 1-1 and 1-2 |

| 1-21 and 1-22 | 1-21 and 1-22 |

| 1-33 and 1-34 | 1-33 and 1-34 |

| 1-39 and 1-40 | 1-39 and 1-40 |

| 2-5 through 2-10 | 2-5 through 2-10 |

| 2-13 and 2-14 | 2-13 and 2-14 |

| 2-19 and 2-20 | 2-19 and 2-20 |

| 2-23 through 2-28 | 2-23 through 2-28 |

| 2-97 and 2-98 | 2-97 and 2-98 |

| 2-199 through 2-202 | 2-199 through 2-202 |

| 2-207 through 2-210 | 2-207 through 2-210 |

| None | 2-210.1 through 2-210.4 |

| 2-211/(2-212 blank) | 2-211/(2-212 blank) |

| 2-385 and 2-386 | 2-385 and 2-386 |

| 2-407 and 2-408 | 2-407 and 2-408 |

| 2-419 and 2-420 | 2-419 and 2-420 |

| 2-441 through 2-444 | 2-441 through 2-444 |

| 2-449 and 2-450 | 2-449 and 2-450 |

| 3-11 through 3-16 | 3-11 through 3-16 |

| 3-21 through 3-38 | 3-21 through 3-38 |

| 3-55 through 3-60 | 3-55 through 3-60 |

Approved for public release; distribution is unlimited.

| Remove pages | Insert pages |

|---|---|

| 3-81 through 3-94 | 3-81 through 3-94 |

| 3-109 through 3-130 | 3-109 through 3-130 |

| 3-133 and 3-134 | 3-133 and 3-134 |

| 3-141 and 3-142 | 3-141 and 3-142 |

| None | 3-142.1 and 3-142.2 |

| 3-143 through 3-146 | 3-143 through 3-146 |

| 4-1 through 4-18 | 4-1 through 4-18 |

| None | 4-18.1 through 4-18.12 |

| 4-19 through 4-24 | 4-19 through 4-24 |

| 4-65 and 4-66 | 4-65 and 4-66 |

| 4-73 through 4-76 | 4-73 through 4-76 |

| 4-79/(4-80 blank) | 4-79 and 4-80 |

| 4-99 through 4-102 | 4-99 through 4-102 |

| 4-109 and 4-110 | 4-109 and 4-110 |

| 5-7 through 5-12 | 5-7 through 5-12 |

| 5-23 and 5-24 | 5-23 and 5-24 |

| 5-27 through 5-30 | 5-27 through 5-30 |

| 6-13 through 6-26 | 6-13 through 6-26 |

| 6-29 through 6-38 | 6-29 through 6-38 |

| 6-51 and 6-52 | 6-51 and 6-52 |

| None | 6-52.1 and 6-52.2 |

| 6-53 and 6-54 | 6-53 and 6-54 |

| 7-1 and 7-2 | 7-1 and 7-2 |

| 7-5 through 7-22 | 7-5 through 7-22 |

| 7-25 through 7-46 | 7-25 through 7-46 |

| 8-11 and 8-12 | 8-11 and 8-12 |

| 8-15 and 8-16 | 8-15 and 8-16 |

| 8-23 through 8-34 | 8-23 through 8-34 |

| 8-63 and 8-64 | 8-63 and 8-64 |

| 8-69 and 8-70 | 8-69 and 8-70 |

| 8-73 and 8-74 | 8-73 and 8-74 |

| INDEX 1 through | INDEX 1 through |

| INDEX 45/(INDEX 46 blank) | INDEX 53/(INDEX 54 blank) |

| DA Form 2028-2 | DA Form 2028 |

By Order of the Secretary of the Army: ERIC K. SHINSEKI General, United States Army Chief of Staff Official: JOEL B. HUDSON Administrative Assistant to the Secretary of the Army 0119703 By Order of the Secretary of the Air Force: RONALD R. FOGLEMAN General, United States Air Force Chief of Staff Official: HENRY VICCELLIO, JR.

General, United States Air Force Commander, Air Force Materiel Command Distribution: To be distributed in accordance with the initial distribution number (IDN) 381020, requirements for TM 9-2320-387-24-1.

TM 9-2320-387-24-1

List Of Effective Pages

NOTE: The portion of the text affected by the changes is indicated by a vertical line in the outer margins of the page.

| Dates of issue for original and changed pages of volume 1 are: |

|---|

| Original . |

| Change |

| Change 2 30 July 2004 |

| Change |

| Change |

| Change |

| Change |

| TOTAL WOMBER OF THOLO IN THIO POREVELLION TO THE POWORTING OF THE TOLLOWING. | ||

|---|---|---|

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

| VOLUME 1 | 1-28 - 1-32 | 2-68 Blank |

| a. | 1-33 - 1-36 | 2-69 - 2-73 |

| b | 1-36.1 - 1-36.2 Added | 2-74 Blank . |

| C | 1-37 - 1-38 | 2-75 - 2-97 |

| d Blank | 1-38.1 - 1-38.4 | 2-98 . |

| A - N | 1-39 - 1-40 | 2-99 - 2-111 |

| 1 | 2-1 | 2-112 |

| 11-111 . | 2-2 - 2-3 | 2-112.1 - 2-112.2 Added |

| İV -Vİ . | 2-4 | 2-113 |

| vii-xiii . | 2-5 | 2-114 - 2-139 |

| xiv Blank | 2-6 | 2-140 Blank |

| 1-1 | 2-7 - 2-11 . | 2-141 - 2-145 |

| 1-2 | 2-12 - 2-14 | 2-146 Blank |

| 1-2.1 - 1-2.9 Deleted | 2-15 - 2-16 | 2-147 - 2-157 |

| 1-2.10 - Blank Deleted . | 2-17 - 2-19 | 2-158 Blank |

| 1-3 - 1-4 | 2-20 - 2-21 | 2-159 - 2-189 |

| 1-4.1 - 1-4.4 | 2-22 - 2-23 | 2-190 Blank |

| 1-4.5 - 1-4.8 Added | 2-24 . | 2-190.1 - 2-190.11 Added . |

| 1-4.9 Added. | 2-25 . | 2-190.12 Added Blank . |

| 1-4.10 Blank Added . | 2-26 . | 2-191 - 2-197 |

| 1-5 - 1-6 | 2-26.1 - 2-26.2 | 2-198 Blank. |

| 1-7 - 1-9 | 2-27 - 2-31 | 2-199 |

| 1-10 . | 2-32 - 2-34 | 2-200 |

| 1-11 . | 2-35 - 2-37 | 2-201 - 2-202 |

| 1-12 . | 2-38 - 2-47 | 2-203 - 2-207 |

| 1-13 - 1-16 | 2-48 . | 2-208 |

| 1-16.1-1-16.2 Added | 2-48.1 - 2-48.2 Added | 2-208.1 - 2-208.2 Added |

| 1-17 . | 2-49 . | 2-209 - 2-210 |

| 1-18 . | 2-50 Blank . | 2-210.1 - 2-210.4 Added |

| 1-19 - 1-23 | 2-51 - 2-58 | 2-211 |

| 1-24 - 1-25 | 2-60 Blank | 2-212 Blank |

| 1-26 . | 2-61 - 2-62 | 2-213 - 2-235 |

| 1-26.1 - 1-26.2 Added | 2-63 - 2-66 | 2-236 Blank. |

| 1-27 . | 2-67 . | 2-237 - 2-245 |

TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS 1,704 CONSISTING OF THE FOLLOWING: *Zero in this column indicates original page.

TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No. . | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 2-246 Blank. | 2-473 Blank. | 3-50 . |

| 2-247 - 2-287 | 2-474 - 2-475 | 3-51 - 3-53 |

| 2-288 Blank | 2-476 | 3-54 - 3-56 |

| 2-289 - 2-303 | 2-477 | 3-57 . |

| 2-304 Blank | 2-478 Blank | 3-58 - 3-60 |

| 2-305 - 2-310 | 2-478.1 - 2-478.8 Blank Added | 3-60.1 - 3-60.2 Added |

| 2-311 | 2-479 - 2-487 | 3-61 - 3-63 |

| 2-312 - 2-346 | 2-488 Blank | 3-64 . |

| 2-347 | 2-488.1 - 2-488.5 Added | 3-64.1 - 3-64.2 Added |

| 2-348 | 2-488.6 Added Blank | 3-65 . |

| 2-349 - 2-373 | 2-489 - 2-522 | 3 -66 - 3-67 . |

| 2-374 Blank | 3-1 | 3-68 - 3-69 |

| 2-375 - 2-383 | 3-2 | 3-70 . |

| 2-384 Blank | 3-3 | 3-71 - 3-75 |

| 2-385 | 3-4 | 3-76 . |

| 2-386 - 2-407 | 3-4.1 - 3-4.2 Added | 3-77 - 3-78 |

| 2-408 | 3-5 - 3-6 | 3-79 - 3-80 |

| 2-409 - 2-417 | 3-7 | 3-81 . |

| 2-418 Blank | 3-8 - 3-9 | 3-82 . |

| 2-419 | 3-10 . | 3-83 . |

| 2-420 - 2-424 | 3-10.1 - 3-10.2 Added | 3-84 . |

| 2-425 | 3-11 - 3-14 | 3-85 . |

| 2-426 | 3-14.1 - 3-14.2 Added | 3-86 . |

| 2-427 - 2-429 | 3-15 . | 3-87 . |

| 2-430 - 2-431 | 3-16 . | 3-88 - 3-90 |

| 2-432 Blank. | 3-17 - 3-20 | 3-91 . |

| 2-433 - 2-442 | 3-21 . | 3-92 . |

| 2-442.1 - 2-442.2 | 3-22 . | 3-93 . |

| 2-443 - 2-450 | 3-23 . | 3-94 . |

| 2-451 | 3-24 . | 3-95 - 3-97 |

| 2-452 | 3-25 - 3-27 | 3-98 - 3-100 . |

| 2-452.1 - 2-452.12 Added . | 3-28 . | 3-101 |

| 2-452.13 Added Blank . | 3-29 - 3-30 | 3-102 |

| 2-452.14 - 2-452.22 Added | 3-31 . | 3-103 |

| 2-445 - 2-446 | 3-32 . | 3-104 |

| 2-447 | 3-33 . | 3-105 |

| 2-448 - 2-449 | 3-34 . | 3-106 - 3-107 |

| 2-450 - 2-452 | 3-35 . | 3-108 Blank |

| 2-453 - 2-454 | 3-36 - 3-38 | 3-108.1 - 3-108.2 Added. |

| 2-455 | 3-39 . | 3-109 Blank |

| 2-456 - 2-459 | 3-40 - 3-41 | 3-110 |

| 2-460 - 2-469 | 3-42 . | 3-110.1 |

| 2-470 Blank | 3-43 . | 3-110.2 Added |

| 2-471 | 3-44 - 3-45 | 3-111 Blank |

| 2-472 | 3-46 - 3-49 | 3-112 - 3-116 |

*Zero in this column indicates original page.

Change 6 B TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 3-116.1 - 3-116.12 Added . | 4-1 - 4-2 | 4-50.1 - 4-50.2 Added |

| 3-117 | 4-2.1 - 4-2.4 Added | 4-50.3 - 4-50.4 |

| 3-118 | 4-3 - 4-4 | 4-51 - 4-55 |

| 3-118.1 - 3-118.2 Added | 4-5 Blank | 4-56 . |

| 3-119 | 4-6 - 4-7 | 4-57 - 4-60 |

| 3-120 - 3-122 | 4-8 | 4-61 - 4-64 |

| 3-122.1 - 3-122.2 Added. | 4-9 - 4-11 . | 4-65 . |

| 3-123 | 4-12 - 4-13 | 4-66 - 4-68 |

| 3-124 - 3-126 | 4-14 . | 4-69 - 4-70 |

| 3-126.1 - 3-126.2 Added | 4-15 - 4-17 | 4-70.1 . |

| 3-127 | 4-18 . | 4-70.2 . |

| 3-128 - 3-130 | 4-18.1 . | 4-71 . |

| 3-131 | 4-18.2 . | 4-72 . |

| 3-132 | 4-18.3 . | 4-72.1. |

| 3-132.1 Added Blank | 4-18.4 . | 4-72.2 . |

| 3-132.2 - 3-132.3 Added | 4-18.5 - 4-18.11 . | 4-73 . |

| 3-132.4 Added Blank | 4-18.12 | 4-74 . |

| 3-133 | 4-19 - 4-20 | 4-74.1 - 4-74.2 Added |

| 3-134 | 4-21 . | 4-75 - 4-76 |

| 3-135 - 3-136 | 4-22 . | 4-77 . |

| 3-137 - 3-138 | 4-23 . | 4-78 . |

| 3-138.1 - 3-138.2 Added. | 4-24 . | 4-79 . |

| 3-139 - 3-140 | 4-25 . | 4-80 . |

| 3-140.1 - 3-140.6 Added. | 4-26 . | 4-80.1 - 4-80.3 Added |

| 3-141 | 4-27 . | 4-80.4 Blank Added . |

| 3-142 | 4-28 Blank . | 4-81 . |

| 3-142.1 - 3-142.3 | 4-29 . | 4-82 - 4-83 |

| 3-142.4 - 3-142.8 | 4-30 . | 4-84 - 4-86 |

| 3-142.9 - 3-142.12 Added | 4-30.1 - 4-30.2 Added | 4-87 . |

| 3-143 | 4-31 - 4-33 | 4-88 - 4-89 |

| 3-144 | 4-34 . | 4-90 . |

| 3-144.1 - 3-144.3 Added | 4-35 - 4-36 | 4-91 . |

| 3-144.4 | 4-36.1 - 4-36.2 Added | 4-92 - 4-94 |

| 3-145 | 4-37 . | 4-95 . |

| 3-146 | 4-38 . | 4-96 . |

| 3-147 - 3-169 Added. | 4-38.1 - 4-38.6 Added. | 4-97 . |

| 3-170 - 3-192 | 4-39 . | 4-98 - 4-100 . |

| 3-193 Added. | 4-40 . | 4-101 |

| 3-194 Added Blank | 4-41 - 4-43 | 4-102 |

| 3-171 | 4-44 . | 4-103 - 4-106 |

| 3-172 | 4-45 . | 4-107 |

| 3-173 - 3-188 Added | 4-46 - 4-47 | 4-108 - 4-109 |

| 3-189 | 4-48 . | 4-110 |

| 3-190 - 3-191 Added | 4-49 Blank | 4-111 - 4-115 |

| 3-192 Blank Added | 4-50 . | 4-116 |

*Zero in this column indicates original page.

TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No. . | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 4-117 | 5-32 . | 6-47 . |

| 4-118 - 4-120 | 5-33 . | 6-48 . |

| 4-120.1 - 4-120.10 Added . | 5-34 . | 6-48.1 Added . |

| 4-121 | 5-34.1 - 5-34.4 Added | 6-48.2 Blank Added . |

| 4-122 | 5-35 . | 6-49 . |

| 4-123 | 5-36- 5-38 . | 6-50 . |

| 4-124 | 5-38.1 Blank Added . | 6-51 - 6-52 |

| 4-125 - 4-129 | 5-38.2 - 5-38.3 Added | 6-52.1 . |

| 4-130 | 5-38.4 Blank Added . | 6-52.2 . |

| 4-131 | 5-39 - 5-40 | 6-53 . |

| 4-132 | 6-1 | 6-54 . |

| 4-132.1 - 4-132.2 Added | 6-2 | 6-55 . |

| 4-133 | 6-3 | 6-56 - 6-62 |

| 4-134 | 6-4 | 6-63 - 6-65 |

| 4-135 - 4-137 | 6-5 | 6-66 . |

| 4-138 | 6-6 | 7-1 - 7-4 |

| 4-139 | 6-7 | 7-4.1 - 7-4.4 Added. |

| 4-140 - 4-144 | 6-8 | 7-5 - 7-8 |

| 4-145 - 4-148 | 6-9 | 7-8.1 - 7-8.2 Added. |

| 5-1 | 6-10 . | 7-9 - 12 |

| 5-2 | 6-11 . | 7-12.1 - 7-12.2 Added. |

| 5-3 | 6-12 - 6-14 | 7-13 - 7-14 |

| 5-4 | 6-15 . | 7-14.1 - 7-14.2 Added. |

| 5-5 | 6-16 - 6-17 | 7-15 - 7-26 |

| 5-6 - 5-10 . | 6-18 - 6-19 | 7-26.1 - 7-26.10 . |

| 5-10.1 - 5-10.4 Added | 6-19 . | 7-27 . |

| 5-7 - 5-10 . | 6-20 . | 7-28 . |

| 5-11 . | 6-21 . | 7-29 . |

| 5-12 . | 6-22 . | 7-30 . |

| 5-13 . | 6-23 . | 7-31 . |

| 5-14 - 5-15 | 6-24 - 6-25 | 7-32 . |

| 5-16 - 5-17 | 6-26 - 6-27 | 7-33 - 7-34 |

| 5-18 . | 6-28 . | 7-34.1 - 7-34.2 |

| 5-19 - 5-21 | 6-29 . | 7-34.3 - 7-34.6 Added. |

| 5-22 . | 6-30 - 6-33 | 7-35 - 7-36 |

| 5-23 . | 6-34 . | 7-36.1 Blank Added . |

| 5-24 . | 6-35 - 6-36 | 7-36.2 - 7-36.3 Added. |

| 5-24.1 - 5-24.2 Added. | 6-37 . | 7-36.4 Blank Added . |

| 5-25 . | 6-38 . | 7-37 . |

| 5-26 . | 6-38.1 - 6-38.4 Added | 7-38 . |

| 5-27 . | 6-39 Blank . | 7-39 - 7-41 |

| 5-28 . | 6-40 - 6-45 | 7-42 . |

| 5-29 . | 6-46 . | 7-43 - 7-45 |

| 5-30 . | 6-46.1 . | 7-46 - 7-54 |

| 5-31 . | 6-46.2 Added . |

*Zero in this column indicates original page.

Change 6 D TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No. . | Page No. . | Page No. . |

|---|---|---|

| 7-55 . | 8-54 . | FP-3 . |

| 7-56 . | 8-55 . | FP-4 Blank . |

| 7-57 . | 8-56 . | FP-5 . |

| 7-58 Blank . | 8-56.1 - 8-56.2 | FP-6 Blank . |

| 7-59 - 7-67 Added | 8-57 - 8-58 | FP-6.1 Added . |

| 7-68 Blank Added . | 8-58.1 - 8-58.6 Added | FP-6.2 Blank Added . |

| 8-1 - 8-4 | 8-59 . | FP-7 . |

| 8-4.1 - 8-4.4 Added | 8-60 . | FP-8 Blank . |

| 8-5 | 8-61 . | FP-9 . |

| 8-6 - 8-7 | 8-62 . | FP-10 Blank |

| 8-8 - 8-14 . | 8-63 . | FP-11 |

| 8-14.1 - 8-14.2 Added | 8-64 . | FP-12 Blank |

| 8-14.3 Blank Added . | 8-64.1 - 8-64.4 | FP-13 |

| 8-14.4 - 8-14.12 Added . | 8-65 . | FP-14 Blank |

| 8-15 - 8-16 | 8-66 . | FP-15 |

| 8-14.3 Blank Added . | 8-66.1 - 8-66.4 | FP-16 Blank |

| 8-14.4 - 8-14.22 Added . | 8-66.5 - 8-66.14 Added | FP-17 |

| 8-14.23 Blank Added | 8-67 . | FP-18 Blank |

| 8-14.24 - 8-14.30 Added | 8-68 - 8-72 | FP-19 |

| 8-17 - 8-18 | 8-72.1 - 8-72.2 Added. | FP-20 Blank |

| 8-19 - 8-20 | 8-73 . | FP-21 |

| 8-20.1 - 8-20.12 Added . | 8-74 Blank | FP-22 Blank |

| 8-21 . | 8-74.1 - 8-74.2 Added | FP-22.1 Added |

| 8-22 . | 8-75 - 8-76 | FP-22.2 Blank Added |

| 8-23 Blank . | 8-77 - 8-83 Added. | FP-23 |

| 8-24 - 8-25 | 8-84 Blank Added . | FP-24 Blank |

| 8-26 . | 9-1 - 9-2 | FP 24.1 Added. |

| 8-27 . | 9-3 - 9-4 | FP 24.2 Blank Added |

| 8-28 - 8-29 . | 9-4.1 Added | FP-25 |

| 8-30 - 8-31 | 9-4.2 Blank Added | FP-26 Blank |

| 8-32 . | 9-5 - 9-6 | FP 26.1 Added |

| 8-33 . | 9-7 | FP 26.2 Blank Added |

| 8-34 . | 9-8- 9-9 . | FP-27 |

| 8-34.1 Blank Added . | 9-10 . | FP-28 Blank |

| 8-34.2 - 8-34.3 Added. | 9-11 - 9-14 | FP-29 |

| 8-34.4 Blank Added . | 9-14.1 - 9-14.4 Added | FP-30 Blank |

| 8-35 . | 9-15 . | FP-31 Added |

| 8-36 - 8-37 | 9-16 . | FP-32 Blank Added. |

| 8-38 - 8-39 | 9-17 . | |

| 8-40 - 8-43 | 9-18 Blank . | VOLUME 2 |

| 8-44 . | Index 1 through Index 68 . | |

| 8-45 . | Index 69 - Index 76. | а. |

| 8-46 - 8-50 | Index 77 - Index 83 | b. |

| 8-51 . | Index 84 Blank Added . | A - I |

| 8-52 . | FP-1 . | J Blank Added |

| 8-53 | FP-2 Blank . | 1 - 111. |

*Zero in this column indicates original page.

TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No. . | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 10-3 - 10-4 | 10-53 | 10-91 |

| 10-5 . | 10-54 - 10-56 | 10-92 - 10-95 |

| 10-6 - 10-7 | 10-56.1 - 10-56.2 | 10-93 - 10-94 |

| 10-8 . | 10-56.3 - 10-56.6 | 10-94.1 - 10.94.2. |

| 10-9 . | 10-56.7 - 10-56.8 Added | 10-95 |

| 10-10 | 10-57 - 10-58 | 10-96 Blank. |

| 10-11 | 10-58.1 | 10-96.1 |

| 10-12 | 10-58.2 Blank Added | 10-96.2 |

| 10-13 | 10-59 | 10-97 |

| 10-14 | 10-60 | 10-98 |

| 10-15 - 10-17 | 10-61 - 10-62 | 10-98.1 |

| 10-18 | 10-63 - 10-64 | 10-98.2 |

| 10-18.1 | 10-65 | 10.98.3. |

| 10-18.2 Blank. | 10-66 | 10-98.4 |

| 10-19 | 10-67 Blank | 10-98.5 |

| 10-20 | 10-68 | 10-98.6 |

| 10-21 - 10-22 | 10-68.1 Added | 10-98.7 |

| 10-23 - 10-25 | 10-68.2 Blank Added | 10-98.8 - 10-98.11 . |

| 10-26 | 10-69 - 10-71 | 10-98.12 Blank . |

| 10-27 - 10-28 | 10-72 | 10-98.13 - 10-98.14 |

| 10-29 | 10-73 - 10-75 | 10-98.15 - 10-98.16 |

| 10-30 - 10-32 | 10-76 | 10-98.17 - 10 -98.18 Added . |

| 10-32.1 - 10-32.2 | 10-76.1 | 10-98.19 - 10-98.20 |

| 10-33 Blank | 10-76.2 | 10-98.21 - 10-98.22 Added |

| 10-34 - 10-35 | 10-76.3 Blank Added | 10-99 - 10-100 . |

| 10-36 - 10-37 | 10-76.4 | 10-101 - 10-102 |

| 10-38 | 10-77 | 10-103 - 10-104 |

| 10-38.1 - 10-38.2 | 10-78 - 10-81 | 10-105 . |

| 10-39 - 10-40 | 10-82 | 10-106 . |

| 10-40.1 - 10-40.6 Added | 10-82.1 | 10-107 . |

| 10-41 - 10-42 | 10-82.2 - 10-82.7 Added | 10-108 - 10-110 |

| 10-42.1 - 10-42.2 | 10-82.8 - 10-82.9 | 10-111 . |

| 10-43 - 10-44 | 10-82.10 - 10-82.11 Added | 10-112 - 10-113 |

| 10-44.1 - 10-44.6 Added | 10-82.12 - 10-82.13 | 10-114 . |

| 10-45 | 10-82.14 - 10-82.18 | 10-115 . |

| 10-46 | Added | 10-116 - 10-119. |

| 10-47 | 10-83 - 10-84 | 10-120 . |

| 10-48 | 10-85 | 10-121 . |

| 10-48.1 Blank Added | 10-86 | 10-122 - 10-125 |

| 10-48.2 - 10-48.3 | 10-87 | 10-126 . |

| 10-48.4 Blank Added | 10-88 | 10-127 . |

| 10-49 | 10-88.1 - 10-88.2 | 10-128 . |

| 10-50 - 10-51 | 10-89 Blank | 10-128.1 Blank Added . |

| 10-52 | 10-90 | 10-128.2 - 10-128.13 Added |

*Zero in this column indicates original page.

Change 6 F TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 10-128.14 | 11-9 . | 11-56 |

| 10-128.15 Added Blank | 11-10 | 11-57 |

| 10-128.16 - 10-128.17 Added . | 11-11 | 11-58 - 11-66 |

| 10-128.18 Blank Added | 11-12 | 11-67 - 11-68 |

| 10-129 - 10-132 | 11-12.1 - 11-12.3 Added | 11-68.1 |

| 10-133 - 10-137 | 11-12.4 Blank Added | 11-68.2 |

| 10-138 . | 11-13 - 11-16 | 11-68.3 - 11.68.5 |

| 10-139 . | 11-17 | 11-68.6 |

| 10-140 . | 11-18 | 11-68.7 |

| 10-141 . | 11-19 | 11-68.8 |

| 10-142 . | 11-20 | 11-68.9 - 11-68.10 |

| 10-143 . | 11-21 | 11-69 |

| 10-144 . | 11-22 | 11-70 - 11-73 |

| 10-145 . | 11-23 | 11-74 - 11-77 Deleted |

| 10-146 - 10-150 | 11-24 | 11-78 - 11-82 |

| 10-150.1 Blank Added . | 11-24.1 - 11-24.2 Added | 11-82.1 |

| 10-150.2 - 10-150.7 Added | 11-24.3 - 11-24.23 Added . | 11-82.2 |

| 10-150.8 Blank Added . | 11-24.24 Blank Added . | 11-83 |

| 10-151 - 10-154 | 11-25 | 11-84 |

| 10-154.1 . | 11-26 | 11-84.1 - 11-84.6 Deleted |

| 10-154.2 . | 11-27 - 11-29 | 11-85 |

| 10-154.1 - 10-154.4 Added | 11-30 - 11-31 | 11-86 - 11-89 |

| 10-155 . | 11-32 - 11-36 | 11-90 |

| 10-156 . | 11-37 | 11-90.1 |

| 10-156.1 - 10-156.2 Added | 11-38 | 11-90.2 |

| 10-157 . | 11-39 | 11-91 Blank |

| 10-158 . | 11-40 | 11-92 - 11-95 |

| 10-158.1 Added . | 11-40.1 | 11-96 - 11-97. |

| 10-158.2 Blank Added . | 11-40.2 Blank Added | 11-98 - 11-99 |

| 10-159 . | 11-41 | 11-100 - 11-101 |

| 10-160 . | 11-42 | 11-102 - 11-103 |

| 10-161 Blank Added . | 11-43 - 11-44 | 11-104 - 11-105 |

| 10-162 - 10-165 Added | 11-45 | 11-106 - 11-107 |

| 10-166 Blank Added . | 11-46 | 11-108 . |

| 11-1 . | 11-46.1 | 11-108.1 - 11-108.7 Added . |

| 11-2 . | 11-46.2 | 11-108.8 Blank Added . |

| 11-2.1 - 11-2.2 Added | 11-46.3 Blank Added | 11-109 . |

| 11-3 Blank . | 11-46.4 | 11-110 . |

| 11-4 . | 11-47 | 11-110.1 - 11-110.2 Added |

| 11-4.1 . | 11-48 - 11-51 | 11-111 - 11-112 |

| 11-4.2 . | 11-52 | 11-112.1 - 11-112.2 Added . |

| 11-5 . | 11-52.1 | 11-113 . |

| 11-6 . | 11-52.2 | 11-114 . |

| 11-7 - 11-8. | 11-53 - 11-55 | 11-115 . |

*Zero in this column indicates original page.

TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No. . | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 11-116 . | 11-189 . | 11-221 - 11-222. |

| 11-117 - 11-120 | 11-190 . | 11-222.1 Added . |

| 11-120.1 - 11-120.2 Added | 11-191 . | 11-222.2 . |

| 11-121 . | 11-192 - 11-193 | 11-223 - 11-224. |

| 11-122 - 11-123 | 11-194 . | 11-224.1 Added |

| 11-124 - 11-125 | 11-195 . | 11-224.2 . |

| 11-126 - 11-127. | 11-196 . | 11-225 - 11-226 |

| 11-128 . | 11-197 . | 11-226.1 Added |

| 11-129 . | 11-198 . | 11-226.2 . |

| 11-130 . | 11-199 . | 11-227 - 11-228. |

| 11-130.1 Blank Added . | 11-200 | 11-228.1 Added |

| 11-130.2 - 11-130.3 | 11-201 . | 11-228.2 . |

| 11-130.4 . | 11-202 . | 11-229 . |

| 11-130.5 - 11-130.6 | 11-202.1 Added . | 11-230 . |

| 11-131 Blank . | 11-202.2 . | 11-230.1 Added . |

| 11-132 . | 11-202.3 Blank Added . | 11-230.2 . |

| 11-132.1 - 11-132.6 Added | 11-202.4 - 11-202.5 Added | 11-231 . |

| 11-132.7 - 11-132.13 . | 11-202.6 Blank Added . | 11-232 . |

| 11-132.14 Blank Added | 11-203 . | 11-232.1 Added |

| 11-133 - 11-138 | 11-204 . | 11-232.2 . |

| 11-233 . | ||

| 11-139 . | 11-205 Blank . | 11-234 . |

| 11-140 . | 11-206 - 11-208 | |

| 11-141 . | 11-208.1 Added . | 11-234.1 Added |

| 11-142 - 145 . | 11-208.2 . | 11-234.2 . |

| 11-146 . | 11-208.3 - 11-208.4 Added | 11-235 - 11-236. |

| 11-147 . | 11-209 . | 11-236.1 Added |

| 11-148 - 11-151 | 11-210 . | 11-236.2 . |

| 11-152 . | 11-210.1 Added . | 11-237 . |

| 11-153 - 11-155 | 11-210.2 Added . | 11-238 . |

| 11-238.1 Added | ||

| 11-156 - 11-157 | 11-211 . | 11-238.2 Blank Added . |

| 11-158 . | 11-212 . | |

| 11-159 - 11-161 | 11-213 . | 11-239 - 11-343 Added |

| 11-162 Blank . | 11-214 . | 11-344 Blank Added . |

| 11-214.1 Added . | 11-345 - 11-413 Added | |

| 11-163 - 11-164 | 11-414 Blank Added . | |

| 11-165 . | 11-214.2 . | 11-415 - 11-430 Added |

| 11-166 . | 11-215 - 11-216 | |

| 11-167 . | 11-216.1 Added . | 11-431 Blank Added . |

| 11-432 - 11-463 Added | ||

| 11-168 - 11-170. | 11-216.2 . | 11-464 Blank Added . |

| 11-171 - 11-183 | 11-217 . | 12-1 . |

| 11-184 . | 11-218 . | 12-2 . |

| 11-185 . | 11-219 . | 12-2.1 . |

| 11-186 . | 11-220 . | 12-2.2 . |

| 11-187 . | 11-220.1 Added . | |

| 12-3 - 12-9 | ||

| 11-188 . | 11-220.2 . | 12-10 |

*Zero in this column indicates original page.

Change 6 H TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No. . | ||

|---|---|---|

| 12-11 | 12-60.5 | 12-143 - 12-145 |

| 12-12 | 12-60.6 | 12-146 . |

| 12-13 - 12-17 | 12-61 | 12-147 . |

| 12-18 | 12-62 | 12-148 . |

| 12-19 - 12-21 | 12-62.1 - 12.62.8 | 12-149 . |

| 12-22 - 12-23 | 12-62.9 - 12-62.17 Added . | 12-150 . |

| 12-24 | 12-62.18 Blank Added . | 12-151 - 12-153 |

| 12-25 Deleted | 12-63 | 12-155 . |

| 12-26 Blank Deleted | 12-64 - 12-65 | 12-156 - 12-160 |

| 12-27 | 12-66 - 12-68 | 12-161 . |

| 12-28 - 12-30 | 12-68.1 | 12-162 . |

| 12-30.1 - 12-30.2 Added | 12-68.2 - 12-68.3 | 12-163 - 12-165 |

| 12-30.3 | 12-68.4 | 12-166 - 12-170 |

| 12-30.4 | 12-68.5 | 12-171 . |

| 12-31 | 12-68.6 | 12-172 . |

| 12-32 | 12-68.7 | 12-173 . |

| 12-33 | 12-68.8 | 12-174 . |

| 12-34 | 12-68.9 - 12-68.18 . | 12-175 . |

| 12-35 - 12-37 | 12-68.19 . | 12-176 - 12-178 |

| 12-38 | 12-68.20 . | 12-179 . |

| 12-39 - 12-40 | 12-68.21 - 12-68.22 | 12-180 - 12-184 |

| 12-41 - 12-46 | 12-68.23 . | 12-185 . |

| 12-47 | 12-68.24 - 12-68.25 | 12-186 . |

| 12-48 - 12-49 | 12-68.26 . | 12-187 . |

| 12-50 Blank | 12-68.27 - 12-68.28 | 12-188 . |

| 12-51 - 12-52 | 12-68.29 - 12-68.30 | 12-189 - 12-191 |

| 12-53 | 12-68.31 Added . | 12-192 . |

| 12-54 | 12-68.32 Blank Added . | 12-193 - 12-195 |

| 12-54.1 | 12-69 - 12-70 | 12-196 . |

| 12-54.2 | 12-71 | 12-197 - 12-201 |

| 12-54.3 | 12-72 - 12-73 | 12-202 . |

| 12-54.4 | 12-74 | 12-203 - 12-205 |

| 12-54.5 - 12-54.6 | 12-75 - 12-77 | 12-206 . |

| 12-55 | 12-78 | 12-207 - 12-209 |

| 12-56 | 12-79 | 12-210 - 12-216 |

| 12-56.1 | 12-80 | 12-217 - 12-20 Added |

| 12-56.2 | 12-81 | 12-221 Blank Added . |

| 12-57 | 12-82 - 12-83 | 12-222 - 12-223 Added. |

| 12-58 - 12-59 | 12-84 | 12-224 Blank Added . |

| 12-60 | 12-85 - 12-131 . | 12-225 - 12-229 |

| 12-60.1 | 12-132 - 12-12-135 . | 12-230 - 12-231 |

| 12-60.2 | 12-136 . | 12-232 - 12-233 |

| 12-60.3 | 12-137 - 12-141 | 12-236 Added |

| 12-60.4 | 12-142 . | 12-234 - 12-235 |

*Zero in this column indicates original page.

1 TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 12-236.1 - 12-236.2 Added | 15-25 | 18-2 . |

| 12-237 - 12-247 Added | 15-26 | 18-3 - 18-5 |

| 12-248 - 12-249 | 15-27 | 18-6 . |

| 12-250 - 12-251 | 15-28 - 15-29 | 18-7 - 18-9 |

| 12-252 - 12-263 | 15-30 - 15-31 | 18-10 |

| 12-264 - 12-70 . | 15-32 | 18-10.1 - 18-10.2 |

| 12-270.1 - 12-270.9 Added. | 15-33 | 18-10.3 - 18-10.7 |

| 12-270.10 Blank Added | 15-34 - 15-35 | 18-10.8 |

| 12-271 - 12-349 Added | 15-36 | 18-10.9 - 18-10.10 . |

| 12-350 Blank Added . | 15-37 - 15-39 | 18-10.11 - 18-10.12 |

| 12-351 - 12-379 Added | 15-40 - 15-41 | 18-11 |

| 12-380 Blank Added . | 15-42 - 15-43 | 18-12 |

| 13-1 . | 15-44 | 18-13 |

| 13-2 . | 15-45 - 15-46 | 18-14 - 18-15 |

| 13-3 . | 15-47 - 15-76 | 18-16 |

| 13-4 Blank . | 15-76.1 - 15-76.36 Added . | 18-17 - 18-19 |

| 14-1 . | 15-77 | 18-20 |

| 14-2 - 14-3 | 15-78 - 15-96 | 18-21 |

| 14-4 - 14-5 | 15-96.1 - 15-96.20 Added . | 18-22 |

| 14-6 . | 15-97 - 15-124 . | 18-23 - 18-27 |

| 14-7 . | 15-124.1 - 15-124.32 Added . | 18-28 |

| 14-8 . | 15-125 . | 18-29 |

| 14-9 - 14-13 . | 15-126 . | 18-30 |

| 14-15 - 14-16 | 15-127 . | 18-31 - 18-33 |

| 14-17 | 15-128 Blank . | 18-34 |

| 14-18 - 14-19 | 16-1 . | 18-35 |

| 14-20 | 16-2 - 16-3 | 18-36 |

| 14-21 | 16-4 - 16-5 | 18-37 |

| 14-22 | 16-6 . | 18-38 |

| 14-23 - 14-28 | 16-7 . | 18-39 - 18-40 |

| 14-25 | 16-8 . | 18-41 |

| 14-26 | 16-9 - 16-10 . | 18-42 |

| 14-27 - 14-28 | 16-11 | 18-43 |

| 15-1 . | 16-12 | 18-44 - 18-45 |

| 15-2 . | 16-13 - 16-15 | 18-46 Blank. |

| 15-3 - 15-5 | 16-16 | 19-1 - 19-6 |

| 15-6 . | 16-17 | 19-6.1 Blank Added . |

| 15-7 - 15-8 | 16-18 | 19-6.2 - 19-6.8 Added. |

| 15-9 - 15-10 . | 16-19 - 16-21 | 19-7 - 19-12 . |

| 15-11 - 15-14 | 16-22 Blank | 19-12.1 - 19-12.6 Added. |

| 15-15 - 15-19 | 17-1 - 17-2 | 19-13 - 19-16 |

| 15-20 | 17-3 - 17-13 Added . | 19-17 Added. |

| 15-21 - 15-23 | 17-14 Blank Added | 19-18 Blank Added |

| 15-24 | 18-1 . | 19-9 - 19-10 . |

*Zero in this column indicates original page.

Change 6 J TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No. . | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 19-11 | 24-15 | 25-36 |

| 19-12 - 19-13 | 24-16 - 24-17 | 25-36.1 |

| 19-14 | 24-18 | 25-36.2 - 25-36.5 |

| 19-15 | 24-19 | 25-36.6 - 25-36.16 . |

| 19-16 Blank | 24-20 - 24-22 | 25-36.17 - 25-36.18 |

| 20-1 - 20-6 | 24-22.1 - 22.4 Added . | 25-36.19 Blank . |

| 20-6.1 - 20-6.6 Added | 24-23 - 24-24 | 25-36.20 . |

| 20-7 - 20-10 . | 24-24.1 - 24-24.2 Added | 25-36.21 - 25-36.32 |

| 20-11 Added | 24-25 - 24-28 | 25-36.33 - 25-36.34 |

| 20-12 Added Blank | 24-28.1 - 24-28.4 Added | 25-36.35 - 25-36.36 |

| 21-1 - 21-2 | 24-29 - 24-32 | 25-36.37 . |

| 21-2.1 - 21-2.4 Added | 24-32.1 - 24-32.4 Added | 25-36.38 - 36.43 Added . |

| 21-3 - 21-4 | 24-33 - 24-34 | 25-36.44 Blank Added . |

| 21-4.1 - 21-4.14 Added . | 24-34.1 -24-34..2 Added | 25-37 |

| 21-5 - 21-8 | 24-35 | 25-38 - 25-41 |

| 21-8.1 - 21-8.2 Added | 24-36 | 25-42 |

| 21-9 - 21-11 . | 24-37 | 25-42.1 - 25-42.2 Added. |

| 21-12 - 21-19 | 24-38 | 25-43 |

| 21-20 | 24-38.1 - 24-38.2 Added | 25-44 - 25-45 |

| 22-1 - 22-3 | 24-39 Blank | 25-46 |

| 22-4 . | 24-40 | 25-47 |

| 22-5 . | 25-1 . | 25-48 |

| 22-6 - 22-7 | 25-2 . | 25-49 |

| 22-8 . | 25-3 . | 25-50 |

| 22-9 - 22-11 . | 25-4 . | 25-50.1 |

| 22-12 Blank | 25-5 - 25-8 | 25-50.2 |

| 23-1 - 23-2 | 25-9 . | 25-51 |

| 23-3 - 23-5 | 25-10 | 25-52 |

| 23-6 . | 25-11 - 25-15 | 25-53 |

| 23-7 - 23-25 Added . | 25-16 | 25-54 |

| 23-26 Blank Added | 25-17 - 25-21 | 25-55 |

| 24-1 - 24-2 | 25-22 | 25-56 |

| 24-2.1 - 24-2.2 Added | 25-22.1 - 25-22.12 Added . | 25-56.1 - 25-56.2 |

| 24-2.3 Blank Added . | 25-23 | 25-57 - 25-58 |

| 24-4 - 24-5 | 25-24 | 25-59 - 25-61 |

| 24-6 . | 25-25 - 25-27 | 25-62 |

| 24-6.1 - 24-6.2 Added | 25-28 | 25-63 |

| 24-7 - 24-8 | 25-29 | 25-64 |

| 24-8.1 - 24-8.2 Added | 25-30 | 25-65 |

| 24-9 - 24-10 . | 25-31 | 25-66 - 25-67 |

| 24-11 | 25-32 | 25-68 |

| 24-12 | 25-33 | 25-69 - 25-71 |

| 24-13 | 25-34 | 25-72 - 25-73 |

| 24-14 | 25-35 | 25-74 - 25-75 |

*Zero in this column indicates original page.

TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No. . | Page No. . | Page No *Change No. |

|---|---|---|

| 25-76 | 25-175 - 25-176 | 28-26.1 - 28-26.2 |

| 25-77 . | 25-177 . | 28-27 - 28-29 |

| 25-78 | 25-178 - 25-180 | 28-30 |

| 25-78.1 - 25-78.2 | 25-181 Added . | 28-30.1 |

| 25-79 | 25-182 Blank Added . | 28-30.2 |

| 25-80 | 26-1 . | 28-31 |

| 25-81 - 25-87 | 26-2 - 26-4 | 28-32 |

| 25-88 | 26-5 - 26-9 | 28-33 - 28-34 |

| 25-89 | 26-10 | 28-35 |

| 25-90 | 27-1 . | 28-36 |

| 25-91 - 25-93 | 27-2 . | 28-37 - 28-39 |

| 25-94 | 27-3 . | 28-40 |

| 25-95 - 25-117 . | 27-4 - 27-6 | 28-41 - 28-43 |

| 25-118 Blank . | 27-7 - 27-9 | 28-44 |

| 25-119 . | 27-10 | 28-45 |

| 25-120 - 25-122 | 27-11 - 27-13 | 28-46 |

| 25-123 - 25-124 | 27-14 | 28-47 |

| 25-125 - 25-127 | 25-15 | 28-48 |

| 25-128 . | 27-16 - 27-22 | 28-49 |

| 25-129 . | 27-23 | 28-50 |

| 25-130 . | 27-24 - 27-29 | 28-51 - 28-53 |

| 25-131 - 25-132 | 27-30 | 28-54 |

| 25-133 - 25-134 | 27-31 | 28-55 |

| 25-135 . | 27-32 - 27-33 | 28-56 |

| 25-136 . | 27-34 | 28-57 - 28-58 |

| 25-137 . | 27-35 | 28-58.1 |

| 25-138 . | 27-36 - 27-37 | 28-58.2 |

| 25-139 - 25-140 | 27-38 | 28-59 |

| 25-141 . | 27-39 | 28-60 |

| 25-142 . | 27-40 Blank | 28-61 |

| 25-143 - 25-150 | 28-1 - 28-2 | 28-62 - 28-64 |

| 25-151 . | 28-3 . | 28-65 |

| 25-152 . | 28-4 - 28-5 | 28-66 |

| 25-153 - 25-158 | 28-6 . | 28-67 - 28-69 |

| 25-159 - 25-160 | 28-7 . | 28-70 |

| 25-161 . | 28-8 . | 28-71 |

| 25-162 . | 28-9 . | 28-72 |

| 25-163 - 25-164 | 28-10 - 28-11 | 28-73 |

| 25-165 . | 28-12 - 28-13 | 28-74 |

| 25-166 - 25-167 | 28-14 | 28-75 - 28-77 |

| 25-168 . | 28-15 - 28-16 | 28-78 |

| 25-169 - 25-172 | 28-17 - 28-18 | 28-80 - 28-82 |

| 25-172.1 - 25-172.4 Added | 28-19 - 29-25 | 28-83 |

| 25-173 - 25-174 | 28-26 | 28-84 - 28-85 |

| 25-174.1 - 25-174.2 Added |

*Zero in this column indicates original page.

Change 6 L TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

|---|---|---|

| 28-86 | 32-5 - 32-6 | D-84.1 - D-84.6. |

| 28-86.1 - 28-86.2 | 32-6.1 - 32-6.2 Added | D-85 . |

| 28-87 - 28-88 | 32-7 - 32-8 | D-86 - D-89 Added |

| 28-89 - 28-90 | 32-9 - 32-10 . | D-90 Blank Added . |

| 28-91 | 32-11 - 32-13 | E-1 - E-5 |

| 28-92 Blank. | 32-14 Blank. | E-6 Blank |

| 29-1 . | 33-1 . | F-1 - F-2 |

| 29-2 . | 33-2 . | G-1 |

| 29-3 - 29-6 | 33-3 - 33-4 | G-2 - G-12 |

| 29-7 . | 33-5 - 33-16 . | G-13 - G-15 Deleted |

| 29-8 - 29-9 | 33-17 - 33-18 | G-16 Blank Deleted . |

| 29-10 | 33-19 | H-1 |

| 29-11 | 33-20 - 33-38 | H-2 |

| 29-12 | 33-39 | H-3 - H-4. |

| 29-13 - 29-17 | 33-40 - 33-67 | H-5 - H-7 Added |

| 29-18 - 29-21 | 33-68 | H-8 Blank Added |

| 29-22 - 29-23 | 33-69 - 33-87 | J-1 - J-2 |

| 29-24 | 33-88 | J-3 Blank Added |

| 29-24.1 Added | 33-89 - 33-109 . | J-4 - J-7 |

| 29-24.2 Blank Added | 33-110 Blank . | J-8 |

| 29-25 | 34-1 . | J-9 - J-12 . |

| 29-26 | 34-2 - 34-3 | J-13 . |

| 29-27 | 34-4 Blank . | J-14 |

| 29-28 Blank | A-1 | J-15 . |

| 30-1 - 30-3 | A-2 | J-16 . |

| 30-4 - 30-9 | B-1 - B-3 | J-17 . |

| 30-10 | B-4 - B-17 . | J-18 - J-20 |

| 30-11 - 30-17 | B-18 - B-21 | J-21 Blank . |

| 30-18 | B-22 . | J-22 |

| 30-19 | B-23 . | J-23 - J-24 |

| 30-20 | B-24 | J-25 . |

| 30-21 | C-1. | J-26 - J-27 |

| 30-22 | C-2 | J-28 . |

| 30-23 - 30-24 | C-3 | J-29 . |

| 30-25 | C-4 | J-30 |

| 30-26 - 30-29 Added | C-5 | J-31 . |

| 30-30 Blank Added | C-6 - C-10 . | J-32 - J-33 |

| 31-1 . | D-1 | J-34 - J-38 |

| 31-2 Blank Added . | D-2 | J-39 . |

| 31-3 - 31-19 Deleted . | D-3 - D-12 | J-40 - J-41 |

| 31-20 Blank Deleted | D-13 . | J-42 - J-45 |

| 32-1 - 32-2 | D-14 - D-65 | J-46 - J-49 |

| 32-3 . | D-66 . | J-50 |

| 32-4 . | D-67 - D-84 | J-50.1 Added . |

*Zero in this column indicates original page.

TM 9-2320-387-24-1

List Of Effective Pages (Contd)

| Page No *Change No. | Page No *Change No. |

|---|---|

| J-50.2 . | K-10 . |

| J-51 . | K-11 - K-13 Added |

| J-52 - J-53 | K-14 - K-15 |

| J-54 - J-56 | K-16 - K-17 Added |

| J-56.1 - J-56.4 | K-18 - K-23 |

| J-57 . | K- 24 - K-27 Added . |

| J-58 . | K-28 Blank Added . |

| J-59 . | L-1 - L-5 Added |

| J-60 . | L-6 Blank Added |

| J-60.1 . | M-1 Added |

| J-60.2 . | M-2 |

| J-61 - J-63 | M-3 Added |

| J-64 - J-65 | M-4 |

| J-66 - J-68 | M-5 Added |

| J-68.1 - J-68.4 Added | M-6 - M-8 |

| J-69 . | M-9 Added |

| J-70 . | M-10 . |

| J-71 . | M-11 Added . |

| J-72 - J-75 | M-12 . |

| J-76 . | M-13 Added . |

| J-77 - J-78 Deleted | M-14 . |

| J-79 . | M-15 Added . |

| J-80 - J-84 | M-16 . |

| J-85 . | M-17 - M-21 Added |

| J-86 . | M-22 . |

| J-87 Blank . | M-23 Added . |

| J-88 . | M-24 . |

| J-89 . | M-25 Added . |

| J-90 - J-94 | M-26 . |

| J-95 . | M-27 Added . |

| J-96 - J-100 . | M-28 |

| J-100.1 - J-100.2 Added | M-29 Added . |

| J-101 - J-102 | M-30 . |

| J-102.1 Added | M-30 - M-33 Added |

| J-102.2 | M-34 Blank Added . |

| J-103 | Index 1 - Index 68 . |

| J-104 - J-112 | Index 69 - Index 75 Added |

| J-113 - J-114 | Index 76 Blank Added . |

| J-115 - J-145 Added | FP-1 . |

| J-146 Blank Added | FP-2 Blank . |

| K-1 | FP-3 . |

| K-2 - K-5 | FP-4 Blank . |

| K-6 - K-7 | FP-5 Added . |

| K-8 - K-9 Added | FP-6 Blank Added . |

*Zero in this column indicates original page.

Change 6 N AIR FORCE TO 36A12-1A-3052-1 MARINE CORPS TM 11033-IN VOL 1 NO. 36A12-1A-3052-1 TECHNICAL MANUAL HEADQUARTERS, NO. 9-2320-387-24-1 DEPARTMENTS OF THE ARMY, NO. 11033-IN VOL 1 THE AIR FORCE AND MARINE CORPS TECHNICAL ORDER WASHINGTON, D.C., 31 DECEMBER 1997

Technical Manual Volume 1 Of 2

UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE FOR TRUCK, UTILITY: S250 SHELTER CARRIER, 4X4, M1113 (2320-01-412-0143) (EIC: B6B); TRUCK, UTILITY: UP-ARMORED CARRIER, 4X4, M1114 (2320-01-413-3739) (EIC: B6C); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, M1151 (2320-01-518-7330) (EIC: BA5); TRUCK, UTILITY: EXPANDED CAPACITY, ARMAMENT CARRIER, IAP/ARMOR READY, M1151A1 (2320-01-540-2038) (EIC: BEG); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, M1152 (2320-01-518-7332) (EIC: BA6); TRUCK, UTILITY: EXPANDED CAPACITY, ENHANCED, IAP/ARMOR READY, M1152A1 (2320-01-540-2007) (EIC: BEH); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, M1165 (2320-01-540-1993) (EIC: BEK); TRUCK, UTILITY: COMMAND AND CONTROL/GENERAL PURPOSE VEHICLE, IAP/ARMOR READY, M1165A1 (2320-01-540-2017) (EIC: BEJ); TRUCK, UTILITY: EXPANDED CAPACITY, TOW ITAS CARRIER, M1167 (2320-01-544-9638).

DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited.

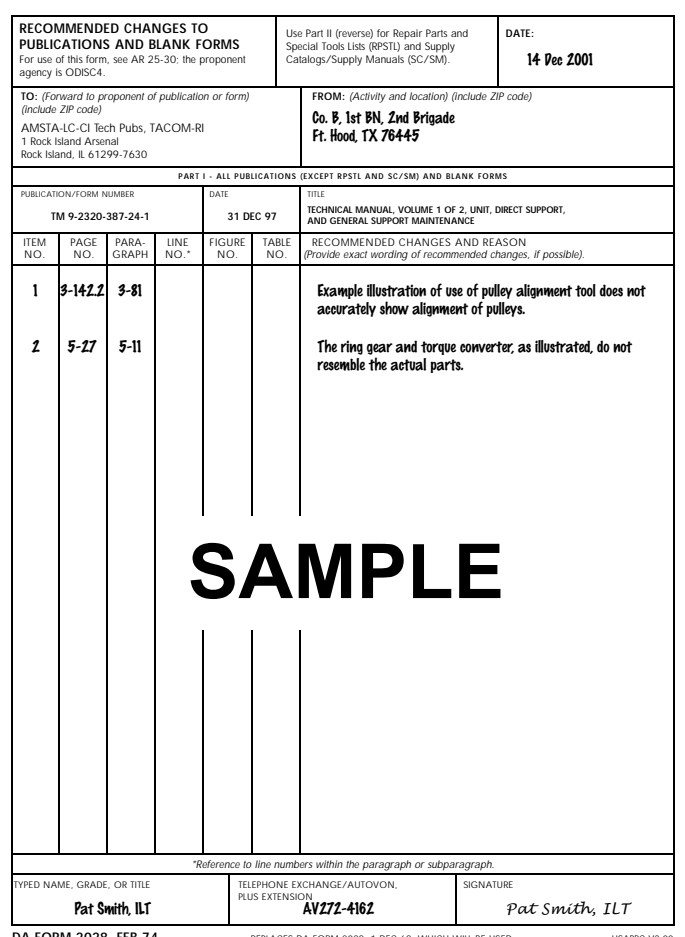

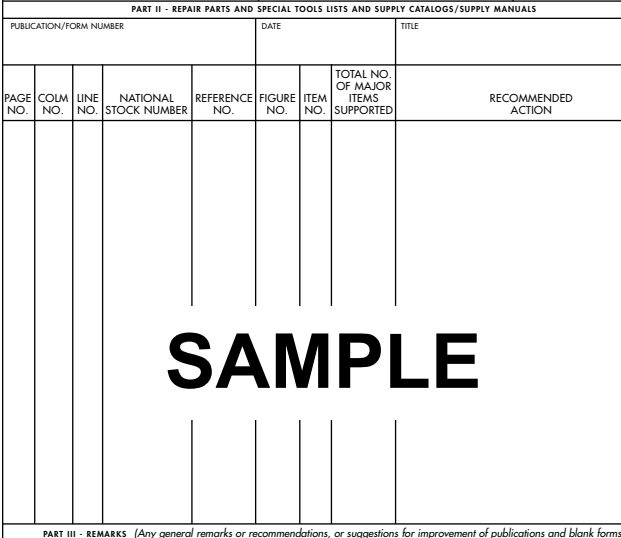

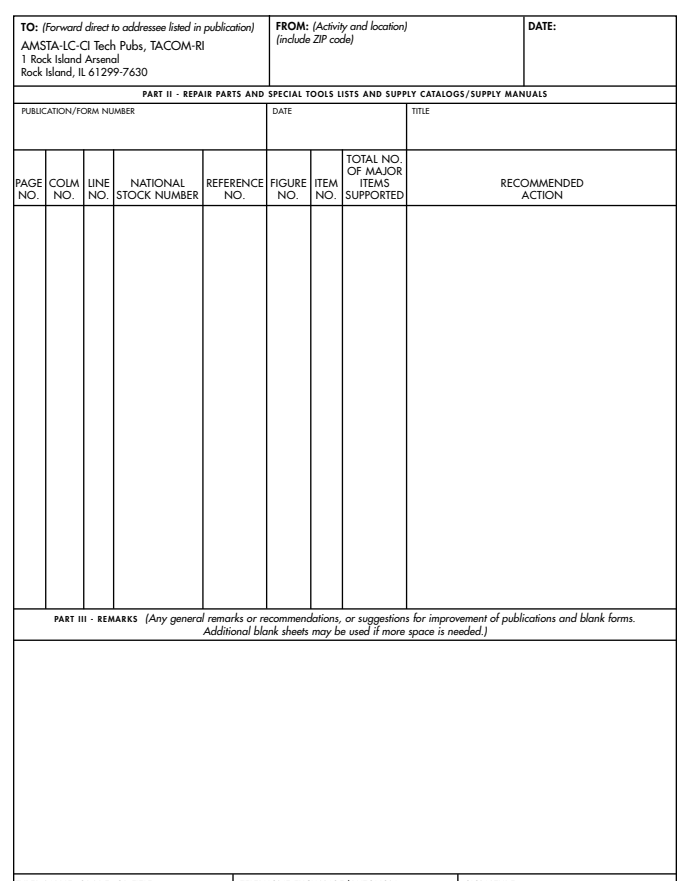

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS (Army) You can help improve this publication. If you find any errors, or if you would like to recommend any improvements to the procedures in this publication, please let us know. The preferred method is to submit your DA Form 2028 (Recommended Changes to Publications and Blank Forms) through the Internet, on the Army Electronic Product Support (AEPS) website. The Internet address is https://aeps.ria.army.mil. The DA Form 2028 is located under the Public Applications section in the AEPS Public Home Page. Fill out the form and click on SUBMIT. Using this form on the AEPS will enable us to respond quicker to your comments and better manage the DA Form 2028 program. You may also mail, e-mail, or fax your comments or DA Form 2028 directly to the U.S. Army TACOM Life Cycle Management Command. The postal mail address is U.S. Army TACOM Life Cycle Management Command, ATTN: AMSTA-LC-LMPP/TECH PUBS, 1 Rock Island Arsenal, Rock Island, IL 61299-7630. The e-mail address is tacomlcmc.daform2028@us.army.mil. The fax number is DSN 793-0726 or Commercial (309) 782-0726. (Marine Corps) Submit notice of discrepancies or suggest changes on a NAVMC 10772. Users without CAC/PKI certificates may submit the NAVMC via the Internet using website http://www.ala.usmc.mil/navmc/part1.htm, You can then fill in and submit the automated NAVMC 10772 Form. NAVMC forms may also be submitted by electronic mail to bmatcommarlogbases@logcom.usmc.mil mailto:mbmatcommarlogbases@logcom.usmc.mil, or by mailing a paper copy of the NAVMC 10772 in an envelope addressed to Commander, Marine Corps Systems Command, Attn: Assistant Commander Acquisition and Logistics (LOG/TP), 814 Radford Blvd., Room 316E, Albany, Georgia 31704-0343. Problems or questions regarding the NAVMC 10772 program should be reported by calling DSN 567-5017 or DSN 567-6439. In addition to electronic submittal of the NAVMC form via the above web links, forward an information copy (cc:) or mail a paper copy to the Logistics Management Specialist at the following address: Logistics Management Specialist, Code PMM151, 814 Radford Blvd., STE 310W, Albany, Georgia 31704-0343.

This manual is published in two parts. TM 9-2320-387-24-1 contains chapters 1 through 9, and TM 9-2320-387-24-2 contains chapters 10 through 33 and appendices A through M. This manual contains a table of contents and alphabetical index for both volumes 1 and 2.

Volume 1 Of 2

| 1-4.10 Blank Added 6 | 2-26 6 | 2-191 - 2-197 0 |

|---|---|---|

| 1-5 - 1-6 5 | 2-26.1 - 2-26.2 6 | 2-198 Blank 0 |

| 1-7 - 1-9 0 | 2-27 - 2-31 6 | 2-199 1 |

| 1-10 5 | 2-32 - 2-34 0 | 2-200 0 |

| 1-11 0 | 2-35 - 2-37 6 | 2-201 - 2-202 1 |

| 1-12 5 | 2-38 - 2-47 0 | 2-203 - 2-207 0 |

| 1-13 - 1-16 0 | 2-48 2 | 2-208 2 |

| 1-16.1-1-16.2 Added 6 | 2-48.1 - 2-48.2 Added 2 | 2-208.1 - 2-208.2 Added 2 |

| 1-17 6 | 2-49 2 | 2-209 - 2-210 2 |

| 1-18 3 | 2-50 Blank 0 | 2-210.1 - 2-210.4 Added 1 |

| iv -vi 6 | 2-4 2 | 2-113 2 |

|---|---|---|

| vii-xiii 0 | 2-5 1 | 2-114 - 2-139 0 |

| xiv Blank 0 | 2-6 5 | 2-140 Blank 0 |

| 1-1 6 | 2-7 - 2-11 3 | 2-141 - 2-145 0 |

| 1-2 5 | 2-12 - 2-14 6 | 2-146 Blank 0 |

| 1-2.1 - 1-2.9 Deleted 5 | 2-15 - 2-16 3 | 2-147 - 2-157 0 |

| 1-2.10 - Blank Deleted 5 | 2-17 - 2-19 6 | 2-158 Blank 0 |

| 1-3 - 1-4 5 | 2-20 - 2-21 3 | 2-159 - 2-189 6 |

| 1-4.1 - 1-4.4 5 | 2-22 - 2-23 5 | 2-190 Blank 0 |

| Change 6 30 June 2009 | ||

|---|---|---|

| TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS 1,704 | CONSISTING OF THE FOLLOWING: | |

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

| VOLUME 1 | 1-28 - 1-32 0 | 2-68 Blank 0 |

| a 0 | 1-33 - 1-36 6 | 2-69 - 2-73 0 |

| b 3 | 1-36.1 - 1-36.2 Added 6 | 2-74 Blank 0 |

| c 5 | 1-37 - 1-38 0 | 2-75 - 2-97 0 |

| d Blank 1 | 1-38.1 - 1-38.4 5 | 2-98 1 |

| A - N 6 | 1-39 - 1-40 5 | 2-99 - 2-111 0 |

| i 6 | 2-1 0 | 2-112 2 |

| LIST OF EFFECTIVE PAGES |

|---|

| NOTE: The portion of the text affected by the changes is indicated by a vertical line in the outer margins of the page. |

| Dates of issue for original and changed pages of volume 1 are: |

| Original 31 December 1997 |

| Change 1 31 October 2001 |

| Change 2 30 July 2004 |

| Change 3 31 May 2006 |

| Change 4 28 February 2007 |

Page

| Page No *Change No. | Page No *Change No. | Page No *Change No. | 2-246 Blank 0 | 2-473 Blank 2 | 3-50 5 |

|---|---|---|---|---|---|

| 2-247 - 2-287 0 | 2-474 - 2-475 2 | 3-51 - 3-53 6 | 2-288 Blank 0 | 2-476 0 | 3-54 - 3-56 2 |

| 2-289 - 2-303 0 | 2-477 2 | 3-57 1 | 2-304 Blank 0 | 2-478 Blank 0 | 3-58 - 3-60 2 |

| 2-305 - 2-310 0 | 2-478.1 - 2-478.8 Blank Added 2 | 3-60.1 - 3-60.2 Added 2 | 2-311 3 | 2-479 - 2-487 0 | 3-61 - 3-63 2 |

| 2-312 - 2-346 0 | 2-488 Blank 0 | 3-64 6 | 2-347 0 | 2-488.1 - 2-488.5 Added 6 | 3-64.1 - 3-64.2 Added 6 |

| 2-348 3 | 2-488.6 Added Blank 6 | 3-65 6 | 2-349 - 2-373 0 | 2-489 - 2-522 0 | 3 -66 - 3-67 2 |

| 2-374 Blank 0 | 3-1 6 | 3-68 - 3-69 5 | 2-375 - 2-383 0 | 3-2 2 | 3-70 2 |

| 2-384 Blank 0 | 3-3 0 | 3-71 - 3-75 0 | 2-385 1 | 3-4 2 | 3-76 2 |

| 2-386 - 2-407 0 | 3-4.1 - 3-4.2 Added 6 | 3-77 - 3-78 0 | 2-408 1 | 3-5 - 3-6 6 | 3-79 - 3-80 2 |

| 2-409 - 2-417 0 | 3-7 0 | 3-81 0 | 2-418 Blank 0 | 3-8 - 3-9 2 | 3-82 2 |

| 2-419 6 | 3-10 6 | 3-83 1 | 2-420 - 2-424 0 | 3-10.1 - 3-10.2 Added 6 | 3-84 2 |

| 2-425 6 | 3-11 - 3-14 6 | 3-85 1 | 2-426 0 | 3-14.1 - 3-14.2 Added 6 | 3-86 2 |

| 2-427 - 2-429 6 | 3-15 6 | 3-87 1 | 2-430 - 2-431 0 | 3-16 1 | 3-88 - 3-90 2 |

| 2-432 Blank 0 | 3-17 - 3-20 0 | 3-91 0 | 2-433 - 2-442 6 | 3-21 6 | 3-92 2 |

| 2-442.1 - 2-442.2 2 | 3-22 2 | 3-93 1 |

| LIST OF EFFECTIVE PAGES (Contd) | ||

|---|---|---|

| Page No *Change No. | Page No *Change No. | Page No *Change No. |

| 3-116.1 - 3-116.12 Added 6 | 4-1 - 4-2 2 | 4-50.1 - 4-50.2 Added 5 |

| 3-117 6 | 4-2.1 - 4-2.4 Added 2 | 4-50.3 - 4-50.4 6 |

| 3-118 0 | 4-3 - 4-4 2 | 4-51 - 4-55 0 |

| 3-118.1 - 3-118.2 Added 6 | 4-5 Blank 2 | 4-56 2 |

| 3-119 6 | 4-6 - 4-7 5 | 4-57 - 4-60 0 |

| 3-120 - 3-122 5 | 4-8 2 | 4-61 - 4-64 2 |

| 3-122.1 - 3-122.2 Added 6 | 4-9 - 4-11 1 | 4-65 5 |

| 3-123 6 | 4-12 - 4-13 2 | 4-66 - 4-68 0 |

| 3-124 - 3-126 1 | 4-14 5 | 4-69 - 4-70 6 |

| 3-126.1 - 3-126.2 Added 6 | 4-15 - 4-17 1 | 4-70.1 5 |

| 3-127 6 | 4-18 2 | 4-70.2 6 |

| 3-128 - 3-130 1 | 4-18.1 1 | 4-71 5 |

| 3-131 2 | 4-18.2 2 | 4-72 6 |

| 3-132 6 | 4-18.3 1 | 4-72.1 5 |

| 3-132.1 Added Blank 6 | 4-18.4 2 | 4-72.2 6 |

| 3-132.2 - 3-132.3 Added 6 | 4-18.5 - 4-18.11 1 | 4-73 5 |

| 3-132.4 Added Blank 6 | 4-18.12 2 | 4-74 3 |

| 3-133 2 | 4-19 - 4-20 2 | 4-74.1 - 4-74.2 Added 3 |

| 3-134 6 | 4-21 0 | 4-75 - 4-76 3 |

| 3-135 - 3-136 0 | 4-22 2 | 4-77 0 |

| 3-137 - 3-138 6 | 4-23 0 | 4-78 2 |

| 3-138.1 - 3-138.2 Added 6 | 4-24 2 | 4-79 1 |

| 3-139 - 3-140 6 | 4-25 0 | 4-80 3 |

| 3-140.1 - 3-140.6 Added 6 | 4-26 2 | 4-80.1 - 4-80.3 Added 3 |

| 3-141 6 | 4-27 0 | 4-80.4 Blank Added 3 |

| 3-142 2 | 4-28 Blank 0 | 4-81 5 |

| 3-142.1 - 3-142.3 2 | 4-29 6 | 4-82 - 4-83 0 |

| 3-142.4 - 3-142.8 6 | 4-30 2 | 4-84 - 4-86 2 |

| 3-142.9 - 3-142.12 Added 6 | 4-30.1 - 4-30.2 Added 6 | 4-87 0 |

| 3-143 5 | 4-31 - 4-33 6 | 4-88 - 4-89 2 |

| 3-144 2 | 4-34 2 | 4-90 3 |

| 3-144.1 - 3-144.3 Added 2 | 4-35 - 4-36 0 | 4-91 0 |

| 3-144.4 3 | 4-36.1 - 4-36.2 Added 6 | 4-92 - 4-94 2 |

| 3-145 2 | 4-37 6 | 4-95 0 |

| 3-146 3 | 4-38 2 | 4-96 2 |

| 3-147 - 3-169 Added 2 | 4-38.1 - 4-38.6 Added 6 | 4-97 0 |

| 3-170 - 3-192 6 | 4-39 6 | 4-98 - 4-100 2 |

| 3-193 Added 6 | 4-40 0 | 4-101 1 |

| 3-194 Added Blank 6 | 4-41 - 4-43 6 | 4-102 5 |

| 3-171 2 | 4-44 0 | 4-103 - 4-106 0 |

| 3-172 5 | 4-45 6 | 4-107 6 |

| 3-173 - 3-188 Added 2 | 4-46 - 4-47 0 | 4-108 - 4-109 0 |

| 3-189 5 | 4-48 5 | 4-110 2 |

| 3-190 - 3-191 Added 2 | 4-49 Blank 5 | 4-111 - 4-115 0 |

| 3-192 Blank Added 2 | 4-50 5 | 4-116 2 |

| *Zero in this column indicates original page. | ||

| Change 6 C |

Volume 2 Of 2

| LIST OF EFFECTIVE PAGES (Contd) | |||||

|---|---|---|---|---|---|

| Page No *Change No. | Page No *Change No. | Page No *Change No. | 4-117 0 | 5-32 2 | 6-47 3 |

| 4-118 - 4-120 2 | 5-33 0 | 6-48 6 | 4-120.1 - 4-120.10 Added 6 | 5-34 2 | 6-48.1 Added 6 |

| 4-121 6 | 5-34.1 - 5-34.4 Added 6 | 6-48.2 Blank Added 6 | 4-122 2 | 5-35 0 | 6-49 6 |

| 4-123 0 | 5-36- 5-38 6 | 6-50 2 | 4-124 2 | 5-38.1 Blank Added 6 | 6-51 - 6-52 5 |

| 4-125 - 4-129 0 | 5-38.2 - 5-38.3 Added 6 | 6-52.1 1 | 4-130 5 | 5-38.4 Blank Added 6 | 6-52.2 5 |

| 4-131 0 | 5-39 - 5-40 6 | 6-53 0 | 4-132 2 | 6-1 0 | 6-54 5 |

| 4-132.1 - 4-132.2 Added 6 | 6-2 6 | 6-55 0 | 4-133 6 | 6-3 0 | 6-56 - 6-62 5 |

| 4-134 2 | 6-4 6 | 6-63 - 6-65 0 | 4-135 - 4-137 0 | 6-5 0 | 6-66 5 |

| 4-138 2 | 6-6 2 | 7-1 - 7-4 6 | 4-139 0 | 6-7 0 | 7-4.1 - 7-4.4 Added 6 |

| 4-140 - 4-144 2 | 6-8 2 | 7-5 - 7-8 6 | 4-145 - 4-148 0 | 6-9 0 | 7-8.1 - 7-8.2 Added 6 |

| 5-1 6 | 6-10 2 | 7-9 - 12 6 | 5-2 2 | 6-11 0 | 7-12.1 - 7-12.2 Added 6 |

| 5-3 0 | 6-12 - 6-14 6 | 7-13 - 7-14 6 | 5-4 2 | 6-15 0 | 7-14.1 - 7-14.2 Added 6 |

| 5-5 0 | 6-16 - 6-17 2 | 7-15 - 7-26 6 | 5-6 - 5-10 6 | 6-18 - 6-19 6 | 7-26.1 - 7-26.10 6 |

| 5-10.1 - 5-10.4 Added 6 | 6-19 5 | 7-27 6 | 5-7 - 5-10 1 | 6-20 1 | 7-28 2 |

| 5-11 6 | 6-21 0 | 7-29 6 | 5-12 2 | 6-22 2 | 7-30 2 |

| 5-13 0 | 6-23 0 | 7-31 6 | 5-14 - 5-15 3 | 6-24 - 6-25 1 | 7-32 2 |

| 5-16 - 5-17 0 | 6-26 - 6-27 0 | 7-33 - 7-34 6 | 5-18 2 | 6-28 2 | 7-34.1 - 7-34.2 6 |

| 5-19 - 5-21 0 | 6-29 0 | 7-34.3 - 7-34.6 Added 6 | 5-22 2 | 6-30 - 6-33 6 | 7-35 - 7-36 6 |

| 5-23 0 | 6-34 1 | 7-36.1 Blank Added 6 | 5-24 6 | 6-35 - 6-36 6 | 7-36.2 - 7-36.3 Added 6 |

| 5-24.1 - 5-24.2 Added 6 | 6-37 1 | 7-36.4 Blank Added 6 | 5-25 6 | 6-38 2 | 7-37 0 |

| 5-26 2 | 6-38.1 - 6-38.4 Added 6 | 7-38 2 | 5-27 0 | 6-39 Blank 6 | 7-39 - 7-41 1 |