hmmwv-manuals

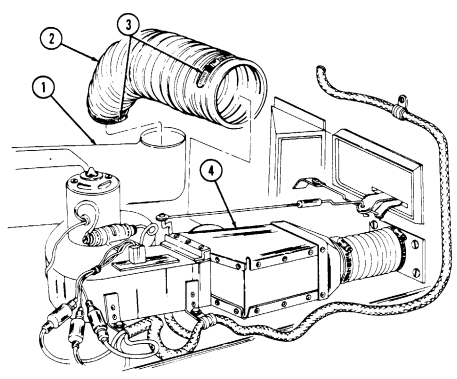

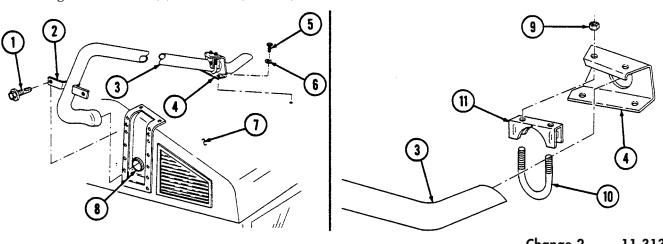

Chapter 11 Special Purpose Bodies Section I. Weapon Carrier Body Maintenance

| INITIAL SETUP: | |||

|---|---|---|---|

| Applicable Models: | Manual References | All vehicles except M996, M996A1, M997, | TM 9-2320-280-10 |

| M997A1, M997A2, M1035, M1035A1, | TM 9-2320-280-24P | M1035A2 | Equipment Condition |

| Tools | Hood raised and secured (TM 9-2320-280-10) | General mechanics tool kit: automotive | |

| (Appendix B, Item 1) | Materials/Parts | ||

| Lubricant (Appendix C, Item 33) | Two O-rings (Appendix G, Item 218) | ||

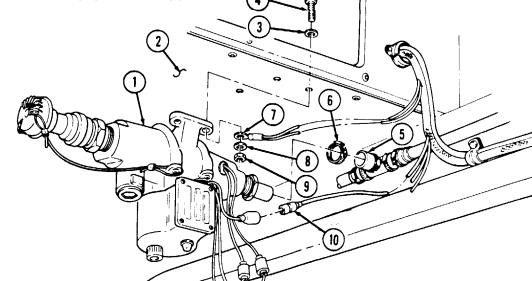

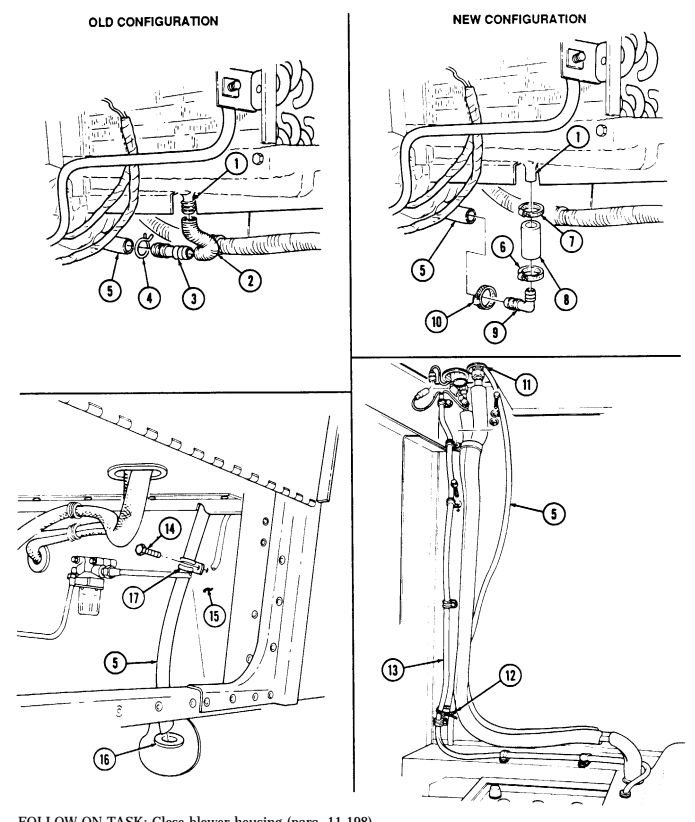

| a. Removal | |||

| CAUTION | Cover or plug power steering gear and hydro-boost connections | ||

| immediately after removing hoses to prevent contamination. | Remove all plugs prior to connecting hoses. | ||

| NOTE | Ensure area around power steering port is clean before removing | ||

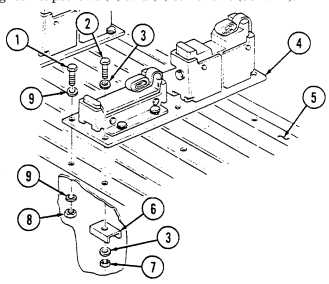

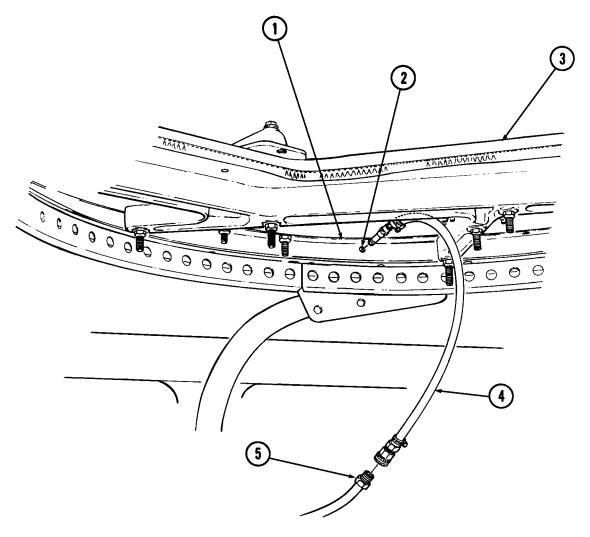

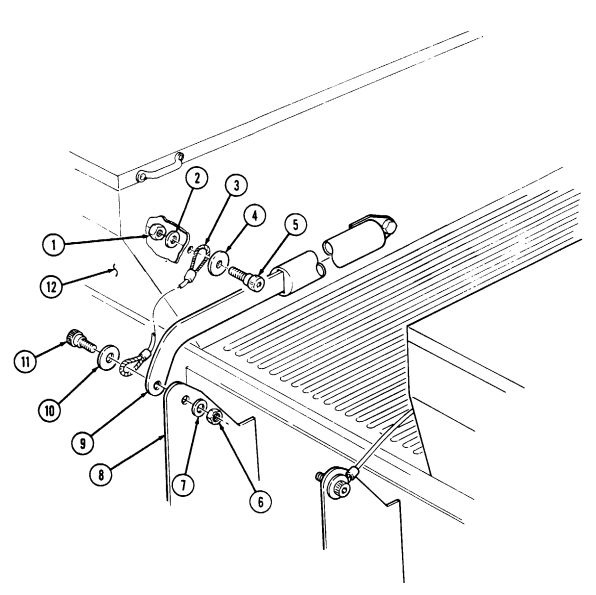

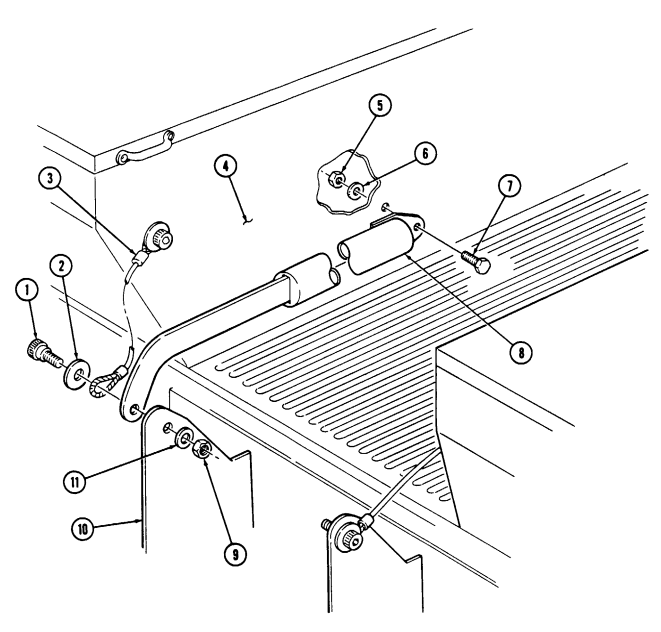

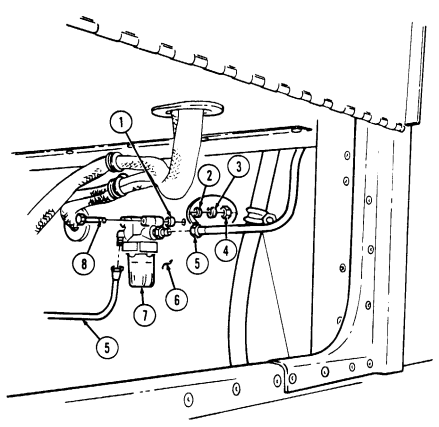

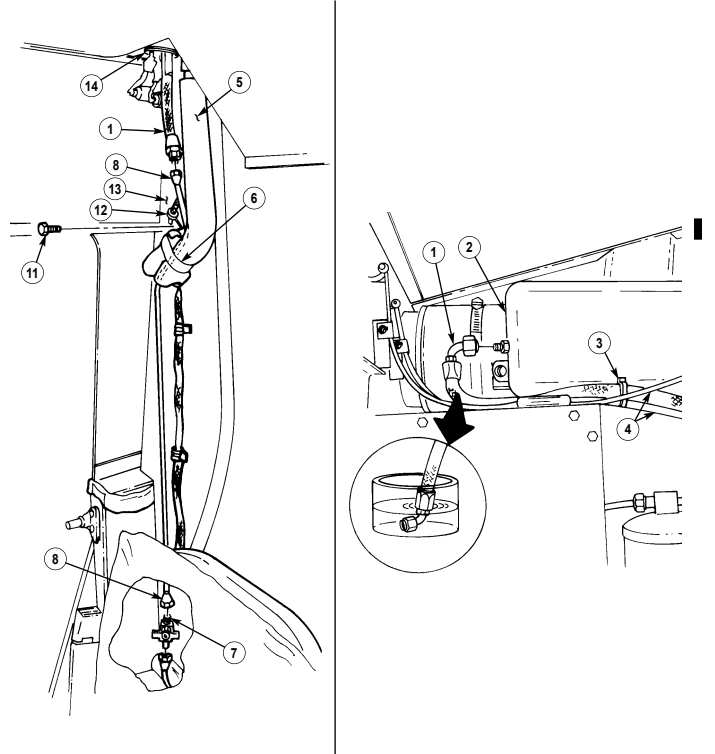

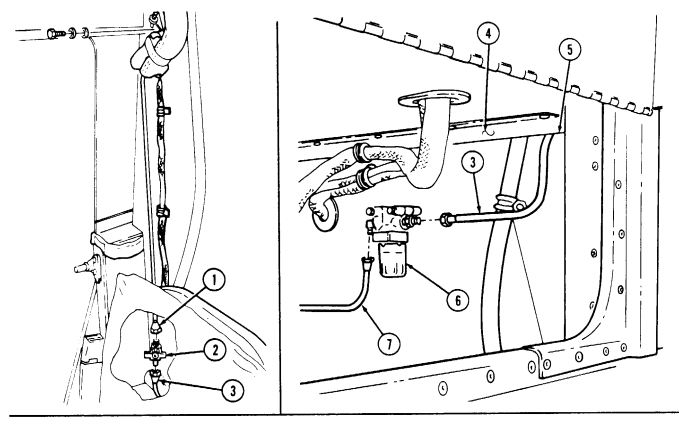

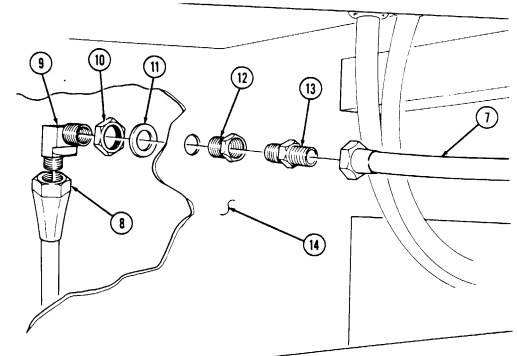

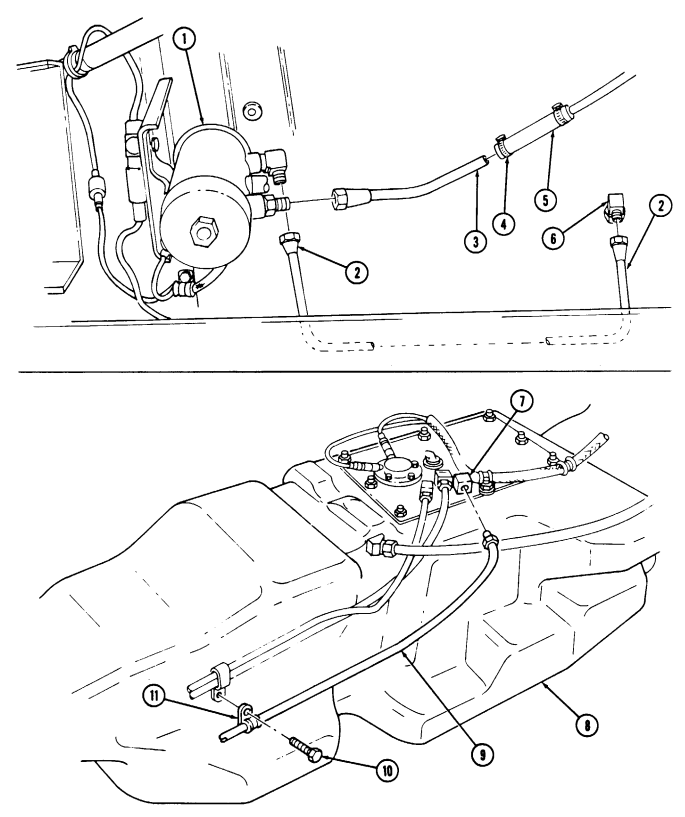

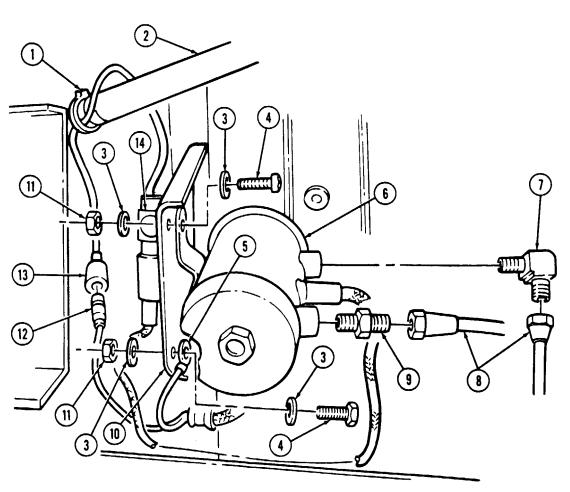

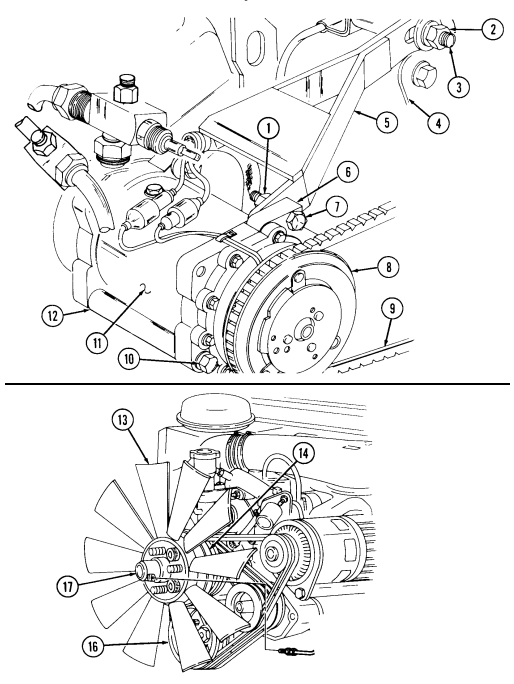

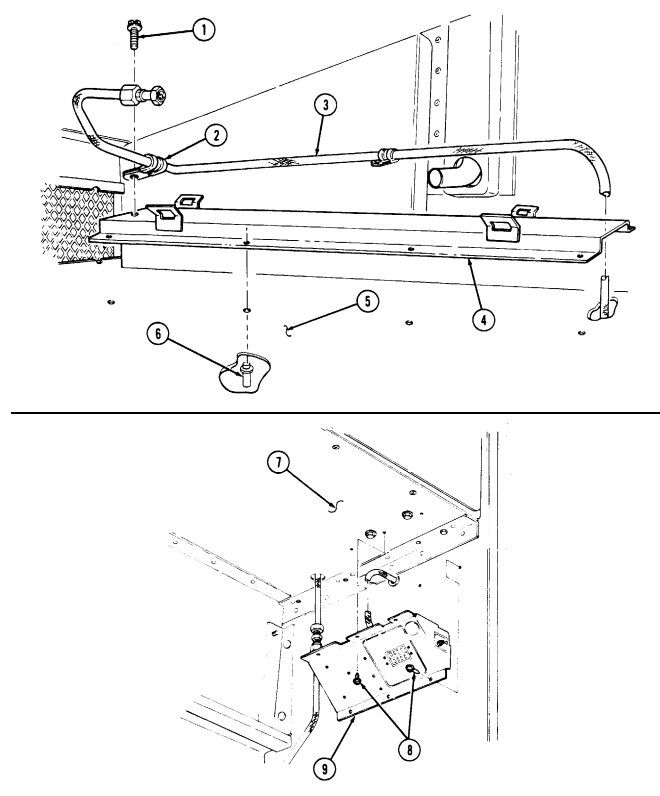

| hose. | 1. | Remove hydraulic hose (2) and O-ring (5) from power steering gear port (6). Discard O-ring (5). | |

| 2. | Remove hydraulic hose (2) from winch outlet port (1) on winch (8). | NOTE | |

| Ensure area around hydro-boost port is clean before removing | hose. | ||

| 3. | Remove hydraulic hose (4) and O-ring (5) from hydro-boost port (3). Discard O-ring (5). | 4. | Remove hydraulic hose (4) from winch inlet port (7). |

| b. Installation | |||

| 1. | Apply lubricant to O-ring (5) and install O-ring (5) on hydraulic hose (4). | 2. | Install hydraulic hose (4) on hydro-boost port (3). |

| 3. | Route hydraulic hose (4) from hydro-boost port (3) to winch (8) and install hydraulic hose (4) to | winch inlet port (7). | |

| 4. | Apply lubricant to O-ring (5) and install O-ring (5) on hydraulic hose (2). | 5. | Install hydraulic hose (2) on power steering gear port (6). |

| 6. | Route hydraulic hose (2) from power steering gear port (6) along side hydraulic hose (4) and install | hydraulic hose (2) on winch outlet port (1). |

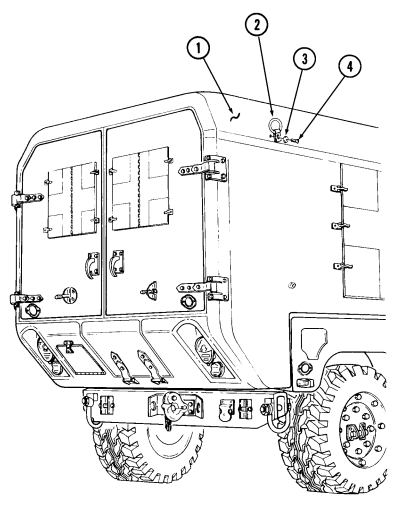

| CHAPTER 11 | |

|---|---|

| SPECIAL PURPOSE BODIES | |

| Section I. | WEAPON CARRIER BODY MAINTENANCE |

| 11-1. | WEAPON CARRIER BODY MAINTENANCE TASK SUMMARY |

| TASK | PROCEDURES |

| PARA. | |

| 11-2. | Ballistic Crew Door Maintenance |

| 11-3. | Ballistic Crew Door Hinge Replacement |

| 11-4. | Ballistic Crew Door Rear Striker Plate Replacement |

| 11-5. | Ballistic Crew Door Front Striker Plate Maintenance |

| 11-6. | Ballistic Crew Door Paddle Lock Replacement |

| 11-7. | Ballistic Crew Door Window Assembly Maintenance |

| 11-8. | Ballistic Crew Door Window Protective Shield Replacement |

| 11-9. | Ballistic Crew Door Window Stop Replacement |

| 11-10. | Ballistic Crew Door Seal Replacement |

| 11-11. | Ballistic Crew Door Latch Replacement |

| 11-12. | Ballistic Crew Door Latch Tube Replacement |

| 11-13. | Cargo Door Shell Door Maintenance |

| 11-14. | Cargo Door Shell Door Wire Handle Lock Replacement |

| 11-15. | Cargo Door Shell Door Grab Handle Replacement |

| 11-16. | Cargo Door Shell Door Handle Latch Replacement |

| 11-17. | Cargo Door Shell Door Latch Maintenance |

| 11-18. | Cargo Door Shell Door Latch Rod Maintenance |

| 11-19. | Cargo Door Shell Door Dovetail Assembly |

| Maintenance | |

| 11-20. | Cargo Door Shell Door Retention Cable Replacement |

| 11-21. | Cargo Door Shell Door Gas Spring Maintenance |

| 11-22. | Cargo Door Shell Door Strap Replacement |

| 11-23. | Cargo Door Shell Door Seal Protector Replacement |

| 11-24. | Cargo Shell Door Seal Replacement |

| 11-25. | Cargo Shell Door Front Striker |

| Replacement | |

| 11-26. | Cargo Shell Door Rear Striker |

| Replacement | |

| 11-27. | Cargo Shell Door Rear Striker Mounting Plate |

| Replacement | |

| 11-28. | Cargo Shell Door Dovetail Spring |

| Replacement | |

| 11-29. | Cargo Shell Door Gas Spring Mounting Bracket |

| Replacement | |

| 11-30. | Cargo Shell Door Liner Replacement |

| 11-30.1. | "B" Pillar Padding Replacement |

| 11-31. | Cargo Shell Roof Insulation Panel |

| Replacement | |

| 11-32. | Hood Side Armor Plate Replacement |

| 11-33. | Hood Center Armor Plate Replacement |

| 11-34. | Hood Top Armored Grille Replacement |

| 11-35. | Hood Front Armored Grille Replacement |

| 11-36. | Right Cowl Armor Plate Replacement |

| 11-37. | Left Cowl Armor Plate Replacement |

| 11-38. | Footwell Armor Plate Replacement |

| 11-39. | Right Wheelhouse Armor Plate Replacement |

| 11-40. | Left Wheelhouse Armor Plate Replacement |

| 11-41. | Tailgate Armor Plate Replacement |

| 11-42. | Weapon Station Hatch Replacement |

| 11-43. | Weapon Station Hatch Handle Replacement |

| 11-44. | Weapon Station Hatch Hinge Pin |

| Replacement | |

| 11-45. | Weapon Station Hatch Hinge Replacement |

| 11-46. | Weapon Station Hatch Holddown Striker |

| Replacement | |

| 11-47. | Weapon Station Tray Seal Replacement |

| 11-48. | Weapon Station Bumper Pad Replacement |

| 11-49. | Weapon Station Tray Lever Replacement |

| 11-50. | Weapon Station Hatch Latch Replacement |

| 11-51. | Weapon Station Hatch Tube Assembly |

| Replacement | |

| 11-52. | Hinge Pivot Bracket and Gunner's Sling |

| Replacement | |

| 11-53. | Gunner's Sling Hook Replacement |

| 11-56. | Turret Lock Replacement |

| 11-57. | TOW Mount Pedestal Replacement |

| 11-58. | TOW Mount Pedestal Cover Replacement |

| 11-59. | TOW Missile Guidance System Pan Replacement |

| 11-60. | Weapon Station Inclinometer Replacement |

| 11-61. | Armament Mount Panel Replacement |

| 11-62. | Armament Cover and Seal Replacement |

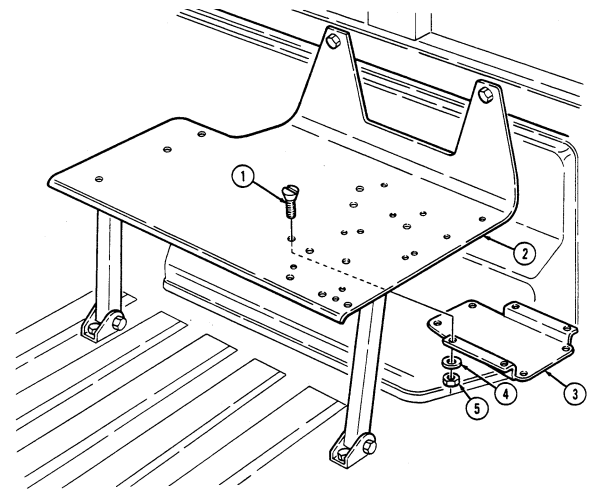

| 11-63. | Gunner's Platform Replacement |

| 11-64. | Gunner's Platform Assembly Maintenance |

| 11-65. | Gunner's Platform Assembly Replacement |

| 11-66. | Vehicle Power Conditioner (VPC) Mounting Bracket Replacement |

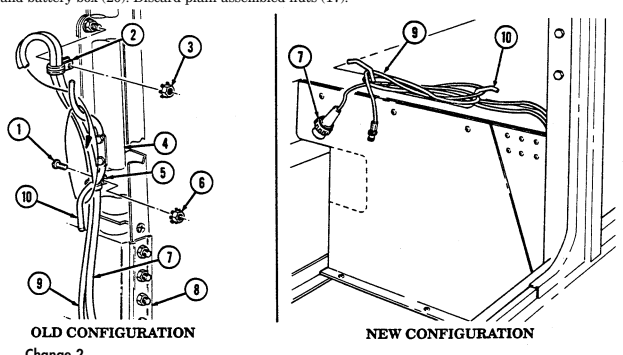

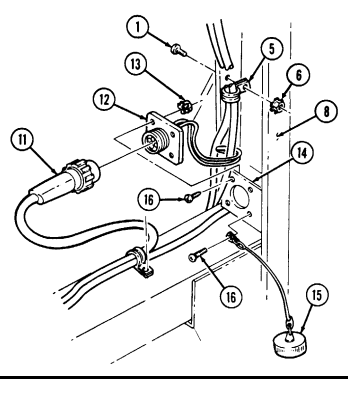

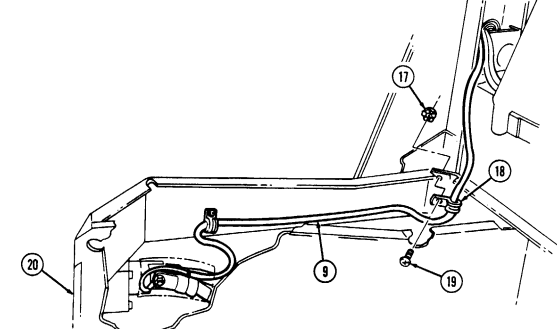

| 11-67. | Tow Wiring Harness Replacement |

| 11-68. | Cable Stowage Cleat Replacement |

| 11-69. | Field Glasses Bracket Replacement |

| 11-70. | Stowage Mount Bracket Replacement |

| 11-71. | Stowage Pedestal Replacement |

| 11-72. | Transversing Unit Mount Adapter |

| 11-74. | M16 Ammo Rack Assembly Replacement |

| 11-75. | TOW Missile Rack Maintenance |

| 11-76. | Water Can Bumper Replacement |

| 11-78. | Tripod Mounting Bracket Replacement |

| 11-79. | Tripod Head Mounting Bracket Replacement |

| 11-80. | Fuel Can Tray and Hose Replacement |

| 11-81. | Day Sight Stowage Bracket Replacement |

| 11-82. | Night Sight Support Replacement |

| 11-83. | Night Sight Coolant Base Replacement |

| 11-84. | Front Night Sight Battery Bracket Replacement |

| 11-85. | Rear Night Sight Battery Bracket Replacement |

| Maintenance | |

| 11-73. | Elevation and Depression Stop Assembly |

| Maintenance | |

| 11-77. | Missile Guidance Set (MGS) Battery Rack Assembly Replacement |

| 11-86. | Boresight Collimeter or Night Sight |

| Mounting Spacers Replacement | |

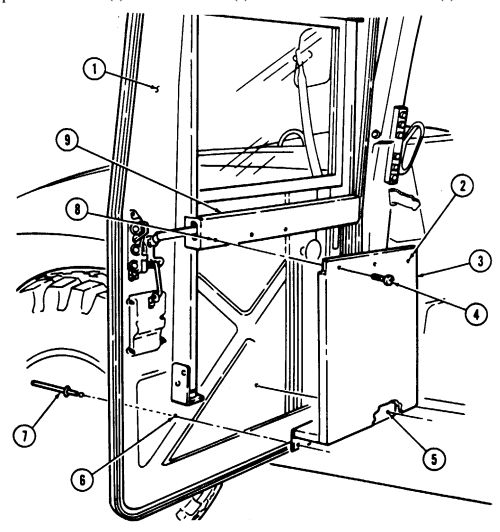

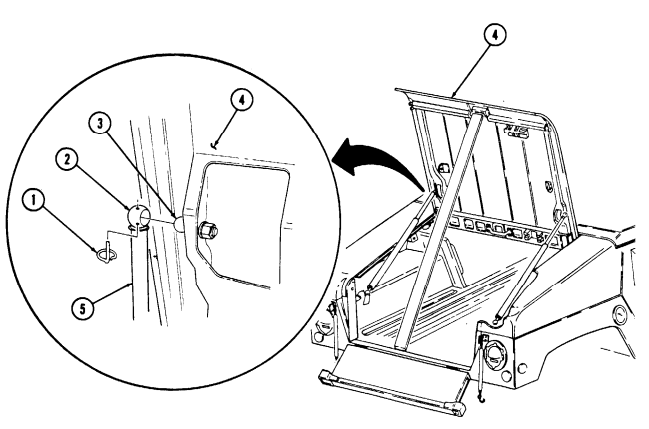

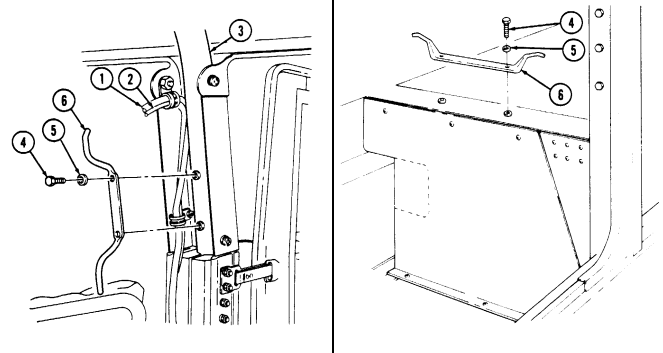

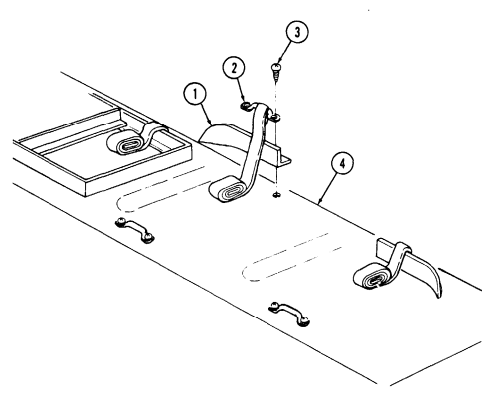

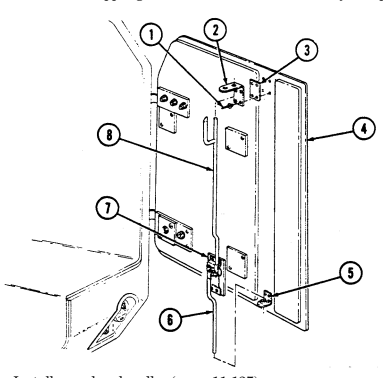

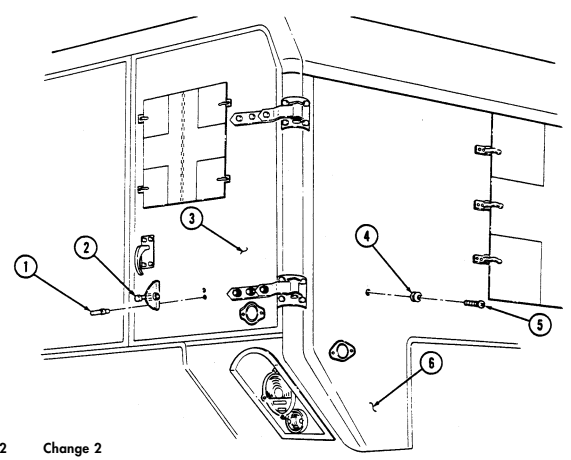

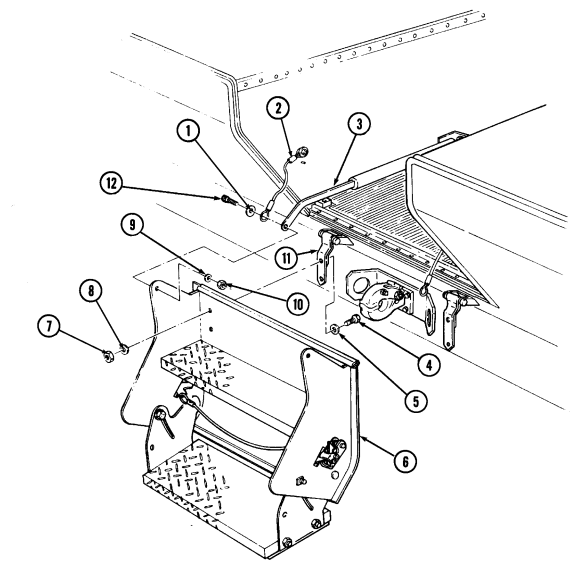

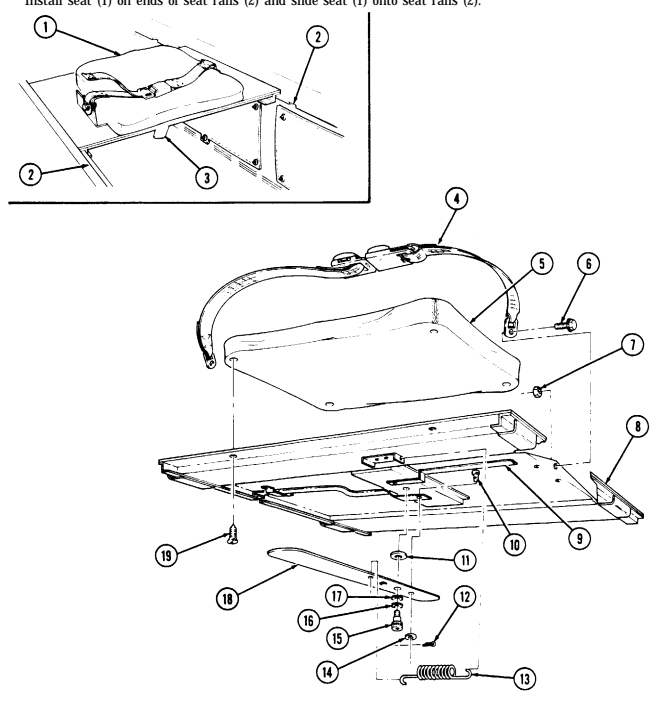

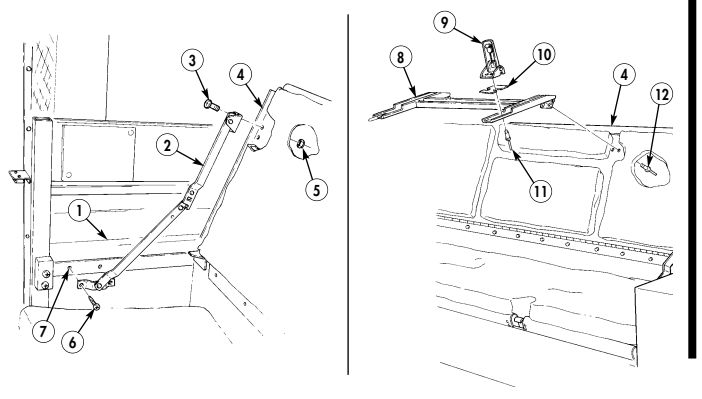

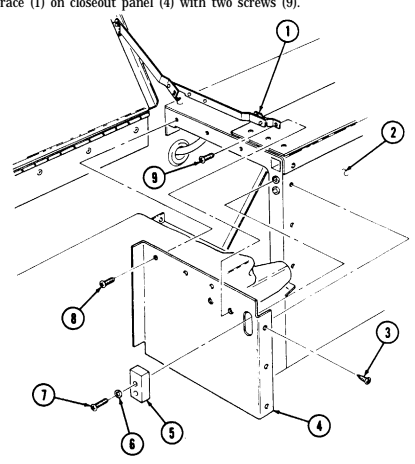

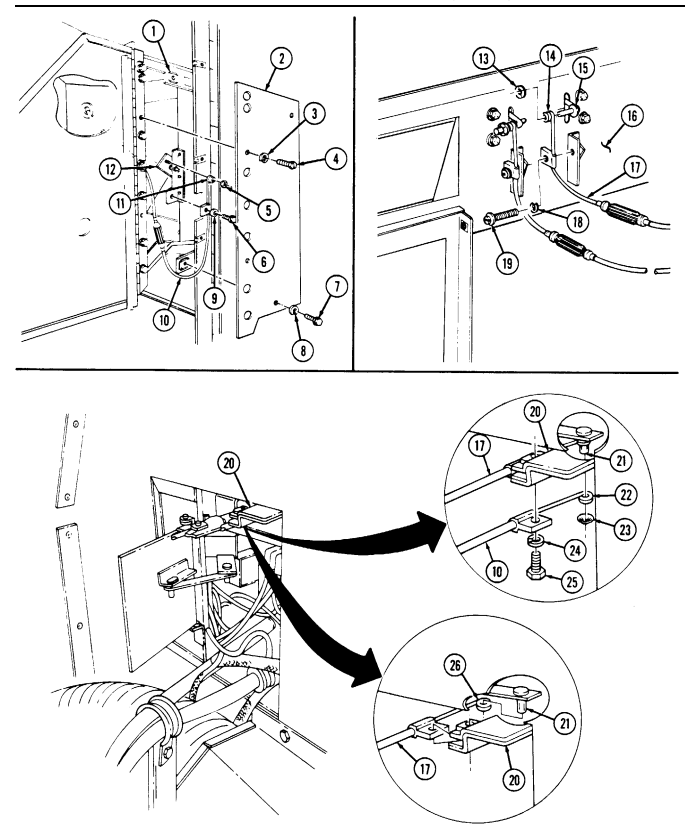

11-2. Ballistic Crew Door Maintenance

This task covers:

a. Removal c. Inspection b. Installation d. Adjustment

INITIAL SETUP:

Applicable Models

All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Six locknuts (Appendix G, Item 87) Spacer plate, 0.125-in. (3.2-mm) thick (Appendix G, Item 296)

Materials/Parts (Cont'D)

Spacer plate, 0.060-in. (1.5-mm) thick (Appendix G, Item 231) Spacer plate, hinge (Appendix G, Item 232) Personnel Required One mechanic One assistant Manual References TM 9-2320-280-24P

-

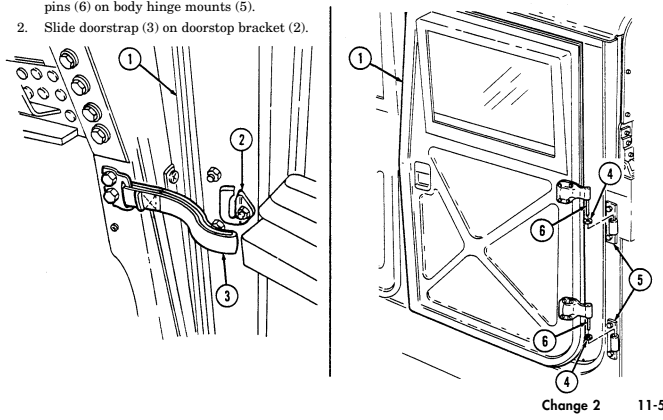

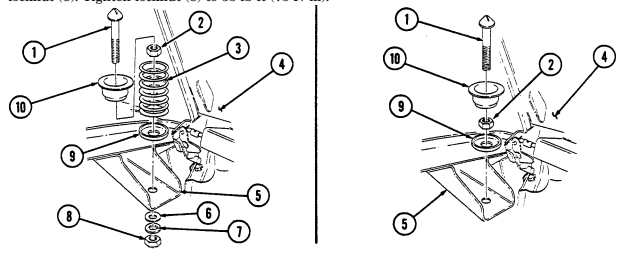

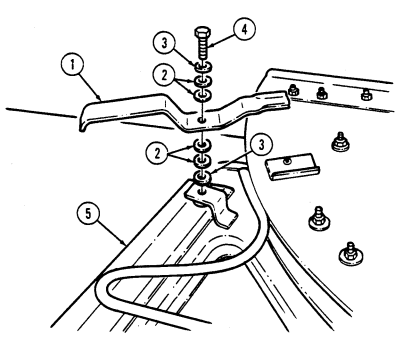

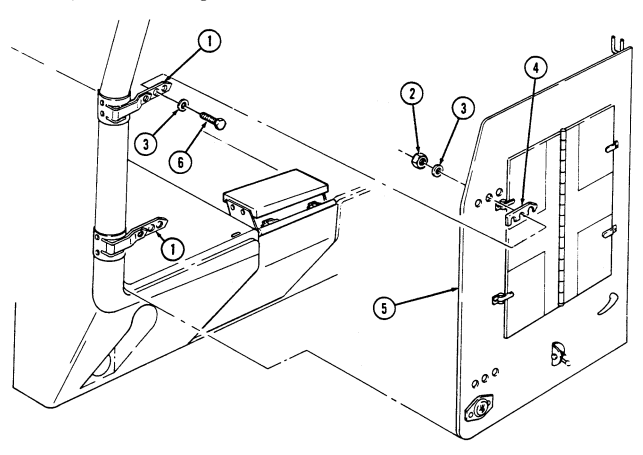

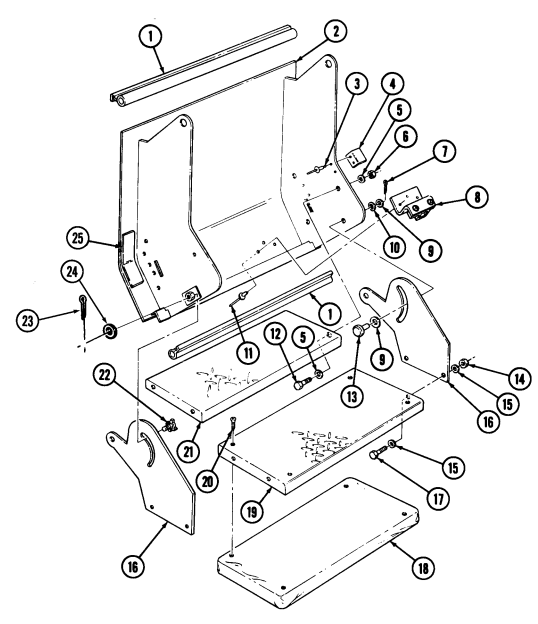

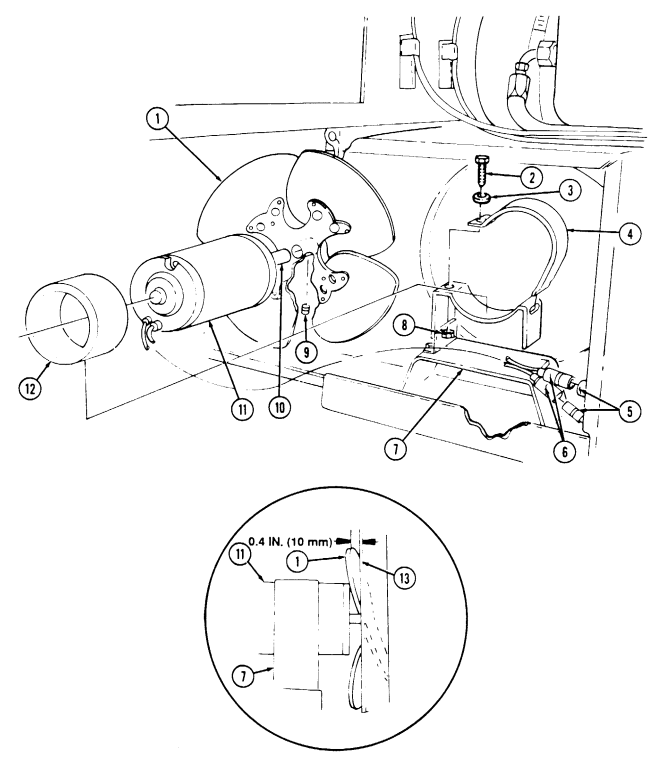

Slide doorstrap (3) off doorstop bracket (2). 2. Open and hold crew door (1) straight out from vehicle. Lift up crew door (1) to remove door hinge pins (6) from body hinge mounts (5) and remove crew door (1) and washers (4) (if present).

-

Hold crew door (1) straight out from vehicle and insert washers (4) (if removed) and door hinge

11-2. Ballistic Crew Door Maintenance (Cont'D)

-

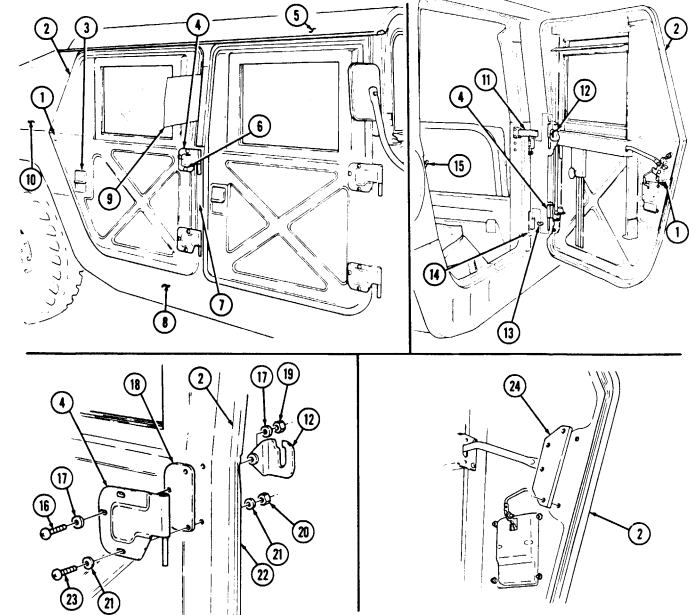

Inspect crew door assembly (2) for proper alignment. Ensure door (2) is centered between pillar (7), roof (5), cargo shell (10), and lower side rail (8). If out-of-alignment condition exists, perform horizontal or vertical adjustment procedures.

-

Inspect crew door assembly (2) to ensure latch (1) is closing completely on striker (15) without extreme force. If latch (1) is out of adjustment, perform latch (1) adjustment procedures.

-

Inspect hinge (4) and latch (1) for adjustment. Insert a piece of paper (9) between crew door assembly (2) and pillar (7), and close door (2). Perform this test at four or five locations around the door (2). Door seals should offer some resistance when paper is pulled out. If door seal does not offer resistance, or resistance is excessive, perform hinge and latch adjustment procedures.

-

Inspect latch (1), hinge (4), and door handle (3) for loose, missing, or unserviceable parts.

I d. Adjustment

Perform steps 1 and 2 for horizontal adjustment. Perform steps 3 through 6 for vertical adjustment. Perform steps 7 through 18 for hinge adjustment and steps 19 through 23 for latch adjustment.

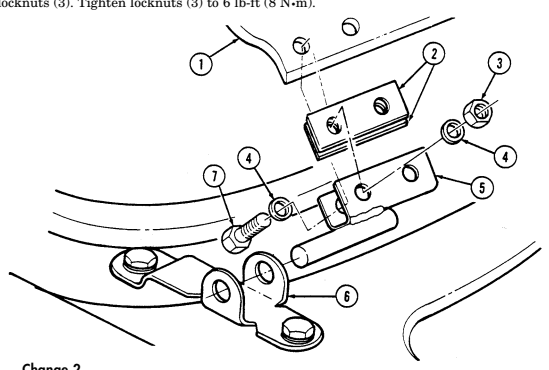

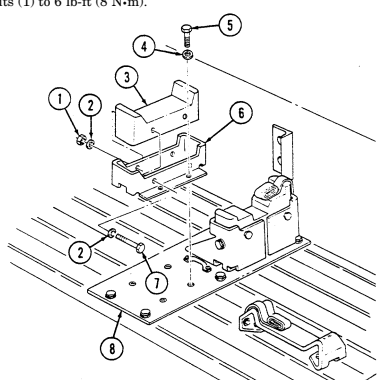

Loosen six screws (6) from two hinges (4) and crew door assembly (2).

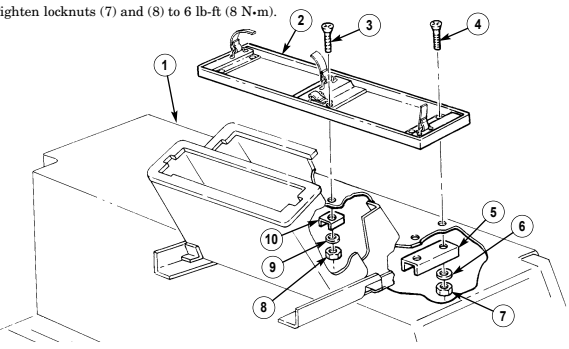

Align and center crew door assembly (2) between pillar (7), roof (5), cargo shell (10), and lower side rail (8). Tighten six screws (6) to 6 lb-ft (8 N-m). Remove door strap (11) from doorstop bracket (12). Open crew door assembly (2) to approximately 45°, and lift and remove door (2) from body hinge mounts (14). Install washer (13) on each door hinge (4), and install crew door assembly (2) on body hinge mounts (14). Check vertical adjustment and repeat steps if necessary. Remove door strap (11) from doorstop bracket (12).

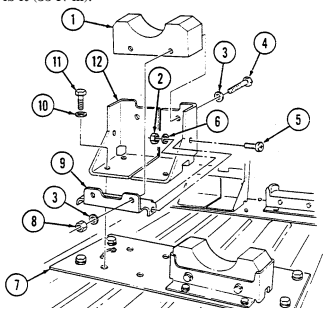

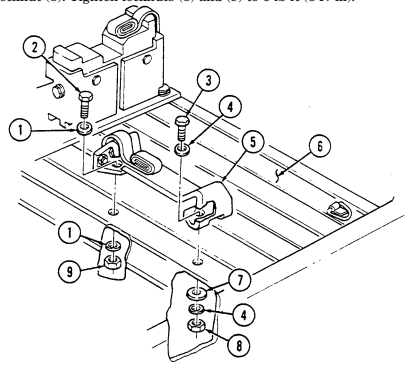

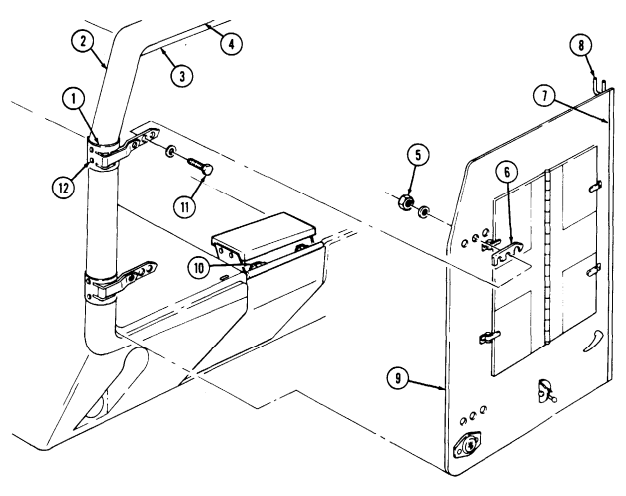

Open crew door assembly (2) to approximately 45°, and lift door (2) and remove washers (13) (if installed) from body hinge mounts (14). Remove locknut (19), washer (17), screw (16), washer (17), and doorstop bracket (12) from crew door assembly (2). Discard locknut (19). Remove five locknuts (20), washers (21), screws (23), washers (21), two hinges (4), and spacer plates (18) (if installed) from crew door assembly (2). Discard locknuts (20).

To increase resistance to that portion of the door seal (22), install two hinge spacer plates (18) between door hinge (4) and outer side of crew door assembly (2). To decrease resistance to that portion of the door seal (22), discard hinge spacer plate (18) between door hinge (4) and outer side of crew door assembly (2). Install two spacer plates (18) (if required) and door hinges (4) on crew door assembly (2) with five washers (21), screws (23), washers (21), and locknuts (20).

Install doorstop bracket (12) on crew door assembly (2) with washer (17), screw (16), washer (17), and locknut (19). Tighten locknuts (19) and (20) installed in steps 13 and 14 to 6 lb-ft (8 Nom). Install two door hinge washers (13) (if removed), position crew assembly door (2) to approximately 45°, and install door hinges (4) on body hinge mounts (14).

Check hinge (4) adjustment and repeat steps if necessary.

Install door strap (11) on doorstop bracket (12).

11-2. Ballistic Crew Door Maintenance (Cont'D)

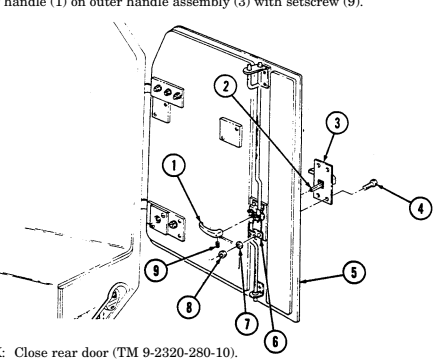

Remove crew door latch (para. 11-11).

s To increase resistance to door seal and adjust rear of crew door assembly, perform step 20.

- To decrease resistance to door seal and adjust rear of crew door assembly, perform step 21.

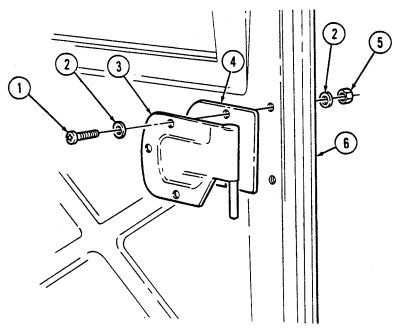

Discard spacer plate(s) (24) from crew door (2). Add spacer plate (24) 0.125-in. (3.2-mm) thick or spacer plate (24) 0.060-in. (1.5-mm) thick to crew door (2).

Install crew door latch (para. 11-11). Check door latch adjustment and repeat steps if necessary.

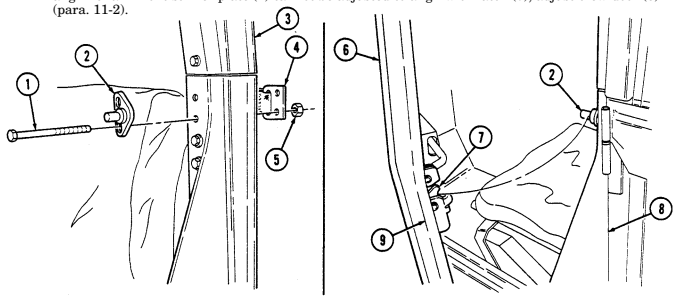

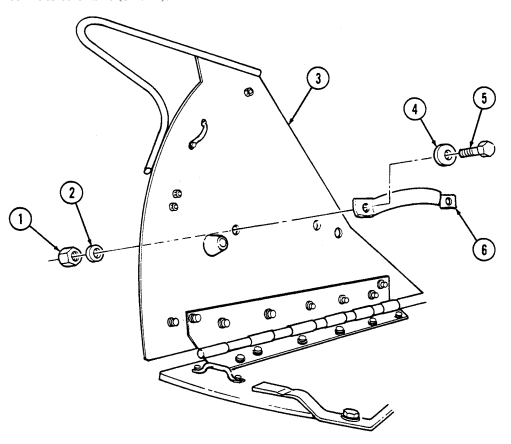

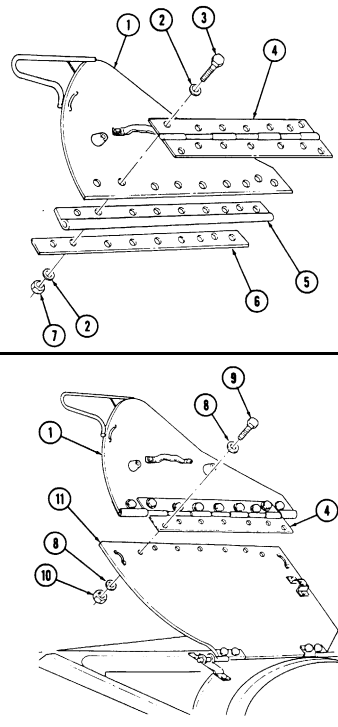

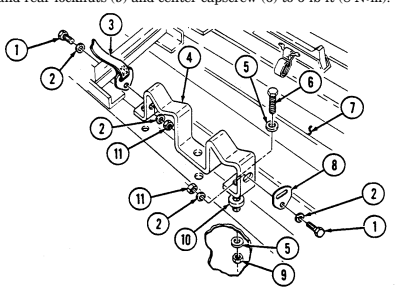

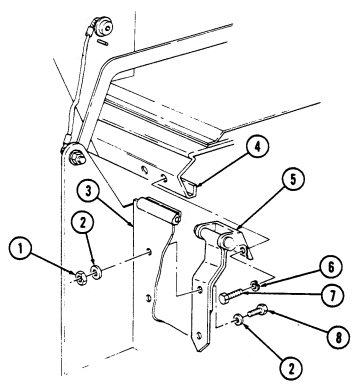

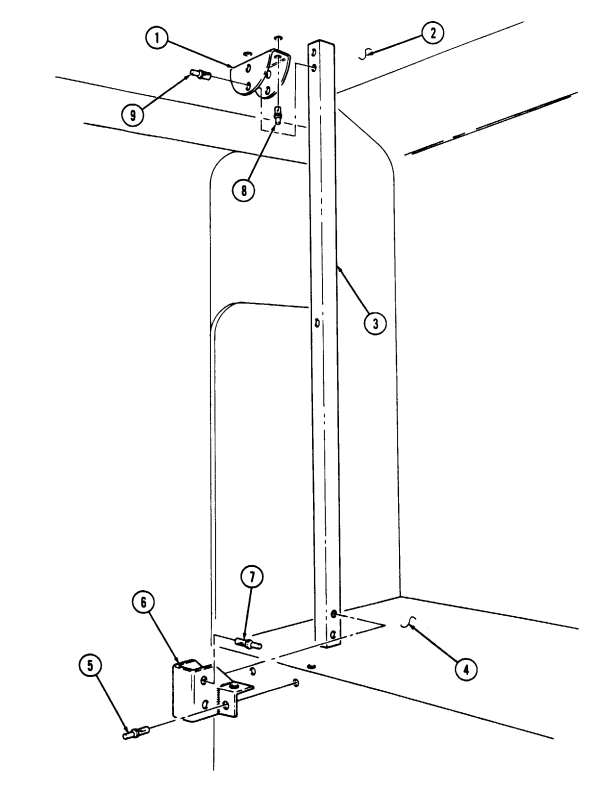

11-3. Ballistic Crew Door Hinge Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation Materials/Parts Three locknuts (Appendix G, Item 87) Manual References TM 9-2320-280-24P Equipment Condition Ballistic crew door removed (para. 11-2).

-

M966, M966A1, M996, M996A1, M997, M997A1, M997A2, M1025, M1025A1, M1025A2, M1026, M1026A1, and M1036 vehicles have one additional hinge shim on the inner door side of each door hinge mounting hardware.

-

On top hinges, note position of doorstop bracket.

a. Removal Remove three locknuts (5), washers (2), screws (1), washers (2), hinge (3), and shim(s) (4) from crew door (6). Discard locknuts (5).

Install shim(s) (4) and hinge (3) on crew door (6) with three washers (2), capscrews (1), washers (2), and

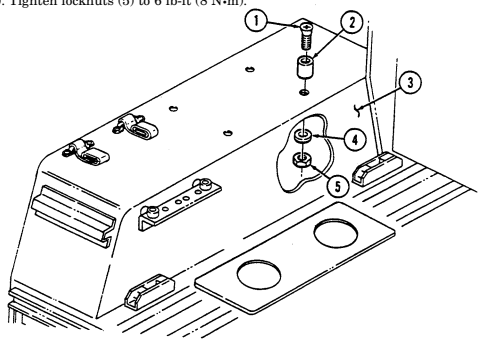

locknuts (5). Tighten locknuts (5) to 6 lb-ft (8 N•m).

locknuts (5). Tighten locknuts (5) to 6 lb-ft (8 N•m).

FOLLOW-ON TASK: Install ballistic crew door (para. 11-2).

11-8 Change 2

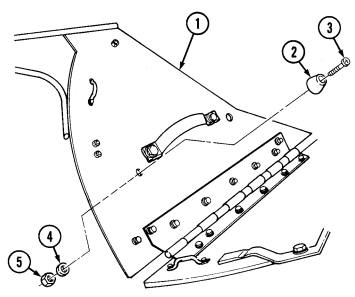

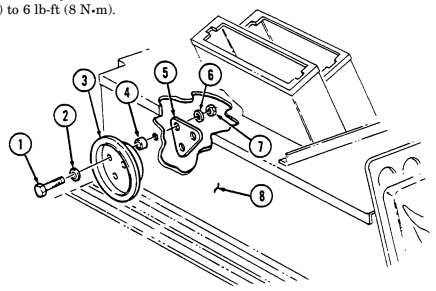

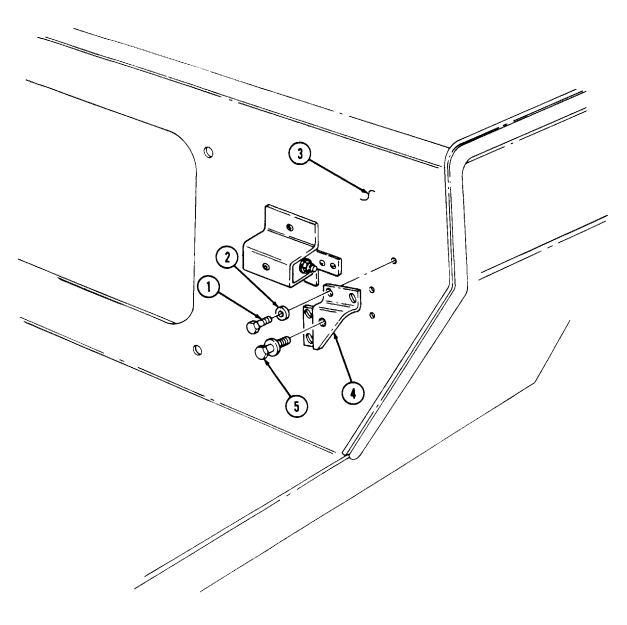

11-4. Ballistic Crew Door Rear Striker Plate Replacement I

This task covers: INITIAL SETUP: Applicable Models Materials/Parts All models except M998, M998A1, M1035, Tape (Appendix C, Item 50) M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Manual References Tools Gereral mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation

| Materials/Parts (Cont'd) |

|---|

| (Appendix G, Item 231) |

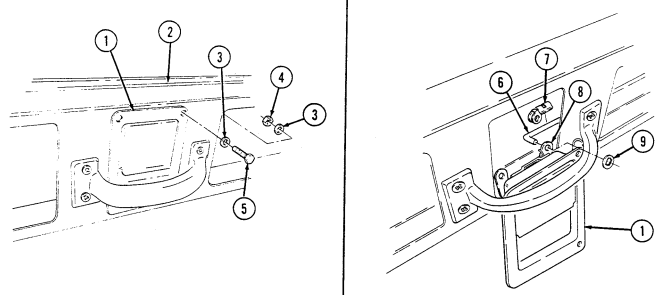

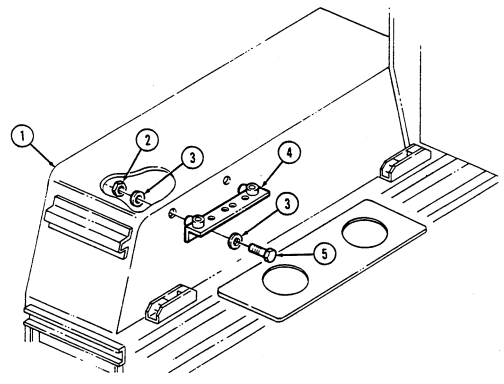

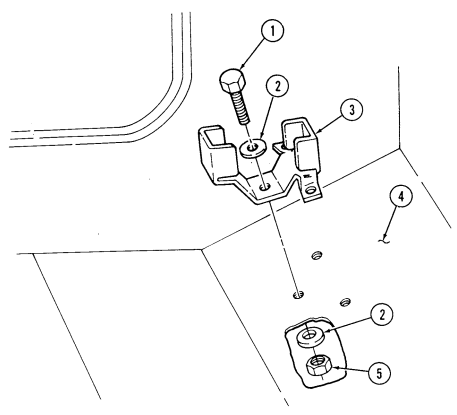

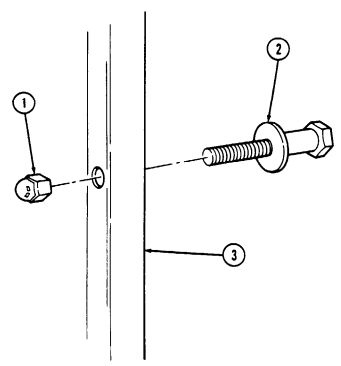

Remove two capscrews (4), washers (3), and rear striker plate (2) from body (1). Remove tape from rear striker plate (2) and discard tape.

I b. Installation Apply tape to rear striker plate (2) mounting surface. Install rear striker plats (2) on body (1) with two

washers (3) and capscrews (4). Tighten capscrews (4) to 8 lb-ft (11 Nom).

washers (3) and capscrews (4). Tighten capscrews (4) to 8 lb-ft (11 Nom).

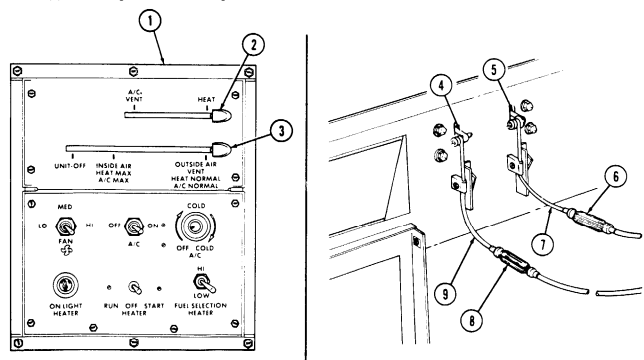

11-5. Ballistic Crew Door Front Striker Plate Maintenance

This task covers: a. Removal c. Adjustment b. Installation

Initial Setup:

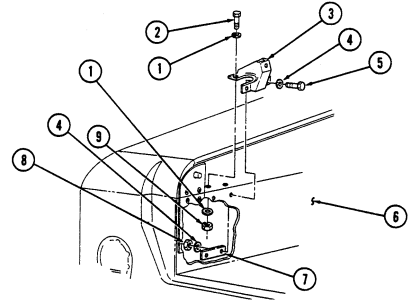

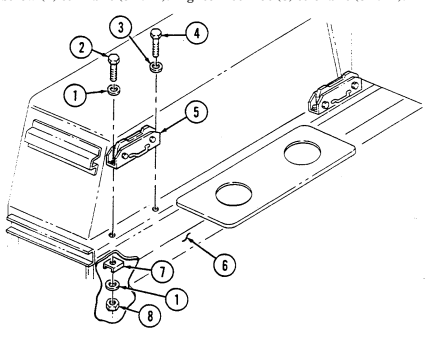

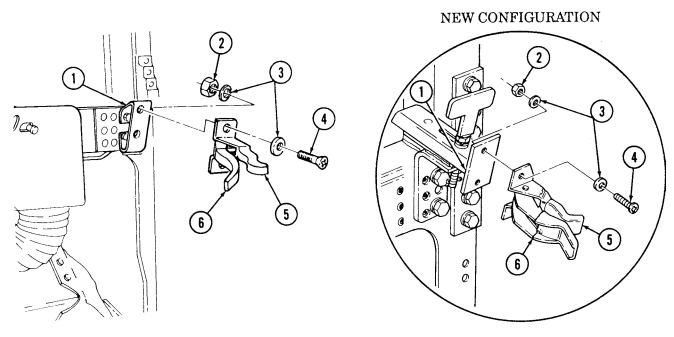

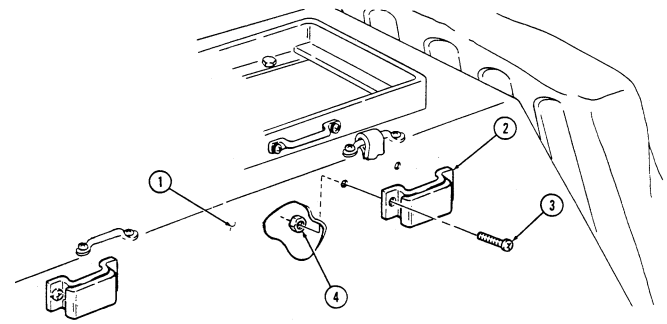

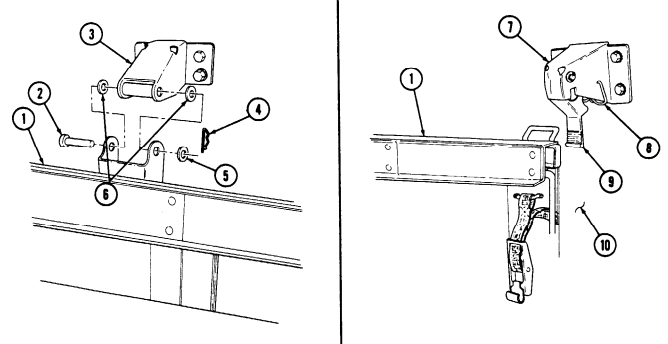

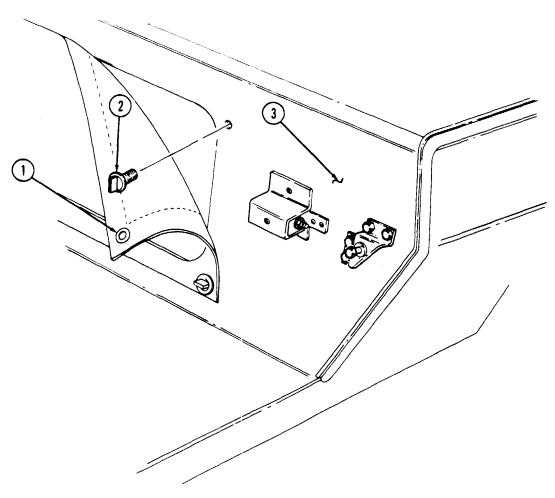

Applicable Models All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal Materials/Parts Tape (Appendix C, Item 50) Two locknuts (Appendix G, Item 86) Manual References TM 9-2320-280-24P Remove two locknuts (5), door strap (4), two capscrews (1), and front striker plate (2) from "B" pillar (3). Discard locknuts (5). Remove tape from front striker plate (2) and discard tape.

Apply tape to front striker plate (2) mounting surface. Install front striker plate (2) on "B" pillar (3) with two capscrews (1), door strap (4), and two locknuts (5). Finger tighten locknuts (5).

C. Adjustment

- Close door (6) ensuring latch (7) latches on front striker plate (2).

Front striker plates are slotted for vertical adjustment.

-

Press crew door (6) slightly inward and upward until seal (9) contacts body (8). Tighten locknuts (5) to 19 lb-ft (26 N•m).

-

Open and close crew door (6) several times to ensure proper latch (7) and front striker plate (2) alignment. If front striker plate (2) cannot be adjusted to align with latch (7), adjust crew door (6)

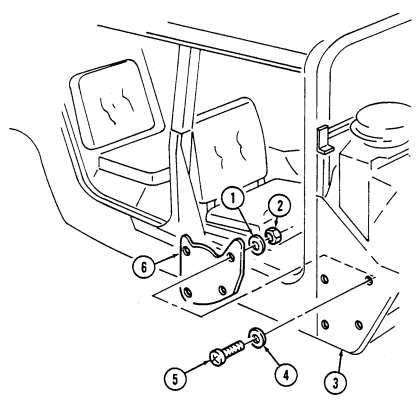

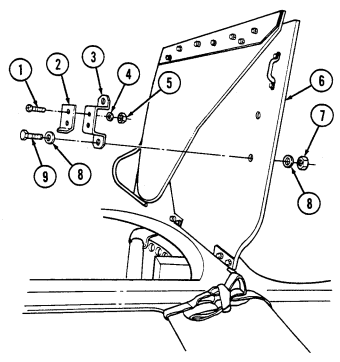

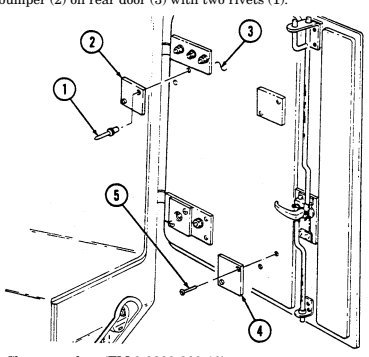

11-6. Ballistic Crew Door Paddle Lock Replacement

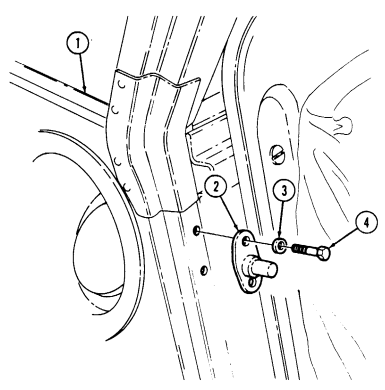

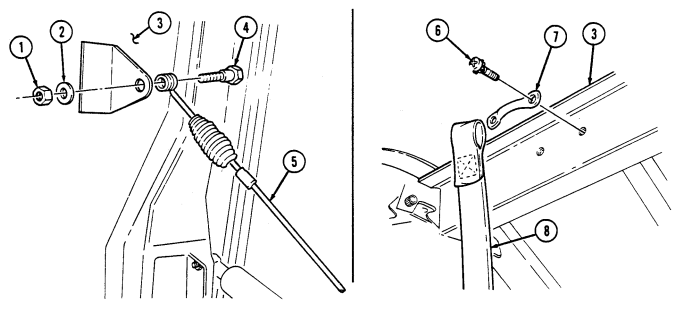

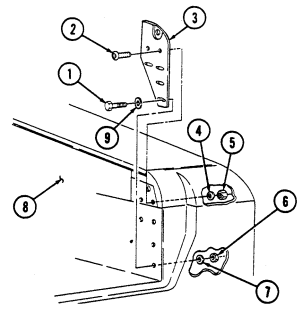

This task covers: INITIAL SETUP: Applicable Models All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation Materials/Parts Four locknuts (Appendix G, Item 85) Manual References TM 9-2320-280-24P a. Removal 1. Release clevis clip (3) from hook (4) and remove hook (4) and clevis clip (3) from paddle lock (2). 2. Remove four locknuts (7), washers (6), screws (5), and paddle lock (2) from crew door (1). Discard locknuts (7).

b. Installation 1. Install paddle lock (2) on crew door (1) with four screws (5), washers (6), and locknuts (7). Tighten locknuts (7) to 12-17 lb-in. (1-2 N•m).

- Connect hook (4) to paddle lock (2) with clevis clip (3).

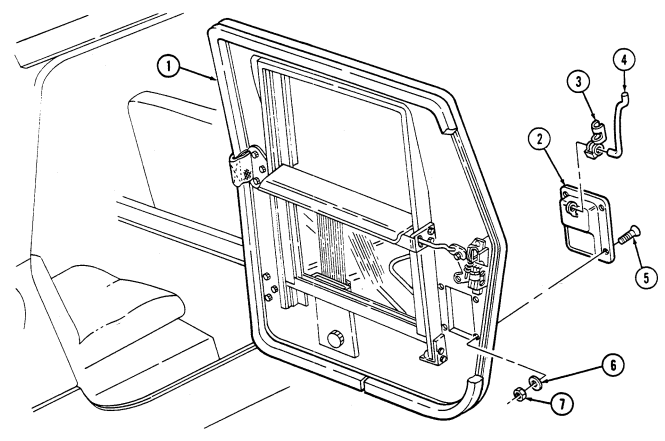

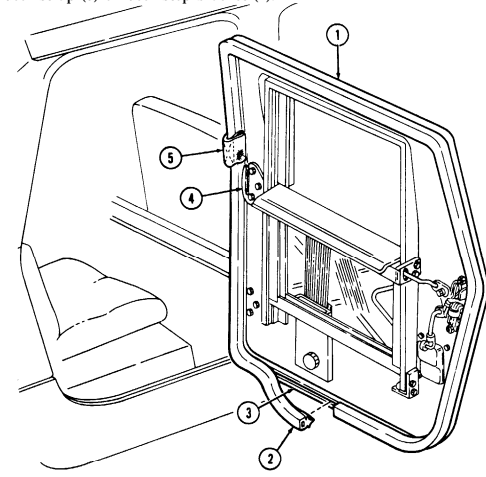

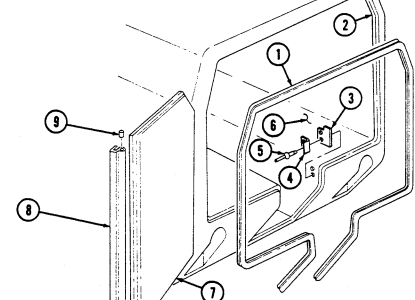

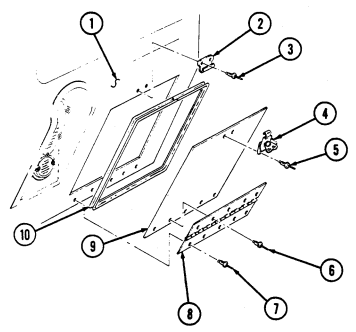

11-7. Ballistic Crew Door Window Assembly Maintenance

This task covers:

a. Removal c. Assembly b. Disassembly d. Installation

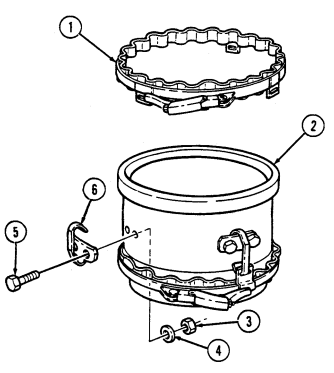

Initial Setup:

Applicable Models All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

Sealing compound (Appendix C, Item 43) Retaining ring (Appendix G, Item 231) Manual References TM 9-2320-280-24P Equipment Condition

- Window stops removed (para. 11-9). - Latch tube removed (para. 11-12).

a. Removal Pull out on window latch knob (4) and slide window (5) down and out from door side rails (1) and guide channel (2).

b. Disassembly 1. Remove latch knob (4) from pin (6).

- Remove four guide pins (7) from window (5).

c. Assembly 3. Apply sealing compound to threads of pin (6) and install latch knob (4) onto pin (6). 4. Install four rollers (8) on guide pins (7).

-

Remove retaining ring (9), pin (6), and spring (10) from window latch (3). Discard retaining ring (9). 3. Remove four rollers (8) from guide pins (7).

-

Apply sealing compound to threads of guide pins (7) and install guide pins (7) on window (5) frame. 2. Install spring (10) and pin (6) on window latch (3) with retaining ring (9).

Align window latch (3) with window guide channel (2) and push window (5) up into guide channel (2) and door side rails (1).

11-7. BALLISTIC CREW DOOR WINDOW ASSEMBLY MAINTENANCE Cont'd)

FOLLOW-ON TASKS: - Install latch tubs (para. 11-12).

- • Install window stops (para. 11-9).

11-8. Ballistic Crew Door Window Protective Shield Replacement

This task covers: a. Initial Installation c. Installation b. Removal INITIAL SETUP: Applicable Models All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Materials/Parts (Cont'D)

Protective shield (Appendix D, Fig. D-65) Two blind rivets (Appendix G, Item 253) Two blind rivets (Appendix G, Item 251) Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Manual References TM 43-0139 TM 9-2320-280-24P

-

The following procedure can be performed to prevent damage to door glass. This task can be accomplished with the approval of the unit commander.

-

Procedures for initial installation and replacement of the protective shields are basically the same for all windows. This procedure covers the left front protective shield.

a. Initial Installation

Initial installation steps apply only to vehicles that have not been previously retrofitted with protective shields.

- Position protective shield (3) on inside of ballistic door (1). 2. Using protective shield (3) as a template, locate and mark three top holes (2) and two bottom holes (5) on inside of ballistic door (1).

Ensure window is closed tightly before drilling holes for the protective shield.

- Drill three 0.156-in. (0.396-cm) diameter holes (8) through ballistic door frame (9). 4. Drill two 0.193-in. (0.490-cm) diameter holes (6) through ballistic door (1). 5. Install protective shield (3) on ballistic door fame (9) with three screws (4).

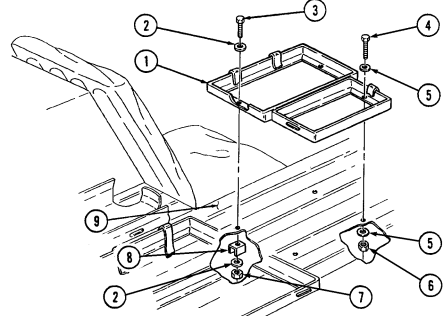

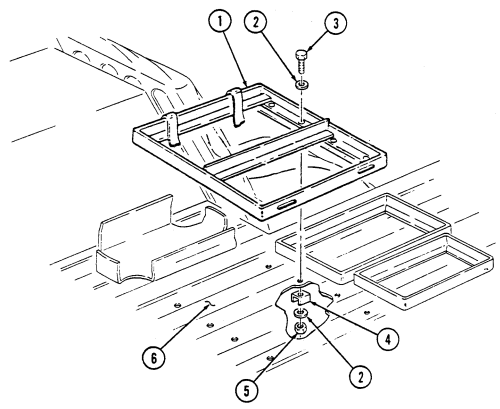

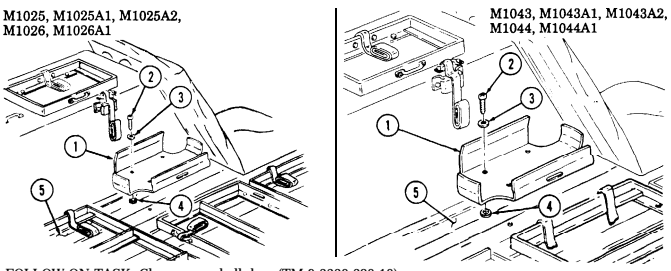

Perform step 6 for M966, M966A1, M996, M996A1, M997, M997A1, M997A2, M1025, M1025A1, M1025A2, M1026, M1026A1, and M1036 vehicles. Perform step 7 for M1043, M1043A1, M1043A2, M1044, M1044A1, M1045, M1045A1, M1045A2, M1046, and M1046A1 vehicles.

- Install protective shield (3) on ballistic door (1) with two 5/32-in. blind rivets (7). 7. Secure protective shield (3) to ballistic door (1) with two 3/16-in. blind rivets (7). 8. Spot paint ballistic door (1) and protective shield (3) as necessary. Refer to TM 43-0139.

11-8. Ballistic Crew Door Window Protective Shield Replacement (Cont'D)

For instructions on replacement of rivets, refer to para. 11-66.

-

Remove two rivets (7) from protective shield (3) and ballistic door 1l). 2. Remove three screws (4) and protective shield (3) from ballistic door frame (9).

-

Install protective shield (3) on ballistic doorframe (9) with three screws (4).

NOTE Perform step 2 for M966, M966A1, M996, M996A1, M997, M997A1, M997A2, M1025, M1025A1, M1025A2, M1026, M1026A1, and M1036 vehicles. Perform step 3 for M1043, M1043A1, M1043A2, M1044, M1044A1, M1045, M1045A1, M1045A2, M1046, and M1046A1 vehicles, 2. Install protective shield (3) on ballistic door (1) with two 5/32-in. blind rivets (7). 3. Install protective shield (3) on ballistic door (1) with two 3/16-in. blind rivets (7).

11-9. Ballistic Crew Door Window Stop Replacement

This task covers: INITIAL SETUP

Applicable Models

All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation Materials/Parts Two locknuts (Appendix G, Item 87) Locknut (Appendix G, Item 88) Manual References TM 9-2320-280-24P

Caution

If both window stops are being replaced, ensure ballistic window is locked in the full up position to prevent damage to window.

a. Removal 1. Remove two locknuts (2), screws (5), washers (4), and window stop bracket (6) from side rail (3).

Discard locknuts (2).

- Remove locknut (7), washer (8), screw (1), and pad (9) from window stop bracket (6). Discard locknut (7).

b. Installation 1. Install pad (9) on window stop bracket (6) with screw (1), washer (8), and locknut (7).

2. Install window stop bracket (6) on side rail (3) with two washers (4), screws (5), and locknuts (2).

2. Install window stop bracket (6) on side rail (3) with two washers (4), screws (5), and locknuts (2).

11-10. Ballistic Crew Door Seal Replacement

This task covers: a.Removal b. Installation INITIAL SETUP: Applicable Models Materials/Parts All models except M998, M998A1, M1035, Detergent (Appendix C, Item 17) M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Manual References TM 9-2320-280-24P Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

-

Slide door strap (5) off doorstop bracket (4).

-

Start at end of-seal (2) and pry seal (2) from seal retainer (3) around crew door (1).

-

Coat seal (2) with liquid detergent. Start at one end of seal (2) and press seal (2) into retainer (3)

around door (1).

- Slide door strap (5) on door stop bracket (4).

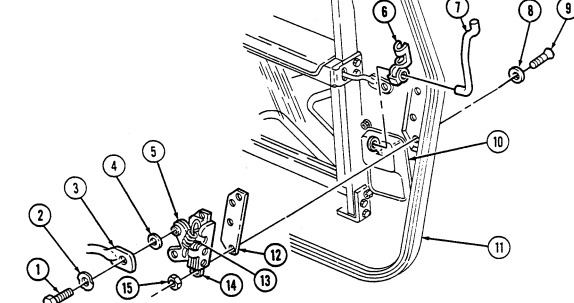

11-11. Ballistic Crew Door Latch Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

A. Removal B. Installation Materials/Parts

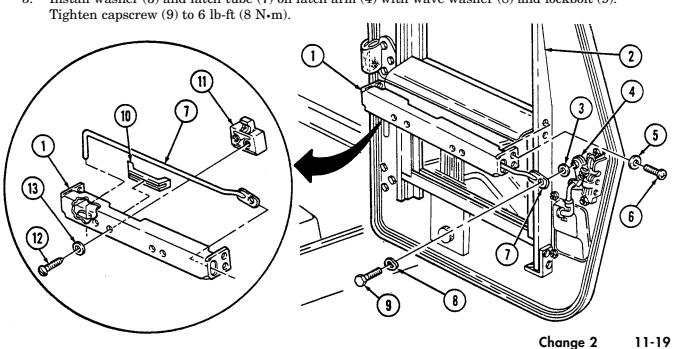

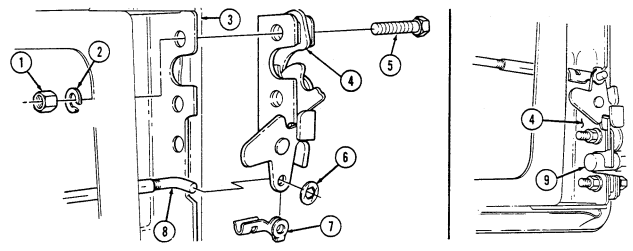

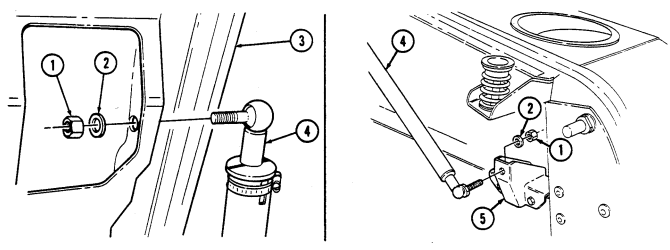

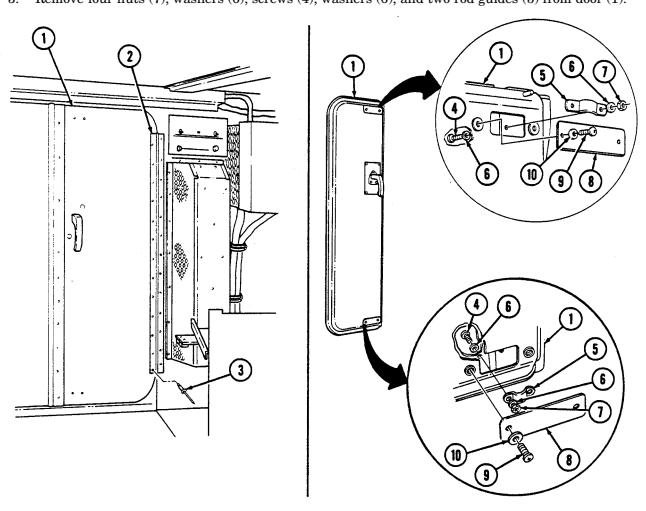

Lockbolt (Appendix G, Item 68) Four locknuts (Appendix G, Item 87) Manual References TM 9-2320-280-24P a. Removal 1. Remove clevis clip (6) and hook (7) from paddle lock (10) and disconnect hook (7) from door latch (14). 2. Disconnect spring (13) from top of latch (14). 3. Remove lockbolt (1), wave washer (2), latch tube (3), and washer (4) from latch arm (5). Discard lockbolt (1).

-

Remove four locknuts (15), washer (8), screws (9), latch (14), and spacer (12) from crew door (11) Discard locknuts (15).

-

Install spacer (12) and latch (14) on crew door (11) with four washers (8), screws (9), and locknuts (15).

Tighten locknuts (15) to 6 lb-ft (8 N•m).

- Connect spring (13) to top of latch (14). 3. Install washer (4) and latch tube (3) on latch arm (5) with wave washer (2) and lockbolt (1).

Tighten lockbolt (1) to 6 lb-ft (8 N•m).

- Install hook (7) on latch (14) and connect other end of hook (7) to paddle lock (10) with clevis clip (6).

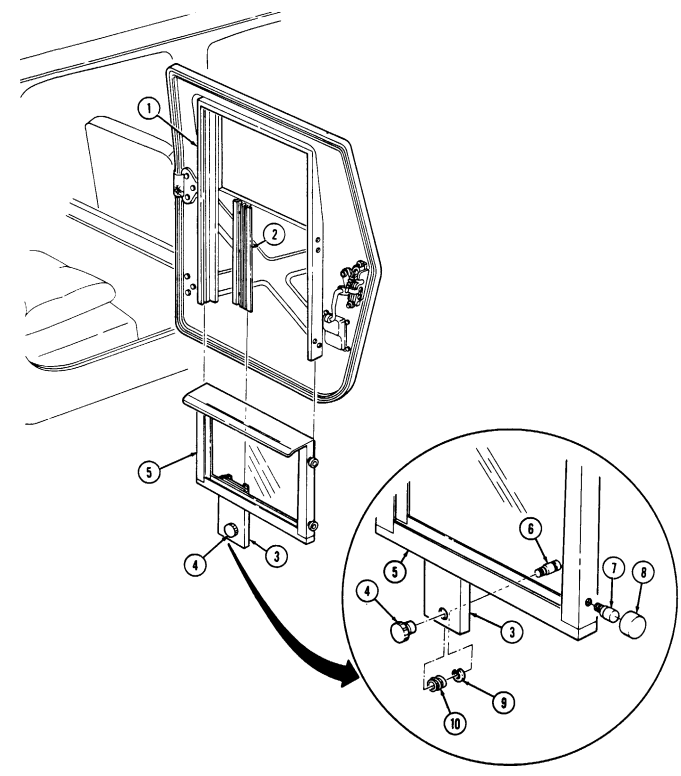

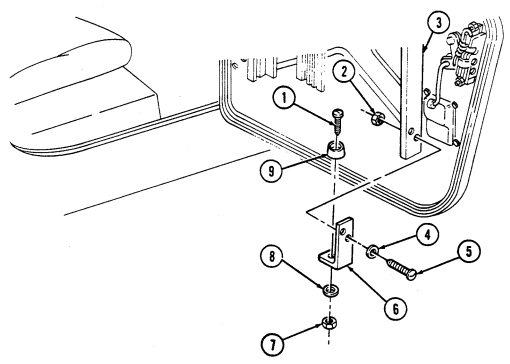

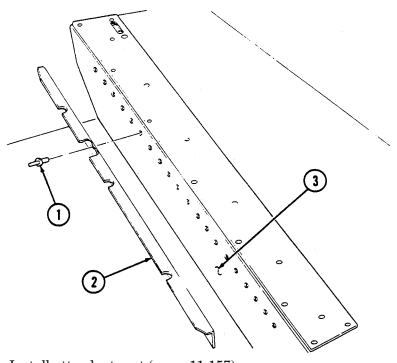

11-12. Ballistic Crew Door Latch Tube Replacement

This task covers: INITIAL SETUP:

Applicable Models

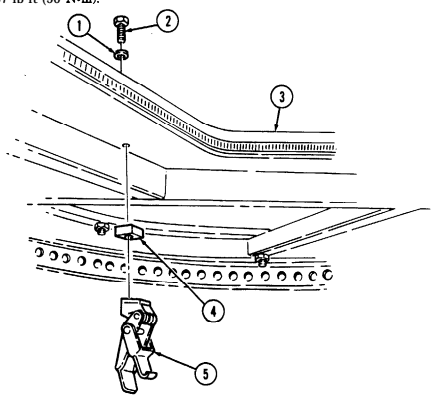

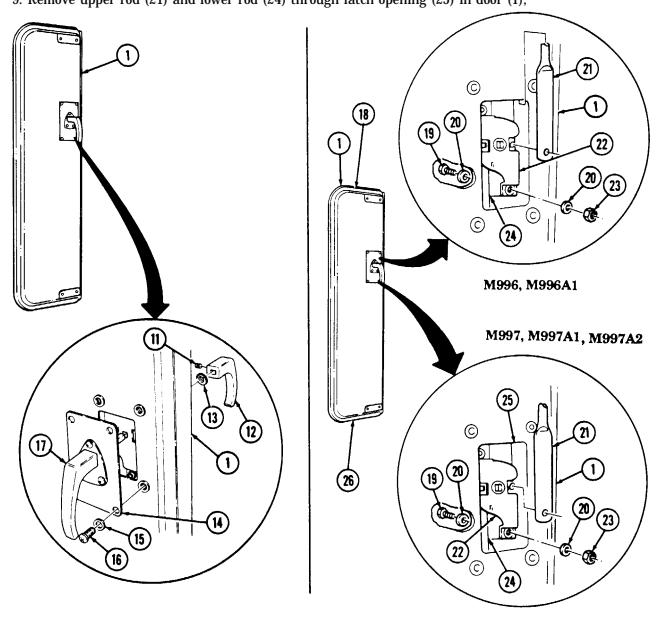

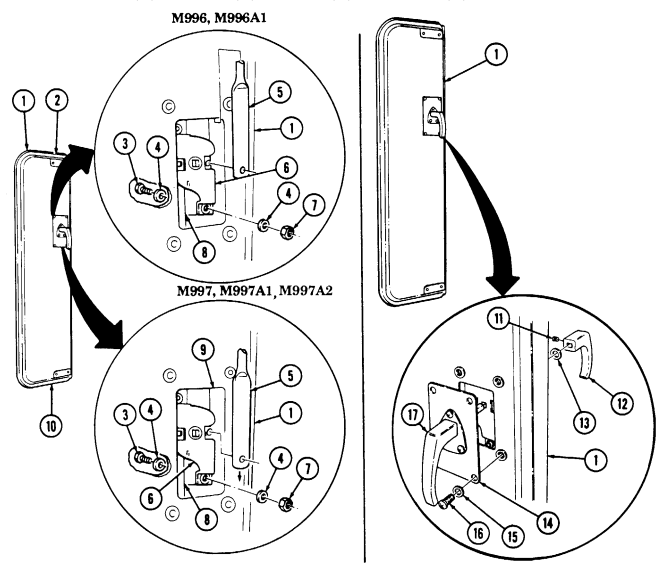

All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal 1. Remove lockbolt (9), wave washer (8), latch tube (7), and washer (3) from latch arm (4). Discard lockbolt (9).

-

Remove four screws (6), washers (5), and bracket (1) from side rails (2). Discard screws (6). 3. Remove two screws (12), washers (13), and guide (11) from bracket (1). 4. Slide latch tube (7) out of bracket (1). 5. Remove protector (10) from bracket (1).

-

Install protector (10) on bracket (1). 2. Slide latch tube (7) into bracket (1). 3. Install guide (11) on bracket (1) with two washers (13) and screws (12). 4. Install bracket (1) on side rails (2) with four washers (5) and screws (6). 5. Install washer (3) and latch tube (7) on latch arm (4) with wave washer (8) and lockbolt (9).

A. Removal B. Installation Materials/Parts

Lockbolt (Appendix G, Item 68) Four screws (Appendix G, Item 282) Manual References TM 9-2320-280-24P

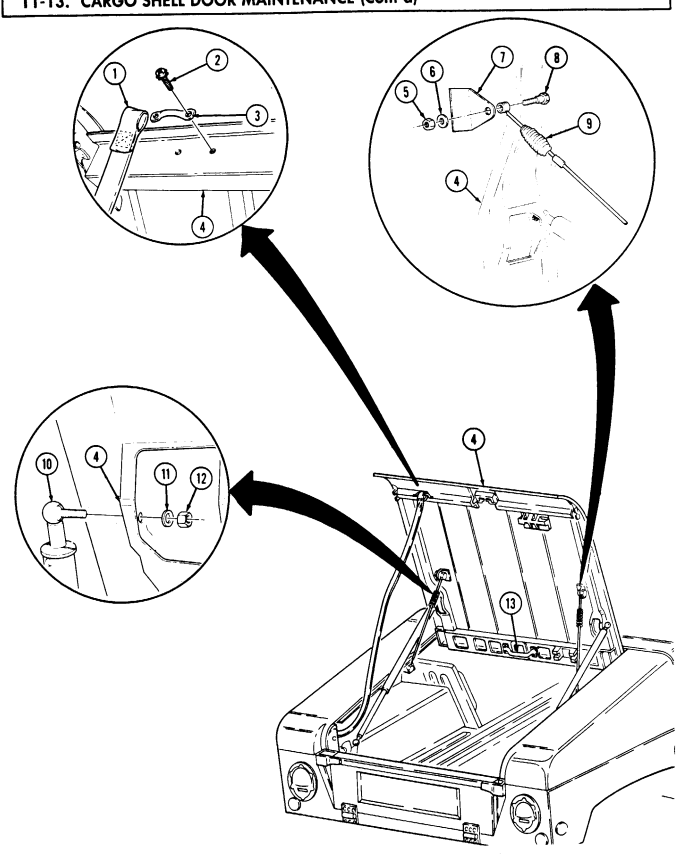

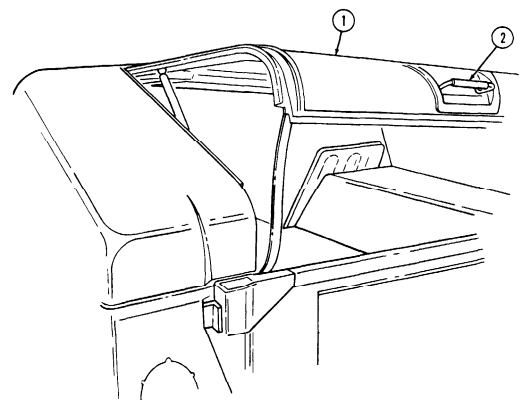

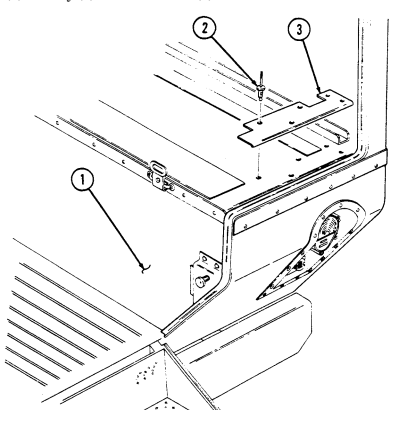

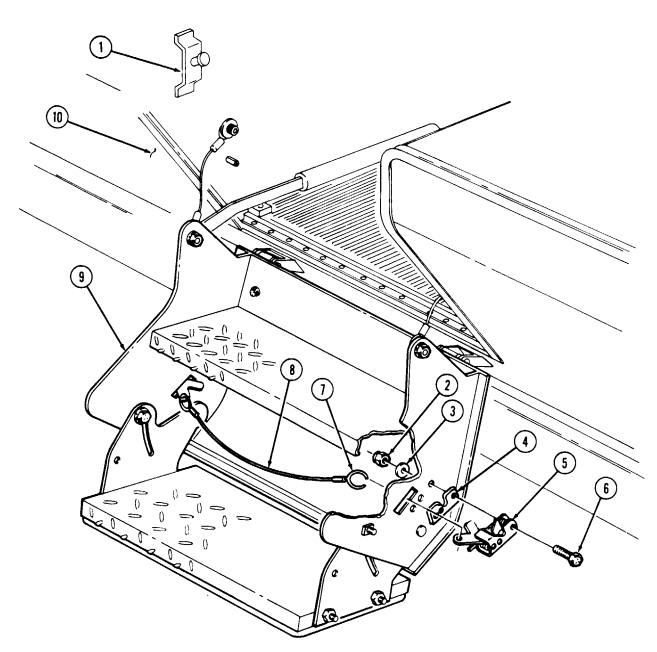

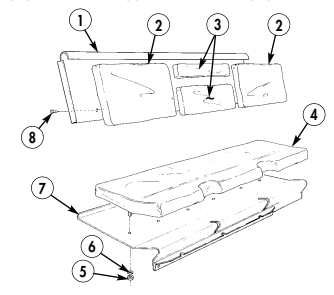

11-13. Cargo Shell Door Maintenance

This task covers: b. Installation

Initial Setup:

Applicable Models All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Two locknuts (Appendix G, Item 70) Two assembled washer screws (Appendix G, Item 279) Two locknuts (Appendix G, Item 79) a. Removal c. Adjustment

Personnel Required

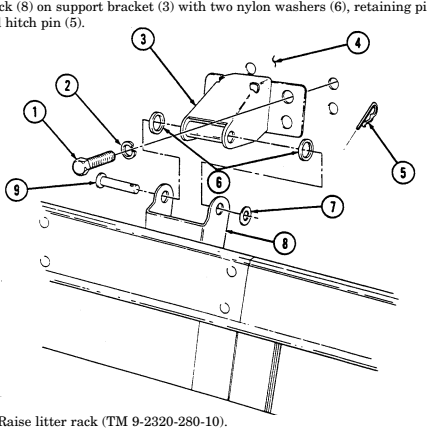

One mechanic One assistant Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Rear end of cargo shell door raised (TM 9-2320-280-10).

General Safety Instructions Never open one end of cargo shell door before ensuring opposite end is securely closed.

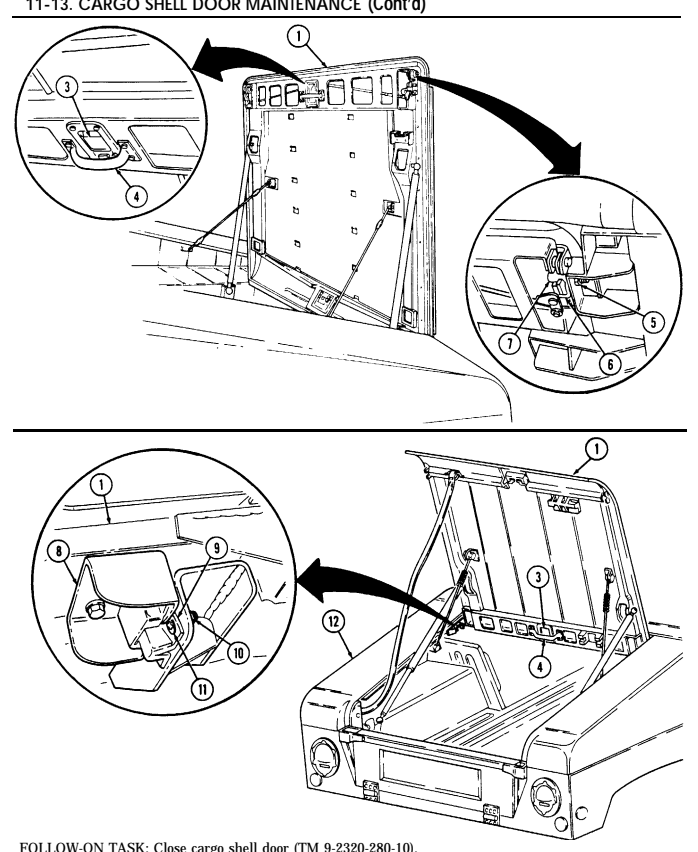

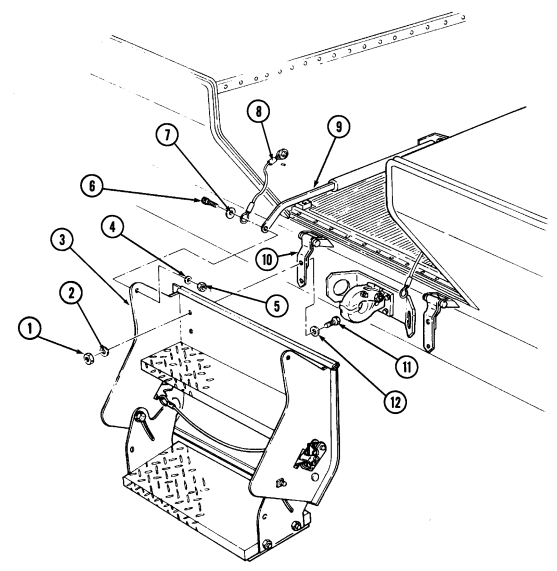

a. Removal

Warning

Opening one end of cargo door before ensuring opposite end is fully closed will cause both ends to open simultaneously, resulting in injury to personnel or damage to equipment.

-

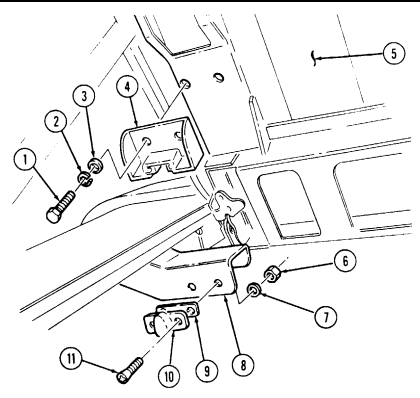

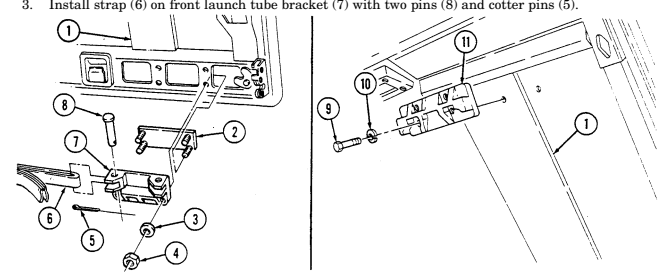

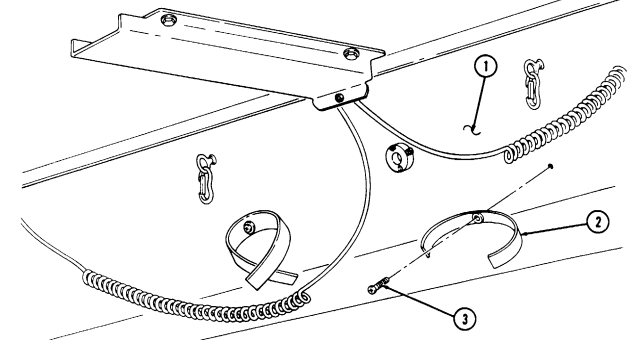

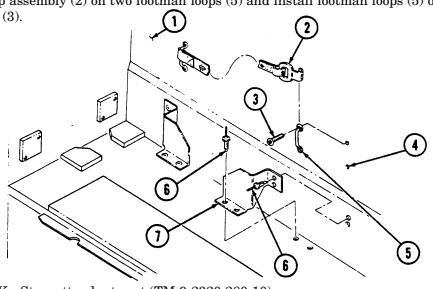

Remove two assembled washer screws (2) and footman loop (3) from strap (1) and cargo door (4). Discard assembled washer screws (2).

-

Lower cargo door (4) slightly, and remove two locknuts (5), washers (6), shoulder bolts (8), and retention cable (9) from two retention cable brackets (7). Discard locknuts (5).

-

Slowly raise cargo door (4) as far as possible to allow removal of gas springs (10) from cargo door (4).

-

Remove two locknuts (12), washers (11), and gas springs (10) from cargo door (4) and lay gas springs (10) inside vehicle. Discard locknuts (12).

-

Lower cargo door (4), release handle latch (13), and remove cargo door (4).

1 1-13. CARGO SHELL DOOR MAINTENANCE (Cont'd)

11-13. Cargo Shell Door Maintenance (Cont'D)

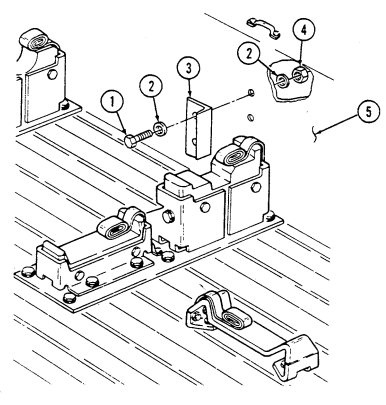

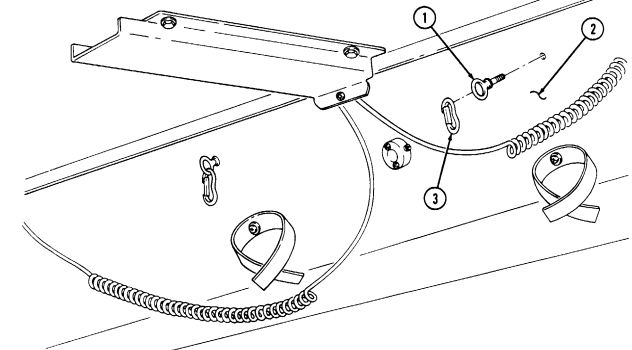

b. Installation 1. Install front latches (5) on front striker pins (6). 2. Push down on cargo door (4) edge to ensure front striker pins (6) are locked in front latches (5). 3. Slowly raise cargo door (4) as far as possible to allow installation of gas springs (1) on cargo door (4).

-

Connect two gas springs (1) to cargo door (4) with two washers (2) and locknuts (3). Tighten locknuts (3) to 15-20 lb-ft (20-27 N•m).

-

Connect two retention cables (14) to retention cable brackets (12) with two shoulder bolts (13), washers (11), and locknuts (10). Tighten locknuts (10) to 85-110 lb-in. (10-12 N•m).

-

Install strap (7) on cargo door (4) with footman loop (9) and two assembled washer screws (8).

To assist closing cargo shell door, a grab loop may be added. Refer to cargo shell door strap replacement (para. 11-22).

- Close cargo door (4), and ensure cargo door (4) is securely latched on rear striker pins (15).

11-13. Cargo Shell Door Maintenance (Cont'D)

11-13. Cargo Shell Door Maintenance (Cont'D)

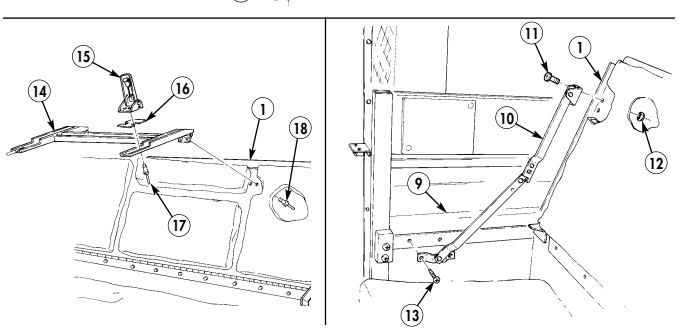

I C. Adjustment I

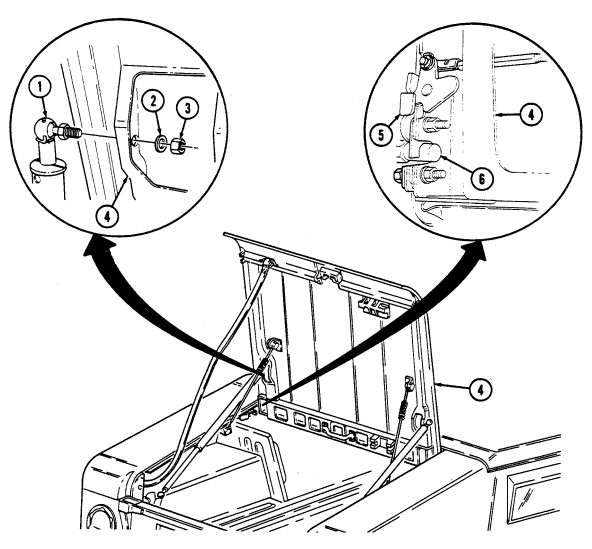

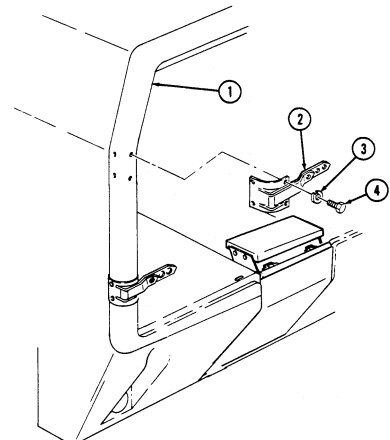

Pull rear wire handle (2) and raise rear end of cargo shell door (1). Perform steps 1 through 4 of a., Removal.

Close cargo door (1).

Release handle latch (3) and push cargo door (1) open. Loosen two front striker pin mounting nuts (5). Loosen two countersunk screws (11) and nuts (10) to allow movement of male dovetail (9).

Close cargo door (1). Ensure front striker pins (7) are secured and centered in front latches (6). Ensure male dovetail (9) is aligned with female dovetail (8).

It maybe necessary to shim front striker pins for proper door alignment and operation.

Pull down on handle (4) to ensure cargo door (1) properly seals to cargo shell (12). With striker pins (7) properly adjusted, tighten striker pin mounting nuts (5) to 35-45 lb-ft (47-61 N.m). Release handle latch (3) and push cargo door (1) open. Tighten two nuts (10) on male dovetail (9) to 85-110 lb-in. (10-12 N.m).

Lower cargo door (1). Ensure front striker pins (7) are secured and centered in front latches (6).

Raise cargo door (1) from rear wire handle (2) and perform steps 3 through 6 of b., Installation.

Insert a piece of paper between door seals and door opening. With cargo door closed, seals should offer resistance when pulling out paper. If door seals do not offer resistance, readjust cargo door.

11-13. CARGO SHELL DOOR MAINTENANCE (Cont'd)

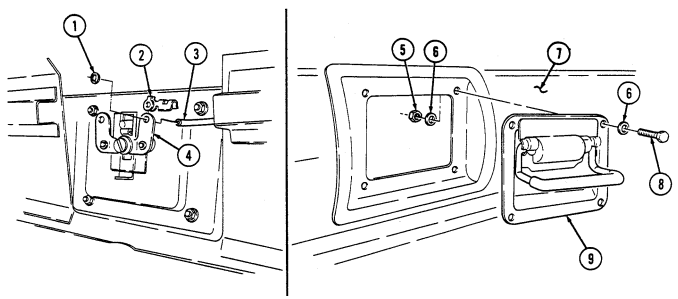

11-14. Cargo Shell Door Wire Handle Lock Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

A. Removal B. Installation Materials/Parts

Sealing compound (Appendix C, Item 45) Two push on nuts (Appendix G, Item 228) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Tailgate lowered (TM 9-2320-280-10).

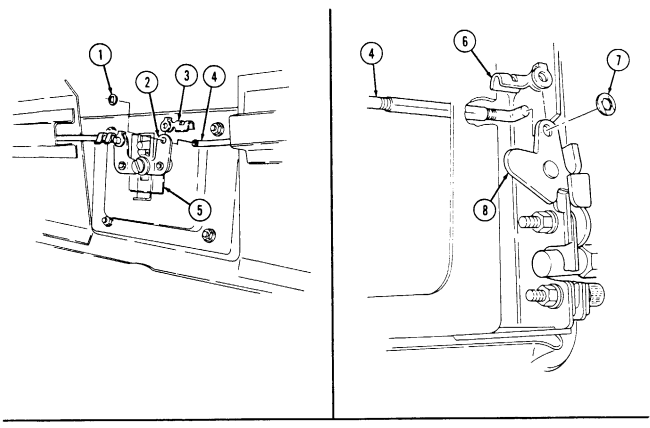

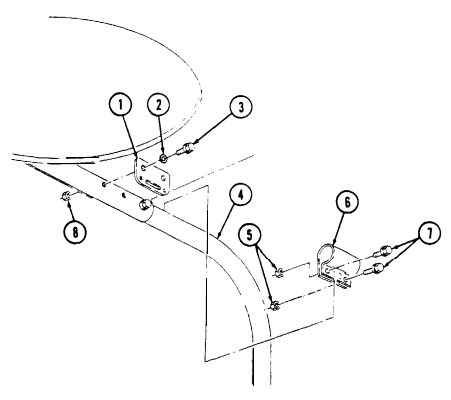

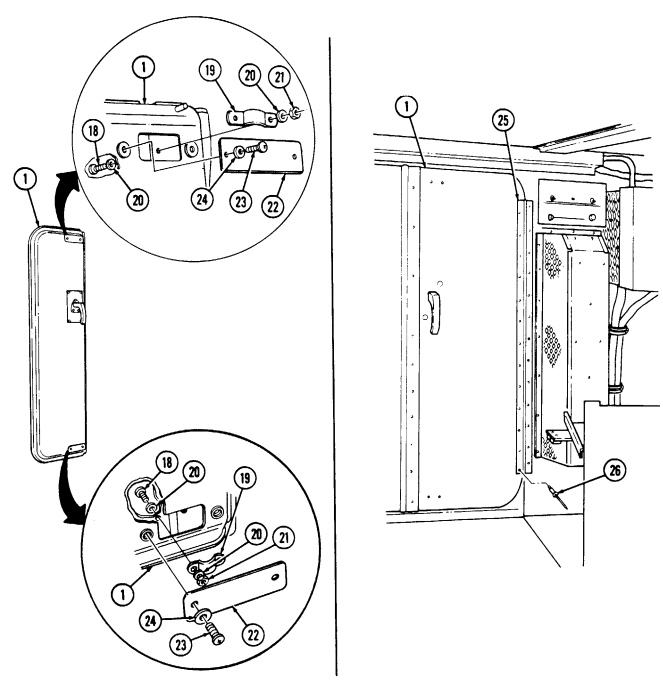

a. Removal 1. Remove two push on nuts (1), rod end clips (2), and latch rods (3) from wire handle lock pivot arms (4). Discard push on nuts (1).

- Remove four nuts (5), washers (6), capscrews (8), washers (6), and wire handle lock (9) from cargo door (7).

b. Installation 1. Apply sealing compound to threads of capscrews (8). 2. Install wire handle lock (9) on cargo door (7) with four washers (6), capscrews (8), washers (6), and nuts (5).

- Install two latch rods (3) on wire handle lock pivot arms (4) with rod end clips (2) and push on

nuts (1).

FOLLOW-ON TASKS: - Raise and secure tailgate (TM 9-2320-280-10).

- Check cargo shell door for proper operation (TM 9-2320-280-10).

11-15. Cargo Shell Door Grab Handle Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

A. Removal B. Installation Materials/Parts

Sealing compound (Appendix C, Item 45) Four lockwashers (Appendix G, Item 173) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Forward end of cargo shell door raised (TM 9-2320-280-10).

Remove four nuts (1), lockwashers (2), washers (3), countersunk screws (6), and grab handle (5) from cargo door (4). Discard lockwashers (3).

- Apply sealing compound to threads of countersunk screw (6). 2. Install grab handle (5) on cargo door (4) with four countersunk screws (6), washers (3),

lockwashers (2), and nuts (1).

FOLLOW-ON TASK: Close cargo shell door (TM 9-2320-280-10).

11-16. Cargo Shell Door Handle Latch Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation

Materials/Parts

Two push on nuts (Appendix G, Item 228) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Forward end of cargo shell door raised (TM 9-2320-280-10).

a. Removal 1. Remove four nuts (4), washers (3), capscrews (5), and washers (3) from handle latch lock (1) and cargo door (2).

- Pull handle latch (1) out and down until latch rods (6) are visible. 3. Remove two push on nuts (9), rod end clips (7), latch rods (6), and handle latch (1) from pivot arms (8). Discard push on nuts (9).

b. Installation 1. Position handle latch (1) to cargo door (2) until latch rods (6) can be connected to handle latch pivot

arms (8) and secure latch rods (6) on pivot arms (8) with two rod end clips (7) and push on nuts (9).

- Install handle latch (1) on cargo door (2) with four washers (3), capscrews (5), washers (3), and nuts (4).

FOLLOW-ON TASK: Check cargo shell door for proper operation (TM 9-2320-280-10).

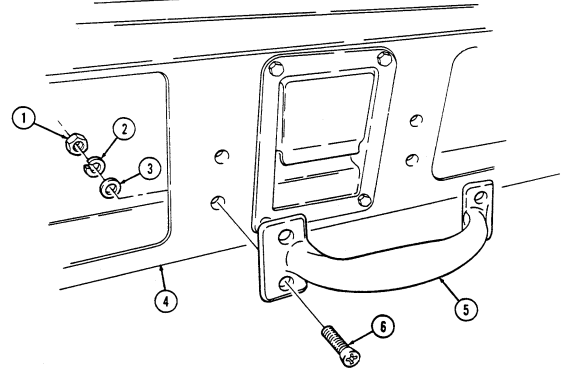

11-17. Cargo Shell Door Latch Maintenance

This task covers: a. Removal c. Adjustment b. Installation

Initial Setup:

Applicable Models All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

Three lockwashers (Appendix G, Item 134) Push on nut (Appendix G, Item 228) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Rear end of cargo shell door raised (TM 9-2320-280-10).

a. Removal 1. Remove push on nut (6), rod end clip (7), and rod (8) from door latch (4). Discard push on nut (6). 2. Remove three nuts (1), lockwashers (2), capscrews (5), and door latch (4) from cargo door (3).

Discard lockwashers (2).

Install door latch (4) on cargo door (3) with three capscrews (5), lockwashers (2), and nuts (1). Do not tighten nuts (1) all the way.

C. Adjustment

- Loosen three nuts (1) from door latch (4) and cargo door (3). 2. Close cargo door (3) ensuring latch (4) is fully engaged on door striker pins (9). 3. Tighten three nuts (1) to 17 lb-ft (23 N•m). 4. Install rod (8) on latch (4) with rod end clip (7) and push on nut (6).

FOLLOW-ON TASKS: - Lubricate door latch (TM 9-2320-280-10).

- Check cargo shell door for proper operation (TM 9-2320-280-10).

11-18. Cargo Shell Door Latch Rod Maintenance

This task covers:

| MI AND AND I MA |

|---|

| b. Installation |

Initial Setup:

Applicable Models All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal c. Adjustment

Materials/Parts

Two push on nuts (Appendix G, Item 228) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Forward end of cargo shell door raised (TM 9-2320-280-10).

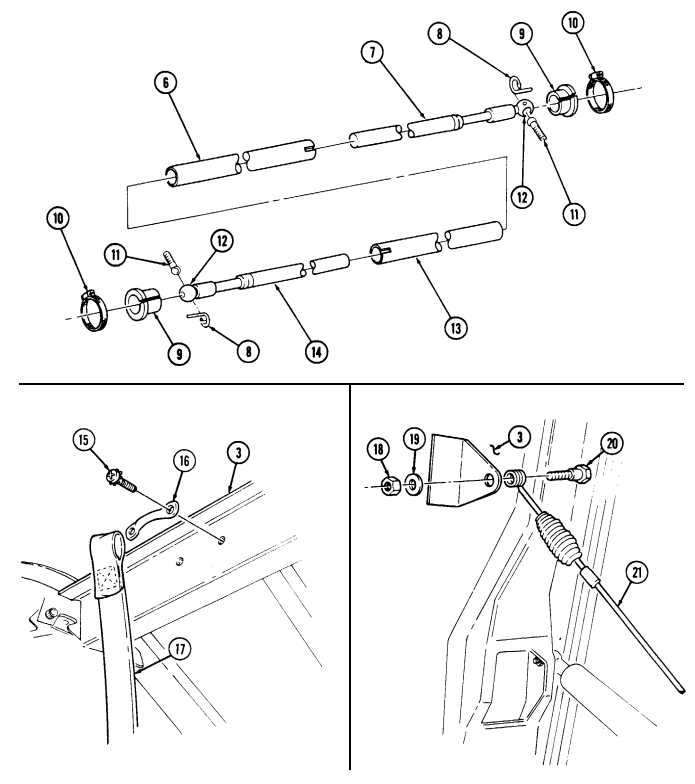

Maintenance procedures for all cargo shell door latch rods are basically the same. This procedure covers the left rear latch rod.

a. Removal 1. Remove push on nut (1), rod end clip (3), and latch rod (4) from pivot arm (2) on wire handle lock (5). Discard push on nut (1).

-

Remove push on nut (7), rod end clip (6), and latch rod (4) from door latch (8). Discard push on nut (7).

-

Connect latch rod (4) to door latch (8) with rod end clip (6). 2. Connect latch rod (4) to pivot arm (2) on wire handle lock (5) with rod end clip (3) and push on nut (1). 3. Close forward end of cargo door.

C. Adjustment

-

Open rear end of cargo door. 2. Close both rear door latches (8) to check latch action. 3. Gently pull wire handle lock (5) and observe movement of door latches (8). If both door latches (8) unlatch at the same time, install push on nut (7) on latch rod (4), no adjustment is necessary. If door latches (8) do not unlatch at the same time, go to step 4.

-

Remove rod end clip (6) from rod (4) and door latch (8). Rotate rod adjuster (9) in, if door latch (8) unlatches after opposite latch (8), or rotate rod adjuster (9) out, if door latch (8) unlatches before opposite door latch (8).

-

Repeat step 4 until door latches (8) unlatch at the same time. 6. Install latch rod (4) on door latch (8) with rod end clip (6) and push on nut (7).

11-18. Cargo Shell Door Latch Rod Maintenance (Cont'D)

FOLLOW-ON TASK: Check cargo shell door for proper operation (TM 9-2320-280-10).

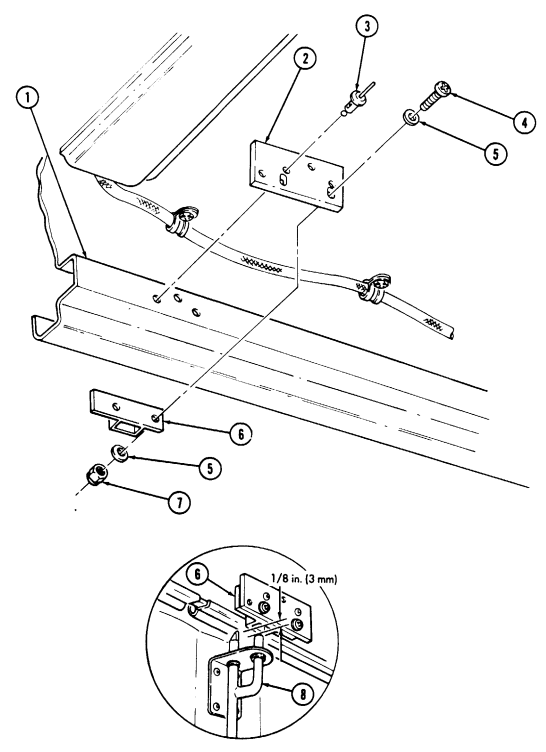

11-19. Cargo Shell Door Dovetail Assembly Maintenance

This task covers: b. Installation

Initial Setup:

Applicable Models All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M 1038, M1038A1,M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal c. Adjustment

Materials/Parts

Two locknuts (Appendix G, Item 70) Two lockwashers (Appendix G, Item 175) Manual References TM 9-2320-280-24P Equipment Condition Rear end of cargo shell door raised (TM 9-2320-280-10).

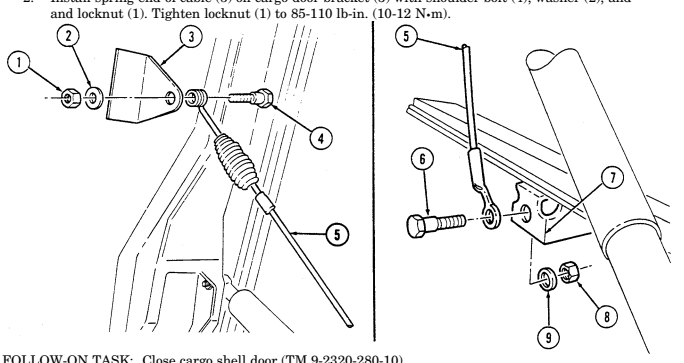

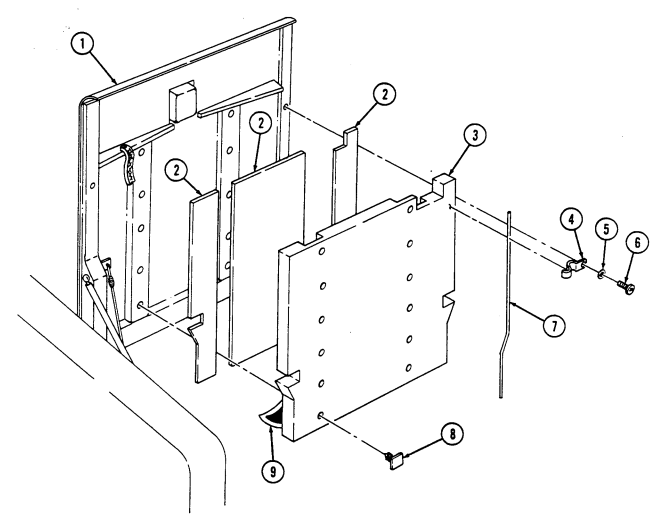

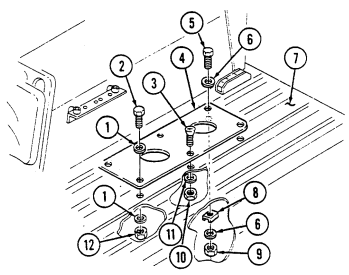

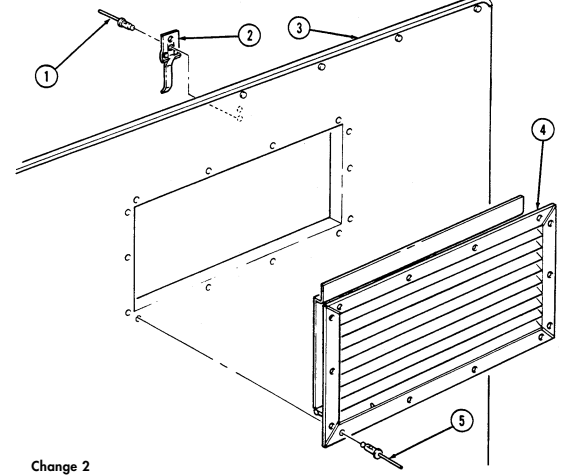

The cargo shell door dovetail assembly is of two-piece construction. The female half is mounted on the cargo door. The male half is mounted on a bracket attached to the left cargo shell. Both halves are adjustable and function as a door alignment device.

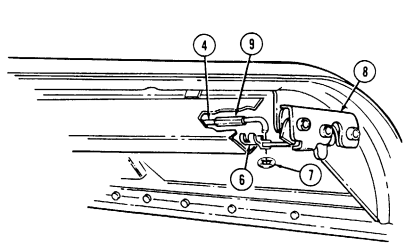

a. Removal 1. Remove two capscrews (1), lockwashers (2), washers (3), and female dovetail (4) from cargo door (5).

Discard lockwashers (2).

-

Remove two locknuts (6), washers (7), countersunk screws (11), male dovetail (10), and shim (9) from cargo shell bracket (8). Discard locknuts (6).

-

Install shim (9) and male dovetail (10) on cargo shell bracket (8) with two countersunk screws (11), washers (7), and locknuts (6). Leave male dovetail (10) loose enough to allow movement from left to right.

-

Install female dovetail (4) on cargo door (5) with two washers (3), lockwashers (2), and capscrews (1). Leave dovetail (4) loose enough to allow movement up and down.

-

Close rear end of cargo door (5).

c. Adjustment 1. Open forward end of cargo door (5). 2. Loosen two capscrews (1) from female dovetail (4) and cargo door (5) until female dovetail (4) will slide up and down.

-

Loosen two countersunk screws (11) and locknuts (6) from male dovetail (10) and cargo shell bracket (8) until male dovetail (10) can be moved from left to right.

-

Gently close cargo door (5) until male dovetail (10) and female dovetail (4) fully seat without interference. Once this condition exists, tighten mounting hardware of dovetails (4) and (10).

-

Open and close cargo door (5) several times to ensure proper dovetail (4) and (10) adjustment. 6. Tighten two capscrews (1) on female dovetail (4) to 10 lb-ft (14 N•m). 7. Tighten two locknuts (6) on male dovetail (10) to 85-100 lb-in. (10-11 N•m).

11-19. CARGO SHELL DOOR DOVETAIL ASSEMBLY MAINTENANCE (Cont'd)

FOLLOW-ON TASK: Close cargo shell door (TM 9-2320-280-10).

11-20. Cargo Shell Door Retention Cable Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation

Materials/Parts

Two locknuts (Appendix G, Item 70) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Forward end of cargo shell door raised (TM 9-2320-280-10).

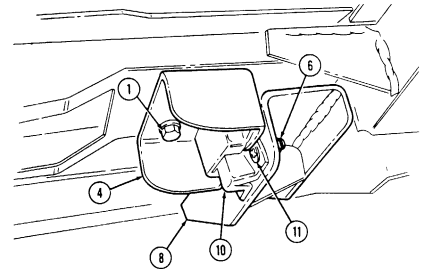

a. Removal

It will be necessary to lower cargo shell door slightly to relieve cable tension during step 1.

-

Remove locknut (1), washer (2), shoulder bolt (4), and spring end of cable (5) from cargo door bracket (3). Discard locknut (1).

-

Remove locknut (8), washer (9), shoulder bolt (6), and cable (5) from left cargo shell bracket (7).

Discard locknut (8).

b. Installation 1. Install cable (5) on cargo shell bracket (7) with shoulder bolt (6), washer (9), and locknut (8).

Tighten locknut (8) to 85-110 lb-in. (10-12 N•m).

- Install spring end of cable (5) on cargo door bracket (3) with shoulder bolt (4), washer (2), and

FOLLOW-ON TASK: Close cargo shell door (TM 9-2320-280-10). 11-34 Change 2

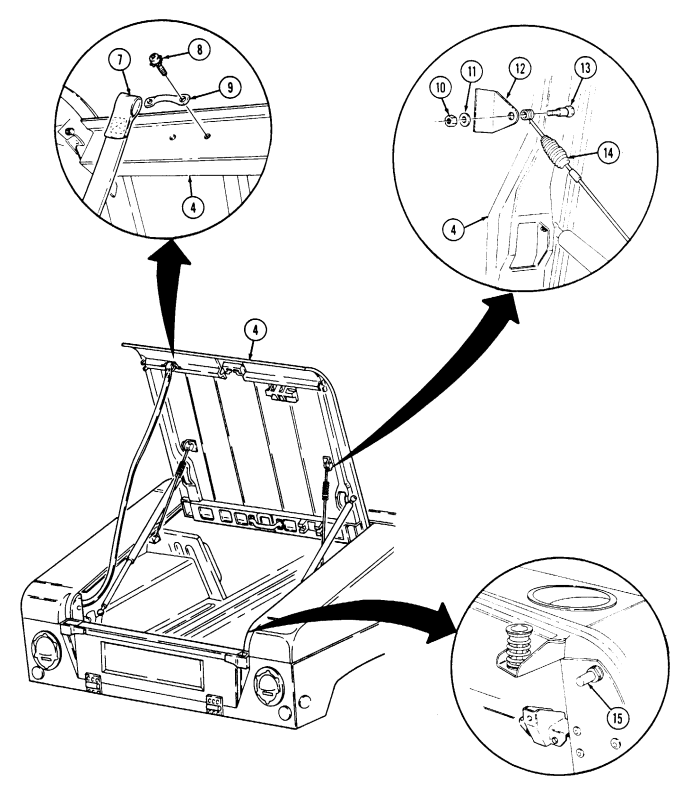

11-21. Cargo Shell Door Gas Spring Maintenance

This task covers: c. Disassembly

Initial Setup: Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

Grease (Appendix C, Item 22) Two locknuts (Appendix G, Item 70) Two retaining rings (Appendix G, Item 234) Two assembled washer screws (Appendix G, Item 279) Two locknuts (Appendix G, Item 79) a. Rotating d. Assembly b. Removal e. Installation Personnel Required One mechanic One assistant Manual References ________________ TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition _________________ Rear end of cargo shell door raised (TM 9-2320-280-10).

General Safety Instructions ______________________

-

Do not attempt to remove gas cylinders from spring rods.

-

One assistant will be required to hold the cargo door open when either one or both gas springs are being removed or installed.

A. Rotating Note

-

Prior to starting any maintenance, ensure forward end of cargo shell door is locked.

-

A 2 x 4 x 79.25 inch long board can used to support cargo door in the open position.

- Remove cargo shell door strap (para. 11-22). 2. Remove cargo shell door retention cable (para. 11-20). 3. Secure rear cargo door (1) in full open position.

11-21. Cargo Shell Door Gas Spring Maintenance (Cont'D)

- Remove four retaining rings (1) from rod sockets (2) on two gas spring assemblies (5).

Warning

Do not attempt to remove gas spring assemblies from ball stubs until cargo door is supported in full open position. Failure to do so may result in injury to personnel or damage to equipment.

-

Remove left and right gas spring assemblies (5) from ball studs (3) on cargo door (4) and body bracket (6).

-

Invert left gas spring assembly (5) 180 degrees and position to right side of vehicle.

-

Invert right gas spring assembly (5) 180 degrees and position to left aide of vehicle. 8. Install left and right gas spring assemblies (5) over ball studs (3) on cargo door (4) and body brackets (6).

-

Install four retaining rings (1) in rod sockets (2) on two gas springs (5).

-

Remove cargo door support.

-

Install cargo shell retention cable (para. 11-20).

-

Install cargo shell door strap (pars.. 11-22).

13. Check operation of cargo shell door (TM 9-2320-280-10).

13. Check operation of cargo shell door (TM 9-2320-280-10).

11-21. Cargo Shell Door Gas Spring Maintenance (Cont'D)

Warning

One assistant will be required to hold the cargo door open when either one or both gas springs are being removed or installed. Failure to do so may result in injury to personnel or damage to equipment.

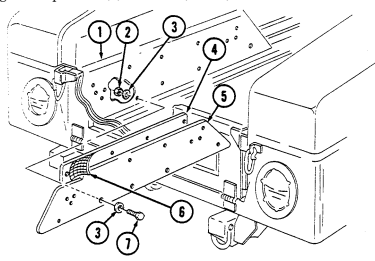

b. Removal 1. Remove two locknuts (1), washers (2), shoulder bolts (4), and retention cables (5) from cargo door (3). Discard locknuts (1).

- Remove two assembled washer screws (6), footman loop (7), and cargo door strap (8) from cargo

door (3). Discard assembled washer screws (6).

11-21. Cargo Shell Door Gas Spring Maintenance (Cont'D)

- Remove two locknuts (1), washers (2), and gas spring assembly (4) from cargo door (3) and body bracket (5). Discard locknuts (1).

c. Disassembly 1. Remove inner spring tube (6) from outer spring tube (13). 2. Remove two retaining rings (8) from ball studs (11) and rod sockets (12). Remove two ball studs (11) from rod sockets (12). Discard retaining rings (8).

- Remove two clamps (10) from bushings (9) and spring rods (7) and (14). Pull spring rods (7) and (14) out of tubes (6) and (13) 1-inch (2.54 cm), and remove two bushings (9).

Warning

Do not attempt to remove gas cylinders from inner spring rod or outer spring rod. High internal pressure will cause cylinder to explode, resulting in injury to personnel.

- Pull inner spring rod (7) from inner tube (6) and outer spring rod (14) from outer tube (13).

d. Assembly 1. Install longer outer spring rod (14) on outer tube (13), leaving about 1-inch (2.54 cm) of the small diameter portion of the rod (14) exposed to install bushing (9).

-

Install bushing (9) on outer spring rod (14). Ensure bushing (9) is fully seated on outer tube (13) and rod socket (12) end is fully seated on bushing (9). Install and tighten clamp (10).

-

Place grease in rod end socket (12), and install ball stud (11) on socket (12) with retaining ring (8). 4. Repeat steps 1-3 for inner tube (6) and inner spring rod (7). 5. Install inner tube (6) into outer tube (13).

e. Installation 1. Install gas spring (4) on body bracket (5) and cargo door (3) with two washers (2) and locknuts (1).

Tighten locknuts (1) to 15-20 lb-ft (20-27 N•m).

-

Install footman loop (16) and cargo door strap (17) on cargo door (3) with two assembled washer screws (15).

-

Install two retention cables (21) on cargo door (3) with two shoulder bolts (20), washers (19), and

locknuts (18). Tighten locknuts (18) to 85-110 lb-in. (10-12 N•m).

11-21. Cargo Shell Door Gas Spring Maintenance (Cont'D)

FOLLOW-ON TASK: Check cargo shell door for proper operation (TM 9-2320-280-10).

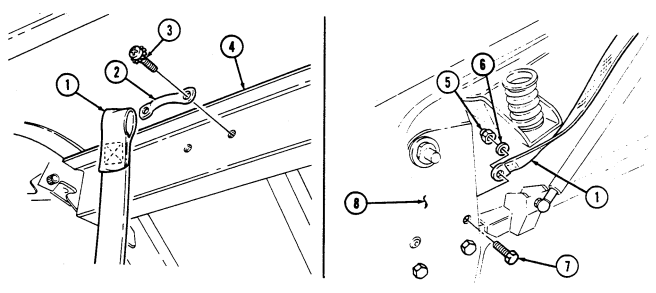

11-22. Cargo Shell Door Strap Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation Materials/Parts Locknut (Appendix G, Item 128) Two assembled washer screws (Appendix G, Item 279) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Rear end of cargo shell door raised (TM 9-2320-280-10).

a. Removal 1. Remove two assembled washer screws (3), footman loop (2), and strap (1) from cargo door (4).

Discard assembled washer screws (3).

- Remove locknut (5), washer (6), capscrew (7), and strap (1) from left striker mounting plate (8).

Discard locknut (5).

b. Installation

To assist closing cargo shell door, a grab loop may be added. Refer to appendix D, figure D-83.

- Install strap (1) on left striker mounting plate (8) with capscrew (7), washer (6), and locknut (5).

Tighten locknut (5) to 25-30 lb-ft (34-41 N•m).

- Install strap (1) and footman loop (2) on cargo door (4) with two assembled washer screws (3).

FOLLOW-ON TASK: Close cargo shell door (TM 9-2320-280-10).

11-40 Change 2

11-23. Cargo Shell Door Seal Protector Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1,M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation

Materials/Parts

Thirteen locknuts (Appendix G, Item 70) Manual References

| Equipment Condition |

|---|

| Forward end of cargo shell door raised |

| Manual References |

|---|

| TM 9-2320-280-10 |

a. Removal Remove thirteen locknuts (4), washers (5), capscrews (2), washers (5), and seal protector (1) from cargo door (3). Discard locknuts (4).

Install seal protector (1) on cargo door (3) with thirteen washers (5), capscrews (2), washers (5), and

locknuts (4). Tighten locknuts (4) to 85-100 lb-in. (10-12 N•m).

locknuts (4). Tighten locknuts (4) to 85-100 lb-in. (10-12 N•m).

FOLLOW-ON TASK: Close cargo shell door (TM 9-2320-280-10).

I 11-24. Cargo Shell Door Seal Replacement

This task covers: lNITIAL SETUP: Applicable Models Materals/Parts .

All models except M998, M998A1, M997, Sealing compound (Appendix C, Item 40) M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, Manual References M1038A1, M1042, M1097, M1097A1, TM 9-2320-280-24P M1097A2 General mechanic's tool kit: (para. 11-23).

automotive (Appendix B, Item 1) a. Removal b. Installation Equipment Condition Tools Cargo shell door seal protector removed Remove seal (1) from cargo door (2). Clean edge around cargo door (2) to remove dirt, corrosion, or remaining adhesive.

- Install seal (1) on cargo door (2), making sure seal (1) is fully seated.

-

Detach seal (1) at rear edge of cargo door (2) only, and apply sealing compound in seal (1) channel the entire length of rear edge of cargo door (2).

-

Install seal (1) on rear edge of cargo door (2), making sure seal (1) is fully seated.

FOLLOW-ON TASK: Install cargo shell door seal protector (para. 11-23).

11-25. Cargo Shell Door Front Striker Replacement

This task covers: INITIAL SETUP: Applicable Models All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation

| Equipment Condition |

|---|

| Rear end of cargo shell door raised |

| (TM 9-2320-280-10). |

| Materials/Parts |

|---|

| Thirteen locknuts (Appendix G, Item 70) |

| Manual References |

| TM 9-2320-280-10 TM 9-2320-280-24P |

Remove locknut (4), washer (2), front striker (3), and washer (2) from body bracket (1). Discard locknut (4).

Install washer (2) and front striker (3) on body bracket (1) with washer (2) and locknut (4). Tighten

locknut (4) to 35-45 lb-ft (47-61 N•m).

locknut (4) to 35-45 lb-ft (47-61 N•m).

FOLLOW-ON TASK: Adjust cargo shell door (para. 11-13).

11-26. Cargo Shell Door Rear Striker Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Locknut (Appendix G, Item 105) a. Removal b. Installation

| Materials/Parts |

|---|

Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition

- Tailgate lowered (TM 9-2320-280-10). - Rear end of cargo shell door raised (TM 9-2320-280-10).

a. Removal Remove locknut (4), washer (3), striker (1), and spacer (2) from striker plate (6) and wheelhouse (5). Discard locknut (4).

b. Installation Install spacer (2) and striker (1) on striker plate (6) and wheelhouse (5) with washer (3) and

locknut (4). Tighten locknut (4) to 190-210 lb-ft (258-285 N•m).

locknut (4). Tighten locknut (4) to 190-210 lb-ft (258-285 N•m).

FOLLOW-ON TASKS: - Raise and secure tailgate (TM 9-2320-280-10).

- Close cargo shell door (TM 9-2320-280-10).

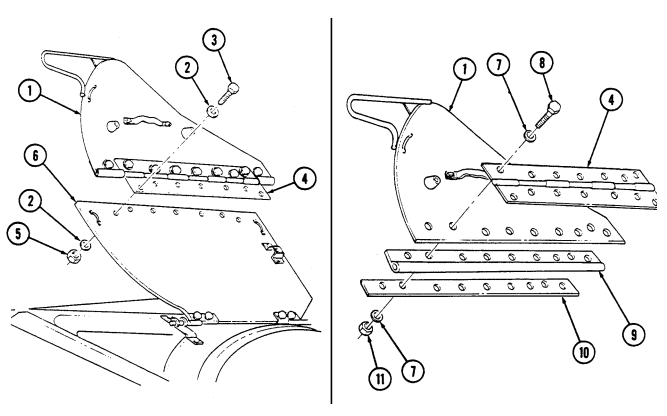

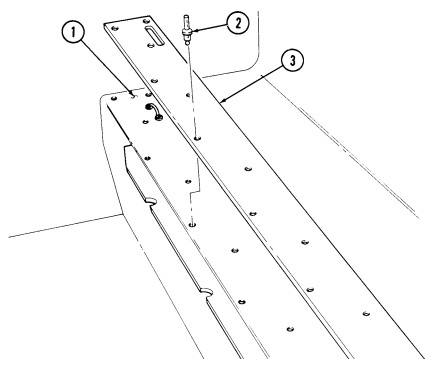

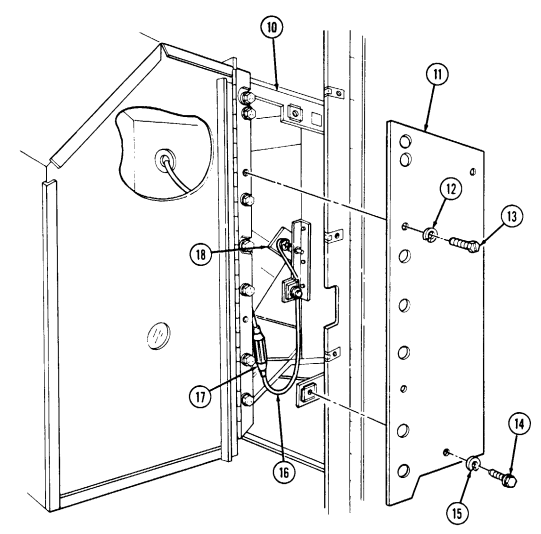

11-27. Cargo Shell Door Rear Striker Mounting Plate Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2 M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Six locknuts (Appendix G, Item 128) a. Removal b. Installation

Personnel Required

One mechanic One assistant Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition

- Rear striker removed (para. 11-26). - Cargo shell door strap removed (left side only) (para. 11-22).

-

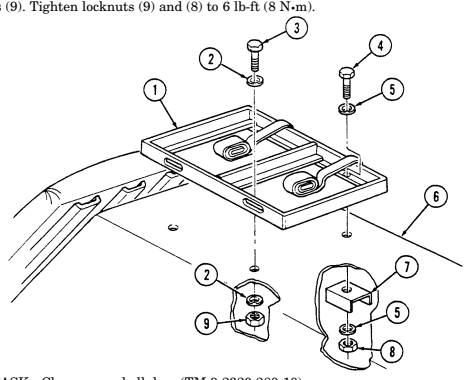

Remove locknut (5), washer (4), and socket head screw (2) from striker mounting plate (3) and wheelhouse (8). Discard locknut (5).

-

Remove five locknuts (6), washers (7), capscrews (1), washers (9), and striker mounting plate (3) from wheelhouse (8). Discard locknuts (6).

b. Installation 1. Install striker mounting plate (3) on wheelhouse (8) with five washers (9), capscrews (1), washers (7), and locknuts (6).

- Secure striker mounting plate (3) to wheelhouse (8) with socket head screw (2), washer (4), and

locknut (5). Tighten locknuts (5) and (6) to 25-30 lb-ft (34-41 N•m).

FOLLOW-ON TASKS: - Install cargo shell door strap (left side only) (para. 11-22).

- Install rear striker (para. 11-26).

11-28. Cargo Shell Door Dovetail Spring Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

Two locknuts (Appendix G, Item 101) Lockwasher (Appendix G, Item 178)

A. Removal B. Installation

Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition

-

Rear end of cargo shell door raised (TM 9-2320-280-10).

-

Tailgate lowered (TM 9-2320-280-10).

Remove locknut (8), lockwasher (7), washer (6), cup (9), spring (3), locknut (2), retainer (10), and head bolt (1) from cargo shell dovetail (5). Discard locknuts (2) and (8) and lockwasher (7).

-

Install retainer (10) and locknut (2) on head bolt (1) and position locknut (2) to end of threads on head bolt (1).

-

Install cup (9) and head bolt (1) on dovetail (5). 3. Lower cargo door. 4. Hold locknut (2) and adjust head bolt (1) up until head bolt (1) touches bottom of cargo door (4). 5. Raise cargo door. 6. Remove head bolt (1) from dovetail (5). 7. Install spring (3), cup (9), and head bolt (1) on dovetail (5) with washer (6), lockwasher (7), and

locknut (8). Tighten locknut (8) to 55 lb-ft (75 N•m).

FOLLOW-ON TASKS: - Close cargo shell door (TM 9-2320-280-10).

- Raise and secure tailgate (TM 9-2320-280-10).

11-46 Change 2

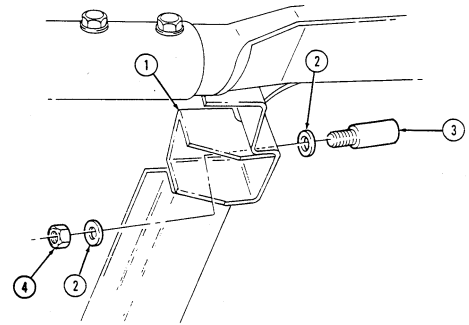

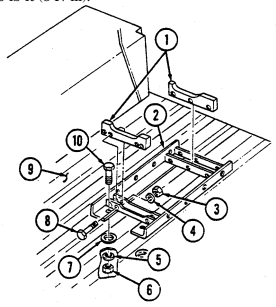

11-29. Cargo Shell Door Gas Spring Mounting Bracket Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Tape (Appendix C, Item 50) Four locknuts (Appendix G, Item 70)

A. Removal B. Installation Personnel Required

One mechanic One assistant Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equiment Condition

- Tailgate lowered (TM 9-2320-280-10). - Gas spring removed (para. 11-21).

-

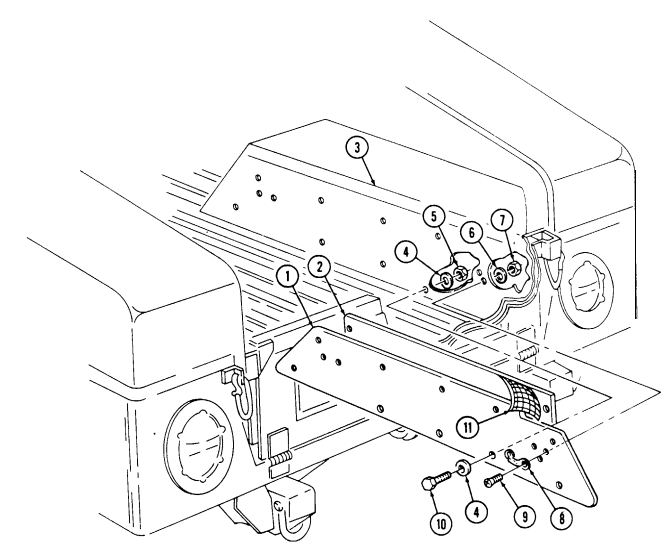

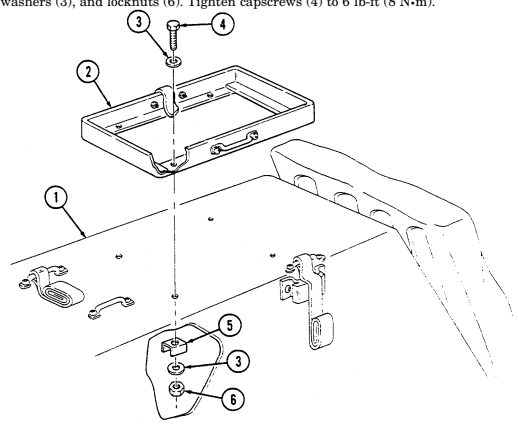

Remove two locknuts (9), washers (1), capscrews (2), and washers (1) from bracket (3) and wheelhouse (6). Discard locknuts (9).

-

Remove two locknuts (8), washers (4), backing plate (7), capscrews (5), washers (4), and bracket (3) from wheelhouse (6). Discard locknuts (8). Remove tape from bracket (3) and discard tape.

-

Apply tape to bracket (3) mounting surfaces. Install bracket (3) on wheelhouse (6) with two washers (4), capscrews (5), backing plate (7), washers (4), and locknuts (8). Tighten locknuts (8) to 8 lb-ft (11 N•m).

-

Secure bracket (3) to wheelhouse (6) with two washers (1), capscrews (2), washers (1), and

locknuts (9). Tighten locknuts (9) to 8 lb-ft (11 N•m).

FOLLOW-ON TASKS: - Install gas spring (para. 11-21).

- Raise and secure tailgate (TM 9-2320-280-10).

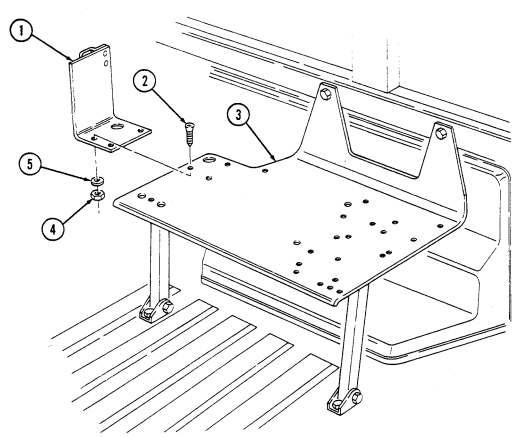

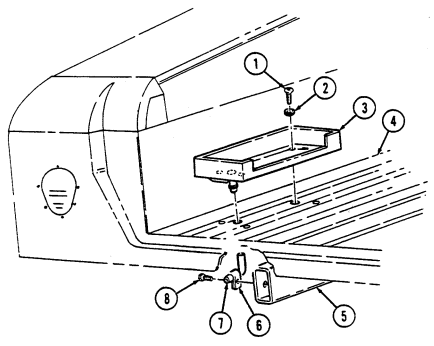

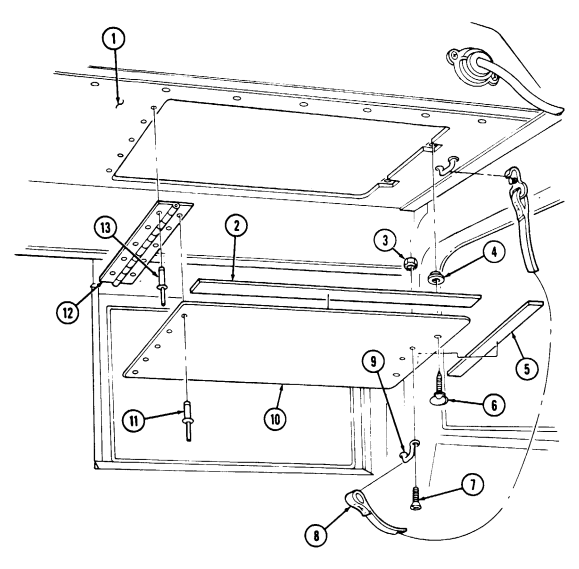

11-30. Cargo Shell Door Liner Replacement

This task covers: INITIAL SETUP:

a. Removal b. Installation

| Applicable Models | Personnel Required |

|---|---|

| All models except M996, M996A1, M997, | One mechanic |

| M997A1, M997A2, M998, M998A1, M1035, | One assistant |

| M1035A1, M1035A2, M1037, M1038, | |

| M1038A1, M1042, M1097, M1097A1, M1097A2 | Manual References |

| Tools | TM 9-2320-280-10 |

| TM 9-2320-280-24P | |

| General mechanic's tool kit: | |

| automotive (Appendix B, Item 1) | Equipment Condition |

| Materials/Parts | - Tailgate lowered (TM 9-2320-280-10). - Rear end of cargo shell door raised |

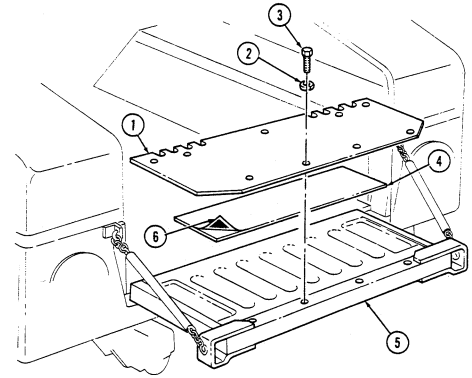

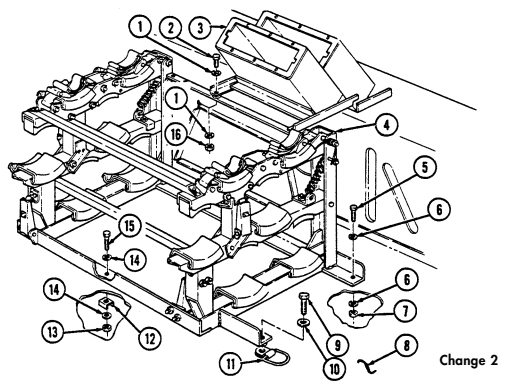

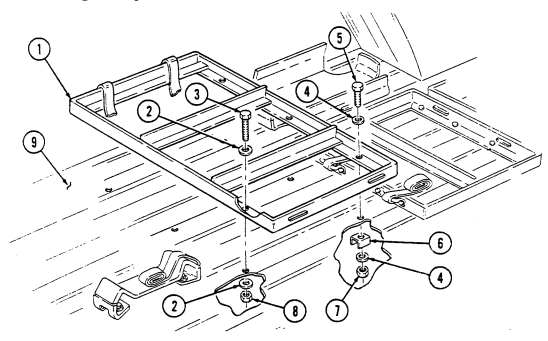

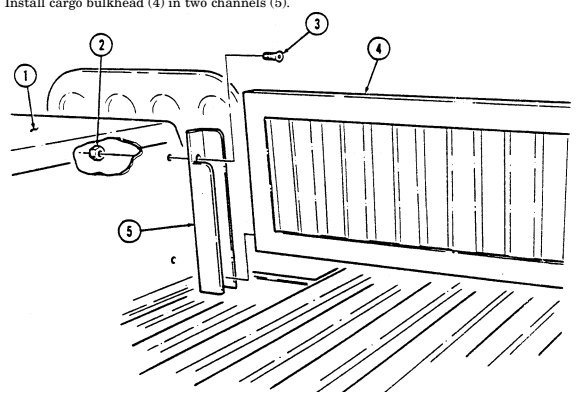

a. Removal 1. Remove ten screws (6), washers (5), clips (4), and two retainers (7) from cargo shell door (1). 2. Remove twelve spring tension fasteners (8) from liner (3) and door (1). Discard spring tension fasteners (8).

- Remove liner (3) and three sound dampeners (2) from door (1). 4. Clean cargo door (1) to remove adhesive.

b. Installation

Ensure surface is free of dirt and oil before applying adhesive backing.

-

Apply three sound dampeners (2) to door (1). 2. Place four spring tension fasteners (8) in two top and two bottom holes of liner (3). Ensure heads of spring tension fasteners (8) are on side of liner (3) without adhesive.

-

Peel paper backing (9) from liner (3). 4. Align liner (3) with door (1), ensuring top and bottom spring tension fasteners (8) in liner (3) align with top and bottom holes in door (1), and install liner (3) on door (1) with top and bottom spring tension fasteners (8). Press entire surface of liner (3) to ensure adhesion.

-

Install eight remaining spring tension fasteners (8) through liner (3) into door (1). 6. Install two retainers (7) on door (1) with ten clips (4), washers (5), and screws (6).

11-30. Cargo Shell Door Liner Replacement(Cont'D)

FOLLOW-ON TASK: Close cargo shell door (TM 9-2320-280-10).

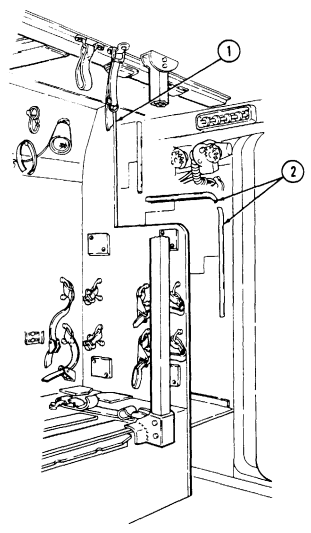

11-30.1. "B" Pillar Padding Replacement

This task covers:

INITIAL SETUP: Applicable Models M966, M1025, M1026, M1036, M1043, M1044, M1045, M1046, M1121 Two locknuts (Appendix G, Item 122)

a. Removal b. Installation

a. Removal

| Personnel Required |

|---|

| One mechanic |

| One assistant |

| Manual References |

| TM 9-2320-280-10 |

- Remove locknut (8), washer (7), capscrew (6), and washer (7) from padding (3) and "B" pillar (11).

Discard locknut (8).

- Remove locknut (10), washer (4), capscrew (5), and washer (4) from padding (3) and "B" pillar (11).

Discard locknut (10).

-

Remove screw (1), washer (2), and padding (3) from"B" pillar (11). 4. Remove edge trim (9) from "B" pillar (11).

-

Install edge trim (9) on "B" pillar (11). 2. Install padding (3) on "B" pillar (11) with washer (2) and screw (1). 3. Secure padding (3) to "B" pillar (11) with washer (4), capscrew (5), washer (4), and locknut (10). 4. Secure padding (3) to "B" pillar (11) with washer (7), capscrew (6), washer (7), and locknut (8).

FOLLOW-ON TASK: Install rifle mounting clamp bracket (if removed) (para. 11-92).

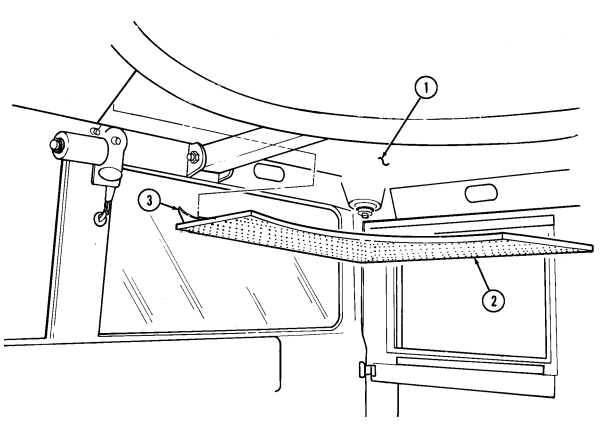

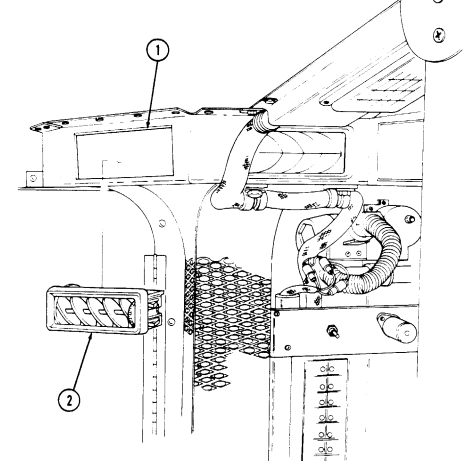

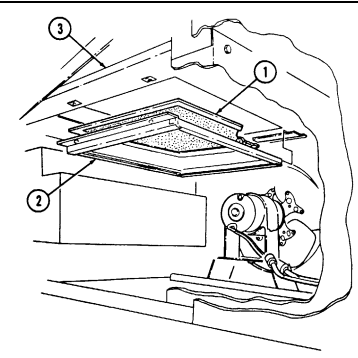

1 1 - 3 1 . Cargo Shell Roof Insulation Panel Replacement

This task covers: INITIAL SETUP: Applicable Models M966, M966A1, M1025, M1025A1, M1025A2, M1026, M1026A1, M1036, M1121 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal 1. Remove insulation panel (2) from roof (1). 2. Clean roof (1) surface to remove adhesive.

b. Installation 1. Spray primer adhesive on roof (1), peel paper backing (3) from panel (2), and install panel (2) on roof (1).

- Press panel (2) surface to ensure adhesion.

A. Removal B. Installation

Materials/Parts Primer adhesive (Appendix C, Item 35) Manual References TM 9-2320-280-24P

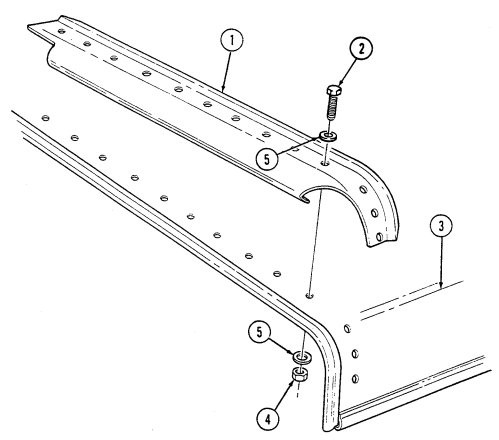

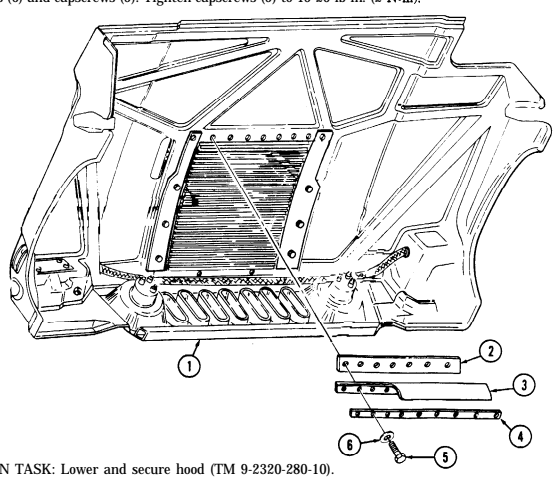

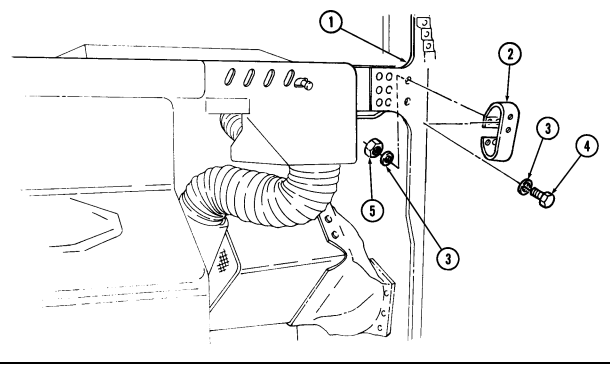

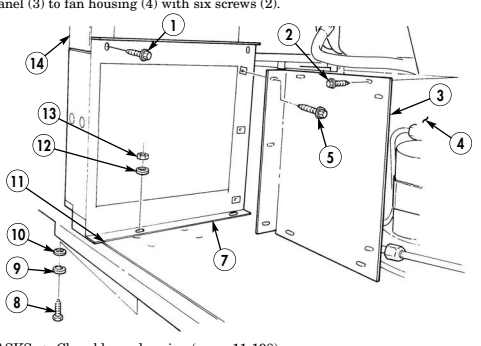

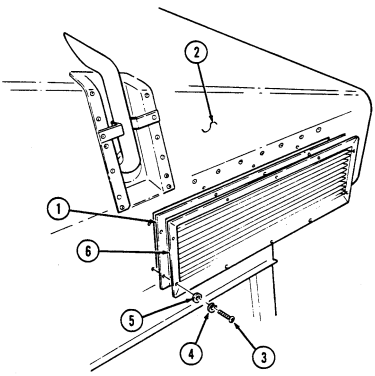

11-32. Hood Side Armor Plate Replacement

This task covers:

a. Removal b. Installation

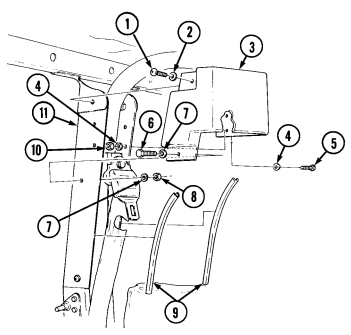

INITIAL SETUP: Applicable Models Manual References All models except M998, M998A1, M1035, TM 9-2320-280-10 M1035A1, M1035A2, M1037, M1038, TM 9-2320-280-24P M1038A1, M1042, M1097, M1097A1, M1097A2 Equipment Condition Tools Hood raised and secured (TM 9-2320-280-10).

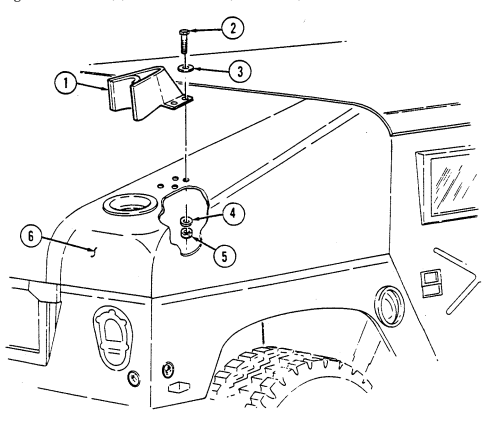

General mechanic's tool kit: automotive (Appendix B, Item 1) Remove four capscrews (4), washers (5), and armor plate (1) from hood (2).

Slide narrow end of armor plate (1) between radiator-to-hood seal (3) and hood (2) until holes align, and

install on hood (2) with four washers (5) and capscrews (4). Tighten capscrews (4) to 15-20 lb-in. (2 N.m).

FOLLOW-ON TASK: Lower and secure hood (TM 9-2320-280-10).

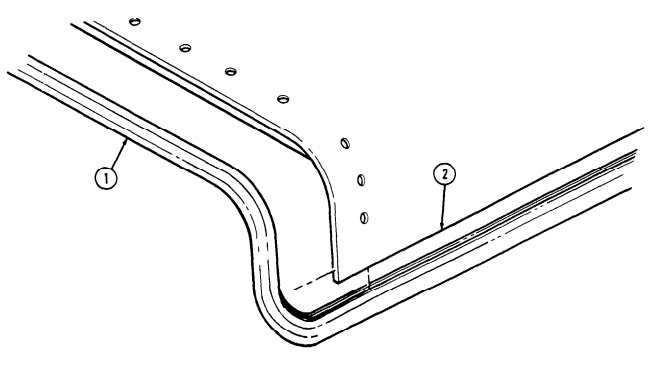

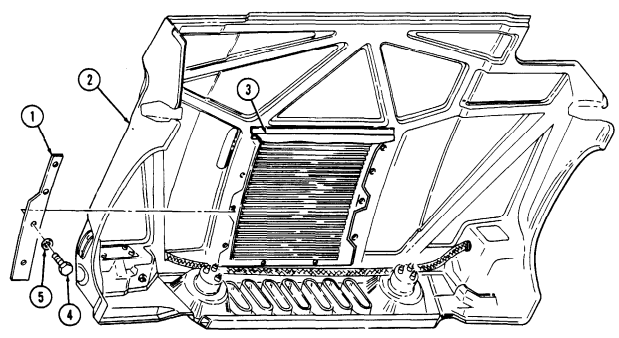

11-33. Hood Center Armor Plate Replacement

This task covers: INITIAL SETUP: Applicable Models Manual References All models except M998, M998A1, M1035, TM 9-2320-280-10 M1035A1, M1035A2, M1037, M1038, TM 9-2320-280-24P M1038A1, M1042, M1097, M1097A1, M1097A2 a. Removal b. Installation Equipment Condition Tools Hood raised and secured (TM 9-2320-280-10).

General mechanic's tool kit: automotive (Appendix B, Item 1)

Remove nine capscrews (5), washers (6), hood seal retainer (4), hood-to-radiator seal (3), and armor plate (2) from hood (1).

IB. Installation

Install armor plate (2), hood-to-radiator seal (3), and hood seal retainer (4) on hood (1) with nine washers (6) and capscrews (5). Tighten capscrews (5) to 15-20 lb-in. (2 N.m).

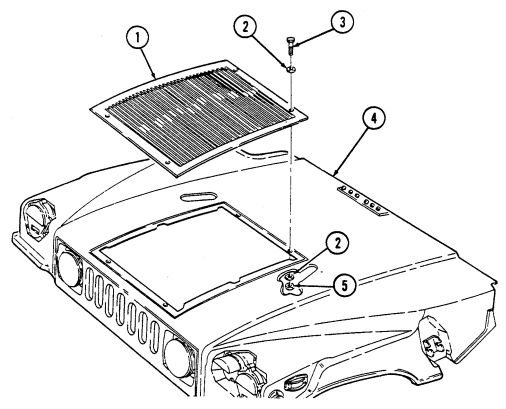

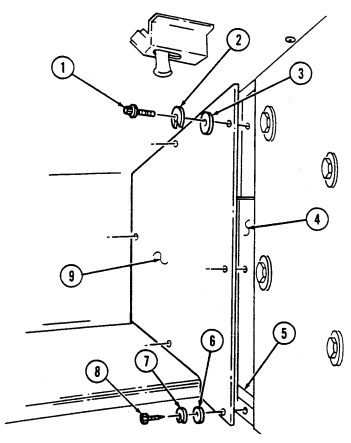

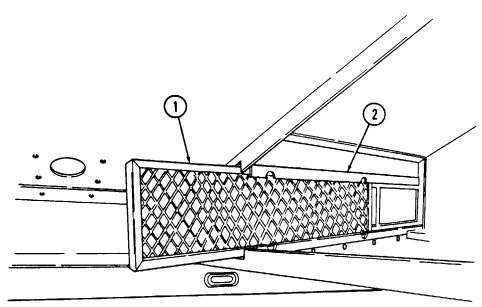

11-34. Hood Top Armored Grille Replacement

This task covers: INITIAL SETUP: Applicable Models All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Four locknuts (Appendix G, Item 70) a. Removal b. Installation Personnel Required One mechanic One assistant Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Hood raised and secured (TM 9-2320-280-10).

a. Removal Remove four locknuts (5), washers (2), capscrews (3), washers (2), and top grille (1) from hood (4). Discard locknuts (5).

b. Installation Install grille (1) on hood (4) with four washers (2), capscrews (3), washers (2), and locknuts (5).

Tighten locknuts (5) to 6 lb-ft (8 N•m).

Tighten locknuts (5) to 6 lb-ft (8 N•m).

FOLLOW-ON TASK: Lower and secure hood (TM 9-2320-280-10).

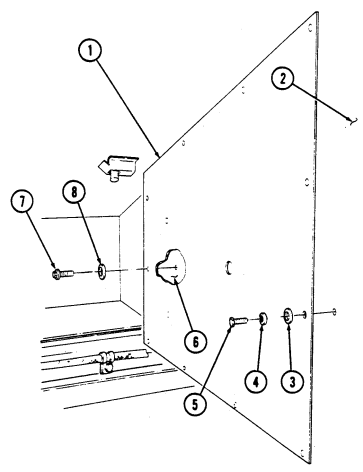

11-35. Hood Front Armored Grille Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive ( Appendix B, Item 1) a. Removal b. Installation

Materials/Parts

Three locknuts (Appendix G, Item 83) Three lockwashers (Appendix G, Item 157) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Hood raised and secured (TM 9-2320-280-10).

- Remove three locknuts (5), washers (4), and carriage bolts (2) from front grille (3) and hood (1).

Discard locknuts (5).

- Remove three capscrews (6), harness clamps (7), lockwashers (8), washers (9), and grille (3) from hood (1). Discard lockwashers (8).

b. Installation 1. Install front grille (3) on hood (1) with three washers (9), lockwashers (8), harness clamps (7), and capscrews (6).

- Secure grille (3) to hood (1) with three carriage bolts (2), washers (4), and locknuts (5).

3. Tighten locknuts (5) to 21 lb-ft (29 N•m). Tighten capscrews (6) to 20-30 lb-in. (2-3 N•m).

3. Tighten locknuts (5) to 21 lb-ft (29 N•m). Tighten capscrews (6) to 20-30 lb-in. (2-3 N•m).

FOLLOW-ON TASK: Lower and secure hood (TM 9-2320-280-10).

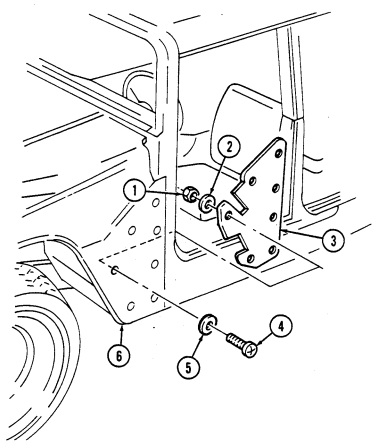

11-36. Right Cowl Armor Plate Replacement

This task covers: INITIAL SETUP: Applicable Models All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

a. Removal b. Installation

| Materials/Parts |

|---|

| Four locknuts ( |

| Equipment Condition |

|---|

| Ballistic crew door removed (para. 11-2). |

| Manual References |

|---|

| TM 9-2320-280-24P |

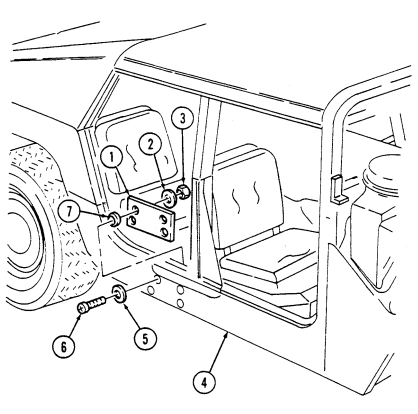

Four locknuts (Appendix G, Item 70) a. Removal Remove four locknuts (2), washers (1), screws (5), washers (4), and armor plate (6) from cowl (3). Discard locknuts (2).

b. Installation Install armor plate (6) on cowl (3) with four washers (4), screws (5), washers (1), and locknuts (2).

Tighten locknuts (2) to 6 lb-ft (8 N•m).

Tighten locknuts (2) to 6 lb-ft (8 N•m).

FOLLOW-ON TASK: Install ballistic crew door (para. 11-2).

11-37. Left Cowl Armor Plate Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

a. Removal b. Installation

| Materials/Parts |

|---|

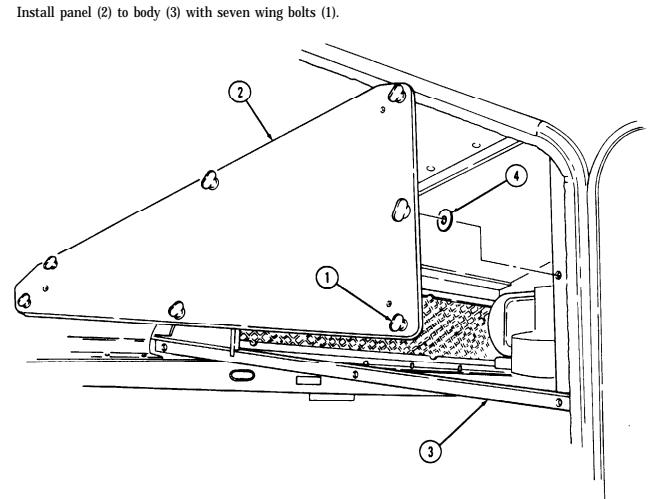

Seven locknuts (Appendix G, Item 70) Manual References TM 9-2320-280-24P Equipment Condition Ballistic crew door removed (para. 11-2).

a. Removal Remove seven locknuts (1), washers (2), screws (4), washers (5), and armor plate (3) from cowl (6) Discard locknuts (1).

Install armor plate (3) on cowl (6) with seven washers (5), screws (4), washers (2), and locknuts (1).

Tighten locknuts (1) to 6 lb-ft (8 N•m).

Tighten locknuts (1) to 6 lb-ft (8 N•m).

FOLLOW-ON TASK: Install ballistic crew door (para. 11-2).

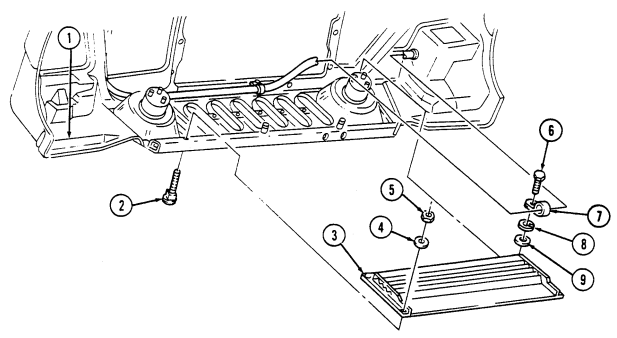

11-38. Footwell Armor Plate Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation Materials/Parts Four locknuts (Appendix G, Item 70) Manual References TM 9-2320-280-24P

Remove four locknuts (3), washers (2), screws (6), washers (5), armor plate (1), and four spacers (7) from body (4). Discard locknuts (3).

Install four spacers (7) and armor plate (1) on body (4) with four washers (5), screws (6), washers (2),

and locknuts (3). Tighten locknuts (3) to 6 lb-ft (8 N•m).

and locknuts (3). Tighten locknuts (3) to 6 lb-ft (8 N•m).

11-39. Right Wheelhouse Armor Plate Replacement

This task covers: INITIAL SETUP: Applicable Models M1025, M1025A1, M1025A2, M1026, M1026A1, M1043, M1043A1, M1043A2, M1044, M1044A1, M1045, M1045A1, M1045A2, M1046, M1046A1 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

Fourteen locknuts (Appendix G, Item 70) Sound dampener (Appendix G, Item 294)

A. Removal B. Installation Personnel Required

One mechanic One assistant

| Equipment Condition |

|---|

| · Rear end of cargo shell door raised |

| (TM 9-2320-280-10). |

| M1045, M1045A1, M1045A2, M1046 |

| TM 9-2320-280-24P |

|---|

| Equipment Condition |

M1045, M1045A1, M1045A2, M1046, and M1046A1 only:

- Night sight support assembly removed (para. 1182).

M1043, M1043A1, M1043A2, M1044, and M1044A1 only:

- Machine gun stop removed (para. 11-100).

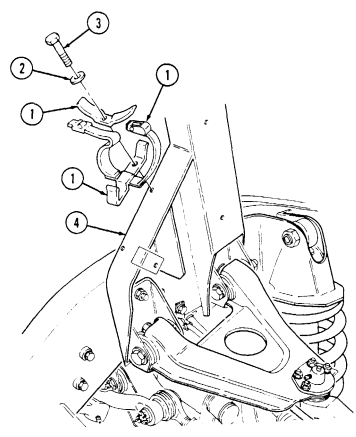

a. Removal 1. Remove four locknuts (7), washers (6), screws (9), and two footman loops (8) from wheelhouse (3).

Discard locknuts (7).

-

Remove ten locknuts (5), washers (4), capscrews (10), washers (4), armor plate (1), and sound dampener (2) from wheelhouse (3). Discard locknuts (5) and sound dampener (2).

-

Clean armor plate (1) to remove adhesive.

-

Peel paper backing (11) from sound dampener (2) and install sound dampener (2) on armor plate (1).

-

Install armor plate (1) on wheelhouse (3) with ten washers (4), capscrews (10), washers (4), and locknuts (5). Tighten capscrews (10) to 6 lb-ft (8 N•m).

-

Install two footman loops (8) on wheelhouse (3) with four screws (9), washers (6), and locknuts (7).

11-39. Right Wheelhouse Armor Plate Replacement (Cont'D)

FOLLOW-ON TASKS: M1043, M1043A1, M1043A2, M1044, and M1044A1 only:

- Install machine gun stop (para. 11-100).

M1045, M1045A1, M1045A2, M1046, and M1046A1 only

- Install night sight support assembly (para. 11-82).

- Close cargo shell door (TM 9-2320-280-10).

11-40. Left Wheelhouse Armor Plate Replacement

This task covers: INITIAL SETUP: Applicable Models M1025, M1025A1, M1025A2, M1026, M1026A1, M1043, M1043A1, M1043A2, M1044, M1044A1, M1045, M1045A1, M1045A2, M1046, M1046A1

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

Ten locknuts (Appendix G, Item 70) Sound dampener (Appendix G, Item 294) Personnel Required One mechanic One assistant

-

Remove ten locknuts (2), washers (3), capscrews (7), washers (3), armor plate (5), and sound dampener (4) from wheelhouse (1). Discard locknuts (2) and sound dampener (4).

-

Clean armor plate (5) to remove adhesive.

-

Peel paper backing (6) from sound dampener (4) and install sound dampener (4) on armor plate (5).

2. Install armor plate (5) on wheelhouse (1) with ten washers (3), capscrews (7), washers (3), and locknuts (2). Tighten capscrews (7) to 6 lb-ft (8 N•m).

2. Install armor plate (5) on wheelhouse (1) with ten washers (3), capscrews (7), washers (3), and locknuts (2). Tighten capscrews (7) to 6 lb-ft (8 N•m).

FOLLOW-ON TASKS: M1043, M1043A1, M1043A2, M1044, and M1044A1 only:

- Install water can bumper (para. 11-109). M1045, M1045A1, M1045A2, M1046, and M1046A1 only: - Install tripod head mounting bracket (para. 11-79) - Close cargo shell door (TM 9-2320-280-10).

A. Removal B. Installation Manual References

TM 9-2320-280-10 TM 9-2320-280-24P

Equiment Condition

- Rear end of cargo shell door raised (TM 9-2320-280-10).

M1045, M1045A1, M1045A2, M1046, and M1046A1 only:

- Tripod head mounting bracket removed (para. 11-79).

M1043, M1043A1, M1043A2, M1044, and M1044A1 only:

- Water can bumper removed (para. 11-109).

11-60 Change 2

11-41. Tailgate Armor Plate Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

A. Removal B. Installation Materials/Parts

Nine lockwashers (Appendix G, Item 135) Sound dampener (Appendix G, Item 295) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Tailgate lowered (TM 9-2320-280-10).

a. Removal 1. Remove nine capscrews (3), lockwashers (2), armor plate (1), and sound dampener (4) from tailgate (5). Discard lockwashers (2) and sound dampener (4).

- Clean armor plate (1) to remove adhesive.

b. Installation 1. Peel paper backing (6) from sound dampener (4) and install sound dampener (4) on armor plate (1).

2. Install armor plate (1) on tailgate (5) with nine lockwashers (2) and capscrews (3). Tighten capscrews (3) to 6 lb-ft (8 N•m).

2. Install armor plate (1) on tailgate (5) with nine lockwashers (2) and capscrews (3). Tighten capscrews (3) to 6 lb-ft (8 N•m).

FOLLOW-ON TASK: Raise and secure tailgate (TM 9-2320-280-10).

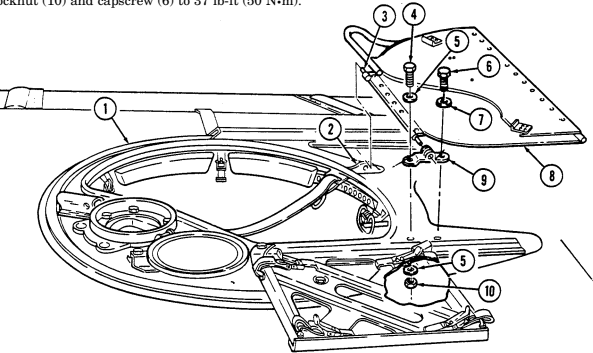

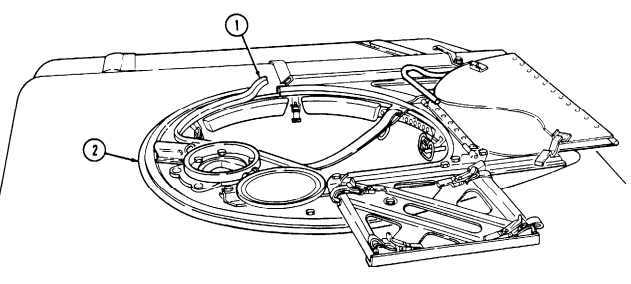

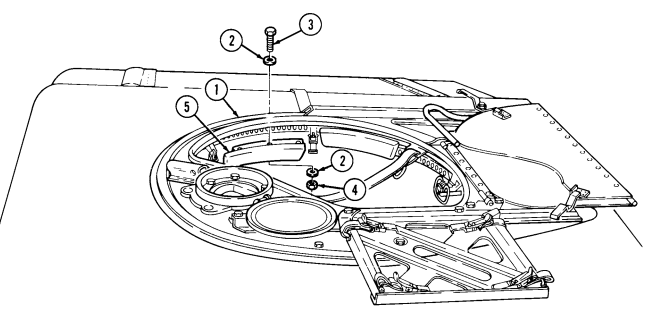

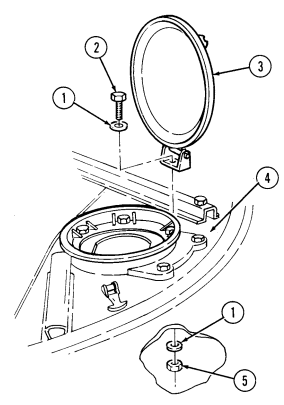

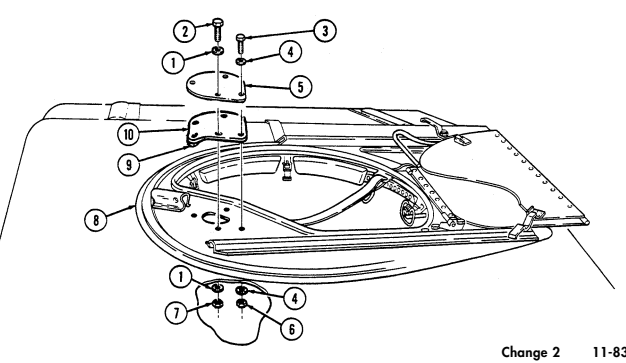

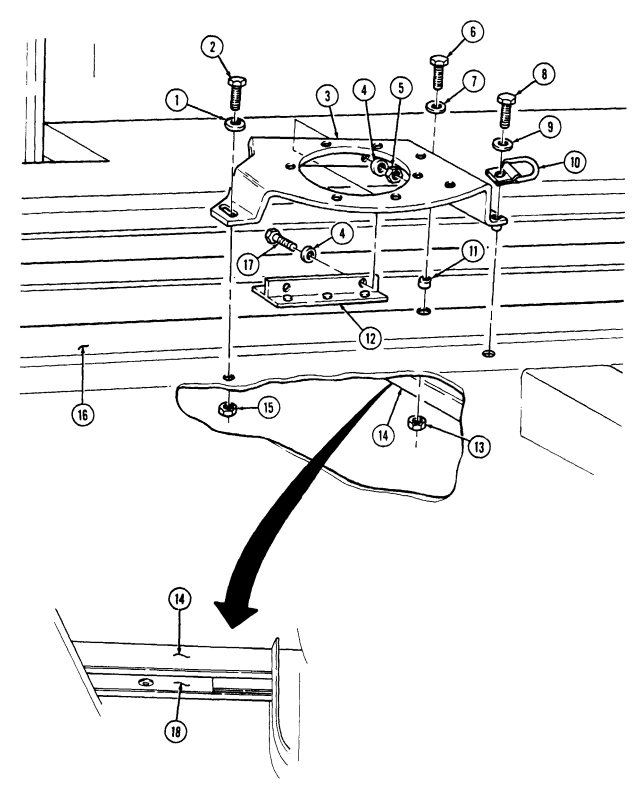

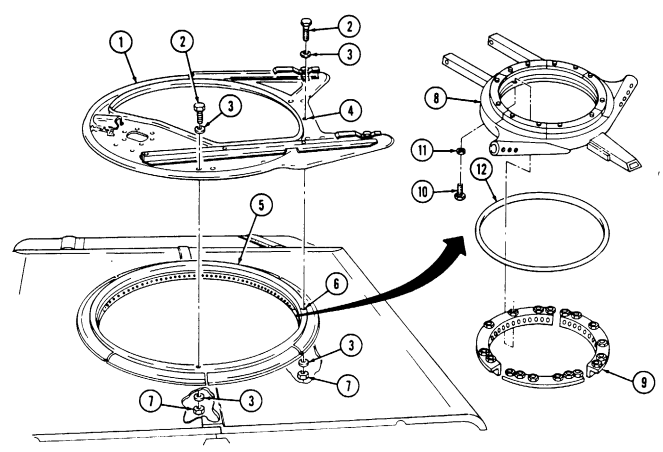

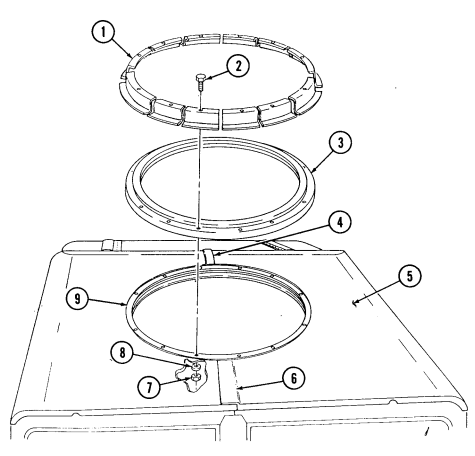

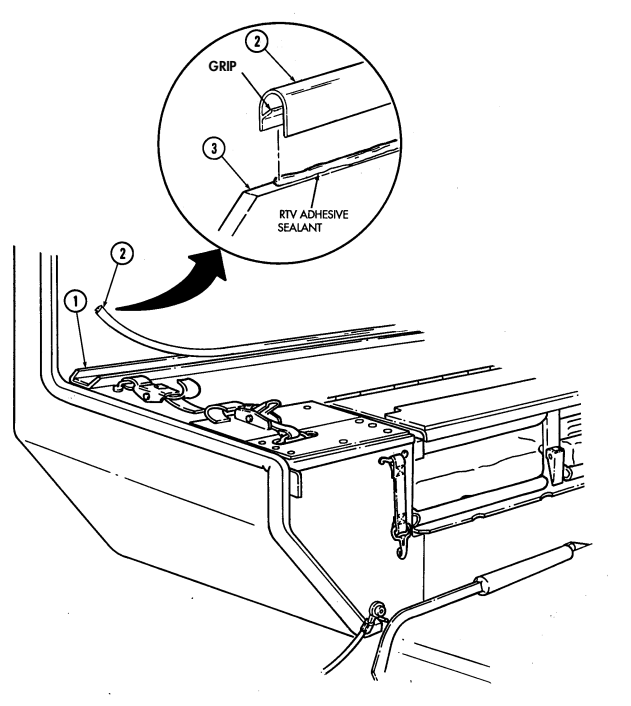

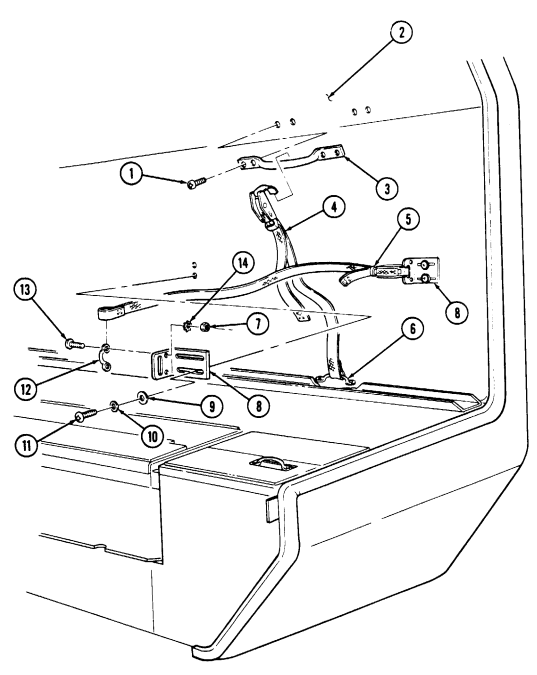

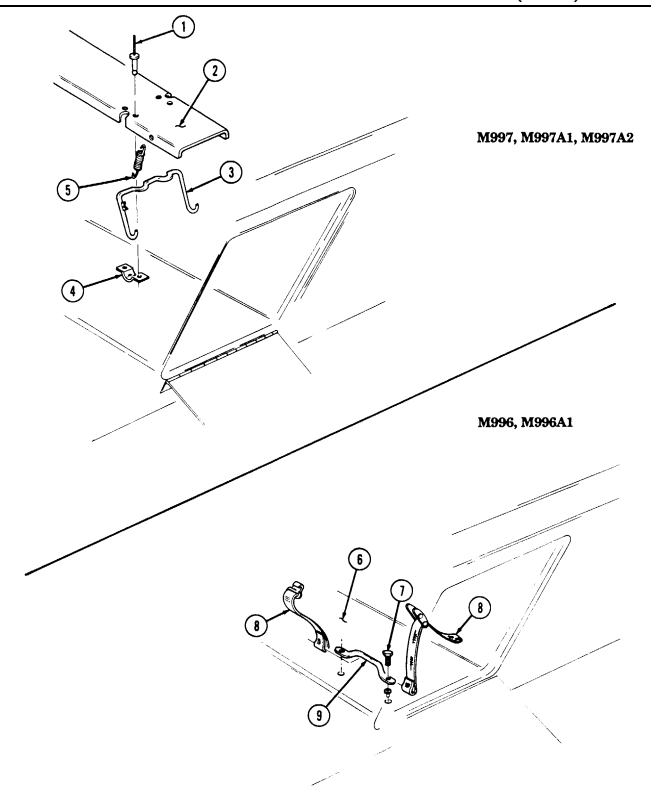

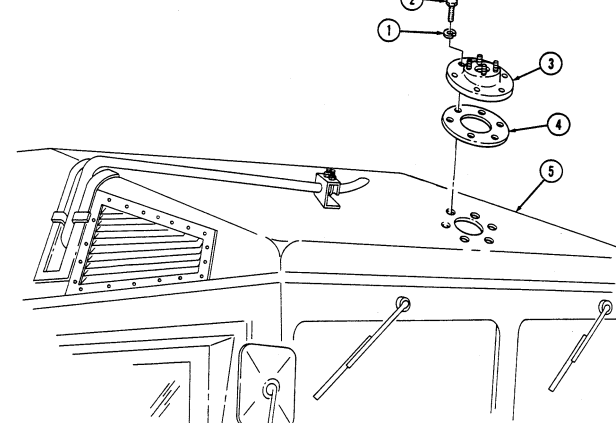

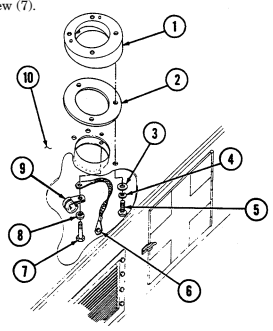

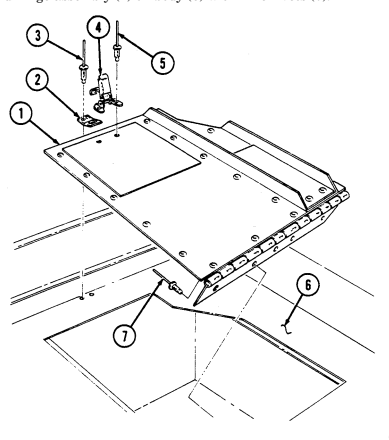

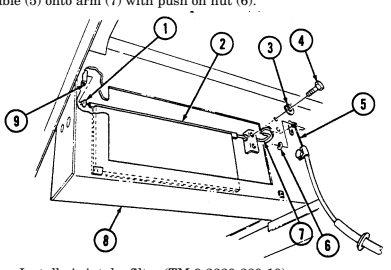

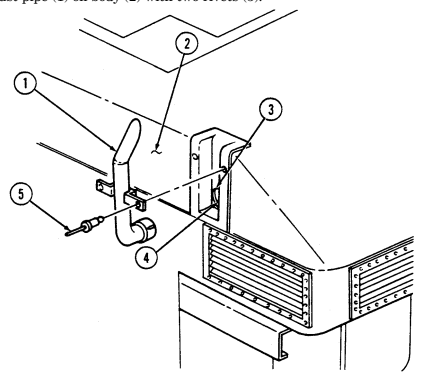

11-42. Weapon Station Hatch Replacement

This task covers: INITIAL SETUP:

Applicable Models

a. Removal b. Installation

Materials/Parts

RTV Sealant (Appendix C, Item 38) Locknut (Appendix G, Item 128) All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2 Tools Manual References TM 9-2320-280-24P General mechanic's tool kit: automotive (Appendix B, Item 1)

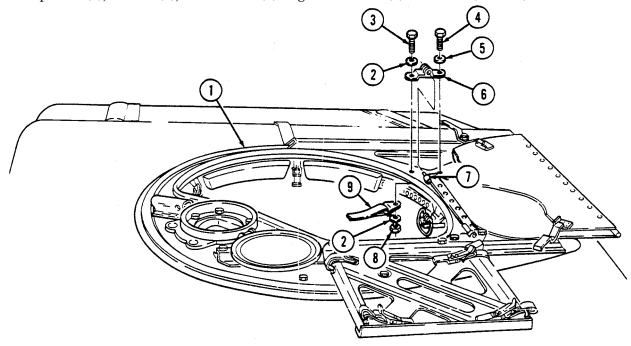

-

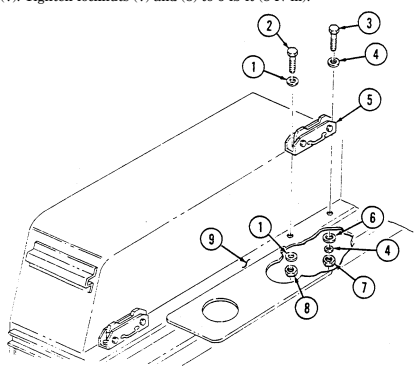

Remove capscrew (6) and washer (7) from hatch pivot bracket (9) and weapon station (1). 2. Remove locknut (10), washer (5), capscrew (4), washer (5), and hatch pivot bracket (9) from weapon station (1). Discard locknut (10).

-

Slide hatch hinge pin (3) out from hatch pivot bracket (2) and remove weapon station hatch (8).

b. Installation

Some hatches may leak water. To prevent water leaks, install NSN 5330-01-190-2227 seal on hatch with RTV sealant.

-

Install weapon station hatch (8) with hatch hinge pin (3) in hatch pivot bracket (2). 2. Install hatch pivot bracket (9) on weapon station (1) with washer (5), capscrew (4), washer (5), and locknut (10).

-

Install hatch pivot bracket (9) on weapon station (1) with washer (7) and capscrew (6). Tighten

locknut (10) and capscrew (6) to 37 lb-ft (50 N•m).

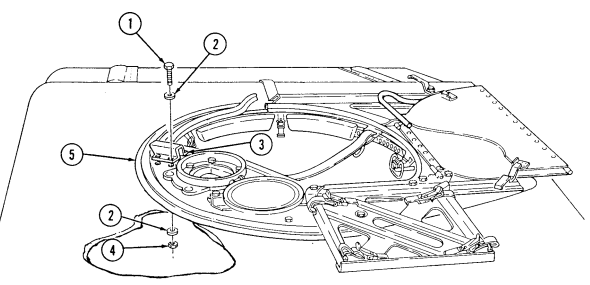

11-43. Weapon Station Hatch Handle Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation Materials/Parts Two locknuts (Appendix G, Item 107) Manual References TM 9-2320-280-24P

Remove two locknuts (1), washers (2), capscrews (5), large washers (4), and handle (6) from hatch (3). Discard locknuts (1). b. Installation Install handle (6) on hatch (3) with two large washers (4), capscrews (5), washers (2), and locknuts (1).

Tighten locknuts to 6 lb-ft (8 N•m).

Tighten locknuts to 6 lb-ft (8 N•m).

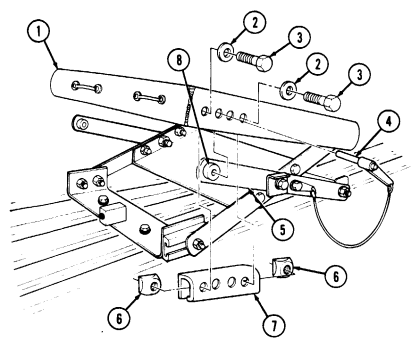

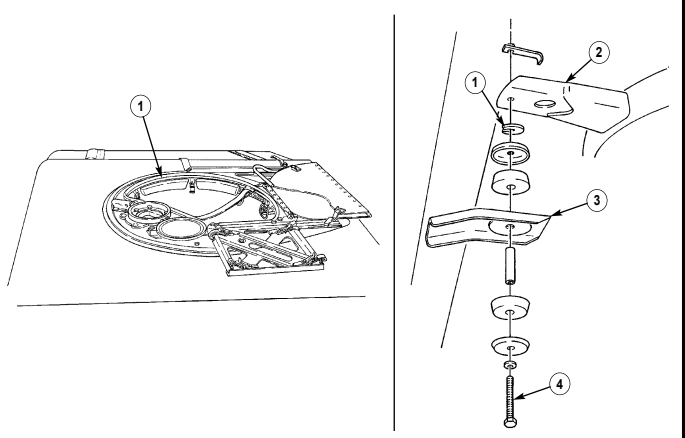

11-44. Weapon Station Hatch Hinge Pin Replacement

This task covers: a. Removal b. Installation INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Two locknuts (Appendix G, Item 70) Manual References TM 9-2320-280-24P

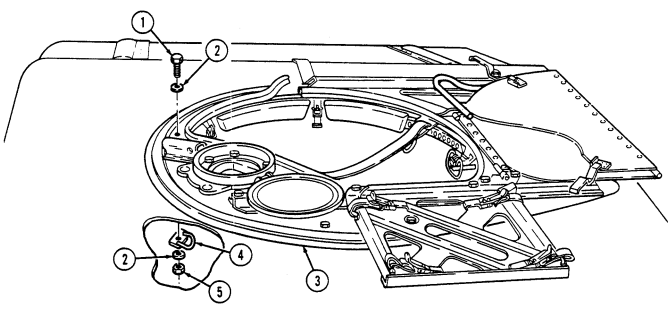

- Remove two locknuts (3), washers (4), capscrews (7), and washers (4) from hatch hinge pin (5) and hatch panel (1). Discard locknuts (3).

NOTE Spacer not required on M1043, M1043A1, M1043A2, M1044, M1044A1, M1045, M1045A1, M1045A2, M1046, and M1046A1 vehicles.

- Remove hatch hinge pin (5) and two spacers (2) from hinge pivot bracket (6) and hatch panel (1).

b. Installation 1. Install hatch hinge pin (5) on hatch panel (1) and slide into hinge pivot bracket (6). Slide two spacers (2) between hatch panel (1) and hinge pin (5) on top side of hatch panel (1).

- Secure hatch hinge pin (5) to hatch panel (1) with two washers (4), capscrews (7), washers (4), and

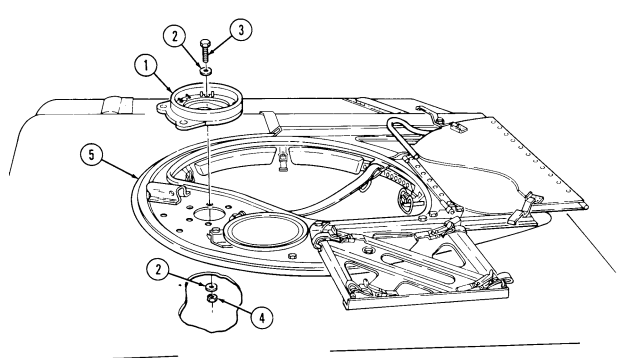

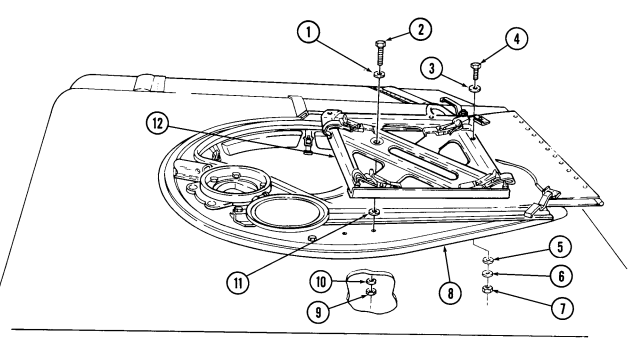

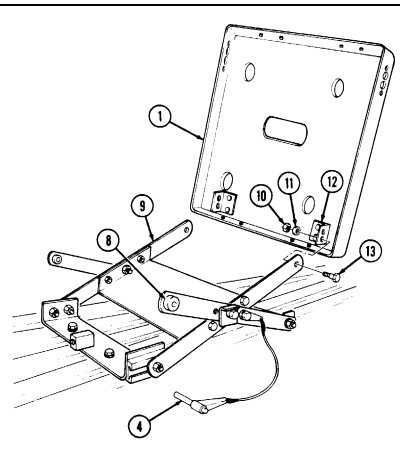

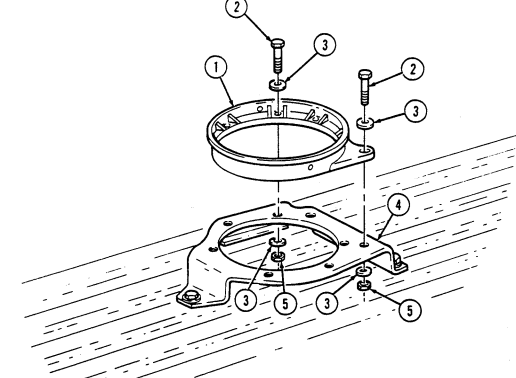

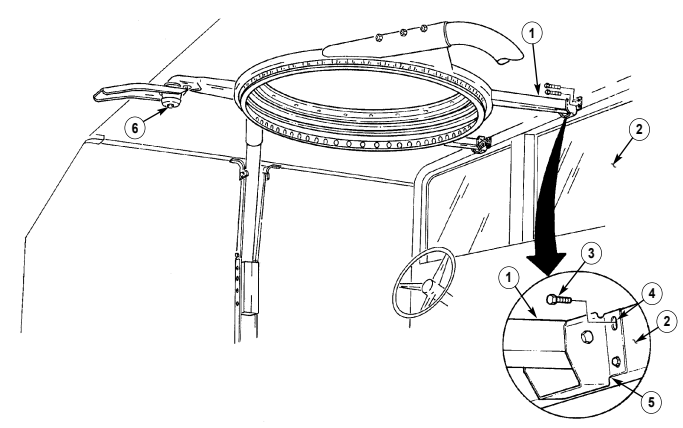

11-45. Weapon Station Hatch Hinge Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Tools

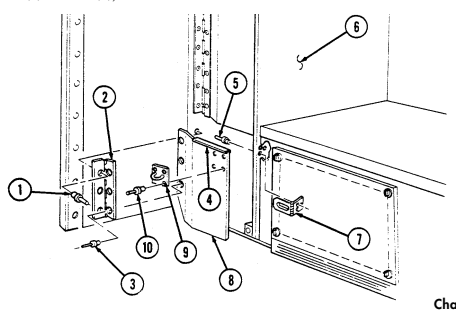

General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation Materials/Parts Sixteen locknuts (Appendix G, Item 70) Manual References TM 9-2320-280-24P a. Removal 1. Remove seven locknuts (5), washers (2), capscrews (3), washers (2), right hatch panel (1), and hinge (4) from left hatch panel (6). Discard locknuts (5).

-

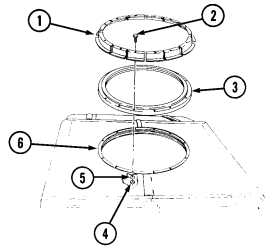

Remove nine locknuts (11), washers (7), capscrews (8), washers (7), retainer (10), seal (9), and hinge (4) from right hatch panel (1). Discard locknuts (11).

-

Inspect seal (9) for damage. Replace if damaged.

11-45. Weapon Station Hatch Hinge Replacement (Cont'D)

-

Install hinge (4), seal (5), and retainer (6) on right hatch panel (1) with nine washers (2), capscrews (3), washers (2), and locknuts (7). Tighten locknuts (7) to 6 lb-ft (8 N-m).

-

Install hinge (4) and right hatch panel (1) on left hatch panel (11) with seven washers (8), capscrews (9), washers (8), and locknuts (10). Tighten locknuts (10) to

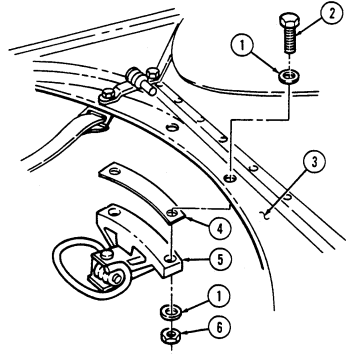

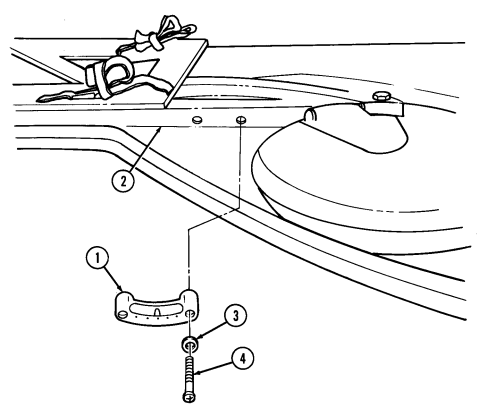

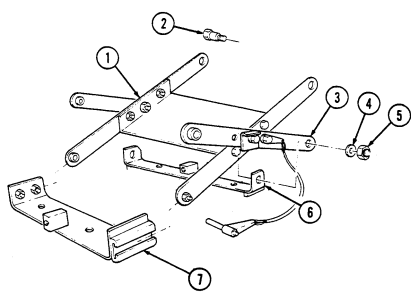

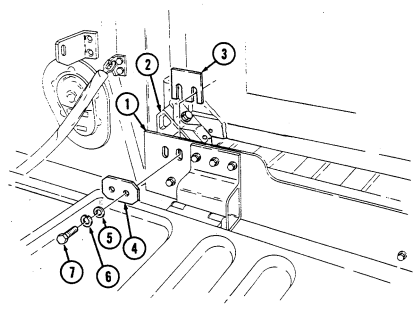

11-46. Weapon Station Hatch Holddown Striker Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) a. Removal b. Installation

Materials/Parts

Two locknuts (Appendix G, Item 70) Two locknuts (Appendix G, Item 107) Manual References TM 9-2320-280-24P a. Removal

This task covers the left hatch panel holddown striker. The right hatch panel holddown striker is mounted directly on the panel.

-

Remove two locknuts (5), washers (4), screws (1), and holddown striker (2) from bracket (3). Discard locknuts (5).

-

Remove two locknuts (7), washers (8), capscrews (9), washers (8), and bracket (3) from left hatch panel (6). Discard locknuts (7).

b. Installation 1. Install striker (2) on bracket (3) with two screws (1), washers (4), and locknuts (5). 2. Install bracket (3) on left hatch panel (6) with two washers (8), capscrews (9), washers (8),

and locknuts (7). Tighten locknuts (7) to 6 lb-ft (8 N•m).

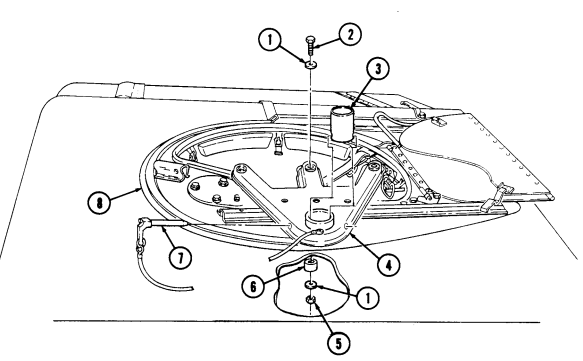

11-47. Weapon Station Tray Seal Replacement

This task covers: INITAL SETUP: Applicable Models Materials/Parts All models except M996, M996A1, M997, Adhesive (Appendix C, Item 3) M997A1 M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, Manual References M1042, M1097, M1097A1, M1097A2 TM 9-2320-280-24P Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

-

Remove seal (1) from weapon station (2).

-

Thoroughly clean the edge of weapon station (2).

a. Removal b. Installation 1. Measure and cut required length of seal (1).

-

Apply a 1/16-in. (1.6 mm) to 1/8-in. (3.2 mm) bead of adhesive to seal (1) lip. 3. Starting somewhere other than at a corner, press seal over the lip of the weapon station (2) tray hatch opening.

-

Allow seal (1) to set and cure undisturbed, for about one hour.

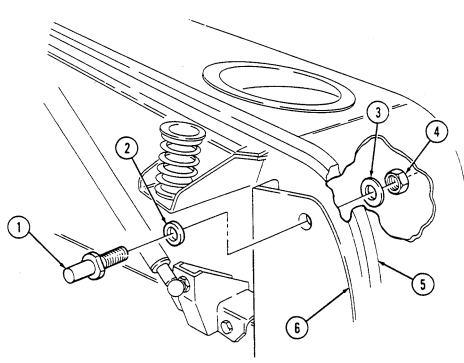

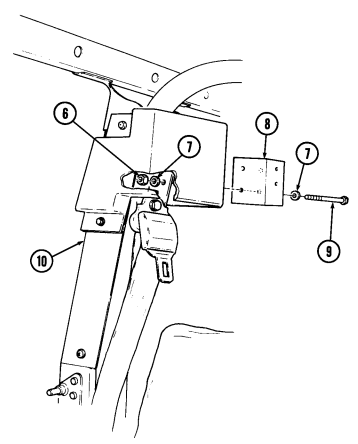

11-48. Weapon Station Bumper Pad Replacement

This task covers: INITIAL SETUP:

Applicable Models

All models except M996, M996A1, M997, M997A1, M997A2, M998, M998A1, M1035, M1035A1, M1035A2, M1037, M1038, M1038A1, M1042, M1097, M1097A1, M1097A2, M1123 a. Removal b. Installation Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Locknut (Appendix G, Item 107) Manual References TM 9-2320-280-24P

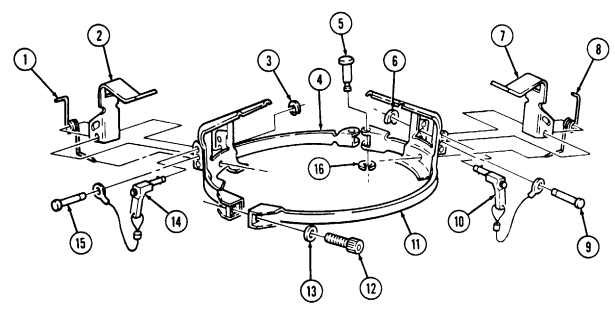

Bumper pads for both sides of hatch are installed basically the same. This procedure covers the right side.