hmmwv-manuals

Appendix A References

A-1. Scope

This appendix lists all forms, field manuals, technical manuals, and other publications required for use with this manual.

A-2. Publications Index

The following index should be consulted frequently for latest changes or revisions and for new publications relating to materiel covered in this manual.

Consolidated Index of Army Publications and Blank Forms . . . . . . . . . . . . . DA PAM 25-30

A-3. Forms

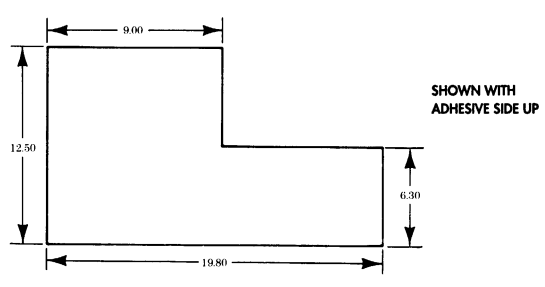

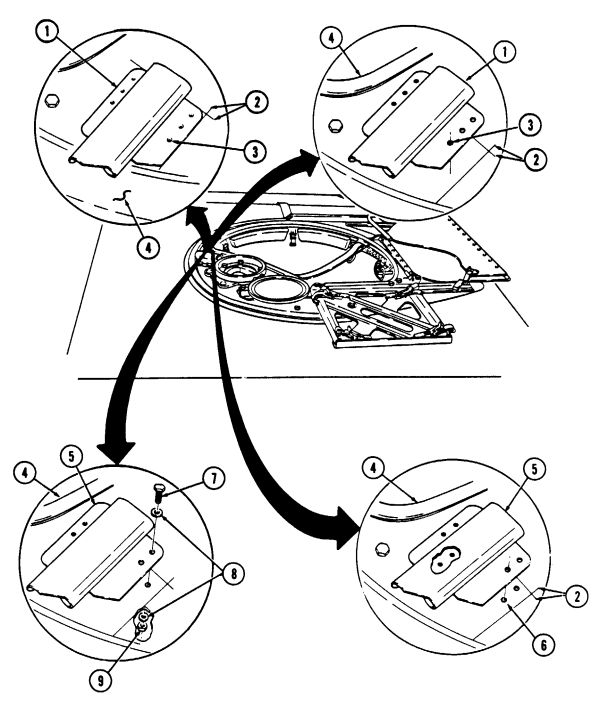

| 1. | Remove antiskid strip (4) from cargo floor (3). |

|---|---|

| 2. | Clean remaining adhesive from cargo floor (3). |

| 3. | Inspect plugs (1) in cargo floor (3) and right wheelhouse (2), and replace plugs (1) if damaged. |

| b. Installation | |

| 1. 2. | Ensure surface of cargo floor (3) is free of dirt and oil. Peel paper backing (5) from antiskid strip (4) and press antiskid strip (4) firmly onto cargo floor (3). |

| A-4. FIELD MANUALS |

|---|

| NBC Protection |

| NBC Decontamination |

| Operation and Maintenance of Ordnance Materiel in Cold Weather (0° to -65°F) FM 9-207 |

| First Aid for Soldiers |

| Manual for the Wheeled Vehicle Driver |

| Browning Machinegun Caliber .50 HB, M2 FM 23-65 |

| Machinegun 7.62-MM, M60 FM 23-67 |

| Basic Cold Weather Manual |

| Northern Operations |

| Army Motor Transport Units and Operations |

| Mountain Operations |

| General Fabric Repair !!! |

| Inspection, Care and Maintenance of Antifriction Bearings | . . TM 9-214 |

|---|---|

| Materials Used for Cleaning, Preserving, Abrading, and Cementing Ordnance | |

| Materiel and Related Materials (Including Chemicals) | TM 9-247 |

| Operator's Manual for Machinegun, Caliber .50 Browning, M2 | . TM 9-1005-213-10 |

| Operator's Manual for M60, 7.62-MM Machinegun | . . TM 9-1005-224-10 |

A-4. Field Manuals A-5. Technical Manuals A-5. Technical Manuals (Cont'D)

| REFERENCES |

|---|

| A-1. SCOPE |

| This appendix lists all forms, field manuals, technical manuals, and other publications required for use |

| with this manual. |

| A-2. PUBLICATIONS INDEX |

| The following index should be consulted frequently for latest changes or revisions and for new publications |

| relating to materiel covered in this manual. |

| Consolidated Index of Army Publications and Blank Forms DA PAM 25-30 |

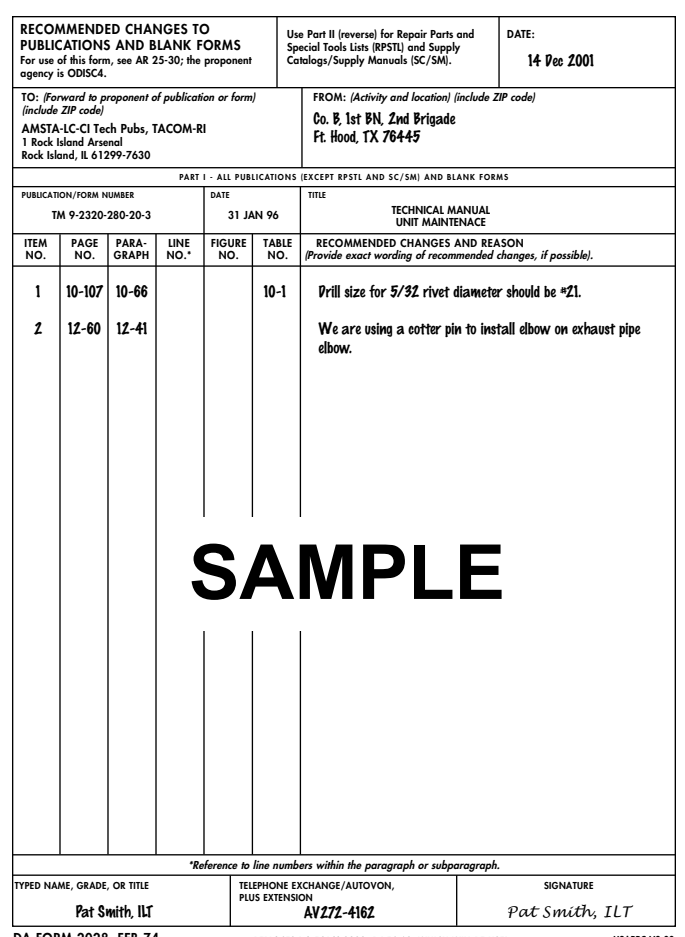

| A-3. FORMS |

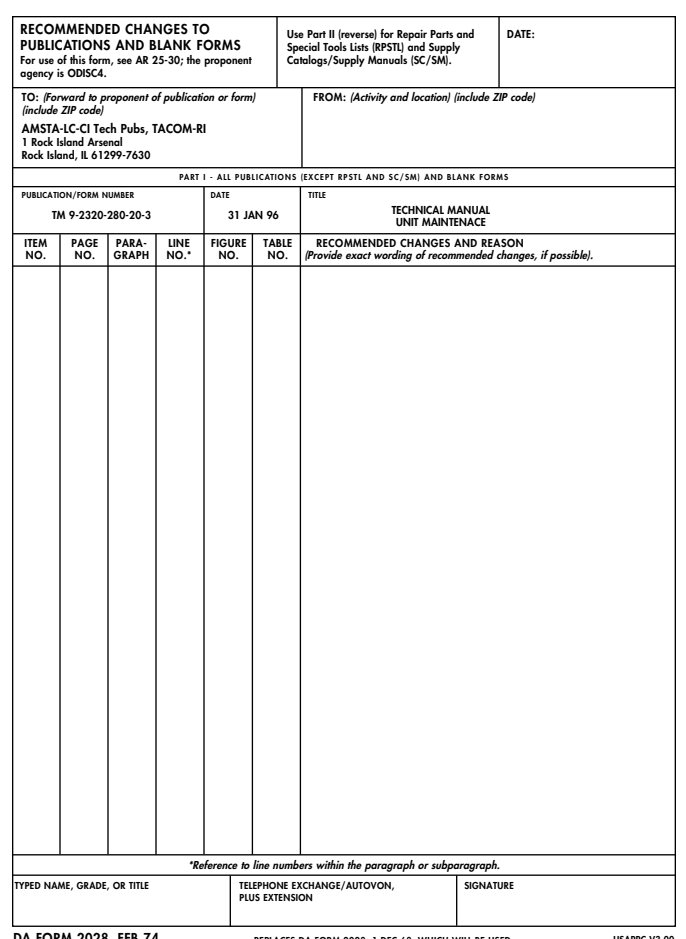

| Recommended Changes to Publications and Blank Forms DA Form 2028 |

| Recommended Changes to Equipment Technical Publications DA Form 2028-2 |

| Hand Receipt/Annex Number DA Form 2062 |

| Exchange Tag DA Form 2402 |

| Equipment Inspection and Maintenance Worksheet DA Form 2404 |

| The Army Maintenance Management System (TAMMS) DA PAM 738-750 |

|---|

| Preventive Maintenance Schedule and Record DD Form 314 |

| Processing and Deprocessing Record for Shipping, Storage, |

| and Issue of Vehicles and Spare Engines DD Form 1397 |

| Quality Deficiency Report Standard Form 368 |

| A-4. FIELD MANUALS |

| NBC Decontamination FM 3-5 |

|---|

| Operation and Maintenance of Ordnance Materiel in Cold Weather (0° to -65°F) FM 9-207 |

| First Aid for Soldiers FM 21-11 |

| Machinegun 7.62-MM, M60 FM 23-67 |

|---|

| Basic Cold Weather Manual FM 31-70 |

| Northern Operations FM 31-71 |

| Army Motor Transport Units and Operations FM 55-30 |

| Mountain Operations FM 90-6 |

| General Fabric Repair FM 10-16 |

| A-5. TECHNICAL MANUALS |

| Inspection, Care and Maintenance of Antifriction Bearings TM 9-214 |

| Materials Used for Cleaning, Preserving, Abrading, and Cementing Ordnance |

| Materiel and Related Materials (Including Chemicals) TM 9-247 |

| Operator's Manual for Machinegun, Caliber .50 Browning, M2 TM 9-1005-213-10 |

| Operator's Manual for M60, 7.62-MM Machinegun TM 9-1005-224-10 |

A-6. Technical Bulletins A-7. Army Regulations A-8. Other Publications

Appendix B Maintenance Allocation Chart

Section I. INTRODUCTION

B-1. The Army Maintenance System (Mac)

a. This section provides a general explanation of all maintenance and repair functions authorized at various maintenance levels under the standard Army Maintenance System Concept.

b. The Maintenance Allocation Chart (MAC) in section II designates overall authority and responsibility for the performance of maintenance functions on the identified end item or component. The application of the maintenance functions to the end item or component will be consistent with the capacities and capabilities of the designated maintenance levels, which are shown on the MAC in column (4) as: Unit - includes two subcolumns, C (operator/crew ) and O (unit) maintenance.

Direct Support - includes an F subcolumn. General Support - includes an H subcolumn. Depot - includes a D subcolumn.

c. Section III lists the tools and test equipment (both special tools and common tool sets) required for each maintenance function as referenced from section II.

d. Section IV contains supplemental instructions and explanatory notes for a particular maintenance function.

B-2. Maintenance Functions

Maintenance functions will be limited to and defined as follows: a. Inspect. To determine the serviceability of an item by comparing its physical, mechanical, and/or electrical characteristics with established standards through examination (e.g., by sight, sound, or feel).

b. Test. To verify serviceability by measuring the mechanical, pneumatic, hydraulic, or electrical characteristics of an item and comparing those characteristics with prescribed standards.

c. Service. Operations required periodically to keep an item in proper operating condition, i.e., to clean (includes decontaminate, when required), to preserve, to drain, to paint, or to replenish fuel, lubricants, chemical fluids, or gases.

d. Adjust. To maintain or regulate, within prescribed limits, by bringing into proper or exact position, or by setting the operating characteristics to specified parameters.

e. Align. To adjust specified variable elements of an item to bring about optimum or desired performance.

f. Calibrate. To determine and cause corrections to be made or to be adjusted on instruments or test, measuring, and diagnostic equipment used in precision measurement. Consists of comparisons of two instruments, one of which is a certified standard of known accuracy, to detect and adjust any discrepancy in the accuracy of the instrument being compared.

g. Remove/Install. To remove and install the same item when required to perform service or other maintenance functions. Install may be the act of emplacing, seating, or fixing into position a spare, repair part, or module (component or assembly) in a manner to allow the proper functioning of an equipment or system.

h. Replace. To remove an unserviceable item and install a serviceable counterpart in its place.

"Replace" is authorized by the MAC and is shown as the 3d position code of the SMR code.

i. Repair. The application of maintenance services, including fault location/troubleshooting, removal/installation, and disassembly/assembly procedures, and maintenance actions to identify troubles and restore serviceability to an item by correcting specific damage, fault, malfunction, or failure in a part, subassembly, module (component or assembly), end item, or system.

j. Overhaul. That maintenance effort (service/action) prescribed to restore an item to a completely serviceable/operational condition as required by maintenance standards in appropriate technical publications (i.e., DMWR). Overhaul is normally the highest degree of maintenance performed by the Army. Overhaul does not normally return an item to like-new condition.

k. Rebuild. Consists of those services/actions necessary for the restoration of unserviceable equipment to a like-new condition in accordance with original manufacturing standards. Rebuild is the highest degree of materiel maintenance applied to Army equipment. The rebuild operation includes the act of returning to zero those age measurements (hours/ miles, etc.) considered in classifying Army equipment/components.

B-3. Explanation Of Columns In The Mac, Section Ii

a. Column (1)-Group Number. Column 1 lists functional group code numbers, the purpose of which is to identify maintenance significant components, assemblies, subassemblies, and modules with the next higher assembly.

b. Column (2)-Component/Assembly. Column 2 contains the names of components, assemblies, subassemblies, and modules for which maintenance is authorized.

c. Column (3)-Maintenance Function. Column 3 lists the functions to be performed on the item listed in Column 2. (For detailed explanation of these functions, see para. B-2.) d. Column (4)-Maintenance Category. Column 4 specifies, by the listing of a work time figure in the appropriate subcolumn(s), the category of maintenance authorized to perform the function listed in Column 3. This figure represents the active time required to perform that maintenance function at the indicated category of maintenance. If the number of complexity of the tasks within the listed maintenance function vary at different maintenance categories, appropriate work time figures will be shown for each category. The work time figure represents the average time required to restore an item (assembly, subassembly, component, module, end item, or system) to a serviceable condition under typical field operating conditions. This time includes preparation time (including any necessary disassembly/assembly time) troubleshooting/fault location time, and quality assurance/quality control time in addition to the time required to perform the specific tasks identified for the maintenance functions authorized in the maintenance allocation chart. The symbol designations for the various maintenance categories are as follows: NOTE When a complete replace or repair task performed at higher level maintenance includes lower level maintenance tasks (equipment condition/follow-on tasks), the lower level work time figures in the MAC must be added to the higher level work time shown in the MAC to determine the total time to accomplish that maintenance function.

| Policy for Safeguarding and Controlling Comsec Material AR 380-40 |

|---|

| Prevention of Motor Vehicle Accidents AR 385-55 |

| Packaging of Material AR 700-15 |

| Army Material Maintenance Policy and Retail Maintenance Operation AR 750-1 |

e. Column (5)-Tools and Equipment. Column 5 specifies, by code, those common tool sets (not individual tools) and special tools, TMDE, and support equipment required to perform the designated function.

f. Column (6)-Remarks. This column shall, when applicable, contain a letter code, in alphabetic order, which shall be keyed to the remarks contained in Section IV.

B-4. Explanation Of Columns In Tool And Test Equipment Requirements, Section Iii

a. Column (1)-Reference Code. The tool and test equipment reference code correlates with a code used in the MAC, Section II, Column 5.

b. Column (2)-Maintenance Category. The lowest category of maintenance authorized to use the tool or test equipment.

c. Column (3)-Nomenclature. Name or identification of the tool or test equipment. d. Column (4)-National Stock Number. The National stock number of the tool or test equipment. e. Column (5)-Tool Number. The manufacturer's part number.

B-5. Explanation Of Columns In Remarks, Section Iv

a. Column (1)-Remarks Code. The code recorded in column 6, Section II. b. Column (2)-Remarks. This column lists information pertinent to the maintenance function being performed as indicated in the MAC, Section II.

TM 9-2320-280-20-3

| i. Repair. The application of maintenance services, including fault location/troubleshooting, |

|---|

| removal/installation, and disassembly/assembly procedures, and maintenance actions to identify troubles |

| and restore serviceability to an item by correcting specific damage, fault, malfunction, or failure in a part, |

| subassembly, module (component or assembly), end item, or system. |

| j. Overhaul. That maintenance effort (service/action) prescribed to restore an item to a completely |

| serviceable/operational condition as required by maintenance standards in appropriate technical |

| publications (i.e., DMWR). Overhaul is normally the highest degree of maintenance performed by the |

| Army. Overhaul does not normally return an item to like-new condition. |

| k. Rebuild. Consists of those services/actions necessary for the restoration of unserviceable equipment |

| to a like-new condition in accordance with original manufacturing standards. Rebuild is the highest degree |

| of materiel maintenance applied to Army equipment. The rebuild operation includes the act of returning to |

| zero those age measurements (hours/ miles, etc.) considered in classifying Army equipment/components. |

| B-3. EXPLANATION OF COLUMNS IN THE MAC, SECTION II |

| a. Column (1)-Group Number. Column 1 lists functional group code numbers, the purpose of which |

| is to identify maintenance significant components, assemblies, subassemblies, and modules with the next higher assembly. |

| b. Column (2)-Component/Assembly. Column 2 contains the names of components, assemblies, |

| subassemblies, and modules for which maintenance is authorized. |

| c. Column (3)-Maintenance Function. Column 3 lists the functions to be performed on the item |

| listed in Column 2. (For detailed explanation of these functions, see para. B-2.) |

| d. Column (4)-Maintenance Category. Column 4 specifies, by the listing of a work time figure in |

| the appropriate subcolumn(s), the category of maintenance authorized to perform the function listed in |

| Column 3. This figure represents the active time required to perform that maintenance function at the |

| indicated category of maintenance. If the number of complexity of the tasks within the listed maintenance |

| function vary at different maintenance categories, appropriate work time figures will be shown for each |

| category. The work time figure represents the average time required to restore an item (assembly, |

| subassembly, component, module, end item, or system) to a serviceable condition under typical field |

| operating conditions. This time includes preparation time (including any necessary disassembly/assembly |

| time) troubleshooting/fault location time, and quality assurance/quality control time in addition to the time |

| required to perform the specific tasks identified for the maintenance functions authorized in the |

| maintenance allocation chart. The symbol designations for the various maintenance categories are as |

| follows: |

| NOTE |

| When a complete replace or repair task performed at higher |

| level maintenance includes lower level maintenance tasks |

| (equipment condition/follow-on tasks), the lower level work |

| time figures in the MAC must be added to the higher level |

| work time shown in the MAC to determine the total time to |

| accomplish that maintenance function. |

| C Operator or crew |

| O Unit maintenance |

| F Direct Support maintenance |

| H General Support maintenance |

| D Depot maintenance |

| e. Column (5)-Tools and Equipment. Column 5 specifies, by code, those common tool sets (not |

| individual tools) and special tools, TMDE, and support equipment required to perform the designated |

| function. |

| f. Column (6)-Remarks. This column shall, when applicable, contain a letter code, in alphabetic |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd) Section II. MAINTENANCE ALLOCATION CHART (Cont'd)

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| 01 | ENGINE | ||||||||

| 0100 | Engine Assembly | Inspect | 0.2 | 0.7 | |||||

| Test | 1.0 | 1,20,21,22,26 | G | ||||||

| Service | 0.5 | 1,2 | |||||||

| Adjust | 1.0 | 41,42 | |||||||

| Replace | 32.7 | 25,145 | |||||||

| Repair | 16.0 | 1,7,10,43-45 | |||||||

| Mount, Engine | Inspect | 0.1 | 2,144,145 | ||||||

| Replace | 1.6 | 1,2,144- | |||||||

| 146,149 | |||||||||

| 0101 | Cylinder Head | Replace | 3.0 | 1,6 | |||||

| Repair | 5.0 | 1,6,8,12-18 | |||||||

| Block, Cylinder | Repair | 10.0 | 1,6-8,12-18 | ||||||

| 0102 | Crankshaft | Replace | 4.0 | 1 | |||||

| Pulley, Crankshaft | Replace | 0.5 | 1,6 | ||||||

| Damper, Vibration | Replace | 0.5 | 1,6 | ||||||

| Bearings, Crankshaft | Replace | 4.0 | 1 | ||||||

| Oil Seals, Crankshaft, Front | Replace | 2.0 | 1 | ||||||

| Oil Seals, Crankshaft, Rear | Replace | 2.0 | 1,6,46 | ||||||

| 0103 | Flywheel | Replace | 3.5 | 1,6 | |||||

| 0104 | Pistons, Connecting Rods | ||||||||

| Rods, Connecting | Replace | 8.0 | 1,6 | ||||||

| Bearings, Connecting Rod | Replace | 2.0 | 1,6 | ||||||

| Pistons | Replace | 8.0 | 1,6 | ||||||

| Rings, Piston | Replace | 7.0 | 1,6,10 | ||||||

| 0105 | Valves, Camshaft, and Timing | ||||||||

| System | |||||||||

| Cover, Rocker Arm | Replace | 1.0 | 1,6 | ||||||

| Valves, Intake and Exhaust | Replace | 3.0 | 6 | ||||||

| Repair | 3.0 | 6,8 | |||||||

| Rocker Arm Assembly | Replace | 2.1 | 1,6 | ||||||

| Springs, Valve | Test | 0.5 | 1,8 | ||||||

| Replace | 2.3 | 1,6 | |||||||

| Rods, Push | Replace | 3.0 | 1 | ||||||

| Lifters | Replace | 6.0 | 1 |

TM 9-2320-280-20-3

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | C | O | F | H | D | Ref Code | Code |

| Gears and Chain, Timing | Replace | 4.0 | 1,6,10 | ||||||

| Camshaft | Replace | 4.0 | 1,6,10 | ||||||

| Bearings, Camshaft | Replace | 4.0 | 1,6,45,47 | ||||||

| 0106 | Engine Lubrication System | ||||||||

| Pan, Oil | Replace | 2.0 | 1,2 | ||||||

| Pump, Oil | Replace | 2.5 | 1,6 | ||||||

| Filter, Oil | Replace | 0.5 | 1,2 | ||||||

| Dipstick and Tube | Replace | 0.2 | 1,2,156 | ||||||

| Oil Cooler Assembly | Inspect | 0.1 | |||||||

| Replace | 0.5 | 1,2 | |||||||

| Repair | 1.0 | 1 | |||||||

| Lines, Oil Cooler | Inspect | 0.2 | |||||||

| Replace | 1.8 | 1 | |||||||

| Valve, Crankcase Depression | Inspect | 0.1 | |||||||

| Regulator | Test | 0.3 | L | ||||||

| Service | 0.3 | 1 | |||||||

| Replace | 0.3 | 1,2 | |||||||

| 0108 | Manifold, Intake | Replace | 3.0 | 1,6 | |||||

| Manifold, Exhaust | Replace | 3.0 | 1,146, | ||||||

| 150,156 | |||||||||

| 03 | FUEL SYSTEM | ||||||||

| 0301 | Injector Nozzle, Fuel | Test | 0.5 | 1,9 | |||||

| Replace | 0.7 | 1,6,49,134, | |||||||

| 146,153 | |||||||||

| 0302 | Lines, Injection Pump | Inspect | 0.1 | ||||||

| Replace | 2.0 | 1,147,148 | |||||||

| Pump, Injection | Inspect | 0.1 | |||||||

| Calibrate | A | 1,9,59-65 | A | ||||||

| Replace | 4.0 | 1,147 | |||||||

| Repair | 0.6 | 5.0 | 1,9,50-57, | O | |||||

| 158-161 | |||||||||

| Fuel Pump | Test | 0.3 | 1,2 | ||||||

| Replace | 1.0 | 1,2 | |||||||

| 0304 | Cleaner Assembly, Air | Inspect | 0.2 | ||||||

| Service | 0.2 | 0.5 | 1 | ||||||

| Replace | 0.2 | 1 | |||||||

| Horn, Air Induction | Inspect | 0.1 | |||||||

| Replace | 0.3 | 1,2 | |||||||

| 0306 | Lines and Fittings, Fuel | Inspect | 0.2 | ||||||

| Replace | 3.2 | 1 | |||||||

| Tank, Fuel | Inspect | 0.1 | |||||||

| Replace | 2.6 | 1,2 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd)

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| 0309 | Filter Assembly, Fuel | Inspect | 0.1 | ||||||

| Service | 0.1 | 0.5 | 1 | B | |||||

| Replace | 0.5 | 2 | |||||||

| 0311 | Glow Plugs | Test | 0.3 | 2 | |||||

| Replace | 0.7 | 1,2,48,155 | |||||||

| 0312 | Accelerator Linkage | Inspect | 0.2 | ||||||

| Adjust | 0.2 | 1 | |||||||

| Replace | 0.8 | 1,2 | |||||||

| Hand Throttle | Inspect | 0.1 | 0.1 | ||||||

| Adjust | 0.2 | 1 | |||||||

| Replace | 0.5 | 1,2 | |||||||

| 04 | EXHAUST SYSTEM | ||||||||

| 0401 | Muffler | Inspect | 0.2 | ||||||

| Replace | 1.9 | 1,2 | |||||||

| Crossover Pipe | Inspect | 0.2 | |||||||

| Replace | 1.2 | 1,2,145, | |||||||

| 150 | |||||||||

| Tailpipe | Inspect | 0.2 | |||||||

| Replace | 0.5 | 1,2 | |||||||

| 05 | COOLING SYSTEM | ||||||||

| 0501 | Radiator | Inspect | 0.1 | 0.2 | |||||

| Test | 0.5 | 2,66 | |||||||

| Replace | 4.3 | 1 | |||||||

| Repair | 3.0 | 1 | |||||||

| Surge Tank | Inspect | 0.1 | |||||||

| Service | 0.1 | 0.5 | 1,2 | C | |||||

| Replace | 0.6 | 1 | |||||||

| 0502 | Shroud, Fan | Inspect | 0.1 | ||||||

| Replace | 4.4 | 1 | |||||||

| Repair | F | F,M | |||||||

| 0503 | Hoses, Lines, and Clamps | Inspect | 0.1 | 0.1 | |||||

| Replace | 2.5 | 1 | |||||||

| Thermostat | Test | 0.2 | |||||||

| Replace | 0.3 | 1,2 | |||||||

| 0504 | Pump, Water | Replace | 3.5 | 1,6 | |||||

| 0505 | Fan | Inspect | 0.1 | 0.1 | |||||

| Replace | 1.0 | 1,2,161 | |||||||

| Fan Drive | Repair | 4.7 | 1,6 | ||||||

| Pulley, Water Pump | Replace | 4.8 | 1,157 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd) TM 9-2320-280-20-3

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | C | O | F | H | D | Ref Code | Code |

| Belts, Drive | Inspect | 0.1 | |||||||

| Adjust | 0.5 | 1,2,67 | |||||||

| Replace | 1.0 | 1,2,67 | |||||||

| 06 | ELECTRICAL SYSTEM | ||||||||

| 0601 | Alternator (60 Ampere) | Inspect | 0.1 | ||||||

| Test | 0.3 | 2,166 | |||||||

| Adjust | 0.3 | 1,163 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| Pulley, Alternator | Replace | 1.2 | 1,2,67 | ||||||

| 0603 | Starter | Inspect | 0.2 | ||||||

| Test | 0.3 | 2 | |||||||

| Replace | 1.9 | 1,2,145, | |||||||

| 146,149 | |||||||||

| Repair | 8.3 | 1,9 | |||||||

| 0607 | Instrument Panel | ||||||||

| Switches | Replace | 0.3 | 1 | ||||||

| Instruments, Gages | Inspect | 0.1 | |||||||

| Replace | 0.5 | 1 | |||||||

| Circuit Breakers | Replace | 0.5 | 1 | ||||||

| 0608 | Control, Directional Signal | Inspect | 0.1 | ||||||

| Replace | 0.3 | 1 | |||||||

| Protective Control Box | Inspect | 0.1 | |||||||

| Replace | 0.3 | 1 | |||||||

| 0609 | Headlight | Inspect | 0.1 | ||||||

| Adjust | 0.2 | 1,2 | |||||||

| Replace | 0.5 | 1 | |||||||

| Lights, Composite, Front | Inspect | 0.1 | |||||||

| and Rear | Replace | 0.1 | 1 | ||||||

| 0610 | Sending Units and Warning | Test | 0.1 | 2 | |||||

| Switches | Replace | 0.1 | 1 | ||||||

| 0611 | Horn Assembly | Inspect | 0.1 | ||||||

| Test | 0.2 | 2 | |||||||

| Replace | 0.3 | 1 | |||||||

| Switch, Horn | Test | 0.2 | 2 | ||||||

| Replace | 0.2 | 1 | |||||||

| 0612 | Battery | Inspect | 0.1 | ||||||

| Test | 0.5 | 2 | |||||||

| Service | 0.2 | 1 | |||||||

| Replace | 1.6 | 1 | |||||||

| Cables, Battery | Inspect | 0.2 | |||||||

| Replace | 0.8 | 1 | |||||||

| Repair | 0.5 | 1,2 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd)

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| 0613 | Wiring Harnesses | ||||||||

| Wiring Harness, Engine | Inspect | 0.3 | |||||||

| Replace | 4.5 | 1,6 | |||||||

| Repair | 0.5 | 1,2 | |||||||

| Wiring Harness, STE/ICE-R | Inspect | 0.3 | |||||||

| Replace | 3.7 | 1,6 | |||||||

| Repair | 0.5 | 1,2 | |||||||

| Wiring Harness, Body | Inspect | 0.4 | |||||||

| Replace | 3.5 | 1,6 | |||||||

| Repair | 0.5 | 1,2 | |||||||

| Wiring Harness, Hood | Inspect | 0.2 | |||||||

| Replace | 1.0 | 1 | |||||||

| Repair | 0.5 | 2 | |||||||

| 0615 | Ambulance Electrical | ||||||||

| System | |||||||||

| Spotlight and Ceiling | Inspect | 0.1 | |||||||

| Light Bulbs | Replace | 0.1 | 1 | ||||||

| Spotlight and Ceiling | Inspect | 0.1 | |||||||

| Light Assemblies | Replace | 0.2 | 1 | ||||||

| Blackout Light Switches | Inspect | 0.1 | |||||||

| Replace | 0.2 | 1 | |||||||

| Backup Lights | Replace | 0.3 | 1 | ||||||

| Control Box | Inspect | 0.1 | |||||||

| Replace | 2.5 | 1 | |||||||

| Control Box Relays, | Replace | 0.3 | 1 | ||||||

| Switches, Fuse Blocks | |||||||||

| Heat/Vent Control | Replace | 0.3 | 1 | ||||||

| Panel (M996) | |||||||||

| Heat, Vent, and | Replace | 10.0 | 1 | ||||||

| A/C Control Box (M997) | |||||||||

| Heat, Vent, and | Replace | 0.3 | 1 | ||||||

| A/C Switches and Relays | |||||||||

| 200 Ampere Alternator | Inspect | 0.2 | |||||||

| Test | 0.3 | 2,166 | |||||||

| Replace | 1.1 | 1 | |||||||

| Adjust | 0.3 | ||||||||

| Repair | 4.0 | ||||||||

| Lighting Wiring Harness | Replace | 3.5 | 1 | ||||||

| NBC Control Box and | Replace | 4.3 | |||||||

| Wiring Harness |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd) TM 9-2320-280-20-3

| (4) | (1) | (2) | (3) | (5) | (6) | Maintenance Level | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Tools and | Group | Maintenance | Remarks | Direct | General | Unit | Equipment | Depot | Support | Support |

| Number | Component/Assembly | Function | Code | Ref Code | F | H | C | O | D | |

| 07 | TRANSMISSION (3L80) | 0705 | Shift Control and Linkage | Inspect | 0.1 | 0.2 | ||||

| Adjust | 0.5 | 1 | Replace | 1.5 | 1,2 | |||||

| Repair | 1.0 | 6 | Modulator, Mechanical | Adjust | 0.1 | 2 | ||||

| Replace | 0.6 | 2 | Switch Neutral Start | Replace | 0.5 | 1 | ||||

| Detent Solenoid | Replace | 1.7 | 1,2 | 0708 | Torque Converter | Replace | 3.3 | 1,2 | ||

| 0710 | Transmission Assembly | Inspect | 0.1 | D | Test | 0.5 | 2,6,145 | |||

| Service | 0.2 | 1,2 | Replace | 5.8 | 1,6,144 | |||||

| Repair | 4.0 | 1,6,70,80 | Transmission Mount | Inspect | 0.2 | |||||

| Replace | 1.0 | 1,6 | Gear Unit | Replace | 1.5 | 1,6,70-73 | ||||

| Repair | 1.3 | 1,6,72-75 | 0713 | Forward Clutch | Replace | 2.0 | 1,6,70-73 | |||

| Repair | 0.6 | 1,6,76,77 | Direct Clutch | Replace | 2.0 | 1,6,70-73,79 | ||||

| Repair | 0.8 | 1,6,76,77 | Intermediate Clutch | Replace | 2.0 | 1,6,70-73 | ||||

| Repair | 0.8 | 1,6,74,75,79 | 0714 | Rear Servo | Replace | 1.0 | 1,6,78 | |||

| Repair | 0.3 | 1,6,78 | Front Servo | Replace | 1.0 | 1,6 | ||||

| Repair | 1.0 | 1,6 | Band, Front and Rear | Replace | 2.5 | 1,6,70-73,79 | ||||

| Governor | Inspect | 0.2 | Replace | 0.5 | 1,6 | |||||

| Control Valve | Replace | 1.3 | 1,6 | Repair | 1.0 | 1,6,10 | ||||

| 0721 | Oil Pump, Transmission | Replace | 1.0 | 1,6,70,71,73,80 | Repair | 1.6 | 1,6,73-75 | |||

| Seal, Oil Pump | Replace | 0.3 | 1,6,80 | Oil Filter, Transmission | Replace | 1.5 | 1,2 | |||

| Oil Cooler Lines | Inspect | 0.2 | Replace | 1.0 | 1 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd) Section II. MAINTENANCE ALLOCATION CHART (Cont'd)

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct | General | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Support | Support | Ref Code | Code | |||

| C | O | F | H | D | |||||

| TRANSMISSION (4L80-E) | |||||||||

| 0705 | Shift Control and Linkage | Inspect | 0.1 | 0.2 | |||||

| Adjust | 0.5 | 1 | |||||||

| Replace | 1.5 | 1,2 | |||||||

| Repair | 1.0 | 1,2 | |||||||

| Throttle Position Sensor | Adjust | 0.1 | 1,63,166,173 | ||||||

| Replace | 0.6 | 1,63,166,173 | |||||||

| Switch, Neutral Start | Replace | 0.5 | 1 | ||||||

| 0708 | Torque Converter | Replace | 3.3 | 1,2 | |||||

| 0710 | Transmission Assembly | Inspect | 0.1 | D | |||||

| Test | 0.5 | 1,2,6, | |||||||

| 93.1,93.2, | |||||||||

| 145,166,173 | |||||||||

| Service | 0.2 | 1,2 | |||||||

| Replace Repair | 5.8 | 4.0 | 1,2,6,144 1,6,70,71,81 | ||||||

| Overhaul | 13.5 | 1,6,70-73, | |||||||

| 79,81-84, | |||||||||

| 92,93,95,172 | |||||||||

| Transmission Mount | Inspect | 0.2 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| Gear Unit | Replace | 1.5 | 1,6,84 | ||||||

| Repair | 1.3 | 1,6,84 | |||||||

| 0713 | Forward Clutch | Replace | 2.0 | 1,6,85, | |||||

| 87,88,172 | |||||||||

| Repair | 0.6 | 1,6,85-88, | |||||||

| 172 | |||||||||

| Direct Clutch | Replace | 2.0 | 1,6,79, | ||||||

| 87,88, | |||||||||

| 172 | |||||||||

| Repair | 0.8 | 1,6,79, | |||||||

| 86-88 | |||||||||

| Intermediate Clutch | Replace | 2.0 | 1,6,84 | ||||||

| Repair | 0.8 | 1,6,79,84 | |||||||

| Fourth Clutch | Replace | 2.0 | 1,6,86-88 | ||||||

| Repair | 0.8 | 1,6,87-89 | |||||||

| Turbine Shaft and | Replace | 2.0 | 1,6 | ||||||

| Overdrive Carrier | Repair | 0.8 | 1,6,79,86,90 | ||||||

| 0714 | Rear Servo | Replace | 1.0 | 1,6 | |||||

| Repair | 0.3 | 1,6 | |||||||

| Front Servo | Replace | 1.0 | 1,6 | ||||||

| Repair | 1.0 | 1,6 | |||||||

| Band, Front and Rear | Replace | 2.5 | 1,6,92,93 | ||||||

| Governor | Inspect | 0.2 | |||||||

| Replace | 0.5 | 1,6 | |||||||

| Control Valve | Replace | 1.3 | 1,6 | ||||||

| Repair | 1.0 | 1,6,10 |

TM 9-2320-280-20-3

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| 0721 | Oil Pump, Transmission | Replace | 1.0 | 1,6,83 | |||||

| Repair | 1.6 | 1,6,83,91 | |||||||

| Seal, Oil Pump | Replace | 0.3 | 1,6,80 | ||||||

| Oil Filter, Transmission | Replace | 1.5 | 1,2 | ||||||

| Lines, Oil Cooler | Inspect | 0.2 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| 08 | TRANSFER | ||||||||

| 0801 | Transfer Case | Inspect | 0.1 | ||||||

| Service | 0.5 | 2 | |||||||

| Replace | 5.2 | 1,6,144 | |||||||

| Repair | 5.7 | 1,6,75,94-106 | P | ||||||

| Overhaul | 10.0 | 1,6,10,75 | |||||||

| 94,106,144 | |||||||||

| Seal, Oil, Input and Output | Replace | 1.3 | 1,2,94 | ||||||

| Shaft | |||||||||

| Yokes, Front and Rear | Replace | 1.2 | 1,2 | ||||||

| Bearings, Output Shaft | Replace | 3.0 | 1,2,75,95-100 | ||||||

| Gear, Speedometer Driven | Replace | 0.5 | 1,2,107 | ||||||

| 0803 | Shift Control and Linkage | Inspect | 0.1 | 0.2 | D | ||||

| Adjust | 0.5 | 1 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| Repair | 1.0 | 1,2 | |||||||

| 09 | PROPELLER SHAFTS | ||||||||

| 0900 | Shafts, Propeller, Front | Service | 0.2 | 1,2 | |||||

| Replace | 1.0 | 1,2 | |||||||

| Repair | 0.5 | 1.2 | 1,2,6 | E | |||||

| Shaft, Propeller, Rear | Service | 0.2 | 1,2 | ||||||

| Replace | 1.0 | 1,2 | |||||||

| Repair | 1.2 | 1,2 | |||||||

| Joints, Universal | Inspect | 0.1 | |||||||

| Service | 0.3 | 2 | |||||||

| Replace | 1.5 | 1,2 | |||||||

| 10 | FRONT AXLE | ||||||||

| 1000 | Halfshaft | Inspect | 0.2 | ||||||

| Replace | 2.2 | 1,2 | |||||||

| Repair | 1.0 | 1,2 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd)

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| 1002 | Differential Assembly | Inspect | 0.1 | ||||||

| Service | 0.5 | 1,2 | |||||||

| Replace | 5.0 | 1,2 | |||||||

| Repair | 10.2 | 1,7,75,94, | |||||||

| 117-124 | |||||||||

| Seal, Output Shaft, Differential | Replace | 1.0 | 1,6,117 | ||||||

| Seal, Pinion, Differential | Replace | 0.3 | 1,6,94 | ||||||

| Differential Cover | Replace | 0.5 | 1,2 | H | |||||

| 1004 | Knuckle and Geared Hub | Inspect | 0.1 | ||||||

| Service | 0.5 | 1,2 | |||||||

| Replace | 2.0 | 1,2,167 | |||||||

| Repair | 1.2 | 1,2,6,75, | K | ||||||

| 126-128,129 | |||||||||

| Bearing, Spindle, Geared Hub | Adjust | 0.9 | 1,2,127 | ||||||

| Seal, Input, Geared Hub | Replace | 2.0 | 1,2,75,126 | ||||||

| Seal, Spindle, Geared Hub | Replace | 1.0 | 1,2,75,127,128 | I | |||||

| Steering Stop | Adjust | 0.5 | 2 | ||||||

| Replace | 0.3 | 2 | |||||||

| Upper Control Arm | Inspect | 0.1 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| Repair | 1.0 | 1,2 | |||||||

| Lower Control Arm | Inspect | 0.1 | |||||||

| Replace | 2.6 | 1,2 | |||||||

| Repair | 1.0 | 1,2 | |||||||

| Ball Joint, Upper and Lower | Replace | 0.6 | 1,2,129,146, | ||||||

| 151 | |||||||||

| 11 | REAR AXLE | ||||||||

| 1100 | Halfshaft | Inspect | 0.2 | ||||||

| Replace | 1.8 | 1,2 | |||||||

| Repair | 1.0 | 1,2 | |||||||

| 1102 | Differential Assembly | Inspect | 0.1 | ||||||

| Service | 0.5 | 1,2 | |||||||

| Replace | 5.0 | 1,2 | |||||||

| Repair | 10.0 | 1,7,75,94, | |||||||

| 117-124 | |||||||||

| Seal, Output Shaft, Differential | Replace | 1.0 | 1,6,117 | ||||||

| Seal, Pinion, Differential | Replace | 0.3 | 1,6,94 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd) TM 9-2320-280-20-3

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| 1104 | Knuckle and Geared Hub | Inspect | 0.1 | ||||||

| Service | 0.5 | ||||||||

| Replace | 2.0 | 2,167 | |||||||

| Repair | 1.2 | 1,2,75,126, | |||||||

| 128,129 | K | ||||||||

| Bearing, Spindle, Geared Hub | Adjust | 0.9 | 1,2,127 | ||||||

| Seal, Input, Geared Hub | Replace | 2.0 | 1,2,75,126 | ||||||

| Seal, Spindle, Geared Hub | Replace | 1.0 | 1,2,75,127, | ||||||

| 128 | |||||||||

| Upper Control Arm | Inspect | 0.1 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| Repair | 1.0 | 1,2 | |||||||

| Lower Control Arm | Inspect | 0.1 | |||||||

| Replace | 2.6 | 1,2 | |||||||

| Repair | 1.0 | 1,2 | |||||||

| Ball Joint, Upper and Lower | Replace | 0.6 | 1,2,129,146, | ||||||

| 151 | |||||||||

| 12 | BRAKES | ||||||||

| 1201 | Parking Brake Lever | Adjust | 0.3 | ||||||

| Replace | 1.0 | 1,2 | |||||||

| Parking Brake Cable | Adjust | 0.5 | 1,2 | ||||||

| Replace | 1.0 | 1,2 | |||||||

| Parking Disc Brake Pad | Inspect | 0.2 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| Dual Service/Parking | Adjust | 0.5 | 1,2 | ||||||

| Brake Cable, Right Rear | Replace | 0.7 | 1,2 | ||||||

| Dual Service/Parking | Adjust | 0.5 | 1,2 | ||||||

| Brake Cable, Left Rear | Replace | 0.5 | 1,2 | ||||||

| Dual Service/Parking | Inspect | 0.1 | |||||||

| Calipers, Rear | Replace | 1.0 | 1,2,162 | ||||||

| Dual Service/Parking | Inspect | 0.2 | |||||||

| Pads, Rear | Replace | 1.0 | 1,2 | ||||||

| 1202 | Service Brakes | Test | 0.1 | ||||||

| Calipers, Front and Rear | Replace | 1.0 | 1,2,152,162 | ||||||

| Repair | 0.5 | 1,6 | |||||||

| Pads, Front and Rear | Inspect | 0.2 | |||||||

| Replace | 1.0 | 1,2,152 | |||||||

| Rotor, Front and Rear | Inspect | 0.1 | 1 | ||||||

| Replace | 1.2 | 1,2 | |||||||

| Repair | 1.5 | 1,6 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd)

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| 1204 | Master Cylinder | Inspect | 0.1 | ||||||

| Service | 0.2 | 2 | |||||||

| Replace | 0.5 | 1,2 | |||||||

| Brake Lines | Inspect | 0.2 | |||||||

| Replace | 1.5 | 1 | |||||||

| Proportioning Valve | Replace | 0.6 | 1,2 | ||||||

| 1205 | Hydro-Boost | Replace | 1.3 | 1,2 | |||||

| 1206 | Pedal, Brake | Replace | 1.0 | 1,2,146,153 | |||||

| 13 | WHEELS AND TIRES | ||||||||

| 1301 | Front Wheel Toe-In | Align | 0.5 | 1 | |||||

| Rear Wheel Toe-Out | Align | 0.5 | 1 | ||||||

| 1311 | Wheel and Tire Assembly | Inspect | 0.1 | 0.1 | |||||

| Service | 0.2 | ||||||||

| Replace | 0.4 | 0.1 | 1,2 | N | |||||

| Repair | 0.5 | 1,2,130 | |||||||

| Runflat Assembly | Replace | 2.2 | 1,2,4,144, | ||||||

| 154,131 | J | ||||||||

| 14 | STEERING | ||||||||

| 1401 | Mechanical Steering | ||||||||

| Wheel, Steering | Replace | 0.7 | 1,2 | ||||||

| Column, Steering | Inspect | 0.1 | |||||||

| Replace | 1.8 | 1,2 | |||||||

| Intermediate Shaft, Steering | Service | 0.2 | 1,2 | ||||||

| Replace | 0.5 | 1,2 | |||||||

| Tie Rod Assembly | Inspect | 0.1 | |||||||

| Service | 0.2 | 1,2 | |||||||

| Adjust | 0.5 | 1,2,167 | |||||||

| Replace | 0.5 | 1,2,129 | |||||||

| Center Link | Inspect | 0.1 | 1,2 | ||||||

| Replace | 0.3 | 1,2,167 | |||||||

| Pitman Arm | Inspect | 0.1 | |||||||

| Replace | 1.0 | 1,2,129 | |||||||

| Idler Arm | Inspect | 0.1 | |||||||

| Replace | 0.3 | 1,2,129 | |||||||

| Camber/castor | Adjustment | 2.2 | 1,138.1 | ||||||

| 1407 | Gear, Power Steering | Inspect | 0.2 | ||||||

| Replace | 0.5 | 1,2 | |||||||

| Repair | 3.7 | 1,6,132, | |||||||

| 133,135 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd) TM 9-2320-280-20-3

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| 1410 | Pump, Power Steering | Inspect | 0.1 | 0.1 | |||||

| Test | 0.5 | 1,2, | |||||||

| 136-138 | |||||||||

| Service | 0.2 | 1,2 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| Repair | 1.0 | 1,2 | |||||||

| Pulley, Power Steering Pump | Replace | 0.5 | 1,2,137 | ||||||

| 1411 | Hoses, Lines, and Fittings | Inspect | 0.2 | ||||||

| Power Steering | Replace | 1.0 | 1 | ||||||

| 15 | FRAME | ||||||||

| 1501 | Frame Assembly | Inspect | 0.5 | ||||||

| Repair | F | 1,5 | F | ||||||

| Crossmember, Transmission | Replace | 2.0 | 1 | ||||||

| Crossmember, Suspension, | Inspect | 0.2 | |||||||

| Front, Brackets, and | Replace | 4.5 | 1,6 | ||||||

| Supports | Repair | 2.0 | 1,5 | ||||||

| Crossmember, Rear | Replace | 2.0 | 1,2 | ||||||

| Bumpers | Replace | 0.5 | 1,2 | ||||||

| 1503 | Pintle, Towing | Inspect | 0.1 | ||||||

| Service | 0.1 | 1 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| Repair | 0.2 | 1,2 | |||||||

| 16 | SPRINGS AND SHOCK ABSORBERS | ||||||||

| 1601 | Springs | Inspect | 0.1 | ||||||

| Replace | 1.0 | 1,2 | |||||||

| 1604 | Absorbers, Shock | Inspect | 0.1 | 0.1 | |||||

| Replace | 0.8 | 1,2 | |||||||

| 1605 | Rod, Stabilizer | Replace | 1.5 | 1,2 | |||||

| Rod, Radius | Inspect | 0.1 | |||||||

| Replace | 1.0 | 1,2 | |||||||

| Repair | 0.5 | 1,2 | |||||||

| 18 | BODY AND HOOD | ||||||||

| 1801 | Body | Inspect | 0.1 | ||||||

| Service | 1.0 | 1 | |||||||

| Replace | F | 1,6 | F | ||||||

| Repair | F | 1,2,139,140 | F | ||||||

| Hood | Inspect | 0.1 | |||||||

| Replace | 1.3 | 1,2 | |||||||

| Repair | F | 1,6 | F |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd)

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| Doors, Rear | Inspect | 0.1 | |||||||

| Replace | 0.2 | 1 | |||||||

| Repair | F | 1,5,139 | F | ||||||

| Cover, Engine Access | Inspect | 0.1 | |||||||

| Replace | 0.1 | 1 | |||||||

| Repair | F | 1,5,139 | F | ||||||

| 1802 | Windshield Assembly, Folding | Inspect | 0.1 | ||||||

| Replace | 2.0 | 1,2 | |||||||

| Repair | F | 1,5,139 | F | ||||||

| Windshield Assembly, Fixed | Inspect | 0.1 | |||||||

| Replace | 2.0 | 1,6 | |||||||

| Repair | F | 1,5,139 | F | ||||||

| Windshield Glass | Inspect | 0.1 | |||||||

| Replace | 1.0 | ||||||||

| 1806 | Seats | Inspect | 0.1 | ||||||

| Replace | 1.0 | 1,2 | |||||||

| Repair | 1.0 | 1,2 | |||||||

| Seatbelts | Inspect | 0.1 | |||||||

| Replace | 0.8 | 1,2 | |||||||

| 1808 | Stowage Racks, Boxes, | Inspect | 0.1 | ||||||

| and Straps | Replace | F | 1,2 | F | |||||

| Repair | F | 1,2 | F | ||||||

| Tailgate | Inspect | 0.1 | |||||||

| Replace | 0.4 | 1,2 | |||||||

| Repair | 1.0 | 1,5,139 | |||||||

| 1812 | TOW Carrier and Armament | ||||||||

| Carrier (M966, M966A1, | |||||||||

| M1025, M1025A1, M1025A2, | |||||||||

| M1026, M1026A1, M1036, | |||||||||

| M1043, M1043A1, M1043A2, | |||||||||

| M1044, M1044A1, M1045, | |||||||||

| M1045A1, M1045A2, M1046, | |||||||||

| M1046A1, M1121) | |||||||||

| Doors, Crew | Inspect | 0.1 | |||||||

| Adjust | 0.3 | 1,2 | |||||||

| Replace | 0.2 | 1 | |||||||

| Repair | F | 1,5,139 | F | ||||||

| Door, Cargo Shell | Inspect | 0.1 | |||||||

| Adjust | 0.3 | 1,2 | |||||||

| Replace | 2.5 | 1,2 | |||||||

| Repair | F | 1,2,139 | F | ||||||

| Glass, Door | Inspect | 0.1 | |||||||

| Replace | 1.0 | 1 | |||||||

| Weapon Station | Inspect | 0.1 | |||||||

| Replace | 1.5 | 1,6 | |||||||

| Gunners Platform | Inspect | 0.1 | |||||||

| Replace | 0.5 | 1 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd) TM 9-2320-280-20-3

| (1) | (2) | (3) | (4) | (5) | (6) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | |||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | |||

| Number | Component/Assembly | Function | C | O | F | H | D | Ref Code | Code | |

| S250 Shelter Carrier | ||||||||||

| (M1037, M1042) | ||||||||||

| Support, Shelter | Inspect | 0.1 | ||||||||

| Replace | 2.0 | 1,2 | ||||||||

| Sling, Tiedown | Inspect | 0.1 | ||||||||

| Replace | 0.3 | 1 | ||||||||

| Soft Top Ambulance | ||||||||||

| (M1035, M1035A1) | ||||||||||

| Rack, Litter | Inspect | 0.1 | ||||||||

| Replace | 1.5 | 1,2, | ||||||||

| Ambulance - 2-Litter | ||||||||||

| (M996, M996A1), | ||||||||||

| 4-Litter (M997, M997A1 | ||||||||||

| M997A2) | ||||||||||

| Door, Rear | Inspect | 0.1 | ||||||||

| Adjust | 0.4 | 1,2 | ||||||||

| Replace | 0.3 | 1,2 | ||||||||

| Door Latch and Handles, | Inspect | 0.1 | ||||||||

| Rear | Replace | 0.5 | ||||||||

| Steps, Rear | Inspect | 0.1 | ||||||||

| Replace | 0.5 | 1,2 | ||||||||

| Repair | 0.6 | 1,2 | ||||||||

| Litter Rack, Upper | Inspect | 0.1 | ||||||||

| Replace | 1.5 | 1,2 | ||||||||

| Doors, Stowage | Inspect | 0.1 | ||||||||

| Replace | 1.0 | 1,2,139 | ||||||||

| Doors, Bulkhead | Inspect | 0.1 | ||||||||

| Replace | 2.0 | 1,2,139 | ||||||||

| Extension Rails, Litter | Repair | 1.2 | 1,2 | |||||||

| NBC Heaters and Brackets | Inspect | 0.1 | ||||||||

| Replace | 0.8 | 1,2 | ||||||||

| NBC Filters and Brackets | Inspect | 0.1 | ||||||||

| Replace | 0.7 | 1,2 | ||||||||

| Ambulatory Patient Seat | Inspect | 0.1 | ||||||||

| Replace | 0.6 | 1,2 | ||||||||

| Heat/Vent Panel (M996, | ||||||||||

| M996A1) | Replace | 0.3 | 1,2 | |||||||

| Heater (M996, M996A1) | Adjust | 1.5 | 1,6 | |||||||

| Replace | 0.8 | 1,2 | ||||||||

| Repair | 3.5 | 1,6 | ||||||||

| Heater (M997, M997A1, | Adjust | 1.5 | 1,6 | |||||||

| M997A2) | Replace | 0.8 | 1,2 | |||||||

| Repair | 3.5 | 1,6 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd)

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | F | H | Ref Code | Code | |||

| C | O | D | |||||||

| 20 | WINCH | ||||||||

| 2001 | Winch Assembly | Service | 0.2 | ||||||

| Replace | 0.6 | 1,2 | |||||||

| Repair | 4.0 | 1,9,159 | |||||||

| Cable, Winch | Inspect | 0.5 | |||||||

| Service | 0.5 | 1 | |||||||

| Replace | 0.4 | 1,2 | |||||||

| Control Assembly, Winch | Inspect | 0.1 | |||||||

| Replace | 0.1 | 1,2 | |||||||

| 22 | BODY ACCESSORY ITEMS | ||||||||

| 2201 | Bows | Inspect | 0.1 | ||||||

| Service | 0.5 | ||||||||

| Replace | 1.0 | 1 | |||||||

| Repair | 0.5 | 1 | |||||||

| Cover, 2-Door Cab | Inspect | 0.1 | 1 | ||||||

| Service | 0.5 | ||||||||

| Replace | 0.5 | 1 | |||||||

| Repair | F | 1,7 | F | ||||||

| Cover, 4-Door Cab | Inspect | 0.1 | 1 | ||||||

| Service | 0.5 | ||||||||

| Replace | 1.5 | 1 | |||||||

| Repair | F | 1,7 | F | ||||||

| Cover, 2-Door Cargo | Inspect | 0.1 | |||||||

| Service | 0.5 | ||||||||

| Replace | 1.0 | 1 | |||||||

| Repair | F | 1,7 | F | ||||||

| Cover, 4-Door Cargo | Inspect | 0.1 | |||||||

| Service | 0.5 | ||||||||

| Replace | 1.0 | 1 | |||||||

| Repair | F | 1,7 | F | ||||||

| Door, Front | Inspect | 0.1 | |||||||

| Service | 0.1 | ||||||||

| Adjust | 0.4 | 1,2 | |||||||

| Replace | 0.2 | 1 | F | ||||||

| Repair | F | 1,7 | F | ||||||

| Cover, Rear Door | Inspect | 0.1 | |||||||

| Service | 0.1 | ||||||||

| Replace | 0.2 | 1 | |||||||

| Repair | F | 1,7 | F | ||||||

| Curtain, Body Cover | Inspect | 0.1 | |||||||

| Service | 0.5 | ||||||||

| Replace | 1.0 | 1 | |||||||

| Repair | F | 1,7 | F |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd) TM 9-2320-280-20-3

| (1) | (2) | (3) | (4) | (5) | (6) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Maintenance Level | Tools and | ||||||||

| Group | Maintenance | Unit | Direct Support | General Support | Depot | Equipment | Remarks | ||

| Number | Component/Assembly | Function | Ref Code | Code | |||||

| C | O | F | H | D | |||||

| 2202 | Motor, Windshield Wiper | Test | 0.3 | 2 | |||||

| Replace | 0.5 | 1,2 | |||||||

| Arm Assembly, Wiper | Inspect | 0.1 | |||||||

| Replace | 0.2 | 1,2 | |||||||

| Linkage, Wiper | Replace | 0.5 | 1 | ||||||

| Motor and Reservoir | Test | 0.2 | 2 | ||||||

| Assembly, Washer | Service | 0.2 | 1 | ||||||

| Replace | 0.1 | 1,2 | |||||||

| Nozzle, Washer | Replace | 0.5 | 1 | ||||||

| Mirror, Rearview | Inspect | 0.1 | |||||||

| Adjust | 0.1 | ||||||||

| Replace | 0.2 | 1,2 | |||||||

| Reflectors | Replace | 0.2 | 1 | ||||||

| Steering Wheel Lock | Replace | 1.0 | 1,139 | ||||||

| 2207 | Ducting, Defroster and Heater | Replace | 1.0 | 1 | |||||

| Controls, Defroster and Heater | Replace | 1.0 | 1 | ||||||

| Heater Assembly | Replace | 1.4 | 1,2 | ||||||

| 2210 | Data Plates | Replace | 0.5 | 1,139 | |||||

| 33 | SPECIAL PURPOSE KITS | ||||||||

| 3303 | Arctic Winterization Kit | Install | 8.0 | 6,139-142 | |||||

| Arctic Heater Kit | Install | 8.0 | 6,139-142 | ||||||

| Pump and Lines, Fuel | Inspect | 0.1 | 0.2 | ||||||

| Replace | 1.0 | 1,2 | |||||||

| Heater | Inspect | 0.1 | |||||||

| Replace | 0.2 | 1 | |||||||

| Control, Heater | Replace | 0.5 | 1 | ||||||

| Repair | 1.0 | 1 | |||||||

| 2-Man Crew Top Kit | Install | 2.0 | 139 | ||||||

| Cover, 2-Door Cab | Inspect | 0.1 | |||||||

| Replace | 0.5 | 1 | |||||||

| Repair | F | 7 | F | ||||||

| Curtain, Body Cover | Inspect | 0.1 | |||||||

| Replace | 0.5 | 1 | |||||||

| Repair | F | 7 | F | ||||||

| 3305 | Deep Water Fording Kit | Install | 4.0 | 1,2 | |||||

| Snorkel, Intake and Exhaust | Inspect | 0.2 | 0.2 | ||||||

| Install | 2.0 | ||||||||

| Replace | 1.5 | 2 | |||||||

| Venting | Inspect | 0.1 | 0.1 | ||||||

| Replace | 1.0 | 1 |

Section II. MAINTENANCE ALLOCATION CHART (Cont'd)

| (1) | (2) | (3) | (5) | (6) | ||

|---|---|---|---|---|---|---|

| Group | Maintenance | Maintenance Level Direct General | Tools and | Remarks | ||

| Number | Component/Assembly | Function | Unit | Support Support Depot | Equipment Ref Code | Code |

| C | O | F H D | ||||

| 3307 | 100 AMP Alternator Kit | Inspect | 0.2 | |||

| Test | 0.3 | 4 | ||||

| Install | 2.5 | 2 | ||||

| Replace | 1.0 | 2 | ||||

| Repair | 1.0 | 9 | ||||

| Troop Seat Kit | Inspect | 0.1 | ||||

| Install | 2.0 | 1,2 | ||||

| Replace | 0.8 | 2 | ||||

| Repair | 1.0 | 4 | ||||

| Communications Kit | Install | 3.0 | 1,2 | |||

| Replace | F | 1 | F | |||

| 47 | GAGES (NON-ELECTRICAL) | |||||

| 4701 | Speedometer | Replace | 0.2 | 1 | ||

| Cable and Housing | Replace | 0.5 | 1 | |||

| 4702 | Gage, Air Restriction | Inspect | 0.1 | |||

| Replace | 0.1 | 1 | ||||

| 52 | AIR CONDITIONER | |||||

| Ambulance (M997, M997A1, | ||||||

| M997A2) | ||||||

| 5203 | Compressor, A/C | Replace | 1.5 | 1,2,19,19.1 | ||

| Repair | 3.0 | 1,2,143 | ||||

| Bracket Mounting, | Replace | 0.4 | 1 | |||

| Compressor | ||||||

| 5205 | Service Valve, A/C | Replace | 0.6 | 2,19,19.1 | ||

| 5217 | A/C Lines and Fittings | Inspect | 0.1 | |||

| Replace | 1.5 | 1,6,19,19.1 | ||||

| Air Conditioner | Inspect | 0.1 | ||||

| Test | 0.3 | |||||

| Service | 1.6 | 2,19,19.1,143 | ||||

| 5230 | Coil, Condensor | Replace | 1.6 | 2,19 | ||

| 5241 | Coil, Evaporator | Replace | 2.0 | 2,19 | ||

| Repair | 0.4 | 2 | ||||

| 5243 | Blower Motor, Condenser | Replace | 0.8 | 1 | ||

| Blower Motor, Evaporator | Replace | 1.0 | 1 | |||

| Repair | 0.6 | |||||

| 5246 | Bottle, Dryer | Replace | 0.3 | 1 |

Section Iii. Tool And Test Equipment Requirements

| (1) Reference Code | (2) Maintenance Category | (3) Nomenclature | (4) National/NATO Stock Number | (5) Tool Number |

|---|---|---|---|---|

| 1 | O | Tool Kit, General Mechanic's | 5180-00-177-7033 | SC5180-90-CL-N26 |

| Automotive | ||||

| 2 | O | Shop Equipment, Automotive Maintenance and Repair: | 4910-00-754-0654 | SC4910-95-CLA74 |

| Organizational Maintenance, | ||||

| Common #1, Less Power | ||||

| 3 | O | Shop Equipment, Automotive | 4910-00-754-0653 | SC4910-95-CLA73 |

| Maintenance and Repair: | ||||

| Organizational Maintenance, | ||||

| Supplemental #1, Less Power | ||||

| 4 | O | Shop Equipment, Automotive | 4910-00-754-0650 | SC4910-95-CLA72 |

| Maintenance and Repair: | ||||

| Organizational Maintenance, | ||||

| Common #2, Less Power | ||||

| 5 | O | Tool Kit, Body and Fender | 5180-00-754-0643 | SC5180-90-N34 |

| 6 | F | Shop Equipment, Automotive | 4910-00-754-0705 | SC4910-95-CLA31 |

| Maintenance and Repair: Field | ||||

| Maintenance, Basic, Less Power | ||||

| 7 | F | Shop Equipment, Automotive | 4910-00-754-0706 | SC4910-95-CLA62 |

| Maintenance and Repair: Field | ||||

| Maintenance, Supplemental #1, | ||||

| Less Power | ||||

| 8 | F | Shop Equipment, Automotive Maintenance and Repair: Field | 4910-00-754-0707 | SC4910-95-CLA63 |

| Maintenance, Supplemental #2, | ||||

| Less Power | ||||

| 9 | F | Shop Equipment, Fuel and Electrical | 4940-00-754-0714 | SC4910-95-CLA01 |

| System Engine: Field Maintenance, | ||||

| Basic, Less Power | ||||

| 10 | F | Shop Equipment, Automotive | 4910-00-348-7696 | SC4910-95-CLA02 |

| Maintenance and Repair: Field | ||||

| Maintenance, Wheeled Vehicles, Post, | ||||

| Camp and Station, Set A | ||||

| 11 | O | Special Tool Kit, Organizational | 5180-01-387-5455 | 57K0267 |

| 11.1 | O | Special Tool Kit, Organizational, | 5180-01-410-8467 | 57K3219 |

| Supplemental ("A2" series only) | ||||

| 12 | F | Special Tool Kit, Direct Support | 5180-01-389-7560 | 57K0268 |

| 13 | H | Special Tool Kit, General Support | 5180-01-389-7561 | 57K0266 |

| 13.1 | H | Special Tool Kit, General Support, | 5180-01-408-7050 | 57K3218 |

| Supplemental ("A2" series only) | ||||

| 13.2 | H | Special Tool Kit, General Support, | 5180-01-357-9692 | 57K0236 |

| Supplemental Transmission |

Section Iii. Tool And Test Equipment Requirements

| (1) Reference | (2) Maintenance | (3) | (4) National/NATO | (5) Tool |

|---|---|---|---|---|

| Code | Category | Nomenclature | Stock Number | Number |

| NOTE | ||||

| The optional metric tool sets listed below are required for maintenance of this | ||||

| vehicle. | ||||

| 14 | O | Metric Wrench Set, 10-32 mm, | 5120-01-119-0010 | OEXM719K |

| Open End/Box End | ||||

| 15 | O | Metric Socket Set, 6-26 mm, Std., 6 pt., | 5120-01-117-3876 | 221FSMY |

| 3/8 in. Drive | ||||

| 16 | F | Metric Socket Set, Std., 6 pt., | 5120-01-112-9543 | B107.5 |

| 3/8 in. Drive, Deep Reach | ||||

| 17 | F | Metric Allen Wrench Kit | 5120-01-046-5079 | B18.3.2M |

| 18 | F | Metric Tap and Die Kit | 5136-01-119-0005 | TDM99117 |

| 19 | F | Tool Kit, Service Refrigeration Unit | 5180-00-596-1474 | SC5180-90-CL-N18 |

| 19.1 | F | Parts Kit, FR-12 Refrigerant | 4130-01-452-8773 | 57K3534 |

| 01 ENGINE | ||||

| 20 | F | Adapter, Compression Gage | 4910-01-238-2551 | J 26999-30 |

| 21 | F | Quick Disconnect | 4730-01-842-5266 | J 25209 |

| 22 | F | 90° Elbow | 4730-00-985-4804 | MS51815-4P |

| 23 | F | Remover, Hydraulic Valve Lifter | 5120-01-209-6870 | J 29834 |

| 24 | DELETED | |||

| 25 | F | Engine Lifting Sling | 4910-01-193-7808 | J 33139 |

| 26 | F | Tester, Engine Compression | 4910-00-785-6437 | J 6692A |

| 27 | DELETED | |||

| 28 | DELETED | |||

| 29 | DELETED | |||

| 30 | DELETED | |||

| 31 | DELETED | |||

| 32 | DELETED | |||

| 33 | DELETED | |||

| 34 | DELETED | |||

| 35 | DELETED | |||

| 36 | DELETED | |||

| 37 | DELETED |

Section Iii. Tool And Test Equipment Requirements

| (1) Reference Code | (2) Maintenance Category | (3) Nomenclature | (4) National/NATO Stock Number | (5) Tool Number |

|---|---|---|---|---|

| 38 | DELETED | |||

| 39 | DELETED | |||

| 40 | DELETED | |||

| 41 | F | Gauge, Timing | 6620-01-231-3671 | MT95 |

| 42 | F | Meter, Dynamic Timing | 5180-01-186-3114 | J 33127 |

| 43 | DELETED | |||

| 44 | H | Stand - Engine Repair | 4910-00-506-0037 | 1725A |

| 45 | DELETED | |||

| 46 | H | Installer, Crankshaft Rear Oil Seal (6.2L) | 5120-01-210-8792 | J 33153 |

| H | Installer, Crankshaft Rear Oil Seal (6.5L) | 5120-01-422-0334 | J 39084 | |

| 47 | H | Remover and Installer, Camshaft Bearings | 5120-01-206-3818 | J 35178 |

| 48 | O | Pliers, Needle Nose, 90° | 5120-01-174-4496 | 497ACP |

| 03 FUEL SYSTEM | ||||

| 49 | F | Remover, Fuel Injection Nozzle | 5120-01-171-5233 | J 29873 |

| 50 | H | Installer, Drive Shaft Bearing | 5120-01-208-7771 | 23805 |

| 51 | H | Installer, Drive Shaft Seal | 5120-01-208-7752 | 22727 |

| 52 | H | Kit, Throttle and Shutoff Shaft Bushing | 5180-01-189-0448 | 18411 |

| 53 | H | Socket, Torx Drive, T27 | 5120-01-367-3534 | FTX27A |

| 54 | H | Support, Governor Weight | 5120-01-197-0236 | 16313 |

| 55 | H | Wrench, End Cap | 5120-01-207-5563 | 20548 |

| 56 | H | Roller to Roller Setting Tool | 5120-01-200-4526 | 19969 |

| 57 | H | Fixture, Holding | 5120-01-208-7753 | 23615 |

| 58 | H | Mandrel, Pilot Tube | 5120-01-208-1767 | 16314 |

| 59 | H | Extractor, Delivery Valve Test Set | 5120-00-816-7059 | 26081 |

| 60 | DELETED | |||

| 61 | H | Linkage Gap Tool | 5210-01-249-0370 | 23080 |

| 62 | H | Indicator, Automatic Advance | 5210-01-249-0368 | 23745 |

| 63 | O | Block, Throttle Lever Gauge | 4820-01-179-4869 | J 33043 |

| 64 | H | Protractor | 6675-01-247-2286 | 22089 |

Section Iii. Tool And Test Equipment Requirements Section Iii. Tool And Test Equipment Requirements

| Reference | (2) Maintenance | (3) | (4) National/NATO | (5) Tool |

|---|---|---|---|---|

| Code | Category | Nomenclature | Stock Number | Number |

| H | Gage, Air Timing | 5220-01-247-0361 | 23715 | |

| 05 COOLING SYSTEM | ||||

| 66 | O | Tester, Radiator | 4910-00-728-8227 | ST255A |

| O | Gage, Belt Tension | 6635-01-093-3710 | J 23600B | |

| 06 ELECTRICAL SYSTEM | ||||

| F | Socket, Torx | 5120-01-227-3159 | TLE60 | |

| O | Starter Pinion Core Shaft Nut Driver | 9530-00-236-7723 | MS14267C001 | |

| 07 TRANSMISSION (3L80) | ||||

| H | Fixture, Transmission Holding | 5120-01-198-7583 | J 8763-02 | |

| 71 | H | Base, Transmission Holding Fixture | 5120-01-144-4484 | J 3289-20 |

| H | Holding Tool, Transmission Gear Unit Assembly | 4910-01-178-8865 | J 21795-02 | |

| 73 | H | Adapter, Slide Hammer, 3/8-16 | 5120-01-130-8865 | J 6471-2 |

| 74 | H | Bushing Service Set | 5180-01-195-9777 | J 21465-01 |

| O | Driver Handle | 5120-00-677-2259 | J8092 | |

| H | Compressor, Clutch Spring | 5120-01-210-8793 | J 4670-01 | |

| H | Adapter, Clutch Spring Compressor | 4910-01-210-1318 | J 21664 | |

| 78 | H | Gage, Band Apply Selector | 4910-01-178-0722 | J 21370 |

| H | Alignment Tool, Intermediate Clutch Pack | 4910-01-209-0729 | J 24396 | |

| F | Installer, Oil Pump Seal | 5120-01-176-1845 | J 21359A | |

| 07 TRANSMISSION (4L80-E) | ||||

| H | Adapter, Holding Tool, Use W/J 8763-02 | 5120-01-422-1326 | J 38655 | |

| H | Adapter, Torque, 3/8 | 5120-01-367-3536 | FTX40A | |

| 83 | H | Removal/Installer Tool, Oil Pump | 5120-01-422-1308 | J 37789-A |

| H | Installer/Remover, Gear Unit | 5120-01-422-1300 | J 38868-A | |

| H | Adapter, Clutch Compressor Spring , Use W/J 23327 | 5120-01-422-1329 | J 38734 | |

| (1) 65 67 68 69 70 72 75 76 77 79 80 81 82 84 85 |

| (1) Reference Code | (2) Maintenance Category | (3) Nomenclature | (4) National/NATO Stock Number | (5) Tool Number |

|---|---|---|---|---|

| 86 | H | Seal Protectors, Forward Clutch Piston, Kit Includes J 38732-1 and J 21362-1 | 5120-01-422-1301 | J 38732 |

| 87 | H | Compressor, Clutch Spring | 4910-01-178-0724 | J 23327 |

| 88 | H | Adapter, Compressor, Clutch Spring, Use W/J 23327 | 5120-01-410-8216 | J 25018-A |

| 89 | H | Seal Piston and Housing, Fourth Clutch, Includes J38731-1, J38731-2, J38731-3 | 5180-01-422-0138 | J 38731 |

| 90 | H | Installer/Sizer/Pusher, Turbine Shaft Seal, Includes J38736-1, J38736-2, J38736-3, J38736-4, J38736-5, J38736-6 | 5120-01-422-7051 | J 38736 |

| 91 | H | Installer/Sizer/Pusher, Oil Pump Seal Ring J 38739-1, J 38739-2, J 38739-3 | 5180-01-422-1294 | J 38739 |

| 92 | H | Gauge Pin, Band Apply, Use W/J 38737 | 5120-01-422-0032 | J 21370-10 |

| 93 | H | Tool Pin Checking, Band Apply | 5120-01-422-1313 | J 38737 |

| 93.1 | O | Jumper, Throttle Position Sensor Adjustment | 6150-01-412-7774 | 12460120 |

| 93.2 | O | Case, Transmission Diagnostic Cable | 5120-01-408-8173 | 12460136 |

| 93.3 | O | Diagnostic Switch Cable | 6150-01-410-8215 | 12460137 |

| 08 TRANSFER (218) | ||||

| 94 | O | Installer, Yoke Seal | 4910-01-179-5530 | J 29162 |

| 95 | H | Adapter, Slide Hammer | 5120-01-391-5131 | J 6471-8 |

| 96 | H | Installer, Front Output Shaft Rear Bearing | 5120-01-195-2721 | J 29163 |

| 97 | H | Installer, Rear Output Shaft Bearing | 5120-01-196-0084 | J 29166 |

| 98 | H | Installer, Front Output Shaft Front Bearing | 5120-01-170-3278 | J 29167 |

| 99 | H | Remover, Front Output Shaft Front Bearing | 5120-01169-4876 | J 29168 |

| 100 | H | Remover, Universal Bearing and Bushing | 5120-01-201-7857 | J 29369 |

| 101 | H | Remover, Input Gear Bearing | 5120-01-195-4551 | J 29170 |

| 102 | H | Installer, Input Gear Bearing | 5120-01-185-7955 | J 29169 |

Section III. TOOL AND TEST EQUIPMENT REQUIREMENTS

Section Iii. Tool And Test Equipment Requirements

| (1) | (2) | (3) | (4) | (5) |

|---|---|---|---|---|

| Reference Code | Maintenance Category | Nomenclature | National/NATO Stock Number | Tool Number |

| 103 | H | Installer, Rear Retainer Bearing | 5120-01-185-8024 | J 7818 |

| 104 | H | Installer, Main Shaft Bearing | 5120-01-265-4872 | J 36307 |

| 105 | H | Remover, Annulus Gear Bushing | 5120-01-185-7956 | J 29185 |

| 106 | H | Installer, Annulus Gear Bushing | 5120-01-247-6629 | J 29185-2 |

| 107 | O | Mirror, Inspection | 5120-00-618-6902 | J 35219 |

| 08 TRANSFER (242) | ||||

| 108 | H | Installer, Bushing Remover/Bearing | 5120-01-357-3633 | J 33826 |

| 109 | H | Installer, Mainshaft Pilot Bearing | 5120-01-389-9992 | J 39636 |

| 110 | H | Installer, Input Gear Seal | 5120-01-357-3632 | J 33831 |

| 111 | H | Installer, Output Shaft Front Bearing | 5120-01-357-3630 | J 33833 |

| 112 | H | Installer, Output Shaft Seal | 5120-01-227-1680 | J 22661 |

| 113 | H | Remover, Extension Housing Bushing | 5120-01-357-3631 | J 33839 |

| 114 | H | Bearing Tool | 5120-01-357-9123 | J 9276-3 |

| 115 | H | Installer, Extension Housing Seal | 5120-01-361-3101 | J 33843 |

| 116 | H | Installer, Bearing and Bushing | 5120-01-185-7960 | J 29174 |

| 116.1 | O | Installer, Inserter | 5120-01-144-1849 | J 38869 |

| 116.2 | O | Installer, Seal | 5120-01-437-0480 | 6888 |

| 116.3 | O | Handle, Drive | 5120-01-026-1666 | C-4171 |

| 116.4 | H | Installer, Output Shaft, Rear Bearing | 5120-01-477-6860 | J 33832 or |

| 5742628 | ||||

| 10 AND 11 FRONT AND REAR AXLE | ||||

| 117 | F | Installer, Axle Shaft and Seal | 5120-01-187-3659 | J 33142 |

| 118 | H | Adapters, Axle Holding Fixture | 5120-01-218-8235 | J 33149-A |

| 119 | H | Spreader, Differential Housing | 4910-00-105-2823 | W129 |

| 120 | H | Remover, Pinion Rear Bearing Cup | 5120-01-185-7957 | J 21786 |

| 121 | H | Remover, Pinion Front Bearing Cup | 5120-01-187-3660 | J21787 |

| 122 | H | Installer, Pinion Rear Bearing Cup | 5120-01-185-7962 | J 8608 |

| 123 | H | Installer, Pinion Front Bearing Cup | 5120-01-185-7964 | J 8611-01 |

| 124 | H | Set, Pinion Setting Gage | 5180-01-216-8643 | J 35199 |

| 125 | H | Set, Pinion Setting Gauge | 5180-01-363-8079 | J 39524 |

| 126 | O | Installer, Geared Hub Input Seal | 5120-01-187-3607 | J 33143 |

| (1) Reference Code | (2) Maintenance Category | (3) Nomenclature | (4) National/NATO Stock Number | (5) Tool Number |

|---|---|---|---|---|

| 127 | O | Wrench, Geared Hub Locknut | 5120-01-185-7963 | J 33144 |

| 128 | O | Installer, Geared Hub Spindle Seal | 5120-01-229-0842 | J 35184 |

| 129 | O | Pickle Fork | 5120-00-880-4268 | 11595179 |

| 13 WHEELS AND TIRES | ||||

| 130 | O | Bubble Balancer | 4910-01-093-0167 | MIL-B-45989 |

| 131 | O | Runflat Compressor | 5120-01-335-5847 | J 39250 or |

| 528236 | ||||

| 14 STEERING SYSTEM | ||||

| 132 | F | Remover and Installer, Adjuster Plug Bearing | 5120-01-185-7965 | J 6221 |

| 133 | F | Remover and Installer, Pitman Shaft Bearing | 5120-01-082-6447 | J 6278 |

| 134 | F | Wrench, Spanner | 5120-01-082-6436 | J 7624 |

| 135 | F | Arbor, Rack Piston | 5120-01-179-1032 | J 21552 |

| 136 | O | Analyzer, Power Steering | 4910-01-185-7966 | 12342943 |

| 137 | O | Installer, Power Steering Pump Pulley | 4910-01-179-2517 | J 25033-B |

| 138 | O | Adapter | 5120-01-231-1709 | J 33141 |

| 138.1 | H | Equipment, Alignment | 4910-01-154-1820 | DFP 134 |

| 18 BODY AND HOOD | ||||

| 139 | O | Tool Kit, Riveter | 5180-01-201-4978 | D-100-MIL-1 |

| 140 | F | Puller, Head, Right Angle | 5130-01-044-7196 | H763-456 |

| 141 | F | Puller, Head, Offset | 5130-01-329-0509 | H781-456 |

| 142 | F | Puller, Head, Straight | 5130-01-104-5370 | H749A-456 |

| 52 AIR CONDITIONER | ||||

| 143 | F | Tool Kit, Compressor | 5180-01-267-2907 | J 29642-C |

| MULTIPURPOSE TOOLS | ||||

| 144 | O | Adapter, Torque, 9/16 in. | 5120-01-367-3582 | SRES 18 |

Section III. TOOL AND TEST EQUIPMENT REQUIREMENTS

Section Iv. Remarks

| (1) | (2) | (3) | (4) | (5) |

|---|---|---|---|---|

| Reference | Maintenance | National/NATO | Tool | |

| Code | Category | Nomenclature | Stock Number | Number |

| 145 | O | Adapter, Torque, 3/4 in. | 5120-01-367-3585 | SRES 24 |

| 146 | O | Adapter, Socket, 3/8 in. to 1/2 in. Drive | 5120-00-240-8702 | 11655788-2 |

| 147 | F | Crowfoot, 3/8 in. Drive, 16 mm | 5120-01-242-8165 | J 35159 |

| 148 | F | Crowfoot, 1/2 in. Drive, 19 mm | 5120-01-230-9421 | J 35160 |

| 149 | O | Crowfoot, 3/8 in. Drive, 5/8 in. | 5120-00-184-8398 FC20 | |

| 150 | O | Crowfoot, 3/8 in. Drive, 9/16 in. | 5120-01-335-1094 | FC 18A |

| 151 | O | Crowfoot, 3/8 in. Drive, 15/16 in. | 5120-01-335-1100 | FC-30A |

| 152 | O | Crowfoot, 3/8 in. Drive, 14 mm | 5120-01-079-8023 | FCOM14 |

| 153 | O | Crowfoot, 3/8 in. Drive, 7/8 in. | 5120-01-335-1099 | FC-28A |

| 154 | O | Crowfoot, 3/8 in. Drive, 11/16 in. | 5120-01-335-1096 | FC-22A |

| 155 | O | Socket, Deep Well, 12 pt., 3/8 in. | 5120-00-277-1463 | FVS121 |

| 156 | O | Driver, Hex-Head, 8 mm | 5120-01-053-4159 | FAM8A |

| 157 | O | Driver, Hex-Head, 6 mm | 5120-01-055-1308 | FAM6A |

| 158 | O | Driver, Hex-Head, 1/8 in. | 5120-01-016-9202 | J 35171 |

| 159 | F | Driver, Hex-Head, 5/32 in. | 5120-01-367-3456 FA5A | |

| 160 | O | Driver, Hex-Head, 1/4 in. | 5120-00-596-8508 FA8A | |

| 161 | O | Driver, Hex-Head, 5/16 in. | 5120-00-683-8602 | FA10B |

| 162 | O | Driver, Hex-Head, 7 mm | 5120-01-437-3658 FAM 7 | |

| 163 | O | Driver, Hex-Head, 3/16 in. | 5120-00-683-8597 FA6A | |

| 164 | O | "C" Clamp | 5120-01-180-0908 | A-A-429 |

| 165 | O | Connector Repair Kit | 5180-00-876-9336 | 7550526 |

| 166 | O | Multimeter | 6625-01-139-2512 | AN/PSM-45 |

Appendix C Expendable/Durable Supplies And Materials List

SECTION I. INTRODUCTION

C-1. Scope

This appendix lists expendable/durable supplies and materials you will need to maintain the M998 series vehicles. These items are authorized to you by CTA 50-970, Expendable Items (Except Medical, Class V, Repair Parts, and Heraldic Items).

C-2. Explanation Of Columns

a. Column (1)-Item Number. This number is assigned to each entry in the listing and is referenced in "Initial Setup" of applicable tasks under the heading of "Materials/Parts." b. Column (2)-Level. This column identifies the lowest level of maintenance that requires the listed item.

C - Operator/Crew O - Unit Maintenance c. Column (3) - National Stock Number. This is the National stock number assigned to the item; use it to request or requisition the item. d. Column (4) - Description. Indicates the Federal item name and, if required, a description to identify the item. The last line for each item listing indicates the Commercial and Government Entity Code (CAGEC) in parentheses followed by the part number. e. Column (5) - Unit of Measure (U/M). Indicates the measure used in performing the actual maintenance function. This measure is expressed by an alphabetical abbreviation (QT, GAL.). If the unit of measure differs from the unit of issue, requisition the lowest unit of issue that will satisfy your requirements.

| (1) | REMARKS | (2) | |

|---|---|---|---|

| CODE | REMARKS | ||

| A | Calibration time will be established when support equipment requirements are | identified. | |

| B | Operator drains water from fuel filter assembly. All other service is performed at | unit level. | |

| C | Operator replenishes coolant. All other service is performed at unit level. | D | Operator inspects shift lever. All other inspections are performed at unit level. |

| E | Direct support maintenance repairs coupling shaft by replacing center bearing. All | other repair is performed at unit level. | |

| F | In this category, no specific times can be established. Time required for repair will | depend on the extent of repair required for damaged components. | |

| G | Simplified test equipment/internal combustion engine (STE/ICE-R) testing times | may vary depending on the type of tests being performed. | |

| H | For vehicles with new brake adapters, P/N 10453002. | I | It is authorized to remove spindle to replace the seal. All other repair is performed |

| at direct support level. | J | Runflat compressor to be used with rubber runflat. | |

| K | If the puller kit is not available at unit level, it can be found in the GSA catalogue, | Blind Hole Puller Set, NSN 5120-00-140-3557. | |

| L | This tool can be found in the MCRL or GSA catalogue, | Manometer, U-Tube, NSN 6685-00-857-4895. | |

| M | Fan shroud repair is limited to repairs that can be made using fiberglass repair kit | (Appendix C, Item 50). Only these repairs that can be made while the shroud is | |

| installed on the vehicle are authorized. | N | Operator can remove and replace wheel assembly, but must notify unit maintenance | |

| to tighten lug nuts to proper torque as soon as possible. | O | Direct support replaces fuel injection pump governor cover gasket, shut-off solenoid, | |

| and cold advance solenoid. | P | Direct support can reseal transfer case and rear transfer case housing with silicone | |

| sealant (RTV), NSN 6850-01-159-4844. |

Section II. EXPENDABLE/DURABLE SUPPLIES AND MATERIALS LIST

Section Ii. Expendable/Durable Supplies And Materials List (Cont'D)

| (1) | (2) | (3) | (4) | (5) |

|---|---|---|---|---|

| ITEM | NATIONAL STOCK | |||

| NUMBER | LEVEL | NUMBER | DESCRIPTION | U/M |

| 1 | O | ADHESIVE: plastic cement | ||

| (04963) 1099 | ||||

| 8040-01-126-1422 | 1 Quart Can | QT | ||

| 2 | O | ADHESIVE: ethyl-2-cyanoacrylate, low viscosity | ||

| (81349) MIL-A-46050C | ||||

| 8040-00-826-3535 | 1 Ounce Bottle | OZ | ||

| 2.1 | O | ADHESIVE: sealant, gray, Uniroyal | ||

| (89619) SILAPRENE M6325-11 | ||||

| 8030-01-347-0964 | 11 Ounce Cartridge | OZ | ||

| 3 | O | ADHESIVE: silicone, black | ||

| (01139) RTV-103 | ||||

| 8040-00-865-8991 | 12 Ounce Cartridge | OZ | ||

| 4 | O | ADHESIVE: synthetic, rubber | ||

| (GA100AJ1) | ||||

| 8040-00-165-8614 | 1 Quart Can | QT | ||

| 5 | O | ADHESIVE: silicone, RTV | ||

| (81349) MIL-A-46164 | ||||

| 8040-00-938-1535 | 12 Ounce Cartridge | OZ | ||

| 6 | O | ADHESIVE: plumbing, solvent cement | ||

| (81349) MIL-A-22010 | ||||

| 8040-00-573-1502 | 1 Pint Container | PT | ||

| 7 | O | ADHESIVE: type II, class II | ||

| (80244) MIL-A-46050-C | ||||

| 8040-01-167-2613 | 5 Ounce Tube | OZ | ||

| 8040-01-090-9320 | 1 Pint | PT | ||

| 8 | O | ADHESIVE: general trim, spray | ||

| (04963) 051135 08080 | ||||

| 8040-01-215-3426 | 24 Ounce Can | OZ | ||

| 9 | O | ADHESIVE SEALANT: RTV silicone rubber, clear | ||

| (71984) SILASTIC 737 RTV | ||||

| N/A | 3 Ounce Tube | OZ | ||

| N/A | 10.3 Ounce Cartridge | OZ | ||

| N/A | 5.5 Gallon Pail | GAL. | ||

| 9.1 | O | ADHESIVE: | ||

| (71984) 732 RTV | ||||

| 8040-00-078-9774 | 6 Ounce Cartridge | OZ |

| (1) | (2) | (3) | (4) | (5) |

|---|---|---|---|---|

| ITEM | NATIONAL STOCK | |||

| NUMBER | LEVEL | NUMBER | DESCRIPTION | U/M |

| 10 | O | ADHESIVE-SEALANT: silicone, RTV, general purpose | ||

| 8040-00-833-9563 | (80244) MIL-A-46106, type I 5 Ounce Tube | OZ | ||

| 11 | C | ANTIFREEZE: arctic-type | ||

| (81349) MIL-A-11755 | ||||

| 6850-00-174-1806 | 55 Gallon Drum | GAL. | ||

| 12 | C | ANTIFREEZE: ethylene glycol, inhibited heavy-duty, single package | ||

| (81349) MIL-A-46153 | ||||

| 6850-00-181-7929 | 1 Gallon Container | GAL. | ||

| 6850-00-181-7933 | 5 Gallon Container | GAL. | ||

| 13 | O | ANTISEIZE COMPOUND: conductive (81349) MIL-A-907 | ||

| 8030-00-059-2761 | 1 Pound Can | LB | ||

| 14 | C | BRAKE FLUID: silicone, automotive, all weather, operational and preservative | ||

| (81349) MIL-B-46176 | ||||

| 9150-01-102-9455 | 1 Gallon Can | GAL. | ||

| 9150-01-123-3152 | 5 Gallon Can | GAL. | ||

| 15 | CHALK, MARKING: (81348) SS-C-255 | |||

| 7510-00-223-6701 | 1 Gross | GR. | ||

| 16 | O | CLEANING AND LUBRICATING COMPOUND: electrical (81349) MIL-C-83360 | ||

| 6850-00-003-5295 | 16 Ounce Can | OZ | ||

| 17 | C | DETERGENT: general purpose, liquid (81349) MIL-D-16791 | ||

| 7930-00-282-9699 | 1 Gallon Container | GAL. | ||

| 17.1 | C | DETERGENT: laundry (81348) PD-245 | ||

| 7930-00-985-6904 | 20 oz. box | OZ | ||

| 18 | C | DRYCLEANING SOLVENT: (81348) P-D-680, type II | ||

| 6850-00-110-4498 | 1 Pint Can | PT | ||

| 6850-00-274-5421 | 5 Gallon Drum | GAL. | ||

| 6850-00-285-8011 | 55 Gallon Drum | GAL. | ||

| 6850-00-637-6135 | Bulk | GAL. |

Section Ii. Expendable/Durable Supplies And Materials List (Cont'D)

Section Ii. Expendable/Durable Supplies And Materials List (Cont'D)

| (1) | (2) | (3) | (4) | (5) |

|---|---|---|---|---|

| ITEM NUMBER | LEVEL | NATIONAL STOCK NUMBER | DESCRIPTION | U/M |

| 19 | C | FUEL OIL: diesel, regular, DF-2 (81348) VV-F-800 | ||

| 9140-00-286-5295 | 5 Gallon Can | GAL. | ||

| 9140-00-286-5296 | 55 Gallon Drum | GAL. | ||

| 20 | C | FUEL OIL: diesel, winter, DF-1 (81348) VV-F-800 | ||

| 9140-00-286-5287 | 5 Gallon Drum | GAL. | ||

| 9140-00-286-5288 | 55 Gallon Drum | GAL. | ||

| 21 | C | FUEL OIL: diesel, arctic, DF-A (81348) VV-F-800 | ||

| 9140-00-286-5282 | 5 Gallon Can | GAL. | ||

| 9140-00-286-5284 | 55 Gallon Drum | GAL. | ||

| 22 | C | GREASE: automotive and artillery (81349) MIL-G-10924 | ||

| 9150-00-935-1017 | 14 Ounce Cartridge | OZ | ||

| 9150-00-190-0904 | 1-3/4 Pound Can | LB | ||

| 9150-00-190-0905 | 6-1/2 Pound Can | LB | ||

| 23 | O | GREASE: ball and roller bearing (73219) 18901 | ||

| 9150-01-095-5512 | Case, 24/14 Ounce Cans | OZ | ||

| 24 | O | GREASE: dielectric colloid (72872) 112X | ||

| N/A | 1 Gallon Container | GAL. | ||