hmmwv-manuals

Chapter 3 - Engine Systems Maintenance

| Chapter 3 | Engine Systems Maintenance TASK SUMMARY |

|---|---|

| TASK | PROCEDURES |

| 3-1 | Lubrication System Maintenance Task Summary |

| 3-2 | Engine Oil Dipstick Tube Replacement |

| 3-3 | Engine Oil Filler Tube Replacement |

| 3-4 | Engine Oil Filter Adapter Replacement |

| 3-5 | Engine Oil Service |

| 3-6 | Oil Pan Replacement |

| 3-7 | Engine Oil Cooler Supply And Return Lines Maintenance |

| 3-8 | Engine And Transmission Oil Cooler Assembly Maintenance |

| 3-9 | Crankcase Depression Regulator (Cdr) Valve And Bracket Maintenance |

| 3-10 | Cdr Valve Hoses Replacement |

| 3-11 | Section II. Fuel System Maintenance |

| 3-12 | Air Cleaner Assembly And Dust Unloader Maintenance (Cont'D) |

| 3-13 | Air Cleaner Filter Element Servicing (Cont'D) |

| 3-14 | Air Horn Replacement |

| 3-15 | Air Horn-To-Air Cleaner Elbow Replacement |

| 3-16 | Air Horn Support Bracket Replacement |

| 3-17 | Air Restriction Gauge Replacement |

| 3-18 | Weathercap Replacement |

| 3-19 | Air Restriction Gauge Hose Replacement |

| 3-20 | Air Intake And Fuel Pump Vent Lines Replacement |

| 3-21 | Drainage Bracket Replacement |

| 3-22 | Fuel Injection Pump Boot Replacement |

| 3-23 | Fuel Pump Replacement |

| 3-24 | Fuel Tank Maintenance (Cont'D) |

| 3-25 | Fuel Tank Supply And Return Lines Replacement |

| 3-26 | Auxiliary Fuel Pickup And Return Lines Replacement |

| 3-27 | Fuel Tank Vent Line And Filter Replacement |

| 3-28 | Fuel Tank Filler Cap And Spout Maintenance |

| 3-29 | Fuel Tank Filler Spout Vent Line Replacement |

| 3-30 | Filler Spout Hose Replacement |

| 3-31 | Fuel Tank Hangers Replacement |

| 3-32 | Fuel Filter Maintenance |

| 3-33 | Fuel Filter Element Maintenance |

| 3-34 | Fuel Filter Drain Hose And Valve Replacement |

| 3-35 | Fuel Injection Pump Return Hose Check Valve Maintenance |

| 3-36 | Fuel Injection Return Hoses Replacement |

| 3-37 | Fuel Drain Back Tube Replacement |

| 3-38 | Glow Plug Replacement |

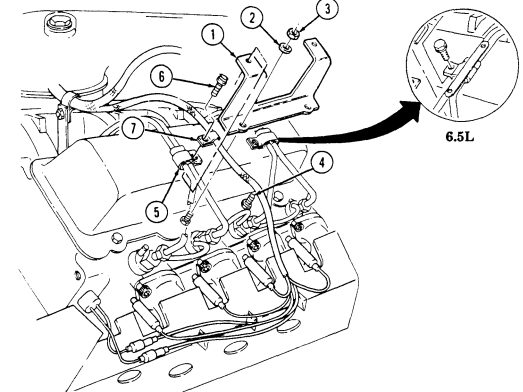

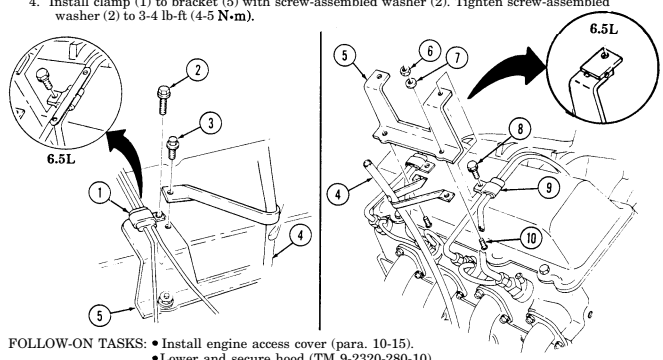

| 3-39 | Right Fuel Injection Lines Bracket Replacement |

| 3-40 | Left Fuel Injection Lines Bracket Replacement |

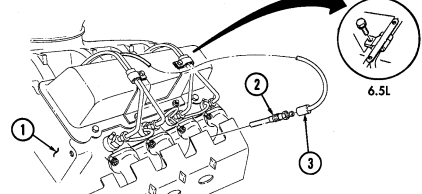

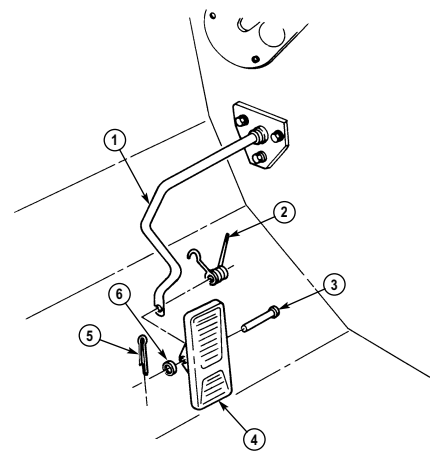

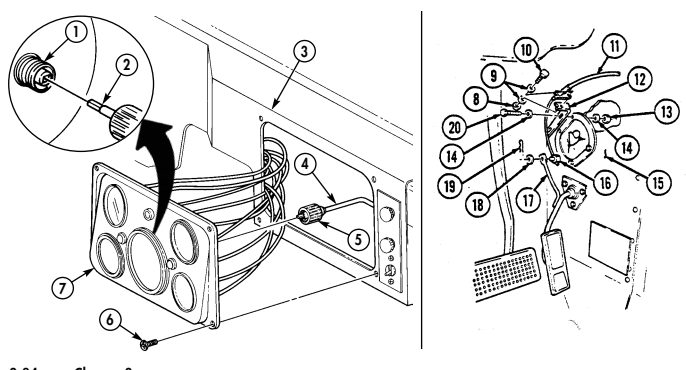

| 3-41 | Accelerator System Maintenance Task Summary |

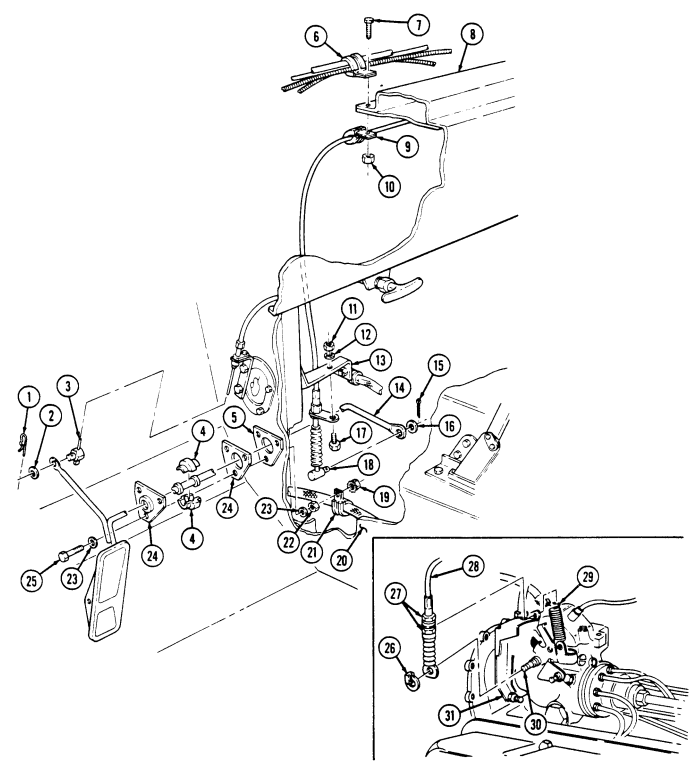

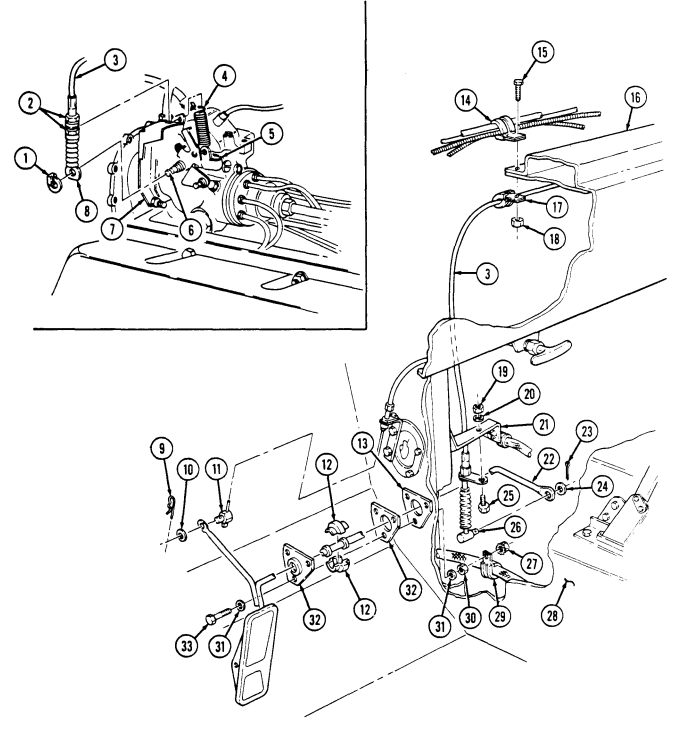

| 3-42 | Accelerator Linkage Maintenance |

| 3-43 | Accelerator Pedal Replacement |

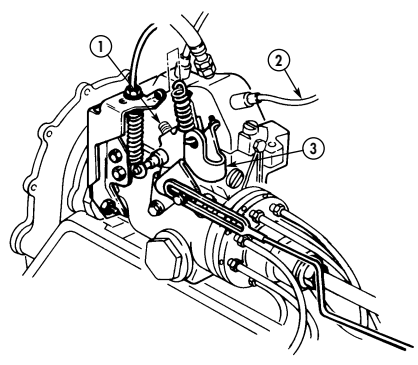

| 3-44 | Engine Idle Speed Adjustment |

| 3-45 | Hand Throttle Control Cable And Bracket Replacement |

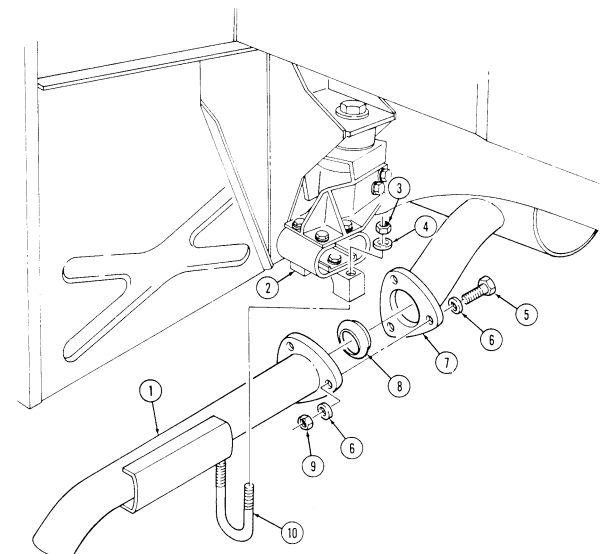

| 3-46 | Exhaust System Maintenance Task Summary |

| 3-47 | Tailpipe Replacement |

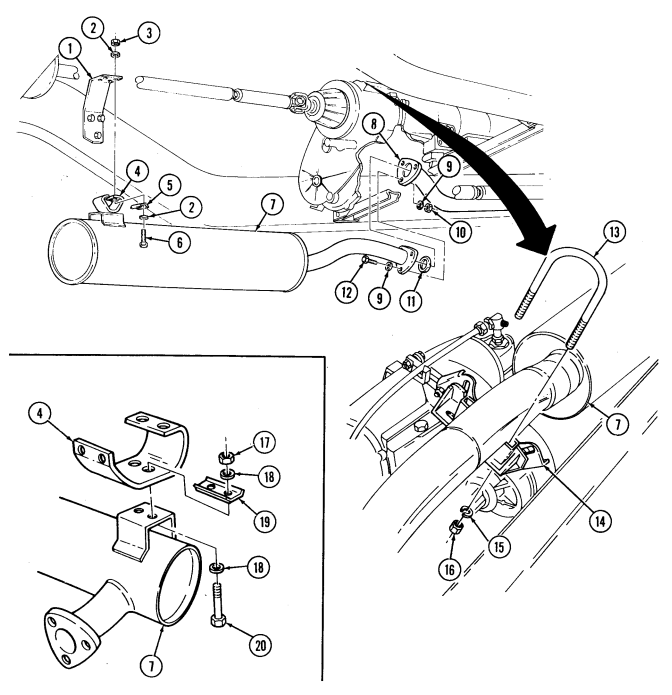

| 3-48 | Muffler And Insulator Replacement (All Models Except M1123 And "A2" Vehicles) |

| 3-49 | Muffler And Catalytic Converter Replacement (M1123 And "A2" Vehicles Only) |

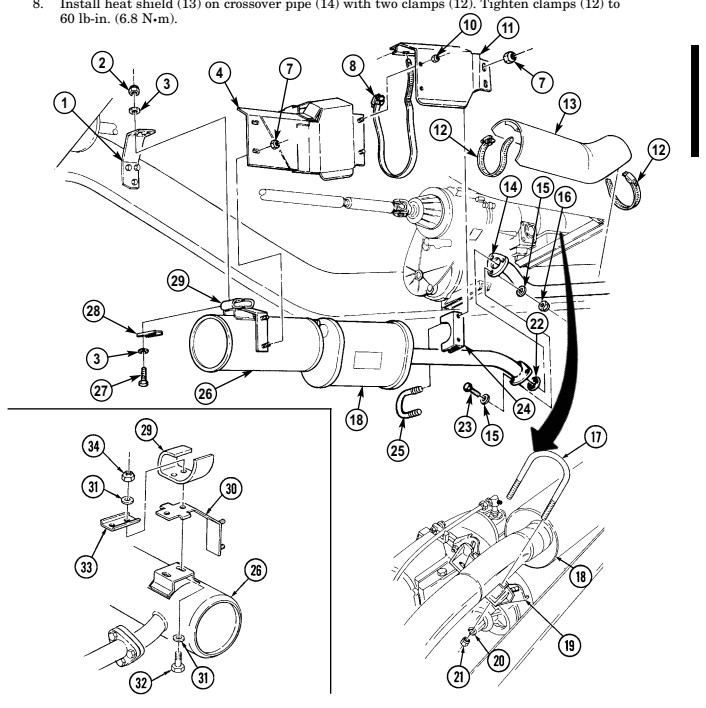

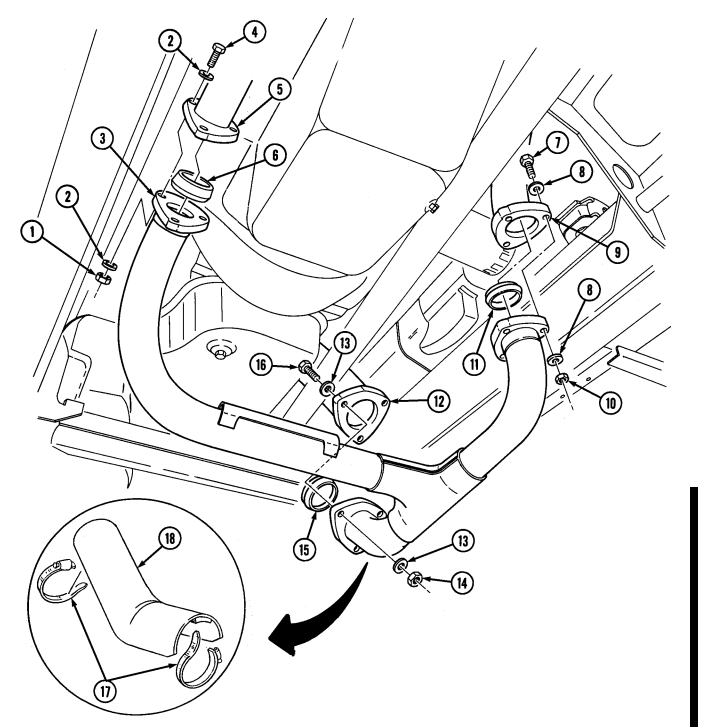

| 3-50 | Crossover Pipe Replacement |

| 3-51 | Tailpipe Hanger Replacement |

| 3-52 | Tailpipe Insulator Replacement |

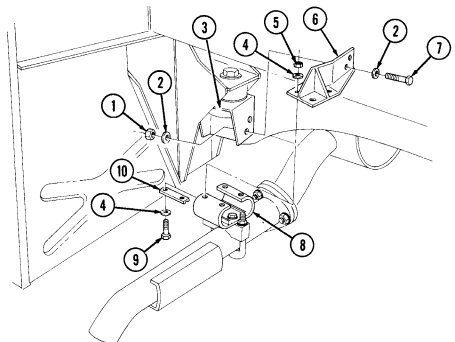

| 3-53 | Muffler Support Bracket Maintenance |

| 3-54 | Right Exhaust Manifold Rear Heat Shield Replacement |

| 3-55 | Right Exhaust Manifold Heat Shield Replacement |

| 3-56 | Left Exhaust Manifold Replacement |

| 3-57 | Right Exhaust Manifold Replacement |

| 3-58 | Muffler Hanger Replacement |

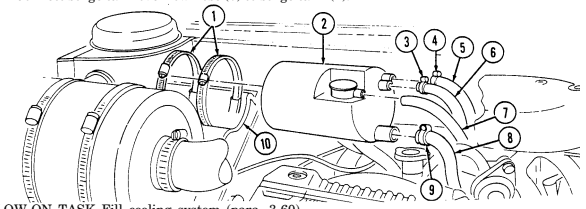

| 3-59 | Cooling System Maintenance Task Summary |

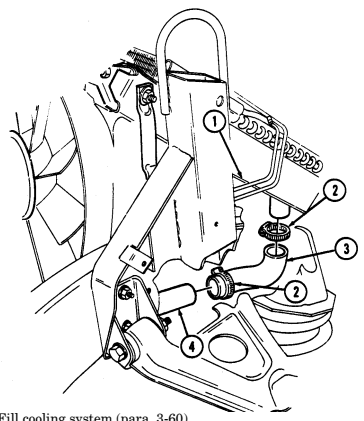

| 3-60 | Cooling System Servicing |

| 3-61 | Radiator And Fan Shroud Assembly Maintenance |

| 3-62 | Airlift To Shroud Shield Assembly Replacement |

| 3-63 | Radiator Support Replacement |

| 3-64 | Surge Tank Replacement |

| 3-65 | Surge Tank-To-Radiator Vent Hose Replacement |

| 3-66 | Surge Tank-To-Water Crossover Vent Hose Replacement |

| 3-67 | Thermostat Bypass Hose Replacement |

| 3-68 | Fan Drive Hose And Quick-Disconnect Replacement |

| 3-69 | Radiator Inlet Hose Replacement |

| 3-70 | Radiator Lower Tube Assembly Replacement |

| 3-71 | Lower Radiator Hose Replacement |

| 3-72 | Water Pump Inlet Hose Replacement |

| 3-73 | Surge Tank-To-Lower Radiator Tube Hose Replacement |

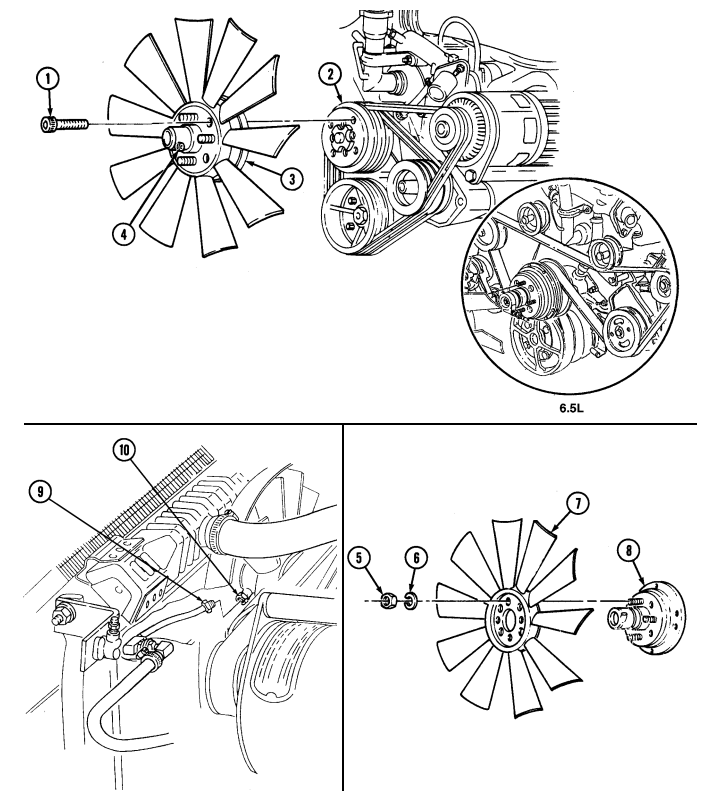

| 3-74 | Surge Tank Overflow Hose Replacement |

| 3-75 | Thermostat Replacement |

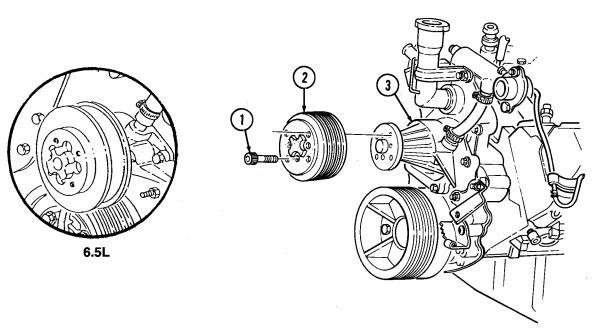

| 3-76 | Water Pump Pulley Replacement |

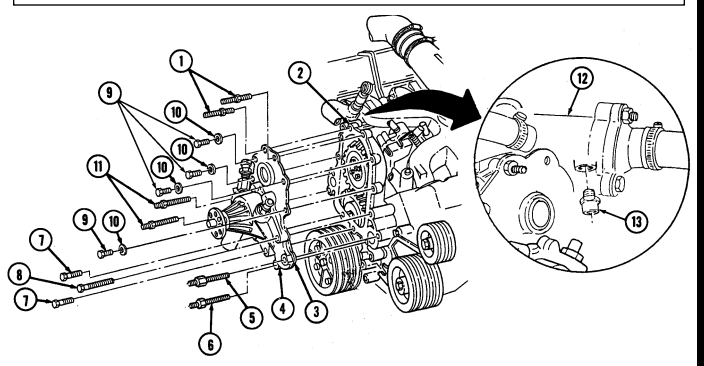

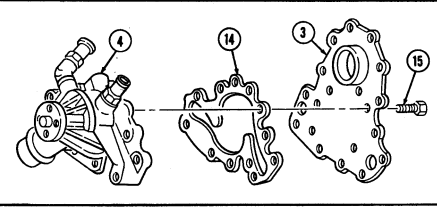

| 3-76 | Water Pump And Adapter Plate Maintenance |

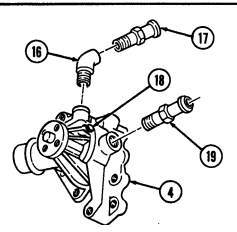

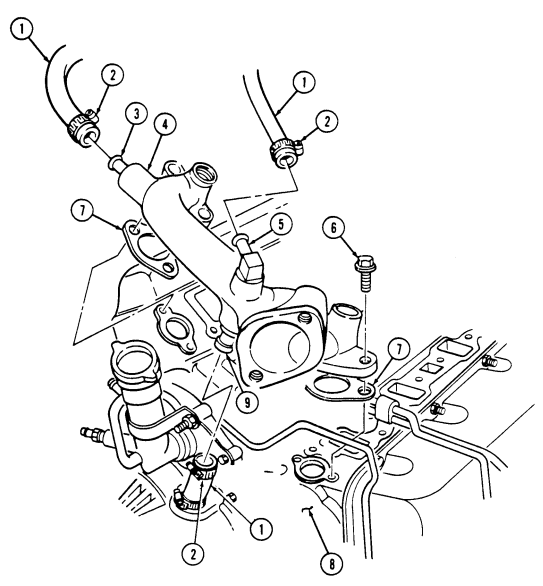

| 3-77 | Water Crossover Maintenance |

| 3-78 | Fan Drive And Fan Blade Maintenance |

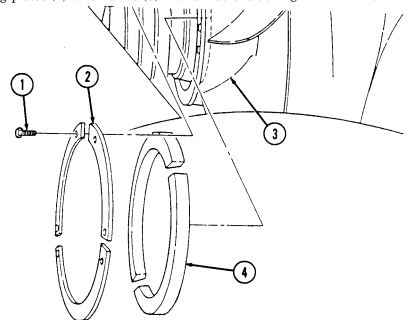

| 3-79 | Fan Drive Friction Lining Replacement |

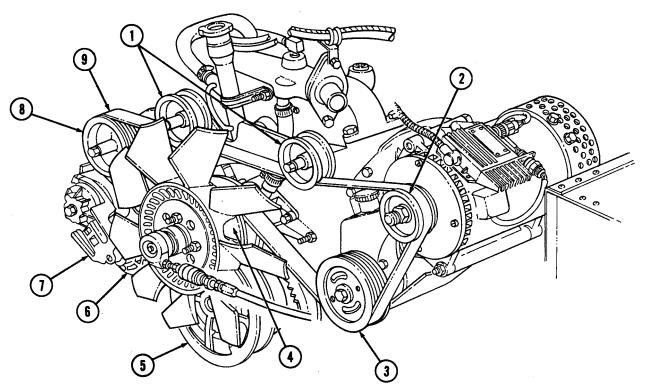

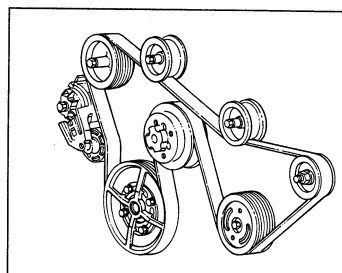

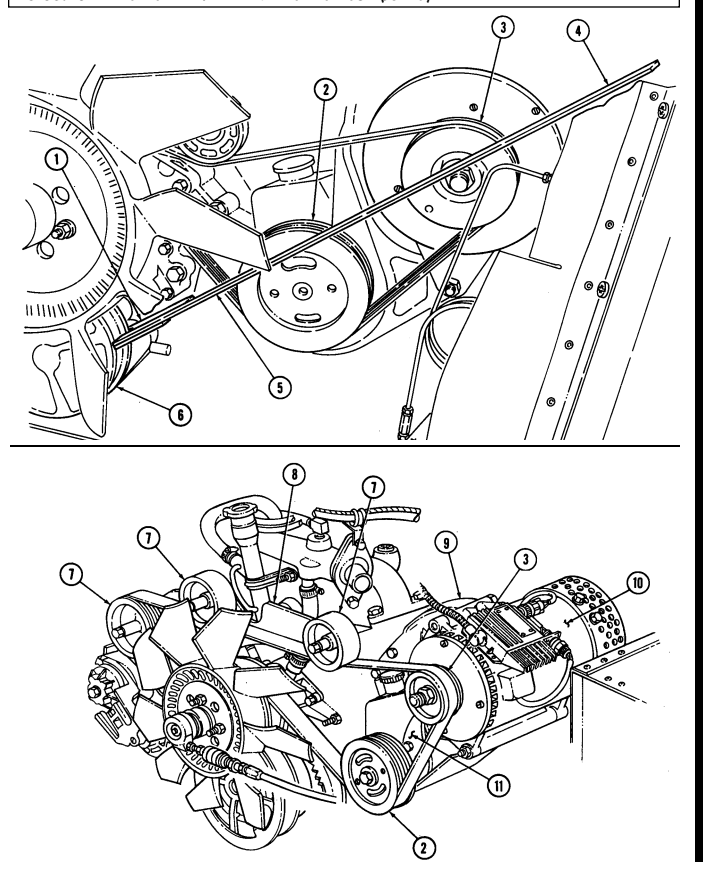

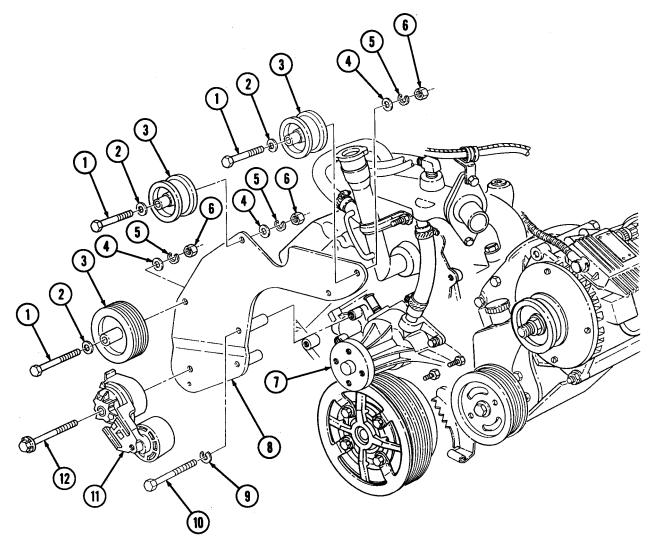

| 3-80 | Power Steering Drivebelt Set Replacement |

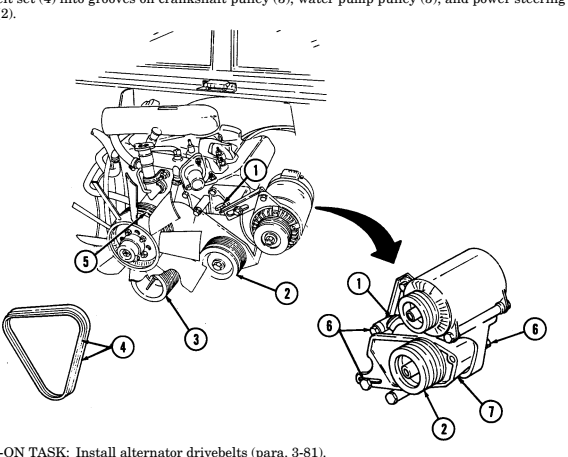

| 3-81 | A Lt E R N Ator Drivebelt Set Replacement |

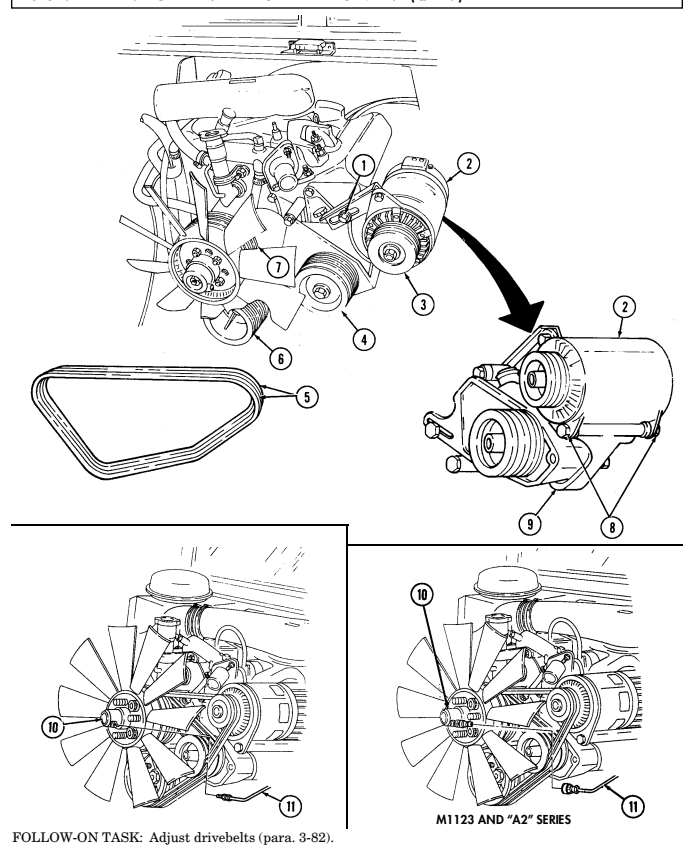

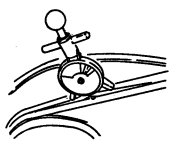

| 3-82 | Drivebelts Adjustment |

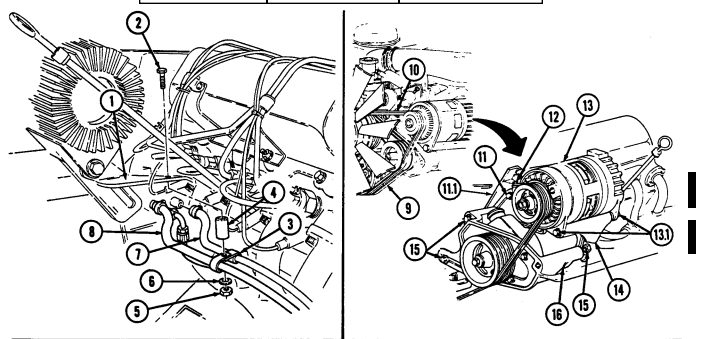

| 3-83 | Serpentine Drivebelt Maintenancee Replacement |

| 3-84 | Tensioner, Idler Pulleys, And Mounting Hardwar |

Section I Lubrication System Maintenance

3-1 Lubrication System Maintenance Task Summary

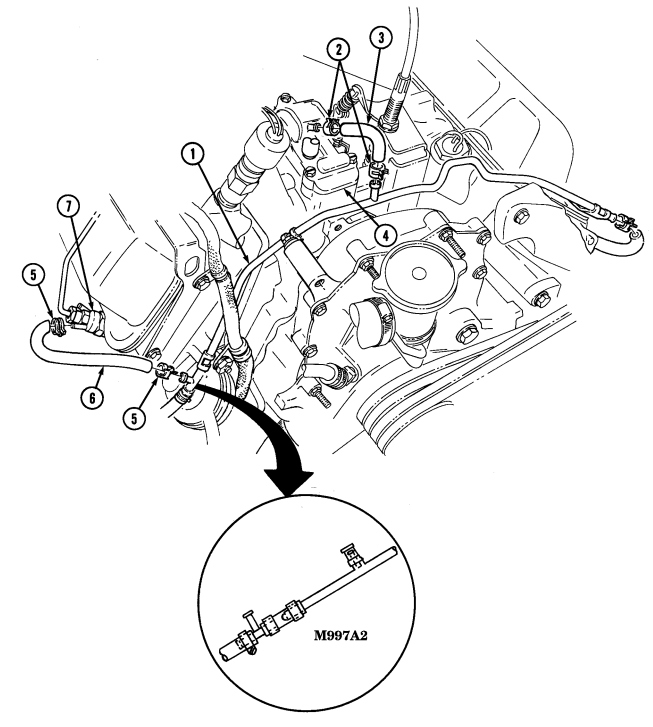

3-2. Engine Oil Dipstick Tube Replacement

This task covers: INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Special Tools Hex-head driver, 8 mm (Appendix B, Item 156)

Materials/Parts

- O-ring (Appendix G, Item 209)

- Plain-assembled nut (Appendix G, Item 201)

- Sealant (Appendix C, Item 38)

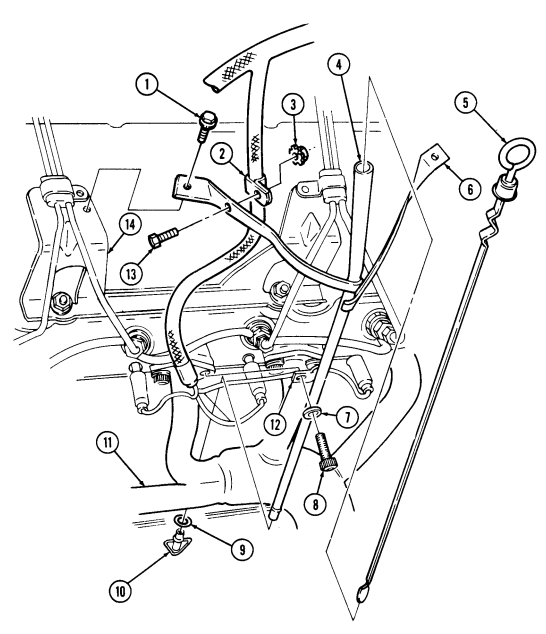

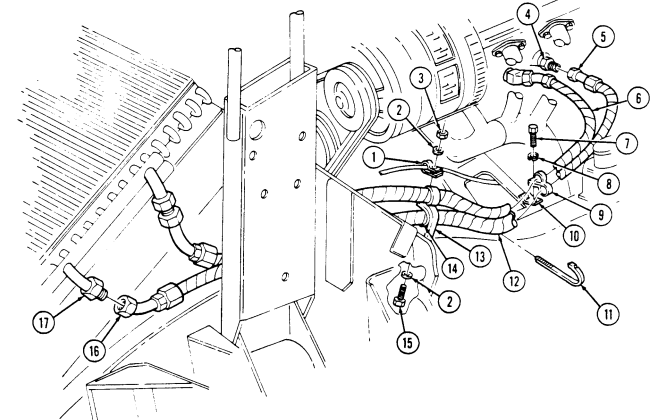

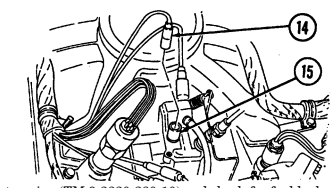

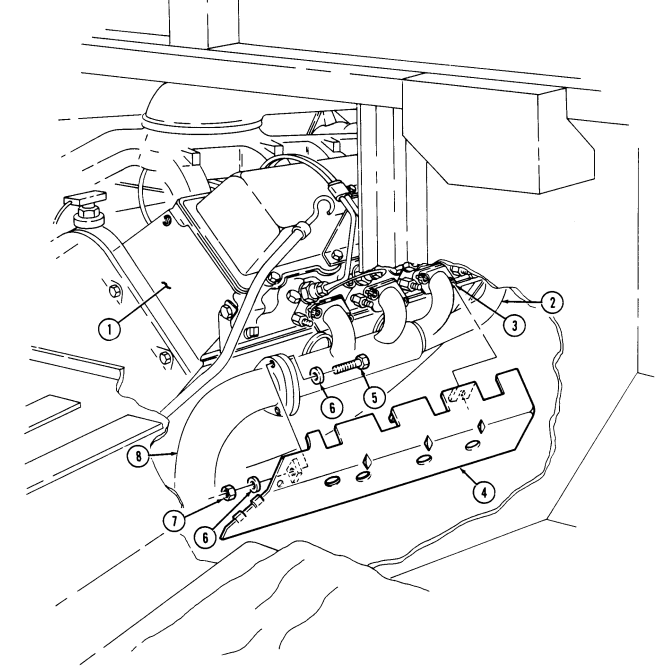

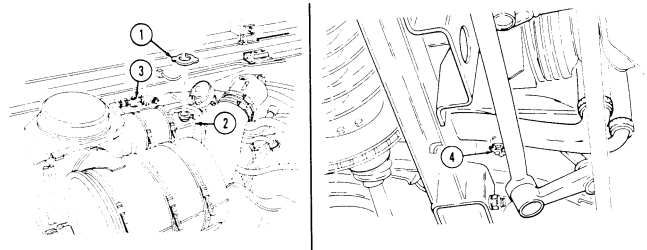

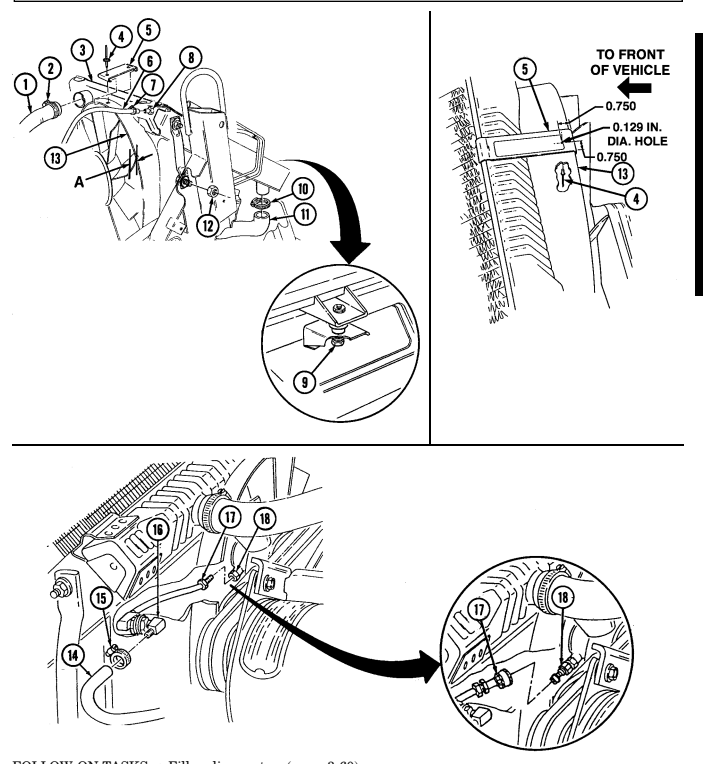

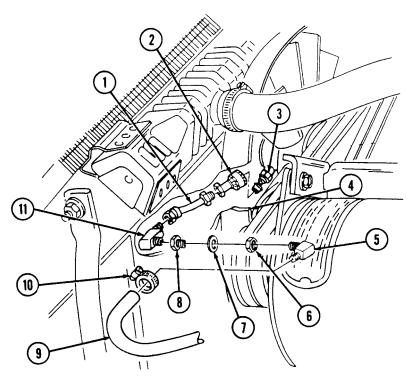

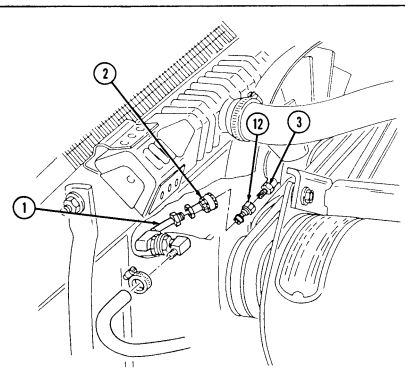

a. Removal

- Remove oil dipstick (5) from oil dipstick tube (4).

- Remove plain-assembled nut (3) and capscrew (13) from harness clamp (2) and upper dipstick tube bracket (6). Discard plain-assembled nut (3).

- Using hex-head driver, remove socket-head screw (8) and washer (7) from lower dipstick tube bracket (12) and exhaust manifold (11).

- Remove two assembled-washer screws (1) from upper dipstick tube bracket (6) and fuel line bracket (14).

- Remove oil dipstick tube (4) from engine oil pan (10). Remove and discard O-ring (9).

b. Installation

- Apply RTV sealant to O-ring (9) and install O-ring (9) on oil dipstick tube (4).

- Install oil dipstick tube (4) in engine oil pan (10).

- Using hex-head driver, secure lower dipstick tube bracket (12) to exhaust manifold (11) with washer (7) and socket-head screw (8). Tighten socket-head screw (8) to 25-33 lb-ft (34-45 N•m).

- Secure upper dipstick tube bracket (6) to fuel line bracket (14) with two assembled-washer screws (1). Tighten assembled-washer screws (1) to 3–4 lb-ft (4-5 N•m).

- Secure harness clamp (2) to upper dipstick tube bracket (6) with capscrew (13) and plain-assembled nut (3).

- Install oil dipstick (5) into oil dipstick tube (4).

a. Removal b. Installation

| Manual References |

|---|

| TM 9-2320-280-1 |

| TM 9-2320-280-10 |

| TM 9-2320-280-24P |

Equipment Condition Hood raised and secured (TM 9-2320-280-10).

FOLLOW-ON TASKS:

- Start engine (TM 9-2320-280-10) and check for oil leaks.

- Lower and secure hood (TM 9-2320-280-10).

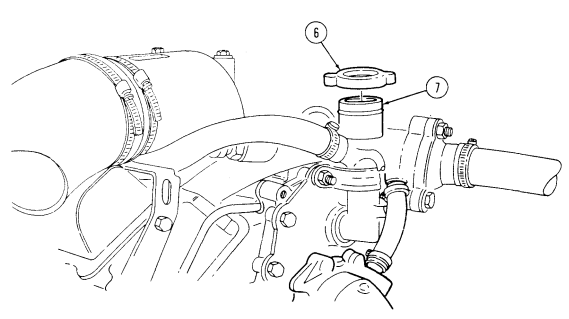

3-3. Engine Oil Filler Tube Replacement

This task covers:

INITIAL SETUP:

- Tools

- General mechanic's tool kit automotive (Appendix B, Item 1) TM 9-2320-280-10 TM 9-2320-280-24P

- Materials/Parts

- Lubricating oil (Appendix C, Item 31)

- Equipment Condition

- Hood raised and secured (TM 9-2320-280-10).

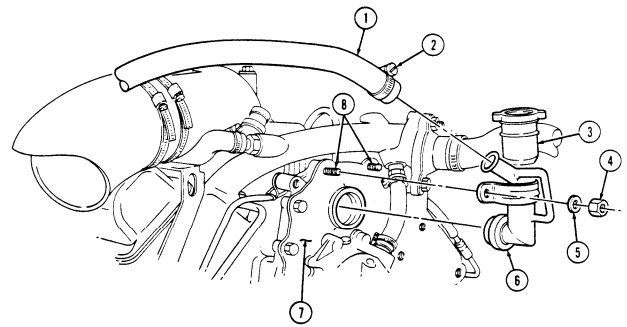

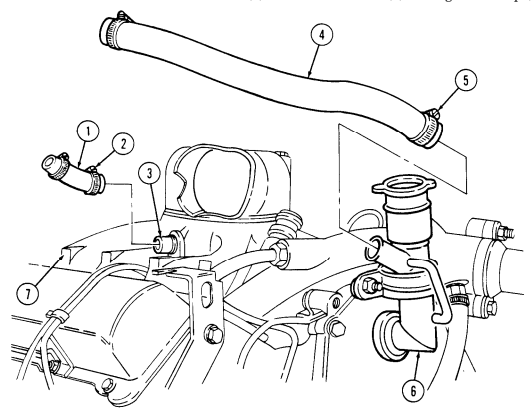

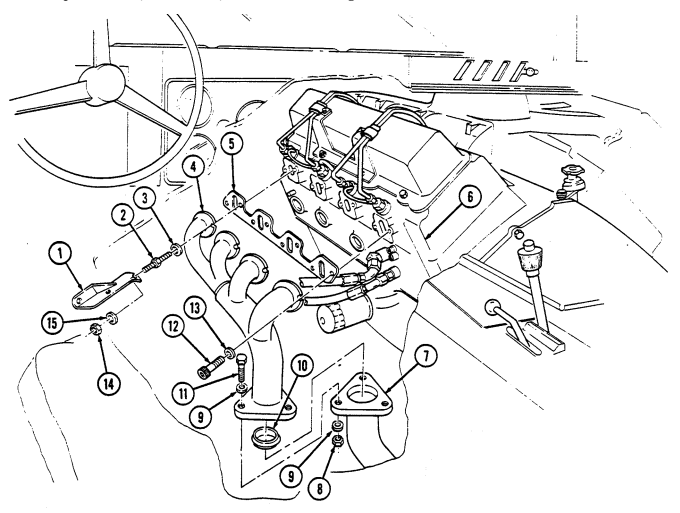

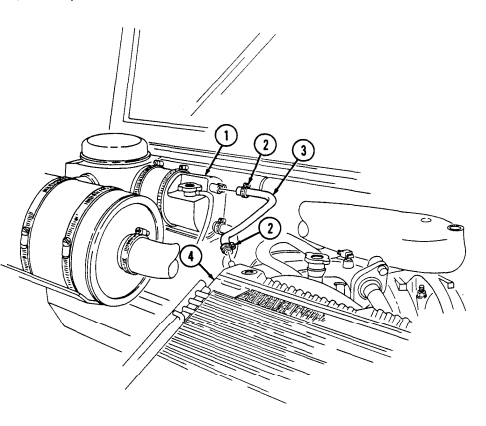

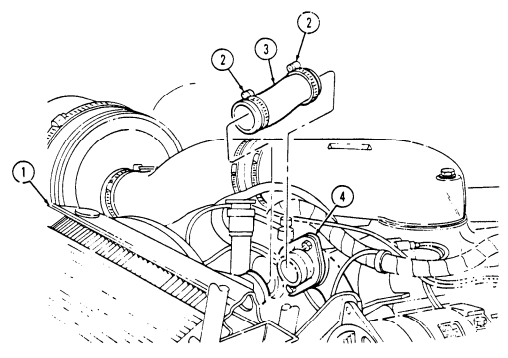

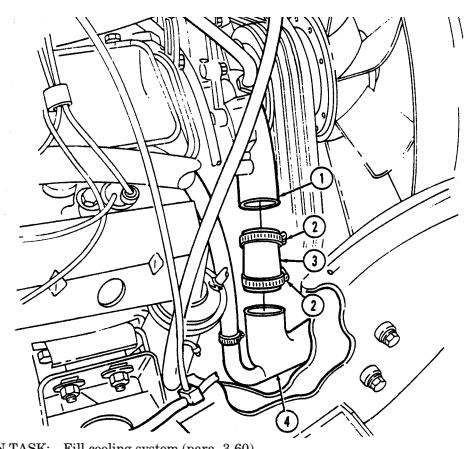

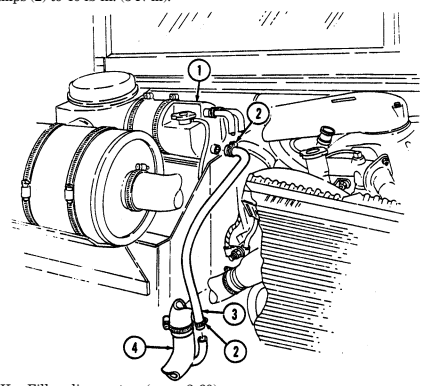

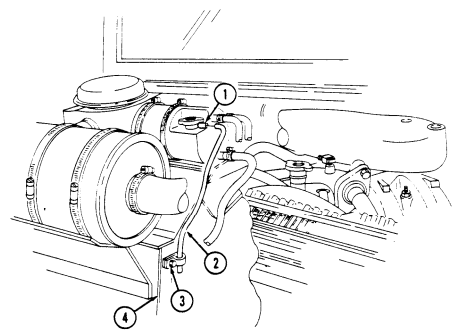

A. Removal

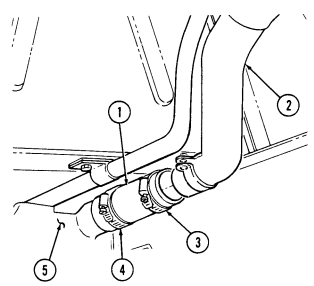

- Loosen clamp (2) and disconnect CDR valve hose (1) from engine oil filler tube (3).

- Remove two nuts (4), washers (5), and engine oil filler tube (3) from timing chain cover (7) and studs (8).

- Inspect grommet (6) for breaks or cracks. Replace if defective.

B. Installation

- Coat grommet (6) with lubricating oil.

- Install engine oil filler tube (3) into timing chain cover (7) with two washers (5) and nuts (4). Tighten nuts (4) to 13-20 lb-ft (18-27 N.m).

- Connect CDR valve hose (1) to engine oil filler tube (3) and tighten clamp (2).

FOLLOW-ON TASK:

- Lower and secure hood (TM 9-2320-280-10).

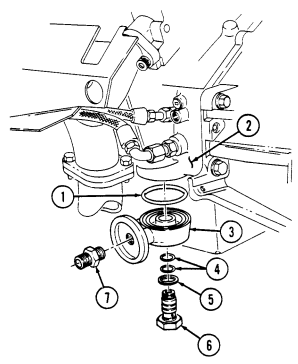

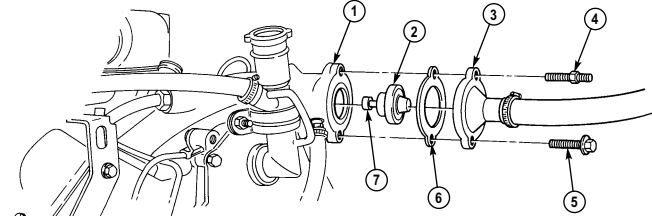

3-4. Engine Oil Filter Adapter Replacement

This task covers: INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Gasket (Appendix G, Item 53) Two O-rings (Appendix G, Item 210) O-ring (Appendix G, Item 211)

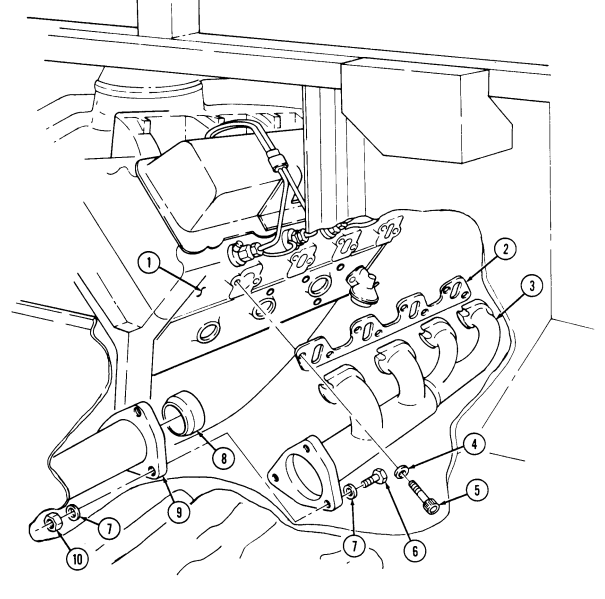

A. Removal

- Inspect reducer boss (7) for damaged threads or cracks. Replace if defective.

B. Installation

- Install reducer boss (7) into oil filter adapter (3) and tighten to 25 lb-ft (34 N•m).

2. Install engine oil filter adapter (3) and O-ring (1) on cylinder block (2) with two O-rings (4),

gasket (5), and adapter bolt (6). Tighten adapter bolt (6) to 50 lb-ft (68 N•m).

2. Install engine oil filter adapter (3) and O-ring (1) on cylinder block (2) with two O-rings (4),

gasket (5), and adapter bolt (6). Tighten adapter bolt (6) to 50 lb-ft (68 N•m).

FOLLOW-ON TASK: Install engine oil filter (para. 3-5).

a. Removal b. Installation

Manual References TM 9-2320-280-24P Equipment Condition Engine oil filter removed (para. 3-5).

-

Remove adapter bolt (6), gasket (5), two O-rings (4), engine oil filter adapter (3), and O-ring (1) from cylinder block (2). Discard O-ring (1), two O-rings (4), and gasket (5).

-

Remove reducer boss (7) from oil adapter (3).

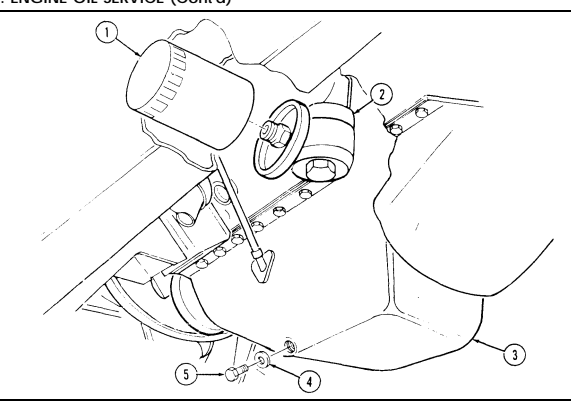

3-5. Engine Oil Service

This task covers:

a. Draining Oil c. Installing Filter b. Removing Filter d. Replenishing Oil

INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Oil filter removal tool (Appendix B, Item 2) Materials/Parts Oil filter (Appendix G, Item 206) (6.2L only) Oil filter (Appendix G, Item 206.1) (6.5L and 6.5L detuned only) Lubricating oil (Appendix C, Item 31) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Hood raised and secured (TM 9-2320-280-10).

General Safety Instructions Do not drain oil when engine is hot.

a. Draining Oil

Do not drain oil when engine is hot. Severe injury to personnel will result.

- Park vehicle on a firm, level surface. - Have drainage container ready to catch oil.

- Remove drainplug (5) and gasket (4) from oil pan (3). Allow oil to drain completely. 2. Install gasket (4) and drainplug (5). Tighten drainplug (5) to 20 lb-ft (27 N•m).

b. Removing Filter

Have drainage container ready to catch oil.

Remove oil filter (1) from filter adapter (2). Discard filter (1).

c. Installing Filter 1. Apply a light coat of oil to filter gasket prior to installation 2. Install oil filter (1) on oil filter adapter (2) and tighten by hand until gasket contacts filter adapter (2). Tighten additional 1/2-3/4 turn by hand.

d. Replenishing Oil

Install a non-vented filler cap only. An incorrect filler cap will not seal properly, causing water to enter and damage engine.

- Remove filler cap (6) from filler tube (7). Fill with oil according to TM 9-2320-280-10. 2. Install filler cap (6) on filler tube (7).

3-5. ENGINE OIL SERVICE (Cont'd)

FOLLOW-ON TASKS: - Lower and secure hood (TM 9-2320-280-10). •

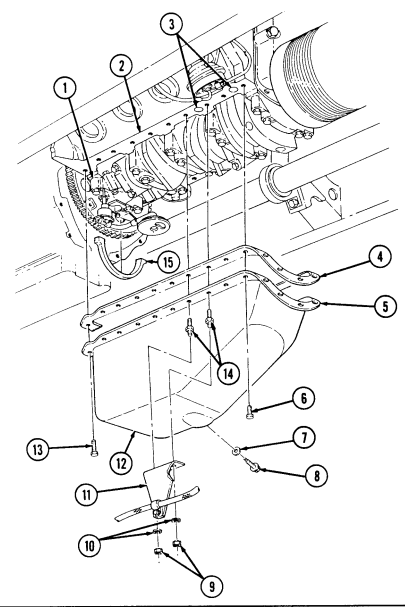

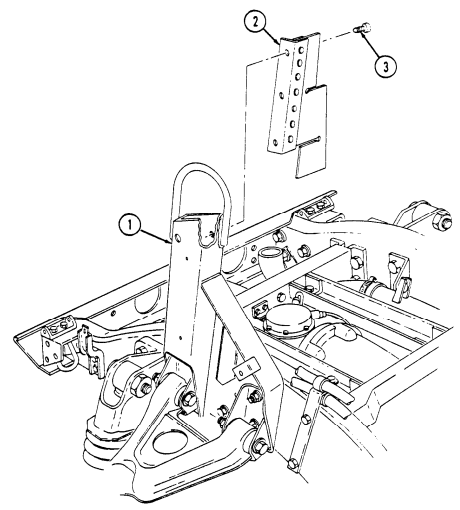

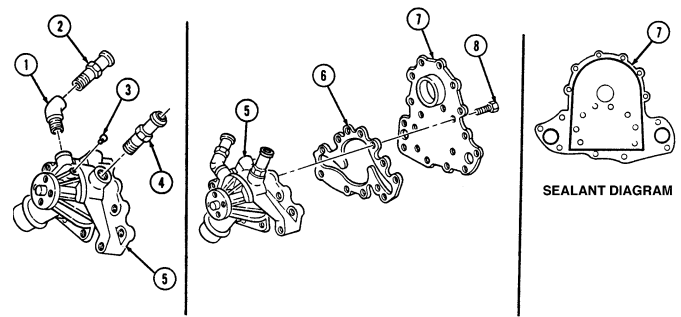

3-6. Oil Pan Replacement

This task covers: INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Oil seal retainer (Appendix G, Item 207) Two lockwashers (Appendix G, Item 135) Oil pan gasket (Appendix G, Item 61) (optional - used on 6.2 L only) Sealant (Appendix C, Item 38) Manual References TM 9-2320-280-10 TM 9-2320-280-24P a. Removal

A. Removal B . Installation Equipment Condition

- Starter removed (para. 4-8). - Oil dipstick tube removed (para. 3-2).

General Safety Instructions Do not drain oil when engine is hot.

Do not drain oil when engine is hot. Severe injury to personnel will result.

Have drainage container ready to catch oil.

-

Remove oil drainplug (8) and gasket (7) and drain oil. Install gasket (7) and oil drainplug (8) after oil is drained.

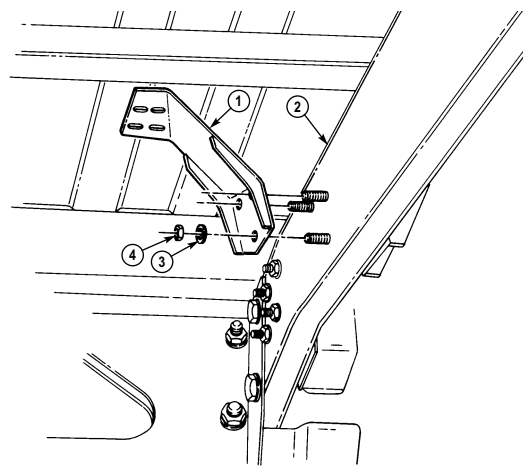

-

Remove two nuts (9), lockwashers (10), and starter cable support bracket (11) from studs (14).

Discard lockwashers (10).

Optional gasket applies to 6.2 L only.

-

Remove twenty capscrews (6), two large capscrews (13), studs (14), oil pan gasket (4) (if installed), and oil pan (12) from cylinder block (2). Remove any sealant remains.

-

Remove oil pan rear seal retainer (15) from rear main cap (1). Discard oil pan rear seal retainer (15). b. Installation 1. Apply a bead of sealant to each end of seal retainer (15) and install oil pan rear seal retainer (15) on rear main cap (1).

-

Perform step 2 for oil pan gasket (if installed). Perform step 3 for applying sealant.

-

Immediately install oil pan after application of sealant.

-

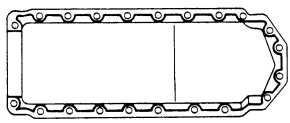

Install oil pan gasket (4) on lip of oil pan (12) and align with bolt holes. 3. Apply a 3/16 in. (5mm) bead of sealant around two large holes (3) on cylinder block (2). Apply a 3/16 in. (5mm) bead of sealant around oil pan sealing surface (5) following sealant diagram shown.

-

Install oil pan (12) on cylinder block (2) with twenty capscrews (6), two large capscrews (13), and studs (14). Tighten capscrews (6) and studs (14) to 4-10 lb-ft (5-14 N•m). Tighten large capscrews (13) to 13-20 lb-ft (18-27 N•m).

-

Install starter cable support bracket (11) on studs (14) with two lockwashers (10) and nuts (9). 6. Tighten oil drainplug (8) to 20 lb-ft (27 N•m).

SEALANT DIAGRAM

FOLLOW-ON TASKS: - Replenish engine oil (TM 9-2320-280-10).

- • - Install oil dipstick tube (para. 3-2).

· Install starter (para. 4-8).

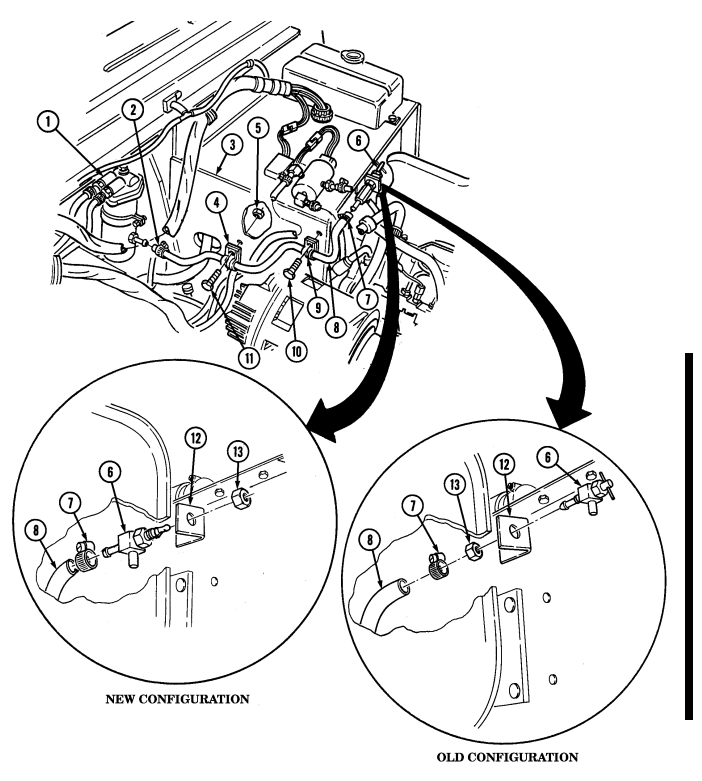

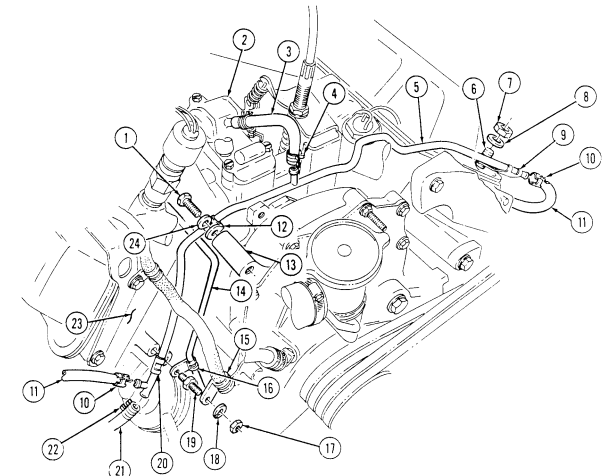

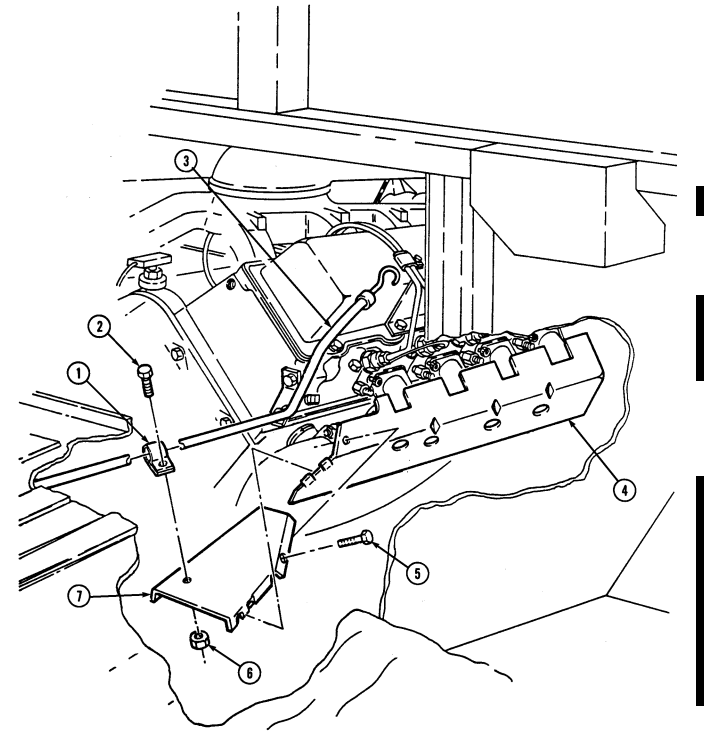

3-7. Engine Oil Cooler Supply And Return Lines Maintenance

This task covers: b. Inspection INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

Tiedown strap (Appendix G, Item 306) Lockwasher (Appendix G, Item 133) Locknut (Appendix G, Item 72) Manual References TM 9-2320-280-10 TM 9-2320-280-24P a. Supply Line Removal c. Supply Line Installation

Equipment Condition

-

Engine left splash shield removed (para. 10-17).

-

Engine access cover removed (para. 10-15).

General Safety Instructions Do not drain oil when engine is hot.

a. Removal

Do not drain oil when engine is hot. Severe injury to personnel will result.

Cover or plug all hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

-

Engine oil cooler supply and return lines are replaced basically the same. This procedure covers supply line replacement.

-

Have drainage container ready to catch oil. - Left splash shield can be modified to add engine access cover.

Refer to appendix D, Figs. D-86 and D-87 for installation.

-

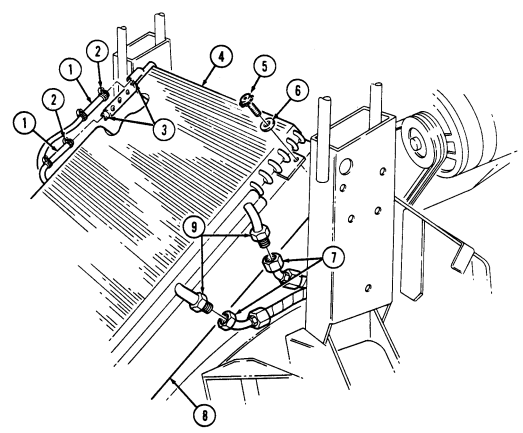

Disconnect supply line connector (5) from adapter (4) and allow oil to drain. 2. Disconnect supply line connector (16) from oil cooler port (17). 3. Remove locknut (3), washer (2), capscrew (15), and washer (2) from supply line clamp (14), brake line clamp (1), and frame bracket (13). Discard locknut (3).

-

Remove capscrew (7), lockwasher (8), and clamp (9) from supply line (12) and engine mount bracket (10). Discard lockwasher (8).

-

Remove tiedown strap (11) from supply line (12) and return line (6). Discard tiedown strap (11). b. Inspection Inspect adapter (4) for damaged threads or cracks. Replace if defective.

c. Installation 1. Position supply line (12) in approximate mounting location along frame. 2. Install supply line clamp (14) and brake line clamp (1) on frame bracket (13) with washer (2), capscrew (15), washer (2), and locknut (3). Tighten locknut (3) to 6 lb-ft (8 N•m).

- Connect supply line connector (16) to oil cooler port (17).

3-7. Engine Oil Cooler Supply And Return Lines Replacement (Cont'D)

- Connect supply line connector (5) to adapter (4).

-

Secure supply line (12) to engine mount bracket (10) with clamp (9), lockwasher (8), and capscrew (7).

-

Secure supply line (12) to return line (6) with tiedown strap (11).

FOLLOW-ON TASKS: Install engine left splash shield (para. 10-17).

Fill oil to proper level (TM 9-2320-280-10). Start engine (TM 9-2320-280-10) and inspect for leaks at engine oil cooler, supply and return lines. Install engine access cover (para. 10-15).

3-8. Engine And Transmission Oil Cooler Assembly Maintenance

This task covers: b. Installation INITIAL SETUP: Tools Equipment Condition a. Removal c. Cleaning and Inspection General mechanic's tool kit: Engine left splash shield removed (para. 10-17).

automotive (Appendix B, Item 1) Power steering cooler removed (para. 8-28).

Manual References General Safety Instructions TM 9-2320-280-10 Do not drain oil when engine is hot.

TM 9-2320-280-24P Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa).

Do not bend transmission oil cooler fins. Damaged fins reduce cooling efficiency, which may damage engine and/or transmission.

a. Removal

Do not drain oil when engine is hot. Severe injury to personnel will result.

Cover or plug all hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

Have drainage container ready to catch oil. Note position of hoses for installation.

-

Disconnect two engine oil cooler supply and return lines (7) from engine oil cooler ports (9).

-

Loosen two hose clamps (2) and disconnect two transmission oil cooler line connector hoses (1) from transmission oil cooler ports (3).

-

Remove four socket-head screw and washer assemblies (5), washers (6) and oil cooler (4) from radiator (8).

-

Install oil cooler (4) on radiator (8) with four washers (6) and socket-head screw and washer assemblies (5).

-

Connect two transmission oil cooler line connector hoses (1) to transmission oil cooler ports (3) and tighten two hose clamps (2). Tighten clamps (2) to 10-20 lb-in. (1-2 N*m).

-

Connect two engine oil cooler supply and return lines (7) to engine oil cooler ports (9).

C. Cleaning And Inspection

-

Remove four socket-head screw and washer assemblies (5) and washers (6) securing oil cooler (4) to radiator (8).

-

Make four two-by-four wood blocks, 2-1/2 inches (63 mm) long. Raise oil cooler (4) 1-1/2 inches (38 mm) and place one block under each comer between oil cooler (4) and radiator (8).

3 - 8 . Engine And Transmission Oil Cooler Assembly Maintenance ( Co N T ' D)

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personal protective equipment (goggles/shield, gloves, etc.).

Using high water pressure when cleaning engine and transmission oil cooler and radiator can cause damage. High water pressure should not be directed at oil cooler or radiator.

-

Using water and compressed air, remove dirt, trash, and insects embedded in oil cooler (4) and radiator fins (8).

-

Inspect oil cooler (4) for breaks, punctures, cracks, and splits. Replace oil cooler (4), if damaged. 5. Remove four wood blocks. 6. Install oil cooler (4) on radiator (8) with four washers (6) and socket-head screw and washer

assemblies (5).

FOLLOW-ON TASKS: - Install power steering cooler (para. 8-28).

- Fill transmission oil to proper level (TM 9-2320-280-10). - Fill engine oil to proper level (TM 9-2320-280-10). - Install engine left splash shield (para. 10-17). - Start engine (TM 9-2320-280-10) and check for leaks.

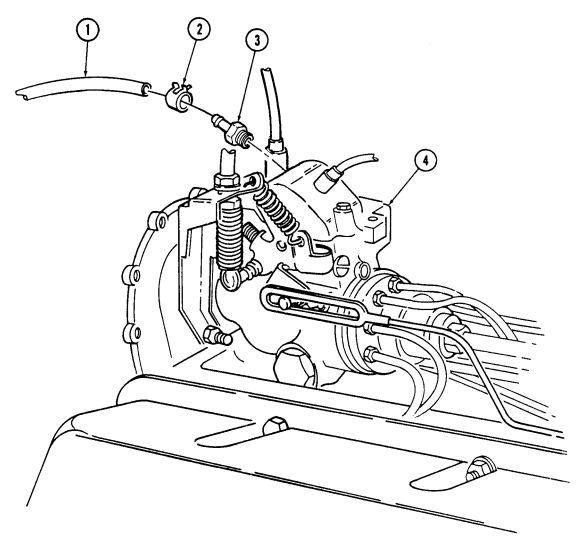

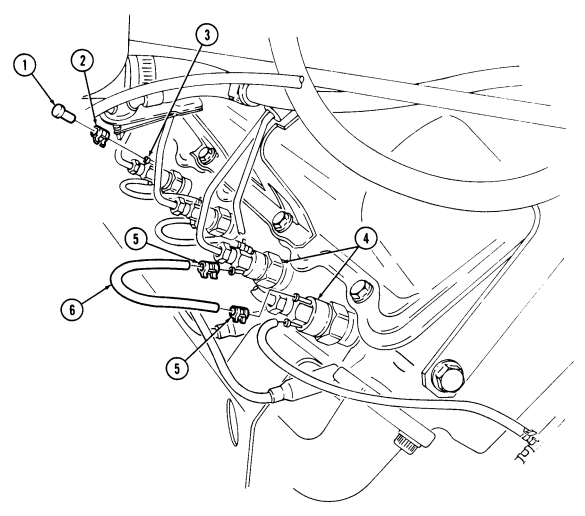

3-9. Crankcase Depression Regulator (Cdr) Valve And Bracket Maintenance

| This task covers: |

|---|

b. Removal d. Installation

INITIAL SETUP:

Tools Manual References

General mechanic's tool kit: TM 9-2320-280-10

automotive (Appendix B, Item 1) TM 9-2320-280-24P

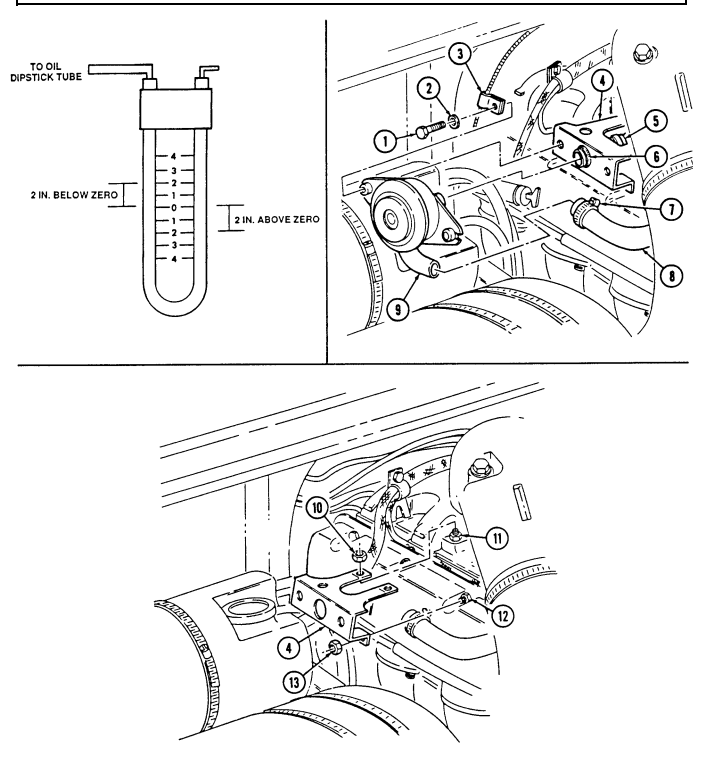

A. Testing

a. Testing c. Cleaning and Inspection

Test Equipment Equipment Condition

Manometer, U-tube Hood raised and secured (TM 9-2320-280-10).

(Appendix B, Section IV, Item L) Engine access cover removed (para. 10-15).

-

Remove engine oil dipstick from oil dipstick tube (para. 3-2).

-

Install manometer in dipstick tube. 3. Connect STE/ICE-R unit to DCA connector.

To read manometer, add amount the water column travels above zero to the amount the water column travels below zero.

-

Start engine and let idle; record water pressure. Pressure should be zero inches of water or a slight vacuum.

-

Increase engine speed to 2,000 rpm; record water pressure. Pressure should be 2-5 inches.

-

If pressures are not within specifications listed in steps 4 and 5, replace CDR valve (9) and repeat test.

-

Install oil dipstick in engine oil dipstick tube (para. 3-2).

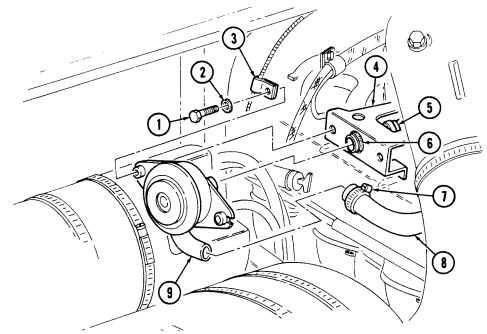

CDR valves on vehicles equipped with deep water fording kit contain two additional vent lines.

-

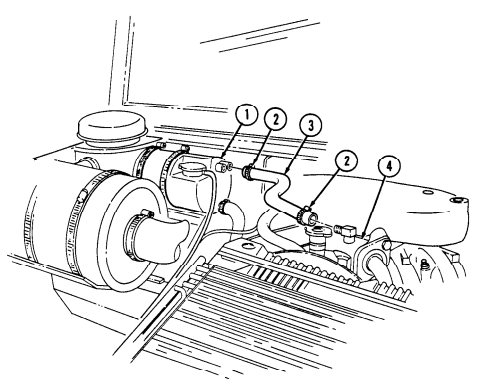

Loosen clamp (7) and discomect CDR valve oil fill tube hose (8) from CDR valve (9). 2. Loosen clamp (6) on CDR valve intake manifold hose (5). 3. Remove two screws (1), washers (2), CDR valve (9), and heater control cable clamp (3) horn CDR valve bracket (4).

-

Remove two nuts (10) from CDR valve bracket (4) and two intake manifold studs (11). 5. Remove two nuts (13) and CDR valve bracket (4) from two valve cover studs (12).

3-9. CRANKCASE DEPRESSION REGULATOR (CDR) VALVE AND BRACKET MAINTENANCE (Cont'd)

3-9. Crankcase Depression Regulator (Cdr) Valve And Bracket Maintenance (Cont'D)

c Cleaning and Inspection

Do not clean CDR valve with drycleaning solvent. Drycleaing solvent will damage the diaphragm inside the CDR valve.

-

Clean oil and carbon deposits from the CDR valve (9) with a clean, lint-flee cloth.

-

Inspect the CDR valve (9) and lines for leaks, cracks, and restrictions. Replace if damaged.

d. Installation 1. 2.

Connect CDR valve (9) to intake manifold hose (5) and tighten clamp (6). Install CDR valve (9) and heater control cable clamp (3) on CDR valve bracket (4) with two washers (2) and screws (1). Tighten screws (1) to 15 lb-ft (20 N.m).

Connect CDR valve oil fill tube hose (8) to CDR valve (9) and tighten clamp (7).

Install CDR valve bracket (4) on two intake manifold studs (12) and two valve cover studs (13).

Secure CDR valve bracket (4) to intake manifold (11) with two nuts (10). Tighten nuts (10) to 15 lb-ft (20 N.m).

Secure CDR valve bracket (4) to valve cover studa (13) with two nuts (14). Tighten nuts (14) to 10 lb-ft (14 N.m).

3-9. CRANKCASE DEPRESSION REGULATOR (CDR) VALVE AND BRACKET MAINTENANCE (Cont'd)

FOLLOW-ON TASKS: - Lower and secure hood (TM 9-2320-280-10).

· Install engine access cover (para. 10-15).

3-10. Cdr Valve Hoses Replacement

This task covers: INITIAL SETUP: Manual References TM 9-2320-280-10 TM 9-2320-280-24P

A. Removal B. Installation

Tools Equipment Condition General mechanic's tool kit: Hood raised and secured (TM 9-2320-280-10).

automotive (Appendix B, Item 1) Engine access cover removed (para. 10-15).

CDR valve and bracket removed (para. 3-9).

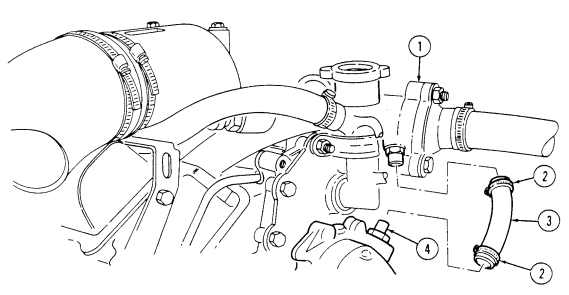

-

Loosen clamp (2) and disconnect CDR valve intake manifold hose (1) from intake manifold (7).

-

Inspect adapter (3) for breaks or cracks. Replace if defective.

-

Loosen clamp (5) and disconnect CDR valve oil fill tube hose (4) from oil fill tube (6).

-

Connect CDR valve oil fill tube hose (4) to oil fill tube (6) and tighten clamp (5).

- Connect to CDR valve intake manifold hose (1) to intake manifold (7) and tighten clamp (2).

FOLLOW-ON TASKS: Install CDR valve and bracket (para. 3-9).

Lower and secure hood (TM 9-2320-280-10).

Install engine access cover (para. 10-15).

Section II. Fuel System Maintenance

| b. Installation a. Removal | |

|---|---|

| Tools Manual References | |

| General mechanic's tool kit | TM 9-2320-280-10 |

| automotive (Appendix B, Item 1) TM 9-2320-280-24P | |

| Materials/Parts Equipment Condition | |

| Lubricating oil (Appendix C, Item 31) Hood raised and secured (TM 9-2320-280-10). | |

| 1. Loosen clamp (2) and disconnect CDR valve hose (1) from engine oil filler tube (3). | |

| 2. Remove two nuts (4), washers (5), and engine oil filler tube (3) from timing chain cover (7) and | |

| studs (8). | |

| 3. Inspect grommet (6) for breaks or cracks. Replace if defective. | |

| 1. Coat grommet (6) with lubricating oil. | |

| 2. Install engine oil filler tube (3) into timing chain cover (7) with two washers (5) and nuts (4). Tighten nuts (4) to 13-20 lb-ft (18-27 N.m). | |

| 3. Connect CDR valve hose (1) to engine oil filler tube (3) and tighten clamp (2). | |

| FOLLOW-ON TASK: Lower and secure hood (TM 9-2320-280-10). |

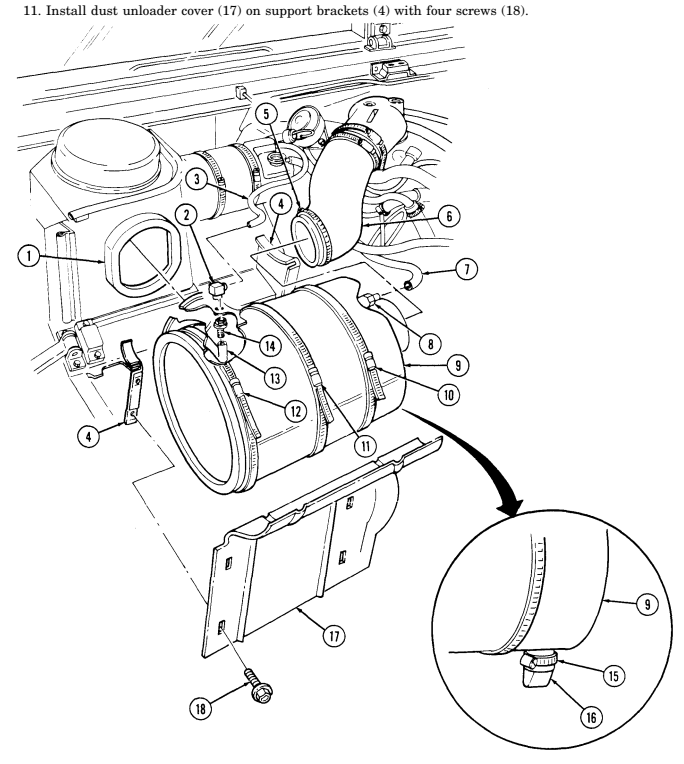

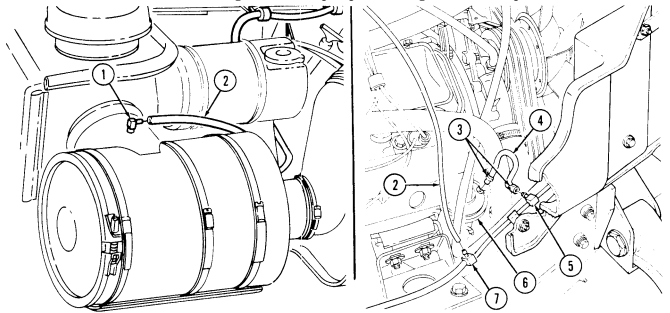

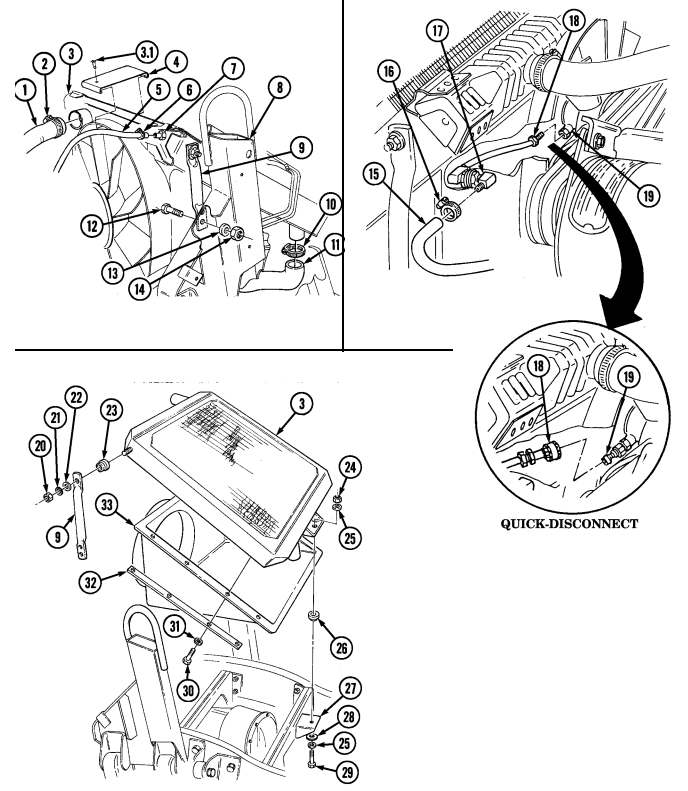

3 - 1 2 . Air Cleaner Assembly And Dust Unloader Maintenance

This task covers: a. Removal c . Installation b. Inspection INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Equipment Condition Hood raised and secured (TM 9-2320-280-10).

Manual Refere n c e s TM 9-2320-280-10 TM 9-2320-280-24P

Note

For dust unloader replacement, perform steps 1 and 2 only.

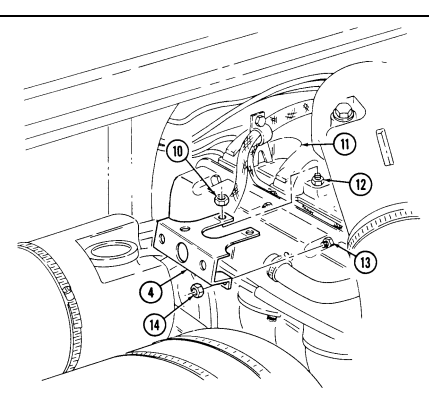

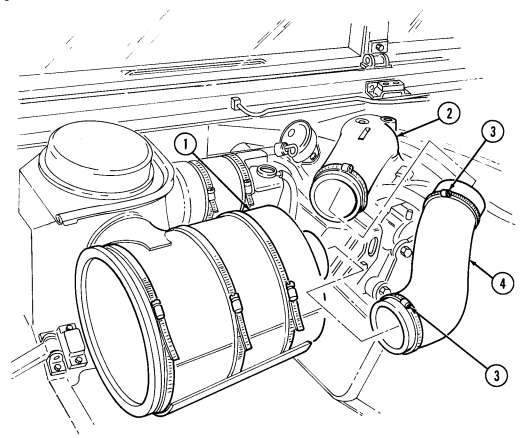

a. Removal 1. Remove four screws (18) and dust unloader cover (17) from support brackets (4). 2. Loosen clamp (15) and remove dust unloader (16) from air cleaner assembly (9). 3. Loosen clamp (5) and disconnect elbow (6) from air cleaner assembly (9). 4. Disconnect air restriction gauge hose (7) from fitting (8). 5. Remove outer strap clamps (10) and (12) securing air cleaner assembly (9) to support brackets (4). 6. Disconnect vent line (3) from elbow (2). 7. Remove air cleaner assembly (9) from support bracket (4). 8. Remove elbow (2) from air cleaner assembly (9). 9. Remove adapter (14) and tube (13) from air cleaner assembly (9).

-

Remove fitting (8) from air cleaner assembly (9).

-

Remove clamp (11) from air cleaner assembly (9).

b. Inspection 1. Inspect gasket (1) for cracks or brakes. Replace gasket (1) if defective. 2. Inspect elbow (2), fitting (8), and adapter (14) for damaged threads or cracks. Replace if defective.

c. Installation

Note

For dust unloader replacement, perform steps 10 and 11 only.

-

Install clamp (11) on air cleaner assembly (9). 2. Install fitting (8) on air cleaner assembly (9). 3. Install tube (13) on adapter (14). 4. Install tube (13) and adapter (14) on air cleaner assembly (9). 5. Install elbow (2) to air cleaner assembly (9). 6. Install air cleaner assembly (9) on support brackets (4) with strap clamps (10) and (12). Make sure clamp tabs are facing downward away from cab before tightening. Tighten the following clamps in sequence as follows: (10), (11), and (12).

-

Connect elbow (6) to air cleaner assembly (9) and tighten clamp (5). 8. Connect air restriction gauge hose (7) to fitting (8). 9. Connect vent line (3) to elbow (2).

3-12. Air Cleaner Assembly And Dust Unloader Maintenance (Cont'D)

- Install dust unloader (16) on air cleaner assembly (9) and tighten clamp (15) to 45-50 lb-in.

(5-6 N.m).

FOLLOW-ON TASK: Lower and secure hood (TM 9-2320-280-10).

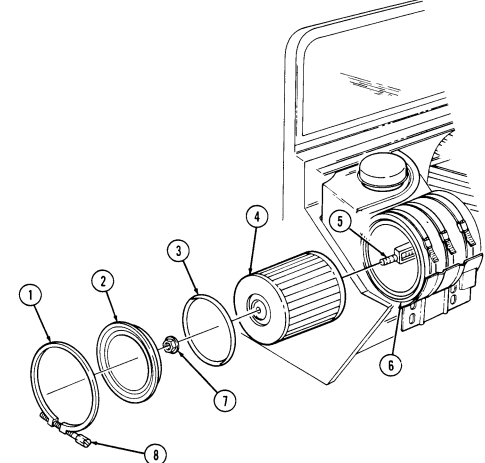

3 - 1 3 . Air Cleaner Filter Element Serv I C I N G

This task covers: a. Removal d. Cleaning b. Inspection e. Installation c. Emergency Cleaning INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Detergent (Appendix C, Item 17) Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition Hood raised and secured (TM 9-2320-280-10).

General Safety Instructions

-

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa).

-

If NBC contamination is suspected, consult NBC officer or NBC NCO for appropriate handling instructions.

-

Improper cleaning methods and use of unauthorized cleaning liquids can injure personnel and cause damage to equipment. Do not use anything other than compressed air, water, and detergent to clean elements.

-

If NBC contamination is suspected, consult NBC officer or NBC NCO for appropriate handling instructions.

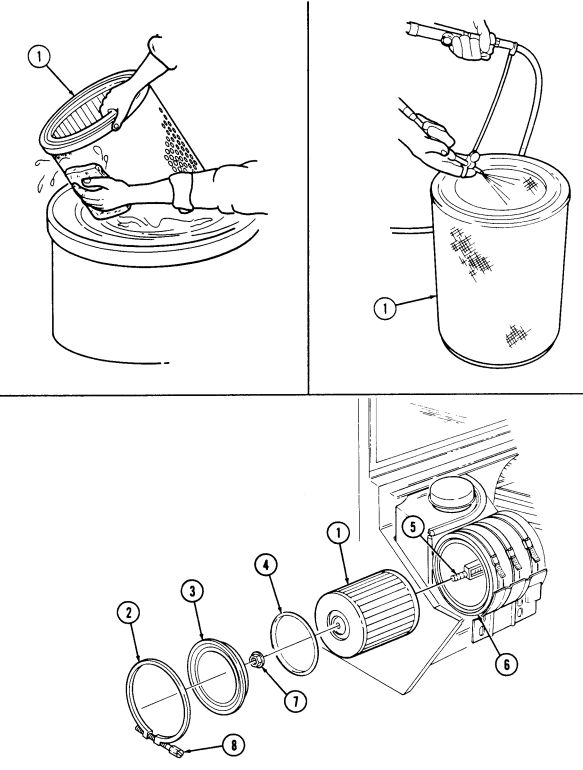

a. Removal 1. Loosen bolt (8), and remove ring clamp (1), cover (2), and gasket (3) from air cleaner assembly (6). 2. Remove nut and washer assembly (7) and filter element (4) from stud (5) and air cleaner assembly (6).

- Cover housing opening with screen or rag to prevent contaminants from entering the air intake system and damaging your engine.

B. Inspection

- Check gasket (3) for dents, tears, rips, and other damage. Make sure the gasket has not taken a set.

Make sure there are no hard dirt ridges on the sealing surfaces.

-

Inspect filter element (4) for holes and tears by looking through the element toward a bright light. If pinpoints of light shine through, replace the element. Holes that are large enough to let light through are large enough to let contaminants through. Another way to check for leaks or damage is to look for uneven dirt patterns. Make sure there is no rust or flaking paint on metal parts of the filter. If the filter has already been cleaned three times, or if you find damage, replace it.

-

Check air cleaner assembly (6) for holes, dents, rust, or any other damage that will interfere with proper sealing and allow unfiltered air to enter and destroy engine.

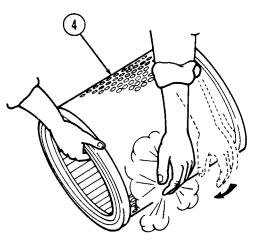

c. Emergency Cleaning

Do not strike ends of filter element on hard surface or damage to filter element may result.

Remove dust or sand from filter element (4) by holding it so neither end faces ground. Gently tap around filter element (4) to free dust and sand.

3-13. Air Cleaner Filter Element Servicing (Cont'D)

3-13. Air Cleaner Filter Element Servicing (Cont'D)

Compressed air used for cleaning purpose will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personnel protective equipment (goggles/shield, gloves, etc.).

Hold nozzle at least one inch away from element (1) and direct compressed air against clean side of element (1) (in direction opposite to normal air flow). Move air stream up and down length of pleats until you can not see dust being blown out.

Prepare a solution of five gallons warm water (80-110° F (26.7-43.3° C)) and approximately one cup of non-sudsing detergent in a container large enough to submerge the element (1). Never use gasoline or solvents of any kind to clean elements. Immerse the element (1) completely in the cleaning solution. Swish for two minutes. Soak the element in the cleaning solution for 15 to 20 minutes, then swish it around again to remove contaminants.

Remove the element (1) from the solution and let it drain.

Rinse the element with cool water (35-80° F (1.7-26.7° C)) from clean side to dirty side (in direction opposite to normal air flow) with a gentle stream of water (no more than 40 psi (275.8 kpa)). If the clean side was contaminated during the soak cycle, rinse the element from both sides.

Air dry the element (1) at normal room temperature until completely dry. Usually overnight is adequate, but temperature and humidity will effect drying time. If you use circulating air, do not exceed 180° F (82.2° C). Do not use compressed air to speed drying time, you will damage your element. Reinspect the element (1) and discard if damaged. If it checks out O.K., mark the date of cleaning on it.

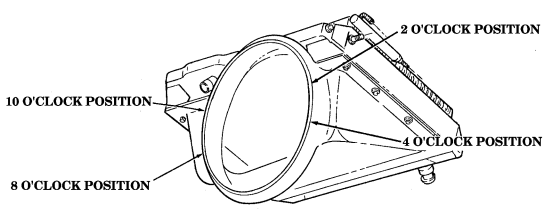

E. Installation

- Remove screen or rag from housing opening. 2. Install filter element (1) into air cleaner assembly (6) and on stud (5) with nut and washer assembly (7). Tighten nut and washer assembly (7) to 20-40 lb-in (2-4 N-m).

When cover clamp is secured to end of filter body assembly, ensure the clamp bolt is between the three and six o'clock position to prevent damaging hood when hood is closed.

- Install cover (3) and gasket (4) on air cleaner assembly (6) with ring clamp (2) as shown. Tighten bolt (8) to 35-40 lb-in (3-4 N-m).

3-13. Air Cleaner Filter Element Servicing (Cont'D)

FOLLOW-ON TASKS: - Lower and secure hood (TM 9-2320-280-10).

- Start engine (TM 9-2320-280-10) and ensure air restriction gauge on instrument panel does not show red.

3-14. Air Horn Replacement

This task covers: INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Two flat washers (Appendix G, Item 37) Gasket (Appendix G, Item 41) Sealing compound (Appendix C, Item 40)

a. Removal b. Installation

| Equipment Condition |

|---|

| Hood raised and se |

| Manual References |

|---|

| TM 9-2320-280-24P |

Hood raised and secured (TM 9-2320-280-10).

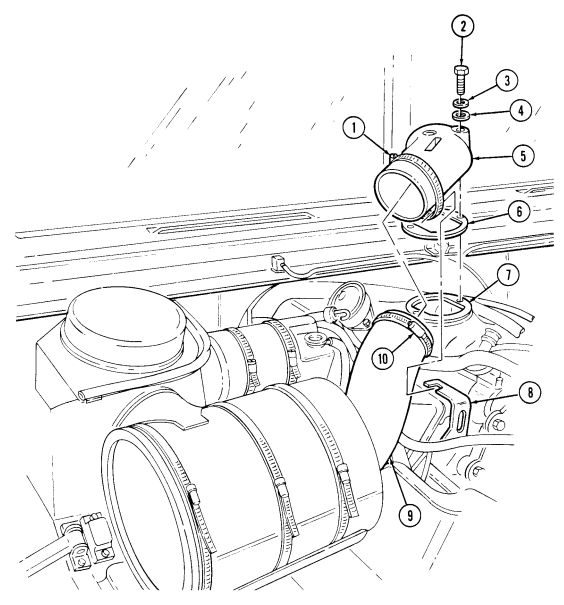

a. Removal 1. Remove two screws (2), washers (3), and flat washers (4) securing air horn (5) to intake manifold (7). Discard flat washers (4).

- Loosen clamp (10) and disconnect air intake elbow (9) from air horn (5).

Cover opening of intake manifold to prevent foreign material from entering engine.

-

Loosen clamp (1) securing air horn (5) to engine lift bracket (8) and slide clamp (1) from engine lift bracket (8). Remove air horn (5) from intake manifold (7).

-

Remove gasket (6) from intake manifold (7). Discard gasket (6). 5. Remove clamp (1) from air horn (5).

B. Installation

-

Install clamp (1) on air horn (5). 2. Install gasket (6) on intake manifold (7). 3. Coat threads of screws (2) with sealing compound. Install air horn (5) on intake manifold (7) with two flat washers (4), washers (3), and screws (2). Tighten screws (2) to 40-45 lb-in. (5-6 N•m).

-

Connect elbow (9) to air horn (5) and tighten clamp (10) to 45-50 lb-in. (5-6 N•m). 5. Slide clamp (1) on engine lift bracket (8) and air horn (5) and tighten clamp (1) to 40-45 lb-in.

(5-6 N•m).

FOLLOW-ON TASK: Lower and secure hood (TM 9-2320-280-10).

3 - 1 5 . Air Horn-To-Air Cleaner Elbow Replacement

This task covers: a. Removal b. Installation INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Equipment Condition Hood raised and secured (TM 9-2320-280-10).

Manual References TM 9-2320-280-10 TM 9-2320-280-24P a. Removal 1. Loosen two clamps (3) and remove elbow (4) from air cleaner assembly (1) and air horn (2). 2. Remove two clamps (3) from elbow (4).

b. Installation 1. Install two clamps (3) on elbow (4). 2. Connect elbow (4) to air cleaner assembly (1) and air horn (2) and tighten two clamps (3). Tighten

clamps (3) to 40-45 lb-in. (5-6 N•m).

FOLLOW-ON TASK: Lower and secure hood (TM 9-2320-280-10).

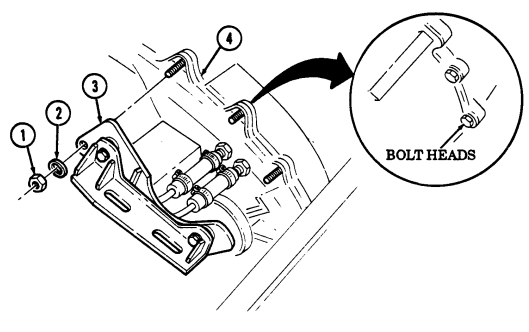

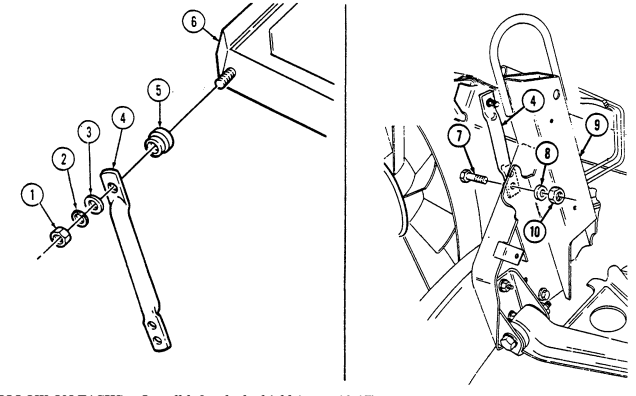

3-16. Air Horn Support Bracket Replacement

This task covers: INITIAL SETUP: Applicable Models All models except M997, M997A1, M997A2, M1036, M1037, M1042 Tools General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

a. Removal b. Installation Manual References TM 9-2320-280-24P Equipment Condition Air horn removed (para. 3-14).

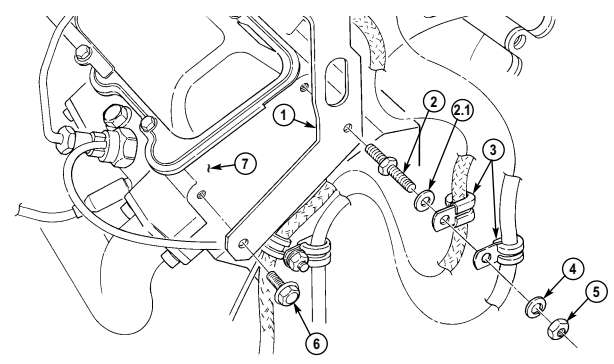

Lockwasher (Appendix G, Item 191) a. Removal 1. Remove nut (5), lockwasher (4), two clamps (3), washer (2.1), and stud (2) from air horn support bracket (1) and cylinder head (7). Discard lockwasher (4).

- Remove capscrew (6) and support bracket (1) from cylinder head (7).

b. Installation 1. Install air horn support bracket (1) on cylinder head (7) with stud (2). 2. Secure air horn support bracket (1) to cylinder head (7) with capscrew (6). Tighten capscrew (6) and stud (2) to 40 lb-ft (54 N•m).

- Install washer (2.1) and two clamps (3) on stud (2) with lockwasher (4) and nut (5).

FOLLOW-ON TASK: Install air horn (para. 3-14).

3-17. Air Restriction Gauge Replacement

This task covers: INITIAL SETUP:

a. Removal b. Installation

| Tools | Manual References |

|---|---|

| General mechanic's tool kit: | TM 9-2320-280-10 |

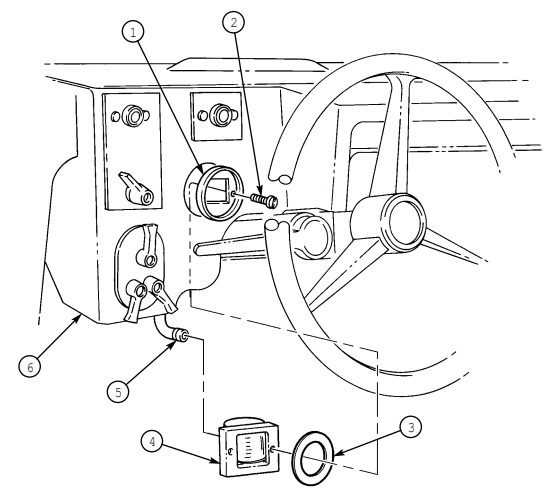

a. Removal 1. Remove two screws (2) and bezel (1) from air restriction gauge (4), and remove gauge (4) and gasket (3) from behind dash panel (6).

- Disconnect air restriction gauge hose (5) from gauge (4) and remove gauge (4).

b. Installation 1. Connect hose (5) to gauge (4). 2. Position gauge (4) and gasket (3) behind dash panel (6) and secure to bezel (1) with two screws (2).

FOLLOW-ON TASK: Start engine (TM 9-2320-280-10) and check operation of air restriction gauge.

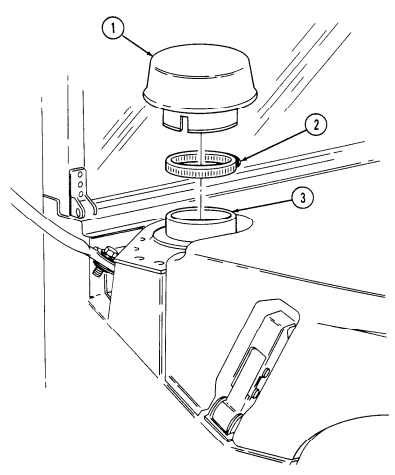

3-18. Weathercap Replacement

This task covers:

| a. Testing | c. Cleaning and Inspection |

|---|---|

| b. Removal | d. Installation |

| Tools | Manual References |

automotive (Appendix B, Item 1) Loosen clamp (2) and remove weathercap (1) from air intake duct (3).

b. Installation Install weathercap (1) on air intake duct (3) with clamp (2). Tighten clamp (2) to 45-50 lb-in. (5-6 Nom).

3-19. Air Restriction Gauge Hose Replacement

This task covers: INITIAL SETUP: Manual References TM 9-2320-280-10 TM 9-2320-280-24P

-

Loosen three clamps (2) from air restriction gauge hose (6) and "A" beam (1).

-

Disconnect hose (6) from air cleaner assembly (7). 3. Disconnect hose (6) from air restriction gauge (4) located behind instrument panel (5).

-

Remove hose (6) by routing out from three clamps (2) through two grommets (3) in "A" beam (1).

b. Installation 1. Route hose (6) through three clamps (2) and two grommets (3) in "A" beam (1) to air cleaner assembly (7) and gauge (4).

- Connect hose (6) to air cleaner assembly (7). 3. Connect hose (6) to gauge (4).

- Tighten three clamps (2) on hose (6) and "A" beam (1).

FOLLOW-ON TASKS: Install engine access cover (para. 10-15).

Lower and secure hood (TM 9-2320-280-10).

a. Removal b. Installation Tools Equipment Condition General mechanic's tool kit: Engine access cover removed (para. 10-15).

automotive (Appendix B, Item 1) Hood raised and secured (TM 9-2320-280-10).

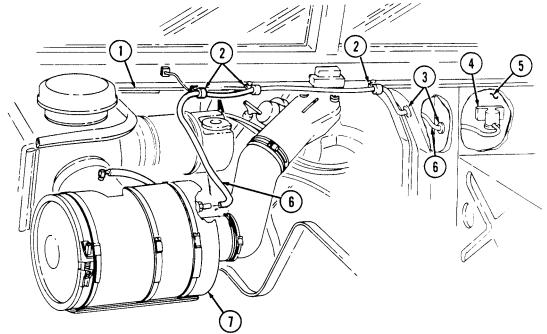

3-20. Air Intake And Fuel Pump Vent Lines Replacement

This task covers: a. Removal b. Installation INITIAL SETUP: Tools Equipment Condition automotive (Appendix B, Item 1) General mechanic's tool kit: Hood raised and secured (TM 9-2320-280-10).

Manual References TM 9-2320-280-10 TM 9-2320-280-24P

For fuel pump vent line replacement, perform steps 2, 3, and 4 only.

a. Removal 1. Remove vent line (2) from air cleaner fitting (1) and tee fitting (7).

- Loosen clamp (3) and disconnect vent line (4) from fuel pump (6). 3. Loosen clamp (3) and remove vent line (4) from tee fitting (5). 4. Remove two clamps (3) from vent line (4).

b. Installation

For fuel pump vent line replacement, perform steps 2 and 3.

- Connect vent line (2) to tee fitting (7) and air cleaner fitting (1). 2. Install two clamps (3) to vent line (4).

3. Install vent line (4) on tee fitting (5) and fuel pump (6) and tighten two clamps (3).

3. Install vent line (4) on tee fitting (5) and fuel pump (6) and tighten two clamps (3).

FOLLOW-ON TASK: Lower and secure hood (TM 9-2320-280-10).

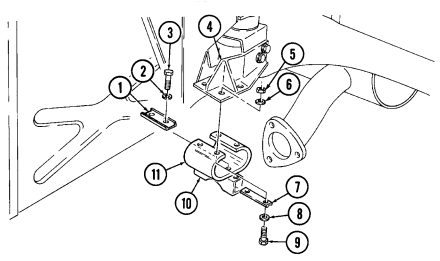

3-21. Drainage Bracket Replacement

This task covers: a. Removal b. Installation INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Equipment Condition Air cleaner assembly removed (para. 3-12).

Manual References TM 9-2320-280-24P a. Removal Remove three screws (2) and drainage bracket (3) from body (1).

b. Installation Install drainage bracket (3) on body (1) with three screws (2).

FOLLOW-ON TASK: Install air cleaner assembly (para. 3-12).

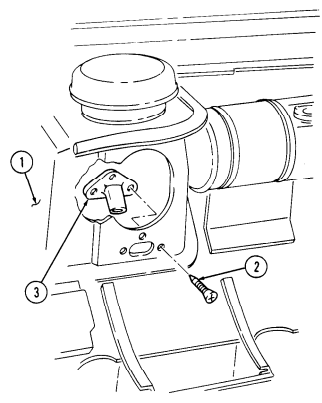

3-22. Fuel Injection Pump Boot Replacement

This task covers: a. Removal b. Installation INITIAL SETUP: automotive (Appendix B, Item 1) Tools Equipment Condition General mechanic's tool kit: Hood raised and secured (TM 9-2320-280-10).

Manual References TM 9-2320-280-10 TM 9-2320-280-24P Remove clamp (3) and boot (2) from injection pump (1).

Install boot (2) on injection pump (1) with clamp (3).

FOLLOW-ON TASK: Lower and secure hood (TM 9-2320-280-10)

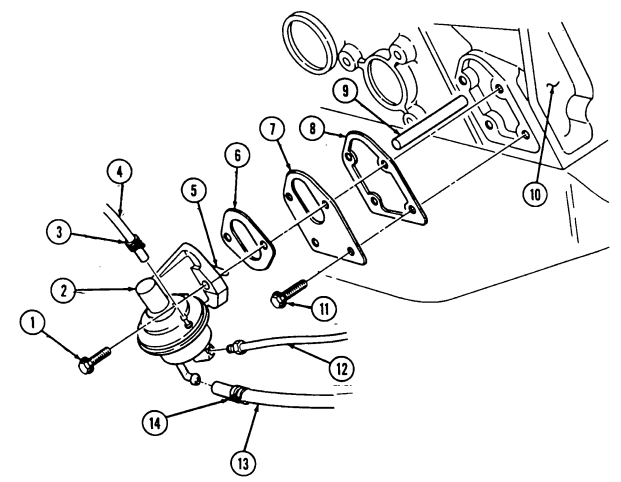

3-23. Fuel Pump Replacement

This task covers: INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Mounting plate gasket (Appendix G, Item 198) Fuel pump gasket (Appendix G, Item 40) Grease (Appendix C, Item 22) Manual References TM 9-2320-280-10 TM 9-2320-280-24P

a. Removal b. Installation

Equipment Condition

Battery ground cable disconnected (para. 4-73).

General Safety Instructions - Do not perform this procedure near fire, flames, or sparks.

- Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be disposed of IAW current directives.

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

a. Removal

Cover or plug all open hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

Have drainage container ready to catch fuel.

-

Loosen clamp (14) and disconnect fuel inlet line (13) from fuel pump (2) and allow fuel to drain into container.

-

Disconnect fuel outlet line (12) from fuel pump (2) and allow fuel to drain into container. 3. Loosen clamp (3) and disconnect vent line (4) from fuel pump (2).

Gaskets installed on some 6.2L engines assembled prior to 1991 may contain asbestos. Gaskets should be removed with a scraper or putty knife and then be disposed of IAW current directives. Inhalation of asbestos fibers can cause respiratory ailments.

-

Remove two capscrews (1), fuel pump (2) and gasket (6) from fuel pump mounting plate (7). Discard gasket (6).

-

Remove two capscrews (11), fuel pump mounting plate (7) and gasket (8) from cylinder block (10).

Discard gasket (8).

- Remove pushrod (9) from cylinder block (10).

3-23. Fuel Pump Replacement (Cont'D)

b. Installation

Place GAA grease on pushrod to retain in cylinder block during installation.

-

Insert pushrod (9) into cylinder block (10). 2. Install gasket (8) and mounting plate (7) into block (10) with two capscrews (1) for alignment of pump (2) to cylinder block (10).

-

Secure gasket (8) and mounting plate (7) to cylinder block (10) with two capscrews (11). Tighten capscrews (11) to 4-7 lb-ft (5-10 N•m) then remove two capscrews (1).

-

Install gasket (6) and fuel pump (2) on fuel pump mounting plate (7) and block (10), ensuring alignment of lever (5) to pushrod (9) with two capscrews (1). Tighten capscrews (1) to 20-30 lb-ft (27-41 N•m).

-

Connect vent line (4) to fuel pump (2) and tighten clamp (3) to 10-20 lb-in. (1-2 N•m). 6. Connect fuel outlet line (12) to fuel pump (2). 7. Connect fuel inlet line (13) to fuel pump (2) and tighten clamp (14).

FOLLOW-ON TASKS: - Connect battery ground cable (para 4-73).

- Start engine (TM 9-2320-280-10) and check fuel pump and hoses for fuel leaks.

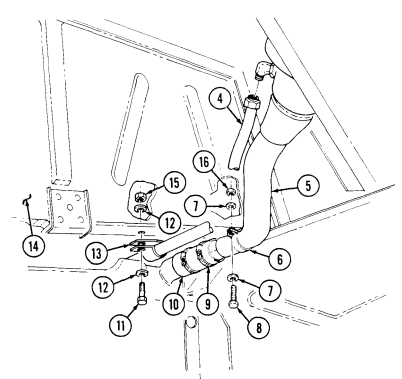

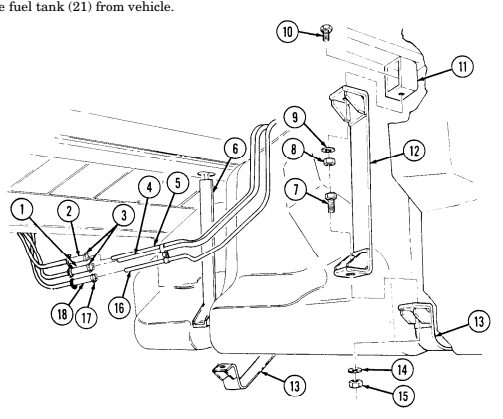

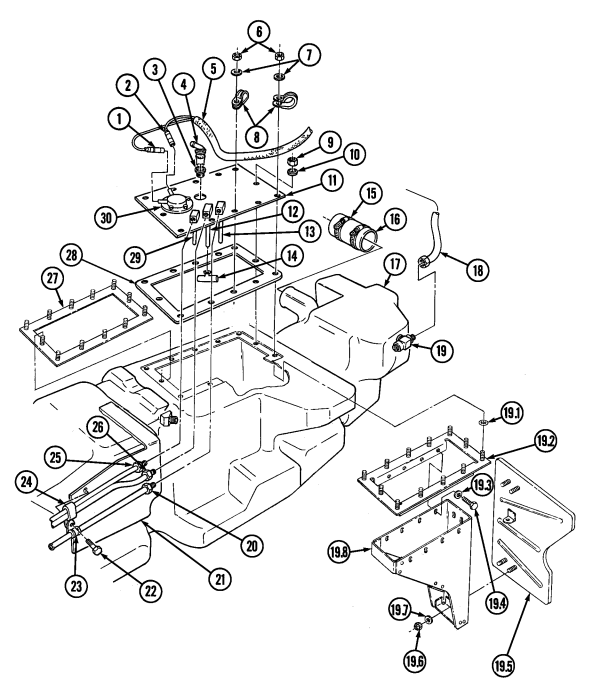

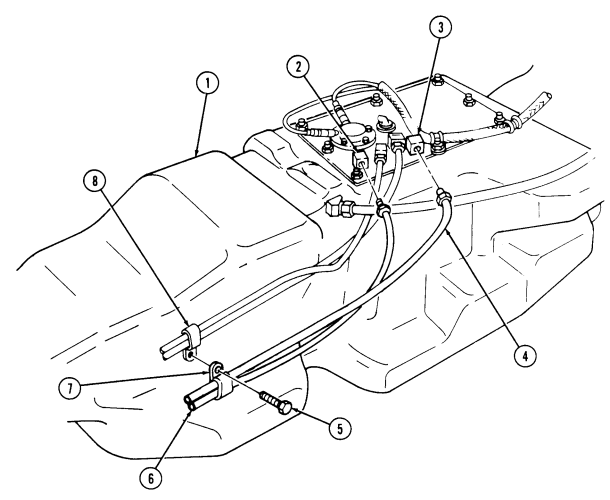

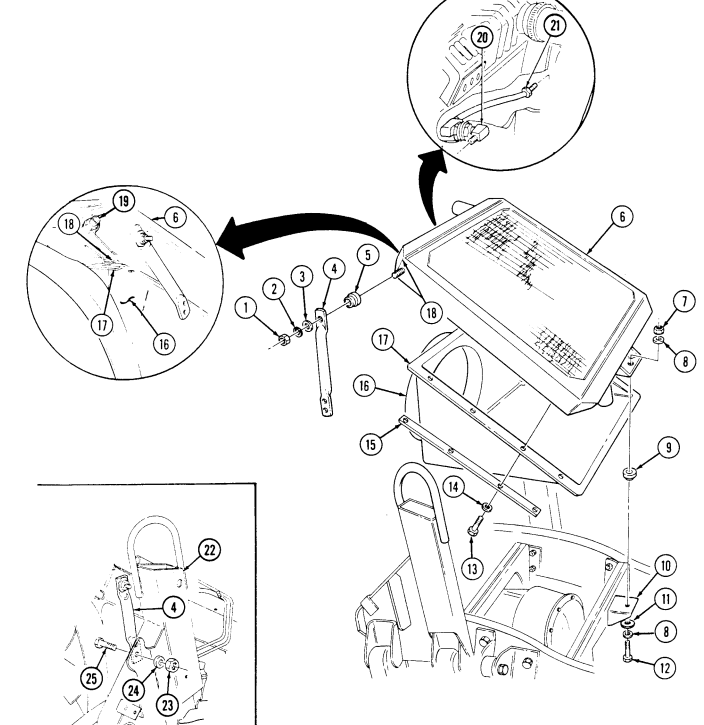

3-24. Fuel Tank Maintenance (Cont'D)

This task covers: c. Disassembly f. Installation INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

Access cover gasket (Appendix G, Item 1) Fifteen locknuts (Appendix G, Item 70) Adhesive (Appendix C, Item 1) Sealing compound (Appendix C, Item 46) Drycleaning solvent (Appendix C, Item 18) Twelve O-rings (Appendix G, Item 215) Personnel Required One mechanic One assistant a. Draining d. Cleaning and Inspection b. Removal e. Assembly

Manual References

TM 9-2320-280-10 TM 9-2320-280-24P

Equipment Condition

-

Battery ground cable disconnected (para. 4-73).

-

Rear propeller shaft removed (para. 6-4).

General Safety Instructions

-

Do not perform this procedure near fire, flames, or sparks.

-

Cleaning will be done in a well-ventilated area and a fire extinguisher will be kept nearby when solvent is used.

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

Have drainage container ready to catch fuel.

A. Draining

- Remove fuel tank filler cap (1). 2. Remove drainplug (3) from fuel tank (2). Allow fuel to completely drain into container.

Do not overtighten drainplug. Drainplug must not turn in hole. Sharp edge of hole may cut rubber.

- Install drainplug (3) flush with bottom of fuel tank (2) and tighten.

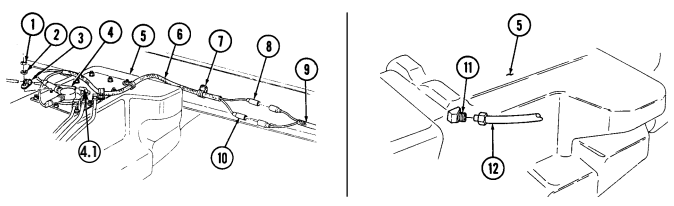

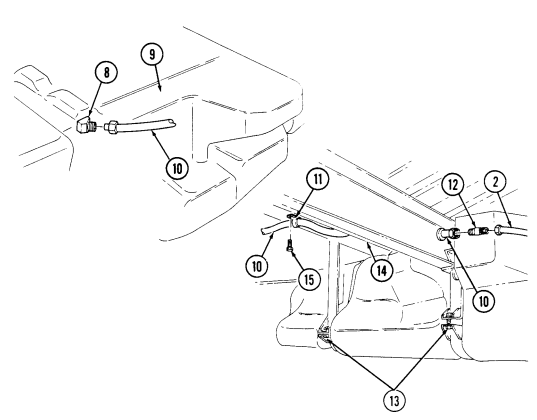

b. Removal 1. Disconnect large vent line (4) from filler spout (5). 2. Remove locknut (15), washer (12), capscrew (11), washer (12), and clamp (13) from vent line (4) and body (14).

Discard locknut (15).

-

Remove locknut (16), washer (7), capscrew (8), washer (7) and clamp (6) from filler spout (5). Discard locknut (16).

-

Loosen clamp (9) and remove hose (10) from filler spout (5).

3-24. Fuel Tank Maintenance (Cont'D)

3-24. Fuel Tank Maintenance (Cont'D)

Remove two nuts (15), washers (14), and capscrews (7) from fuel tank support straps (6) and (12) and remove lower straps (13).

Loosen two clamps (3) and disconnect fuel supply hoses (1) and (2) from fuel return line (4) and supply line (5).

Perform step 7 if vehicle is equipped with an arctic heater and/or troop/cargo wintenzation kit.

Loosen clamp (17) and disconnect fuel supply hose (18) from arctic heater and/or troop/cargo heater fuel supply line (16).

Disconnect vent line (20) from tee (19).

Remove capscrew (22) and clamp (23) securing vent line (20) to body (24). Remove locknut (8), washer (9), capscrew (10) and rear strap (12) from strap bracket (11). Discard locknut (8). Lower fuel tank (21) for access to vent line (29) and clamp (28).

Disconnect vent line (20) from fitting (25) on fuel tank (21). Remove locknut (26) and washer (27) securing clamp (28) and vent line (29) to fuel tank (21). Discard locknut (26).

Disconnect vent line (29) from vent line housing (30).

Prior to removal, tag leads for installation.

Disconnect jumper leads 58J (33) and 28B (35) from body wiring harness (34).

Bend clamp (32) down and remove jumper harness (31).

3-24. Fuel Tank Maintenance (Cont'D)

3-24. Fuel Tank Maintenance (Cont'D)

c. Disassembly 1. Thoroughly clean outside of tank (17) to prevent dirt contamination. 2. Disconnect fuel supply line (26) from fuel supply tube (12) and fuel return line (25) from fuel return tube (29).

Note

Perform step 3 if vehicle is equipped with an arctic heater.

-

Disconnect arctic heater fuel supply line (20) from arctic heater fuel supply tube (13). 4. Remove capscrew (22) and clamp (24) securing fuel supply line (26), fuel return line (25), and shield (21) to fuel tank (17). Remove arctic heater fuel supply line (20), and clamp (23) if installed.

-

Remove two locknuts (6) and washers (7) securing two clamps (8) and jumper harness (5) to access cover (11). Discard locknuts (6).

Note

Prior to removal, tag leads for installation.

- Disconnect jumper harness leads 28B (1) and 58J (2) from fuel level sender (30) and remove jumper harness (5).

Note

Perform steps 7 and 8 for vehicles with fuel tank P/N 12358588.

-

Remove nine locknuts (9) and washers (10) securing access cover (11), gasket (28), and retainer (27) to fuel tank (17). Discard locknuts (9).

-

Remove access cover (11), gasket (28), and retainer (27) from fuel tank (17). Discard gasket (28).

Note

Perform steps 8.1 through 8.5 for vehicles with fuel tank P/N 12460105.

8.1. Remove nine locknuts (9), washers (10), access cover (11), gasket (28), and retainer (19.2) from fuel tank (17). Discard locknuts (9) and gasket (28).

8.2. Remove eight capscrews (19.4), washers (19.3), and retainer (19.2) from support baffle (19.8). 8.3. Remove twelve O-rings (19.1) from retainer (19.2). Discard O-rings (19.1). 8.4. Remove four locknuts (19.6), washers (19.7), and support baffle (19.8) from fuel tank baffle (19.5).

Discard locknuts (19.6).

8.5. Remove support baffle (19.8) and fuel tank baffle (19.5) from fuel tank (17).

- Match mark position of elbow fittings on access cover (11).

Note

Note position of fuel strainer for installation.

-

Remove fuel strainer (14) from fuel supply tube (12).

-

Remove fuel supply tube (12) from access cover (11).

-

Remove fuel return tube (29) from access cover (11).

Note

- Perform step 13 if vehicle is equipped with an arctic heater. - Vehicles not equipped with an arctic winterization kit will have a plug instead of an arctic heater fuel supply tube.

- Remove arctic heater fuel supply tube (13) from access cover (11). 14. Remove vent valve (4) and grommet (3) from access cover (11). 15. Remove vent line (18) from tee (19). 16. Loosen clamp (15) and remove filler spout hose (16) from tank (17).

3-24. Fuel Tank Maintenance(Cont'D)

3-24. Fuel Tank Maintenance (Cont'D)

d. Cleaning and Inspection

________ Warning

Drycleaning solvent is flammable and will not be used near an open flame. A fire extinguisher will be kept nearby when the solvent is used. Use only in well-ventilated places. Failure to do this may result in injury to personnel or damage to equipment.

-

Use drycleaning solvent to clean access cover (3), fuel supply line (11), fuel return line (10), arctic heater fuel supply line (9), fuel supply tube (4), fuel return tube (13), arctic heater fuel supply tube (5), and inside fuel tank (7).

-

Inspect access cover (3), fuel supply line (11), fuel return line (10), fuel supply tube (4), fuel return tube (13), strainer (6), tee (8), fitting (12), vent line housing (2), and grommet (1) for cracks, wear, and breaks. Replace if cracked, worn, or broken.

-

Inspect arctic heater fuel supply line (9) and arctic heater fuel supply tube (5) for cracks, wear, and breaks, if installed. Replace if cracked, worn, or broken.

-

Inspect sending unit (14) for damage. Replace if damaged.

________

3-24. Fuel Tank Maintenance(Cont'D)

1

3-24. Fuel Tank Maintenance (Cont'D)

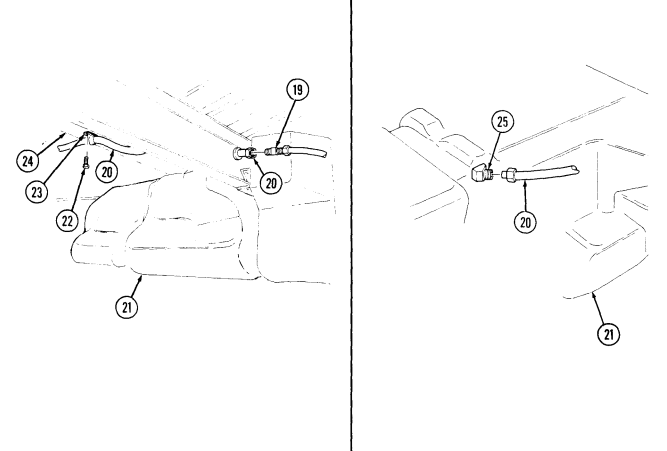

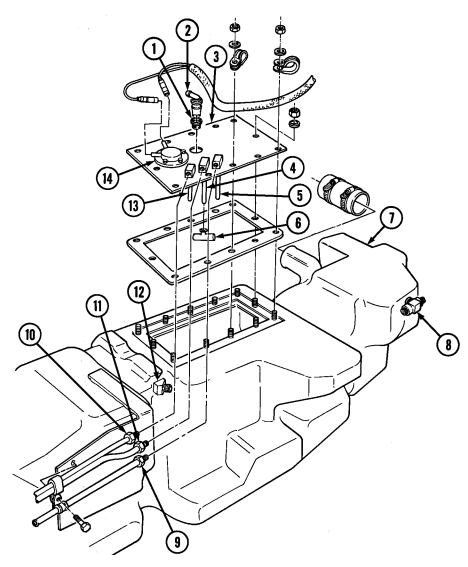

e. Assembly

Note

-

Use pipe sealant on all vent line and fuel line connector threads before installation.

-

Use fittings from old tank if installing new tank.

-

Install vent line (18) to tee fitting (19). 2. Install filler spout hose (16) on tank (17) and secure with clamp (15). 3. Apply sealing compound to threads of fuel supply tube (12), and install and align fuel supply tube (12) on access cover (11).

-

Apply sealing compound to threads of fuel return tube (29), and install and align fuel return tube (29) on access cover (11).

Note

Perform step 5 only if vehicle has an arctic heater installed.

-

Apply sealing compound to threads of arctic heater fuel supply line (13), and install and align arctic heater fuel supply line (13) on access cover (11).

-

Install grommet (3) and vent valve (4) to access cover (11). 7. Install fuel strainer (14) on fuel supply tube (12).

Note

Perform steps 7.1 through 7.4 for vehicles with fuel tank P/N 12460105.

7.1 Insert fuel tank baffle (19.5) and support baffle (19.8) into fuel tank (17). 7.2 Secure support baffle (19.8) to fuel tank baffle (19.5) with four washers (19.7) and locknuts (19.6). 7.3 Install twelve O-rings (19.1) on retainer (19.2), and secure retainer (19.2) to support baffle (19.8) with eight washers (19.3) and capscrews (19.4).

7.4 Apply adhesive to threads of nine locknuts (9), and install retainer (19.2), gasket (28), and access cover (11) on fuel tank (17) and with nine washers (10) and locknuts (9). Tighten locknuts (9) to 72 lb-in. (8 N•m).

Note Perform step 8 for vehicles with fuel tank P/N 12358588.

-

Apply adhesive to threads of nine locknuts (9), and install retainer (27), gasket (28), and access cover (11) on fuel tank (17) with nine washers (10) and locknuts (9). Tighten locknuts (9) to 72 lb-in. (8 N•m).

-

Connect jumper harness leads 28B (1) and 58J (2) to fuel level sender (30).

-

Apply adhesive to threads of two locknuts (6) and secure jumper harness (5) to fuel tank (17) with two clamps (8), washers (7), and locknuts (6). Tighten locknuts (6) to 72 lb-in. (8 N•m).

-

Connect fuel supply line (26) to fuel supply tube (12), and fuel return line (25) to fuel return tube (29).

Note

Perform step 12 if vehicle has an arctic heater installed.

- Connect arctic heater fuel supply line (20) to arctic heater fuel supply tube (13). 13. Secure shield (21), return line (25), supply line (26), clamp (24), and arctic heater fuel supply line (20) and clamp (23) if installed, to fuel tank (17) with capscrew (22).

3-24. FUEL TANK MAINTENANCE(Cont'd)

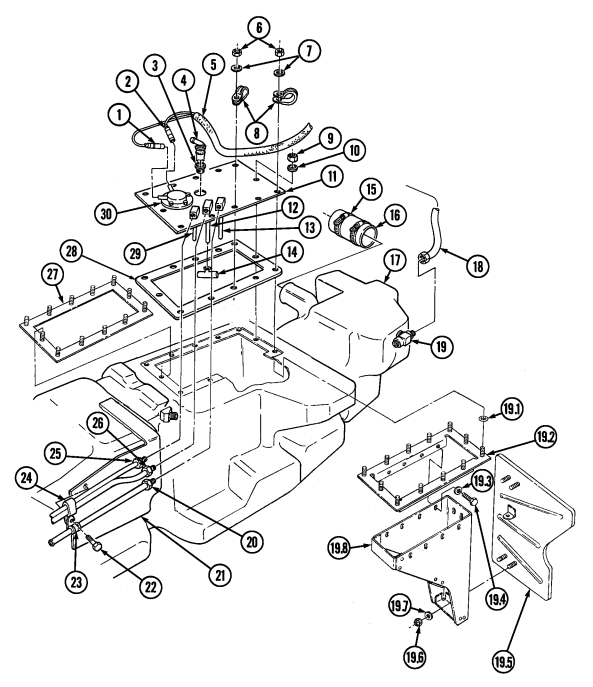

3-24. Fuel Tank Maintenance (Cont'D)

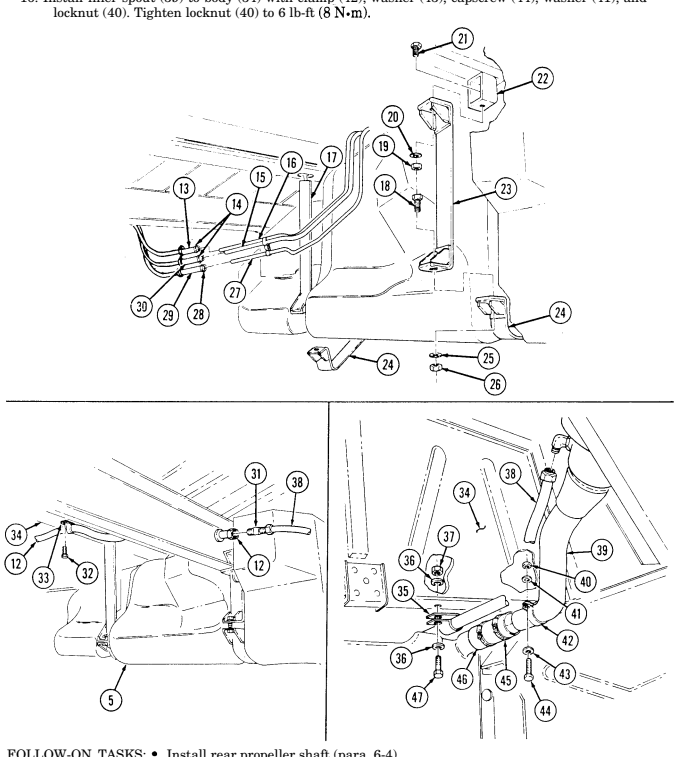

f. Installation 1. Position fuel tank (5) under vehicle. 2. Install jumper harness (6) on clamp (7) and bend clamp (7) up. 3. Connect jumper harness leads 58J (8) and 28B (10) to body wiring harness (9).

Use sealing compound on all vent line connector threads before installation.

3.1. Connect vent line (4) to vent line housing (4.1).

-

Connect vent line (4) to fuel tank (5) with clamp (3), washer (2), and locknut (1). Tighten locknut (1) to 6 lb-ft (8 N•m).

-

Connect vent line (12) on fitting (11) on fuel tank (5).

Apply adhesive to threads of capscrews.

- Install rear strap (23) on strap bracket (22) with capscrew (21), washer (20), and locknut (19). Tighten locknut (19) to 37 lb-ft (50 N•m).

Ensure front straps are flush with fuel tank and to right side of dimple in slot.

-

Raise fuel tank (5) and install two support straps (24) to straps (17) and (23) with two capscrews (18), washers (25), and locknuts (26). Do not tighten locknuts (26).

-

Connect vent line (12) to tee (31) on vent line (38). 9. Secure vent line (12) to body (34) with clamp (33) and screw (32).

-

Connect fuel supply hoses (13) and (30) to fuel return and supply lines (16) and (15) and secure with clamps (14).

Perform step 11 if vehicle is equipped with an arctic heater and/or troop/cargo winterization kit.

- Connect fuel supply hose (29) to arctic heater and/or troop/cargo heater fuel supply line (27) and secure with clamp (28).

Ensure upper and lower straps are 1/2 in. (12 mm) apart after tightening nuts. Straps should not touch when properly installed. Straps must be replaced if upper or lower straps touch.

-

Tighten locknuts (26) to 23-27 lb-ft (31-37 N•m).

-

Connect vent line (38) to filler spout (39). 14. Secure vent line (38) to body (34) with clamp (35), washer (36), capscrew (47), washer (36), and locknut (37).

3-24. Fuel Tank Maintenance (Cont'D)

-

Install filler spout (39) into hose (46) and tighten clamp (45).

-

Install filler spout (39) to body (34) with clamp (42), washer (43), capscrew (44), washer (41), and

· Connect battery ground cable (para. 4-73). · Fill fuel tank (TM 9-2320-280-10) and check for leaks.

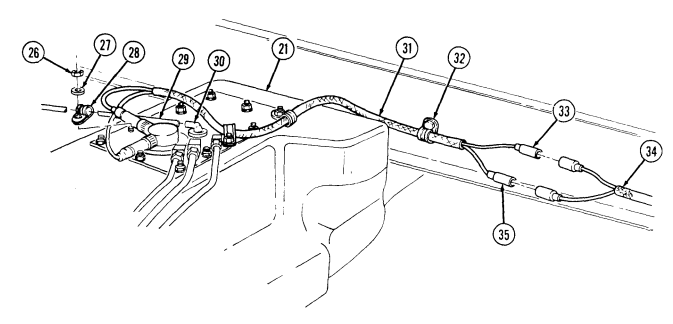

3-25. Fuel Tank Supply And Return Lines Replacement

This task covers: INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B,Item 1)

a. Removal b. Installation

Equipment Condition Engine right splash shield removed (para. 10-20).

General Safety Instructions Do not perform this procedure near fire, flames, or sparks.

Materials/Parts Two locknuts (Appendix G, Item 70) Manual References TM 9-2320-280-10 TM 9-2320-280-24P

________ W__ARn_I_N_G_

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

a. Removal

Ca_U_T_Io_N

Cover or plug all open hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

Have drainage container ready to catch fuel.

-

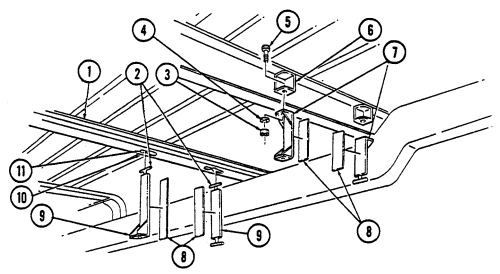

Loosen clamps (7) and disconnect hoses (6) from fuel tank return and supply lines (8). 2. Remove two locknuts (1), capscrews (5), washers (4), clamps (3) and return and supply lines (8) from front body bracket (2) and rear body bracket (10). Discard locknuts (1).

-

Remove three clips (9) securing lines together.

B. Installation

-

Install return and supply lines (8) on front body bracket (2) and rear body bracket (10) with two clamps (3), washers (4), capscrews (5), and locknuts (1).

-

Connect supply and return lines (8) to hoses (6) and tighten clamps (7). 3. Secure fuel supply and return lines (8) together with three clips (9).

FOLLOW-ON TASKS: - • Install engine right splash shield (para. 10-20).

- • - • - Fill fuel tank (TM 9-2320-280-10) and check for fuel leaks.

3-26. Auxiliary Fuel Pickup And Return Lines Replacement

This task covers: INITIAL SETUP: Applicable Models M1097, M1097A1, M1097A2, M1123 Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Sealing compound (Appendix C, Item 44) Tiedown strap (Appendix G, Item 311)

a. Removal b. Installation

Manual References TM 9-2320-280-24P Equipment Condition Fuel tank removed (para. 3-24).

General Safety Instructions Do not perform this procedure near fire, flames, or sparks.

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

a. Removal

Cover or plug all open hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

Have drainage container ready to catch fuel.

-

Remove screw (5) and clamp (7), securing fuel return line (6) and fuel pickup line (4) to fuel line clamp (8).

-

Remove fuel pickup line (4) from supply tube (3) on fuel tank (1). 3. Remove fuel return line (6) from supply tube (2).

b. Installation

Substitute tiedown strap for spring clamp when clamp is not available.

- Apply sealing compound to threads of fuel return line (6) and fuel pickup line (4). 2. Install fuel return line (6) to supply tube (2) on fuel tank (1). 3. Install fuel pickup line (4) to supply tube (3). 4. Install clamp (7) on fuel return line (6) and fuel pickup line (4) and secure to fuel line clamp (8) with screw (5).

3-26. Auxiliary Fuel Pickup And Return Lines Replacement (Cont'D)

3-27. Fuel Tank Vent Line And Filter Replacement

This task covers: INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Tiedown strap (Appendix G, Item 312) Locknut (Appendix G, Item 70)

a. Removal b. Installation

Manual References TM 9-2320-280-10 TM 9-2320-280-24P Equipment Condition

- Fuel tank removed (para. 3-24). - Hood raised and secured (TM 9-2320-280-10).

Cover or plug all open hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

For fuel tank vent line filter replacement, perform steps 5, 8, and 9 only.

A. Removal

- Remove clip (9) securing fuel tank vent line (3) to vent line (6). 2. Remove two capscrews (2) securing clamps (1) and (7) and vent lines (3) and (6) to brackets (8). 3. Remove tiedown strap (4) securing vent line (6) and fuel lines (5). Discard tiedown strap (4). 4. Disconnect vent line (3) from elbow (16). 5. Loosen two clamps (14) and remove vent line (15) from vent line filter (13) and elbow (16). 6. Remove two clamps (14) from vent line (15). 7. Remove two clamps (1) from vent line (3).

Perform step 8 only when deep water fording kit is installed.

- Disconnect deep water fording vent line (19) from vent line filter (13). 9. Remove capscrew (18), washer (11), locknut (12) clamp (10) and vent line filter (13) from body bracket (17). Discard locknut (12).

b. Installation

For fuel tank vent line filter replacement, perform steps 1, 2, and 5 only.

- Install clamp (10) and vent line filter (13) to body bracket (17) with washer (11), capscrew (18), and locknut (12).

Perform step 2 only when deep water fording kit is installed.

- Connect deep water fording vent line (19) to vent line filter (13).

3-27. Fuel Tank Vent Line And Filter Replacement (Cont'D)

-

Install two clamps (1) on vent line (3).

-

Install two clamps (14) on vent line (15).

-

Install vent line (15) to vent line filter (13) and elbow (16) and tighten two clamps (14).

-

Connect vent line (3) to elbow (16).

-

Install vent line (3) to vent line (6) and fuel lines (5) with tiedown strap (4).

-

Install vent lines (3) and (6) and two clamps (1) and (7) to brackets (8) with two capscrews (2).

-

Secure vent line (3) to vent line (6) with clip (9).

FOLLOW-ON TASKS: - Install fuel tank (para. 3-24).

· Lower and secure hood (TM 9-2320-280-10).

3-28. Fuel Tank Filler Cap And Spout Maintenance

This task covers: c. Installation INITIAL SETUP:

Tools

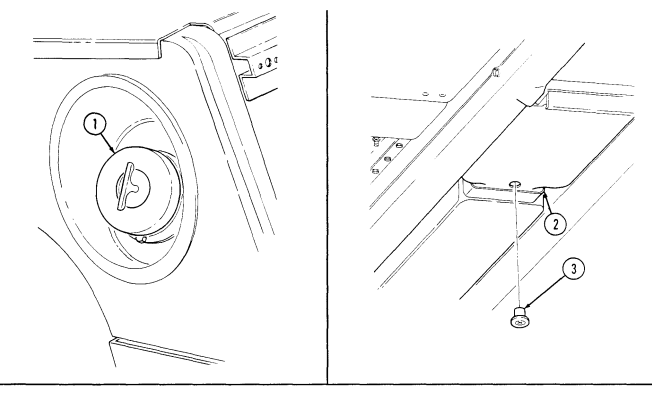

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Four locknuts (Appendix G, Item 70) Sealing compound (Appendix C, Item 44) Manual References TM 9-2320-280-10 TM 9-2320-280-24P a. Removal d. Fuel Filler Chain Removal b. Inspection e. Fuel Filler Chain Installation Equipment Condition Fuel tank drained (para. 3-24).

General Safety Instructions Do not perform this procedure near fire, flames, or sparks.

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

A. Removal

b. Inspection 1. Unscrew filler cap "T" handle (7) and remove filler cap (6) from filler spout (12). 2. Detach cap chain clip (8) from filler spout (12) and remove filler cap (6). 3. Disconnect vent line (1) from fitting (2). 4. Remove three locknuts (3), washers (4), capscrews (5), and washers (4) from spout mounting ring (9).

Discard locknuts (3).

- Loosen clamp (17) securing filler spout (12) to hose (18). 6. Remove locknut (13), washer (14), capscrew (16), washer (14), and clamp (15) from filler spout (12).

Discard locknut (13).

- Push filler spout (12) out of spout mounting ring (9) and remove filler spout (12) from hose (18). 8. Remove fitting (2) from filler spout (12). 9. Using handle (10), remove screen (11) from filler spout (12).

Inspect screen (11) for damage, debris, or blockage. Replace if damaged or if debris or blockage is detected.

C. Installation

-

Apply sealing compound to fitting (2) and install fitting (2) on filler spout (12). 2. Align filler spout (12) with hose (18) and push filler spout (12) into hose (18). 3. Install filler spout mounting ring (9) to body with three washers (4), capscrews (5), washers (4), and locknuts (3).

-

Secure hose (18) to filler spout (12) and tighten clamp (17). 5. Secure filler spout (12) to body with clamp (15), washer (14), capscrew (16), washer (14), and locknut (13).

Tighten locknut (13) to 6 lb-ft (8 N•m).

- Apply sealing compound to fitting (2) and connect vent line (1) to fitting (2).

3 - 2 8 . Fuel Tank Filler Cap And Spout Maintenance ( C O N T ' D )

- Using handle (10), install screen (11) in filler spout (12). 8. Attach filler cap chain clip (8) to filler spout (12). 9. Install filler cap (6) to filler spout (12) and secure with "T" handle (7).

d. Fuel Filler Chain Removal

Note

Replacement chain manufacturing instructions can be found in appendix D, figure 15.1.

- Unscrew "T" handle (7) and remove filler cap (6) from filler spout (12). 2. Detach cap chain clip (8) from filler spout (12) and remove chain clip (8) from chain (5.1). 3. Pry open link holding chain (5.1) to cap (6), and remove chain (5.1) from cap (6).

e. Fuel Filler Chain Installation 1. Pry open link on end of chain (5.1) and attach to filler cap (6). Close link.

2. Hook chain clip (8) through last link at opposite end of chain (5.1) and attach to filler spout (12). 3. Install filler cap (6) to filler spout (12) and secure with "T" handle (7).

2. Hook chain clip (8) through last link at opposite end of chain (5.1) and attach to filler spout (12). 3. Install filler cap (6) to filler spout (12) and secure with "T" handle (7).

FOLLOW-ON TASK: Fill fuel tank (TM 9-2320-280-10) and check filler spout for fuel leaks.

3-29. Fuel Tank Filler Spout Vent Line Replacement

This task covers:

| Tools |

|---|

INITIAL SETUP:

a. Removal b. Installation

Equipment Condition Rear propeller shaft removed (para. 6-4).

| Manual References |

|---|

| TM 9-2320-280-24P |

Materials/Parts Locknut (Appendix G, Item 70) Adhesive (Appendix C, Item 1) Sealing compound (Appendix C, Item 46)

A. Removal

-

Disconnect vent line (2) from fuel filler spout elbow (3). 2. Remove locknut (7), washer (5), capscrew (4), and washer (5) securing vent line (2) and clamp (6) to body (1). Discard locknut (7).

-

Disconnect and remove vent line (2) from tee (12). 4. Disconnect vent line (10) from tee (12). 5. Remove capscrew (15) securing vent line (10) and clamp (11) to body (1). 6. Loosen two nuts (13) to allow access to elbow (8). 7. Disconnect vent line (10) from elbow (8) on fuel tank (9), cut vent line (10), and remove vent line (10) from crossmember (14).

b. Installation

Use sealing compound on all vent line connector threads before installation.

- Install vent line (10) and connect to elbow (8) on fuel tank (9).

Upper and lower straps should be approximately 1/2 in. (12 mm) apart after tightening locknuts. Straps should not touch when properly installed. Straps must be replaced if upper and lower straps touch.

-

Apply adhesive to threads of nuts (13) and tighten nuts (13) to 23-27 lb-in. (3-5 N•m). 3. Install clamp (11) and vent line (10) to body (1) with capscrew (15). 4. Route vent line (10) through crossmember (14). 5. Connect vent line (10) to tee (12). 6. Install vent line (2) and connect to tee (12). 7. Install vent line (2) and clamp (6) on body (1) with washer (5), capscrew (4), washer (5), and locknut (7). Tighten locknut (7) to 6 lb-ft (8 N•m).

-

Connect vent line (2) to fuel filler spout elbow (3).

3-29. FUEL TANK FILLER SPOUT VENT LINE REPLACEMENT (Cont'd)

FOLLOW-ON TASK: Install rear propeller shaft (para. 6-4).

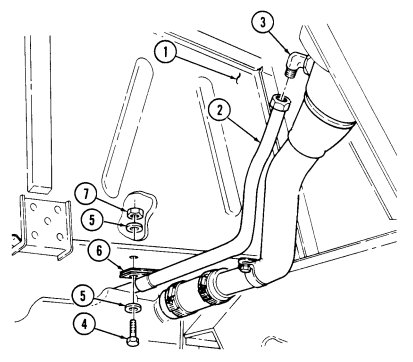

3-30. Filler Spout Hose Replacement

This task covers: a. Removal b. Installation INITIAL SETUP: General mechanic's tool kit: Fuel tank drained (para. 3-24).

automotive (Appendix B, Item 1) General Safety Instructions TM 9-2320-280-10 sparks.

TM 9-2320-280-24P Tools Equipment Condition Manual References Do not perform this procedure near fire, flames, or

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

a. Removal 1. Loosen clamps (4) and (3) securing hose (1) to fuel tank (5) and to filler spout (2).

- Slide hose (1) on to filler spout (2) until disconnected from fuel tank (5). Remove hose (1) from filler spout (2).

b. Installation

Position clamps attaching filler hose to fuel tank as shown.

- Install hose (1) on filler spout (2) and slide on filler spout (2) until the hose (1) clears fuel tank (5). 2. Connect hose (1) to fuel tank (5) and tighten clamps (3) and (4).

FOLLOW-ON TASK: Fill fuel tank (TM 9-2320-280-10) and check for leaks.

3-31. Fuel Tank Hangers Replacement

This task covers: INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Adhesive (Appendix C, Item 1) a. Removal

a. Removal b. Installation

| Manual References |

|---|

| TM 9-2320-280-24P |

| Equipment Condition |

| Fuel tank removed (para. 3-24). |

- Remove two nuts (3), washers (4), screws (5), and rear hangers (7) from supports (6). 2. Twist two front hangers (9) until tee handles (2) clear slots (11) in supports (1) and remove front hangers (9).

Perform step 3 for "A2" vehicles only.

- Inspect four insulators (8) on front and rear hangers (9) and (7). Remove insulators (8) if damaged.

b. Installation

Perform step 1 for "A2" vehicles only.

- Install four insulators (8) on front and rear hangers (9) and (7) (if removed.) 2. Install two front hangers (9) by inserting tee handles (2) up through slots (11) in supports (1). Twist hangers (9) so that tee handles (2) are resting across slots (11) against side of ridge (10).

NOTE Apply adhesive to threads of screws.

- Install two rear hangers (7) on supports (6) with screws (5), washers (4), and nuts (3).

Tighten nuts (3) to 37 lb-ft (50 N•m).

FOLLOW-ON TASK: Install fuel tank (para. 3-24).

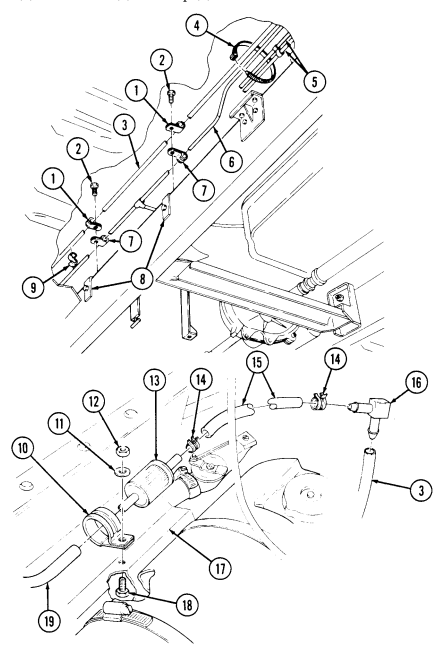

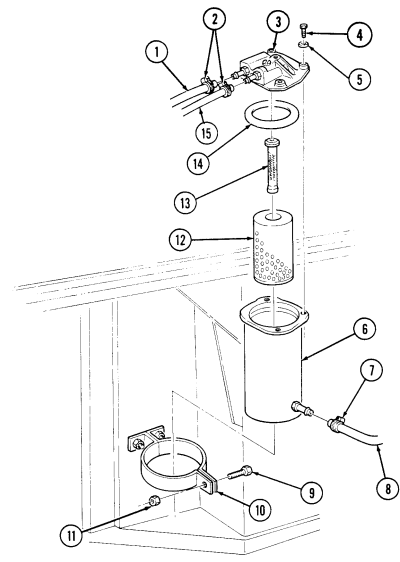

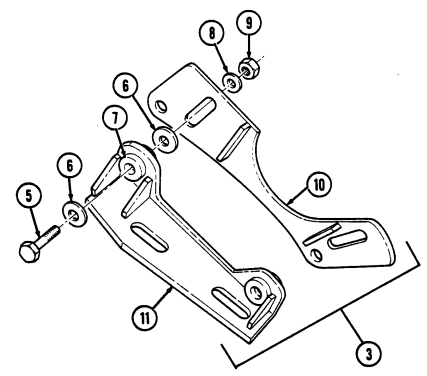

3-32. Fuel Filter Maintenance

This task covers: a. Removal c. Bleeding b. Installation INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1)

Materials/Parts

Two lockwashers (Appendix G, Item 134) Sealing compound (Appendix C, Item 44) Fuel filter bleeder tool (Appendix D, Figure D-63) (optional) Manual References TM 9-2320-280-10 TM 9-2320-280-24P a. Removal

Equipment Condition

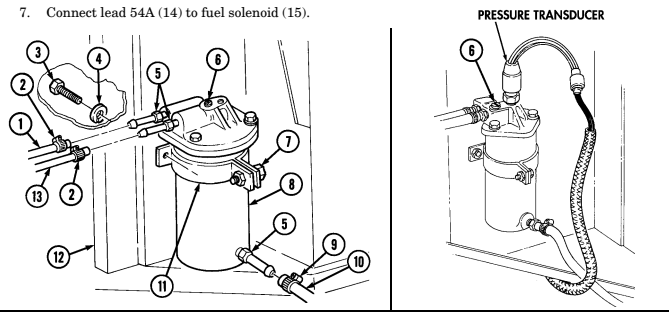

- Hood raised and secured (TM 9-2320-280-10). - Engine access cover removed (para. 10-15). - Fuel pressure transducer removed (para. 4-26).

General Safety Instructions Do not perform this procedure near fire, flames, or sparks.

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

Cover or plug all hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

Have drainage container ready to catch fuel.

-

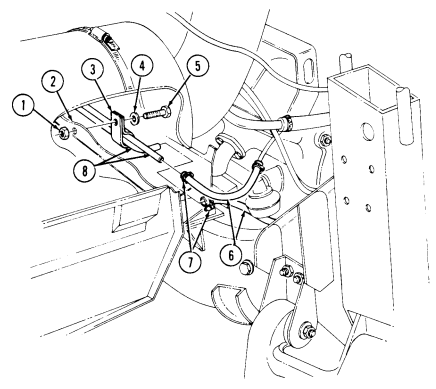

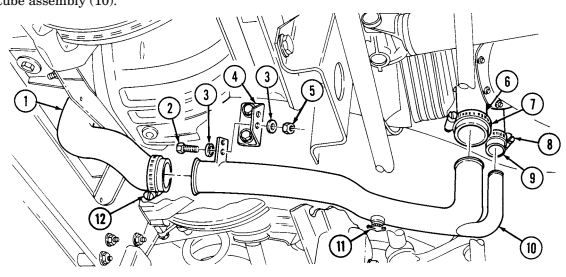

Loosen two hose clamps (2) and disconnect fuel inlet hose (1) and fuel outlet hose (13) from fuel filter (8).

-

Loosen hose clamp (9) and disconnect fuel filter drain hose (10) from fuel filter (8). 3. Pull back insulation to allow access to capscrews (3) and remove two capscrews (3), lockwashers (4), and fuel filter bracket (11) from body (12). Discard lockwashers (4).

-

Loosen capscrew (7) and remove fuel filter (8) from fuel filter bracket (11). 5. Remove three fittings (5) from fuel filter (8).

B. Installation

-

Apply sealing compound to threads of three fittings (5). Install three fittings (5) to fuel filter (8). 2. Install fuel filter (8) in fuel filter bracket (11) and tighten capscrew (7). 3. Install fuel filter bracket (11) on body (12) with two capscrews (3) and lockwashers (4). Tighten capscrews (3) to 15 lb-ft (20 N•m).

-

Connect drain hose (10) to fuel filter (8) and tighten clamp (9) to 10-20 lb-in. (1-2 N•m). 5. Connect fuel inlet hose (1) and fuel outlet hose (13) to fuel filter (8) with two hose clamps (2).

Tighten clamps (2) to 10-20 lb-in. (1-2 N•m).

3 - 3 2 . Fuel Filter Maintenance (Co N T ' D)

c. Bleeding

Note

The bleeder tool described in 2, 3, and 5 is optional. The tool prevents fuel spilling on engine.

- Install fuel pressure transducer (para. 4-26). 2. Remove fuel filter bleed screw (6) and install bleeder tool into the hole. 3. Place open end of bleeder tool hose in clean, clear container. 4. Disconnect lead 54A (14) from solenoid (15).

______ Caution

Do not operate starter continuously for more than 20 seconds, wait 10 to 15 seconds between periods of operation. Failure to do this will result in damage to the starter.

-

Crank engine and watch fuel. When air bubbles stop coming through the line, remove bleeder tool and replace bleed screw (6). Dispose of fuel in accordance with local SOP.

-

Tighten bleed screw (6) to 40-50 lb-in. (4-6 N•m).

FOLLOW-ON TASKS: - Start engine (TM 9-2320-280-10) and check for fuel leaks.

- Lower and secure hood (TM 9-2320-280-10). - Install engine access cover (para. 10-15).

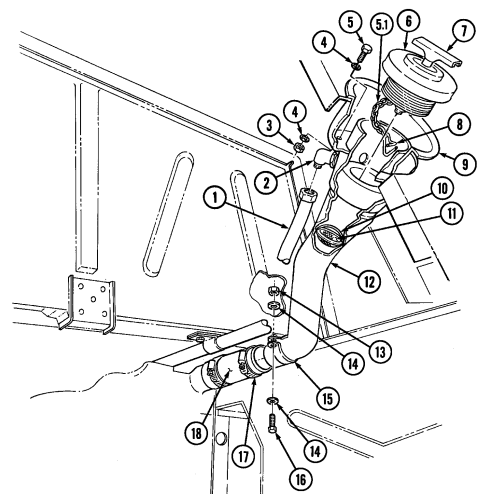

3-33. Fuel Filter Element Maintenance

This task covers: a. Element Removal c. Element Installation b. Cleaning and Inspection INITIAL SETUP: Tools General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Filter element kit (Appendix G, Item 32)

Equipment Condition

Fuel pressure transducer removed (para. 4-26).

General Safety Instructions

-

Do not perform this procedure near fire, flames, or sparks.

-

Cleaning will be done in a well-ventilated area and a fire extinguisher will be kept nearby when solvent is used.

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

CAUTION Cover or plug all hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

A. Element Removal

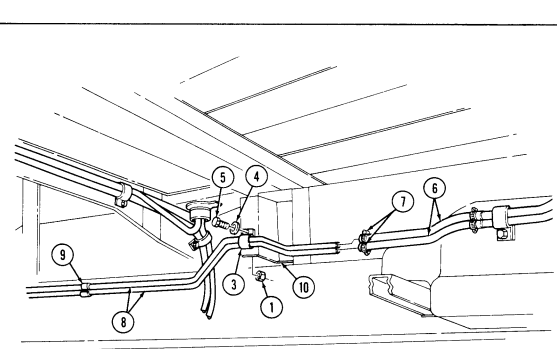

-

Loosen two hose clamps (2), and disconnect fuel inlet hose (1) and fuel outlet hose (15) from fuel filter cover (3).

-

Loosen hose clamp (7) and disconnect fuel filter drain hose (8) from filter housing (6). 3. Remove capscrew (9), nut (11), and filter housing (6) from fuel filter bracket (10). 4. Remove three capscrews (4) washers (5) and cover (3) from filter housing (6). 5. Remove O-ring seal (14) from filter housing (6). Discard O-ring seal (14). 6. Remove filter element (12) and separator (13) from filter housing (6). 7. Remove separator (13) from filter element (12). Discard filter element (12).

B. Cleaning And Inspection Warning

Drycleaning solvent is flammable and will not be used near an open flame. A fire extinguisher will be kept nearby when the solvent is used. Use only in well-ventilated places. Failure to do this may result in injury to personnel and/or damage to equipment.

- Use drycleaning solvent to clean all metallic parts. 2. Inspect filter housing (6) and cover (3) for distortion or damage. Replace if damaged. 3. Inspect separator (13) for dirt, contamination, or damage. Replace if dirty, contaminated, or damaged.

Manual References TM 9-2320-280-24P

3-33. Fuel Filter Element Maintenance (Cont'D) C. Element Installation

Install filter element (12) into filter housing (6). Install separator (13) on filter element (12).

Install O-ring seal (14) into filter housing (6). Install cover (3) on filter housing (6) with three washers (5) and capscrews (4). Tighten capscrews (4) to 50-60 lb-in. (6-7 N*m). Install filter housing (6) in fuel filter bracket (10) with capscrew (9) and nut (11). Connect fuel filter drain hose (8) to filter hosing (6) and tighten clamp (7) to 10-20 lb-in. (1-2 Nero).

Connect fuel inlet hose (1) and fuel outlet hose (15) to fuel filter cover (3) and tighthen clamps (2) to 10-20 lb-in. (1-2 Nom).

FOLLOW-ON TASK: Bleed fuel filter (para. 3-32).

3-34. Fuel Filter Drain Hose And Valve Replacement

This task covers: INITIAL SETUP:

Tools

General mechanic's tool kit: automotive (Appendix B, Item 1) Materials/Parts Plain-assembled nut (Appendix G, Item 201) Manual References TM 9-2320-280-10 TM 9-2320-280-24P

a. Removal b. Installation

| Manual References |

|---|

One assistant Equipment Condition Hood raised and secured (TM 9-2320-280-10).

General Safety Instructions Do not perform this procedure near fire, flames, or sparks.

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

a. Removal

Cover or plug all open hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

-

For fuel filter drain valve replacement, perform steps 5 and 6 only.

-

Have drainage container ready to catch fuel.

- Loosen clamp (2) and disconnect fuel filter drain hose (8) from fuel filter assembly (1). 2. Loosen clamp (7) and disconect drain hose (8) from fuel filter drain valve (6). 3. Remove plain-assembled nut (5), capscrew (11), clamp (4), and drain hose (8) from cowl panel (3).

Discard plain-assembled nut (5).

- Remove capscrew (10), drain hose (8), and clamp (9) from panel (3). 5. Remove nut (13) and fuel filter drain valve (6) from bracket (12).

b. Installation

For fuel filter drain valve replacement, perform steps 5 and 6 only.

-

Install drain hose (8) and clamp (4) to cowl panel (3) with capscrew (11) and plain-assembled nut (5).

-

Install clamp (9) and drain hose (8) to panel (3) with capscrew (10). 3. Connect drain hose (8) to fuel filter drain valve (6) with clamp (7). 4. Connect drain hose (8) to fuel filter assembly (1) with clamp (2). 5. Install fuel filter drain valve (6) to bracket (12) with nut (13).

3-34. Fuel Filter Drain Hose And Valve Replacement (Cont'D)

FOLLOW-ON TASKS: - Start engine (TM 9-2320-280-10) and check for oil leaks.

- Start en

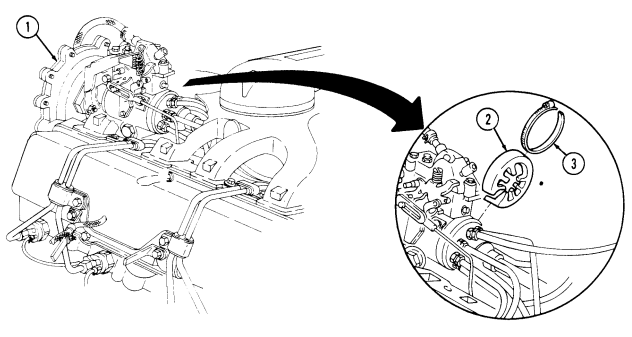

3-35. Fuel Injection Pump Return Hose Check Valve Maintenance

This task covers: a. Removal c. Installation b. Cleaning and Inspection INITIAL SETUP: automotive (Appendix B, Item 1) Air horn removed (para. 3-14).

TM 9-2320-280-24P or sparks.

Tools Equipment Condition General mechanic's tool kit: Hood raised and secured (TM 9-2320-280-10).

Manual References General Safety Instructions TM 9-2320-280-10 Do not perform this procedure near fire, flames, Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa).

Warnin G

Diesel fuel is highly flammable. Do not perform this procedure near fire, flames, or sparks. Severe injury or death will result.

Cover or plug all hoses and connections immediately after disconnection to prevent contamination. Remove all plugs prior to connection.

A. Removal

- Loosen clamp (2) and disconnect hose (1) from injection pump check valve (3). 2. Remove check valve (3) from injection pump (4).

Warnin G

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personal protective equipment (goggles/shield, gloves, etc).

B. Cleaning And Inspection

Examine the lower end of the check valve (3) where the ball seats for evidence of debris. If debris is present, blow compressed air through the check valve. Replace check valve (3) if debris remains or if check valve (3) fails to function properly.

c. Installation 1. Install check valve (3) on injection pump (4). 2. Connect hose (1) on check valve (3) with clamp (2).

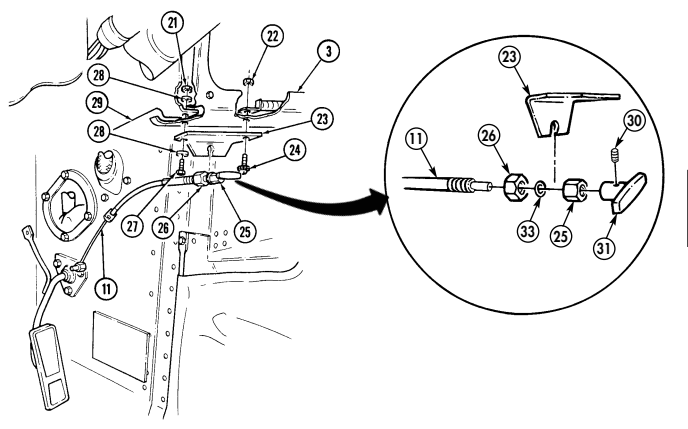

3-35. Fuel Injection Pump Return Hose Check Valve Maintenance (Cont'D)