hmmwv-manuals

Chapter 2 Service And Troubleshooting Instructions

| Task | Description |

|---|---|

| 2-1 | Common Tools And Equipment |

| 2-2 | SPECIAL TOOLS, TMDE, AND SUPPORT EQUIPMENT |

| 2-3 | REPAIR PARTS |

| 2-4 | General |

| 2-5 | General Inspection And Servicing Instructions |

| 2-6 | Specific Inspection And Servicing Instructions |

| 2-7 | G E N E R A L |

| 2-8 | I N T E Rva L S |

| 2-9 | R E P O Rting Repa I R S |

| 2-10 | . General Service And Inspection Procedures |

| 2-11 | Specific Pmcs Procedures |

| 2-12 | General |

| 2-13 | . Electrical/Mechanical Systems Troubleshooting Electrical/Mechanical Troubleshooting |

| 2-14 | How To Use This Troubleshooting Guide |

| 2-15 | Glossary Of Abbreviations And Commonly Used Terms |

| 2-16 | Electric Circuit Description |

| 2-17 | Startability Tests |

| 2-18 | Engine Running Tests |

| 2-19 | Cooling System Tests |

| 2-20 | Lubrication System Tests |

| 2-21 | Electrical Tests |

| 2-22 | Fuel System Tests |

| 2-23 | Air Intake/Exhaust Tests |

| 2-24 | Compression/Mechanical Tests |

| 2-25 | Engine Cooling Tests |

| 2-26 | Engine Lubrication Tests I |

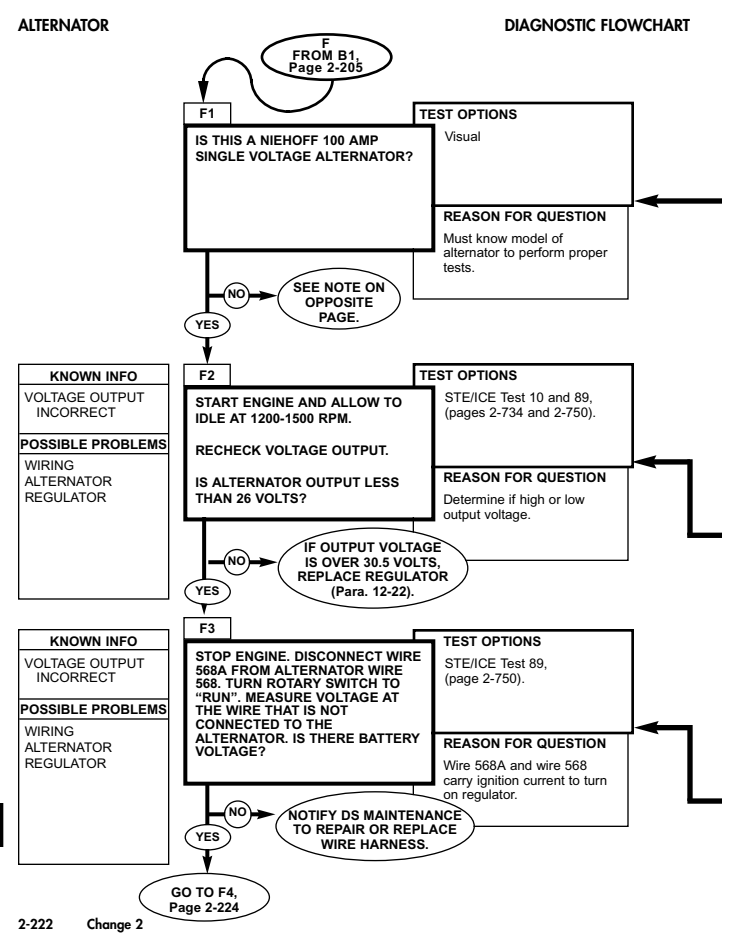

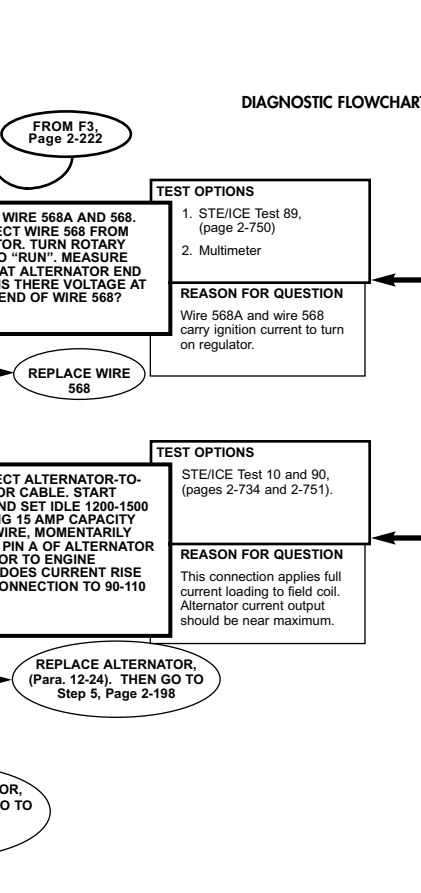

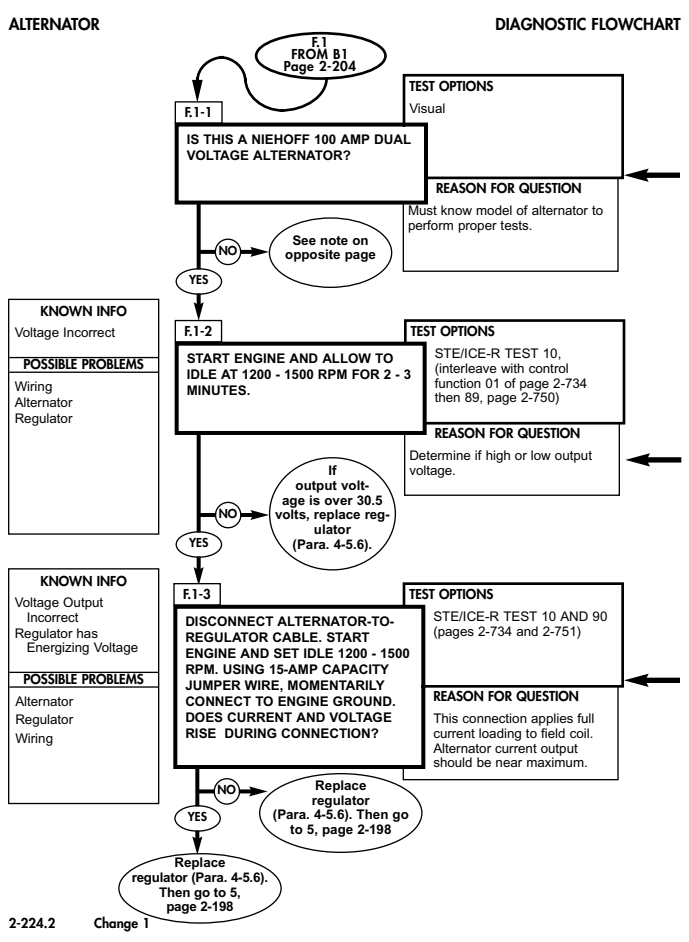

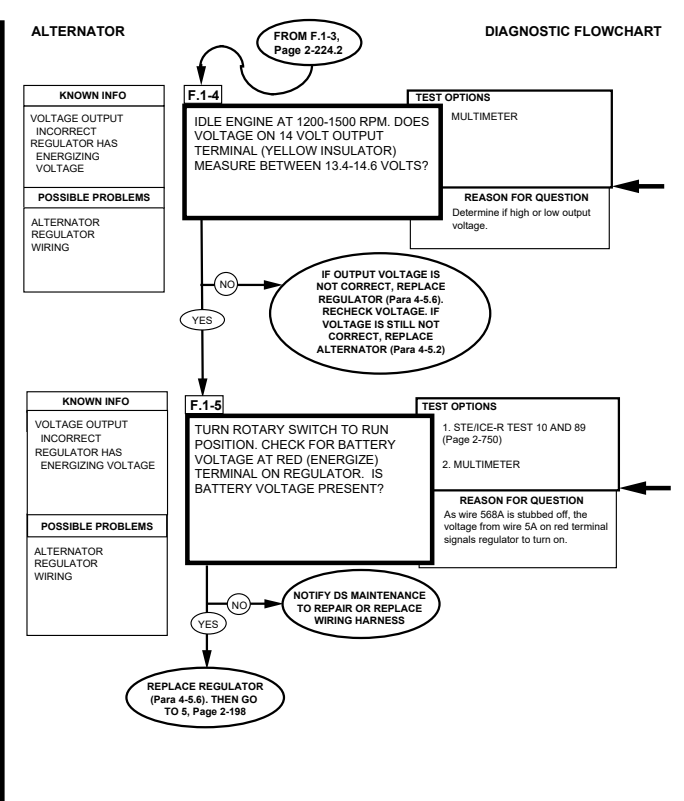

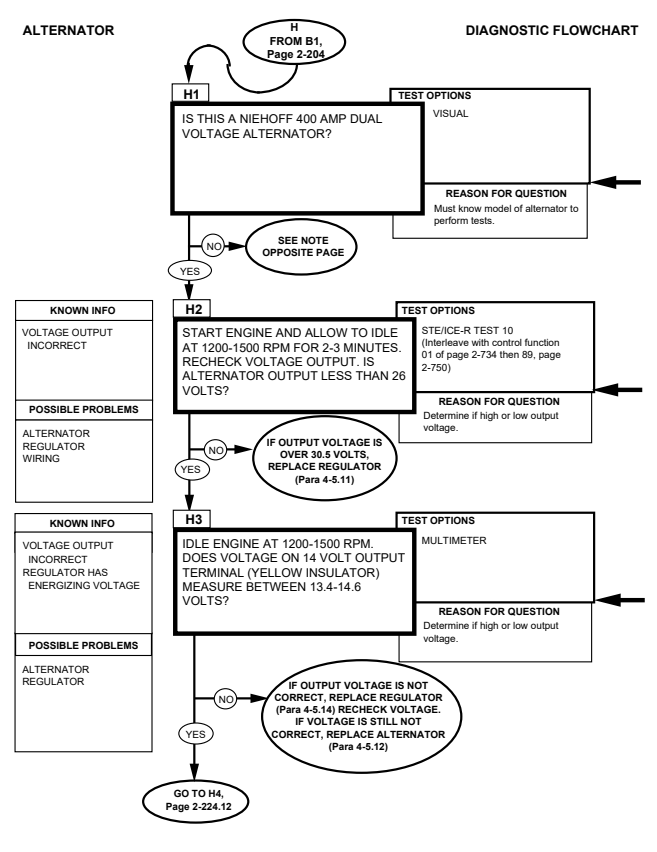

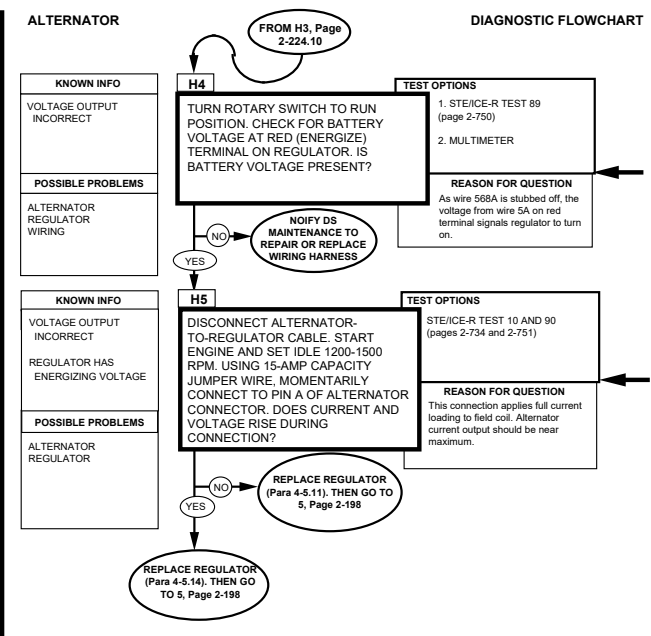

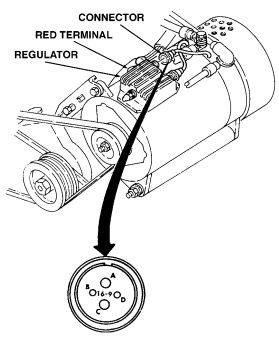

| 2-27 | Alternator Tests |

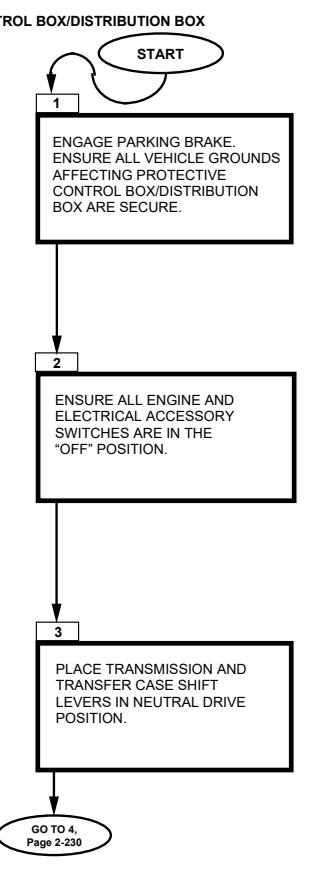

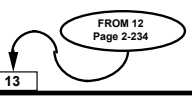

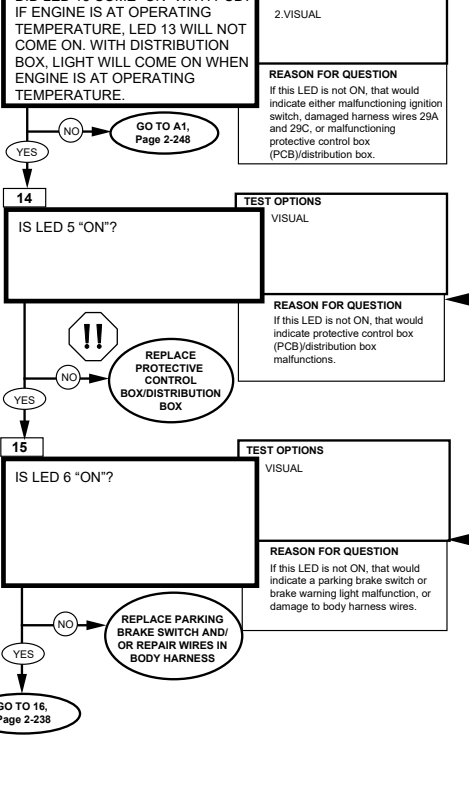

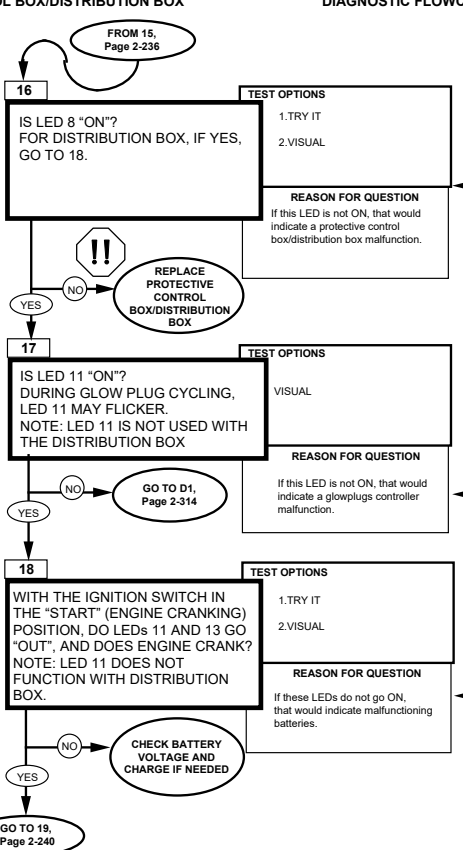

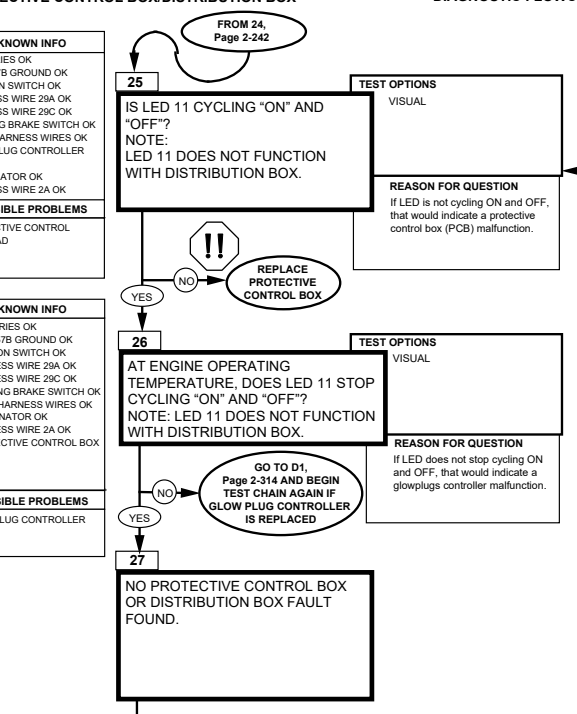

| 2-28 | Protective Control Box/Distribution Box Tests |

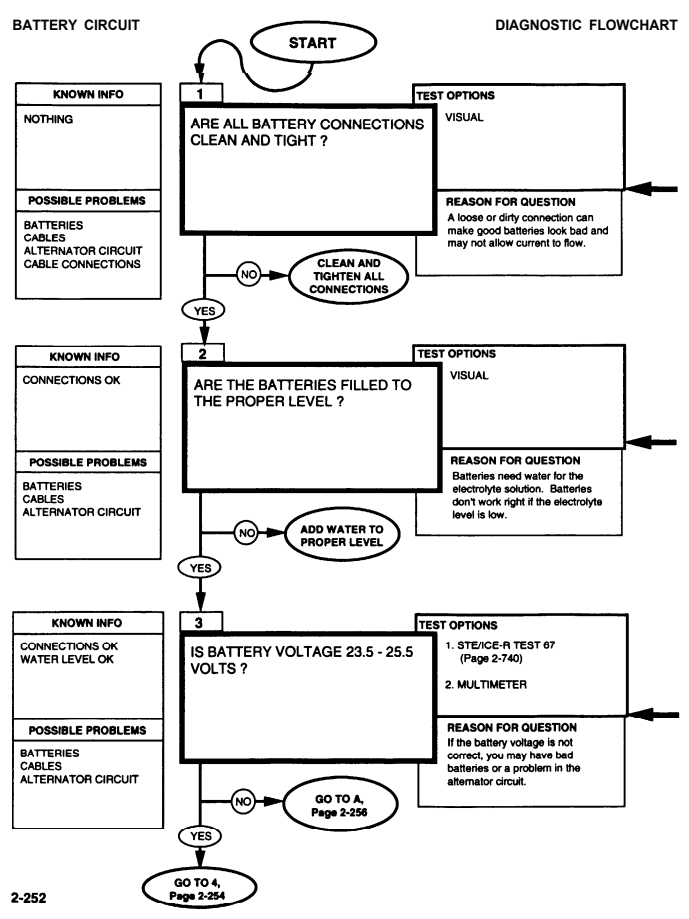

| 2-29 | Battery Circuit Test 1 |

| 2-30 | Starter Circuit Tests |

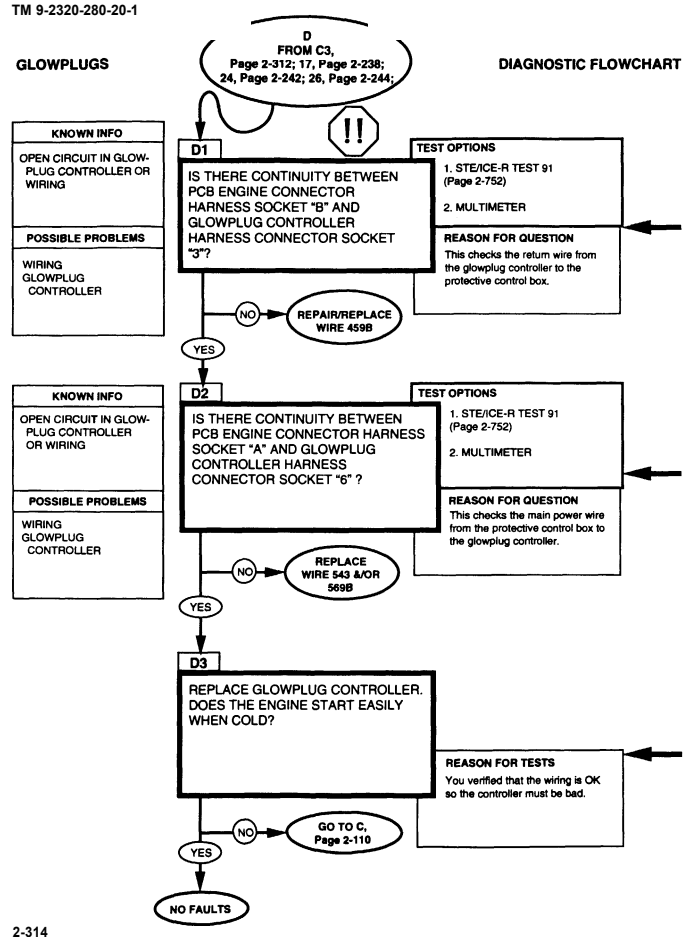

| 2-31 | Glowplugs Circuit Tests (Protective Control Box) |

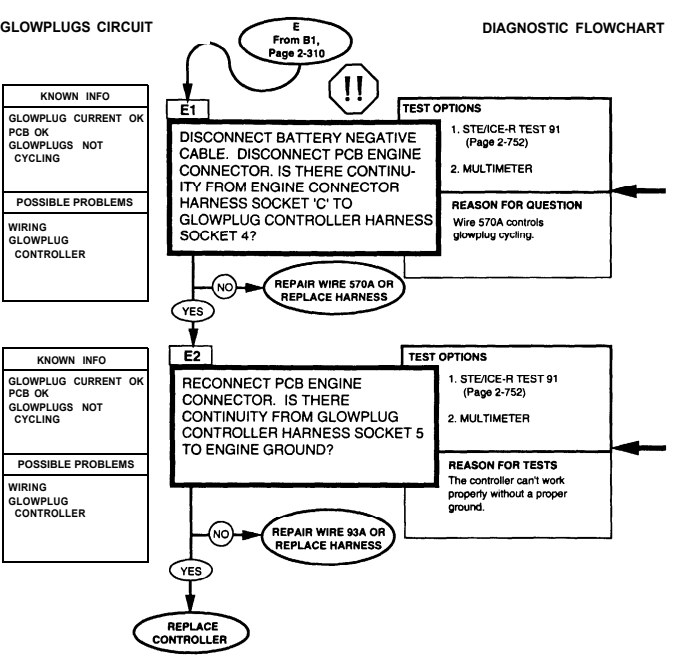

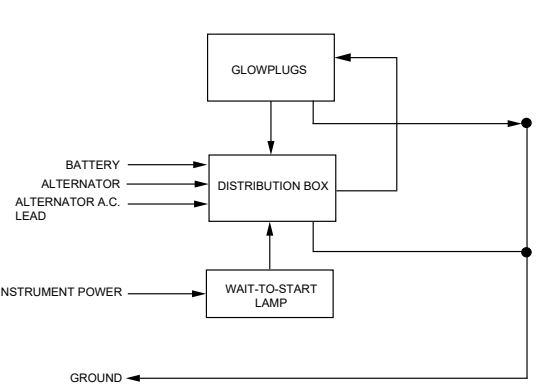

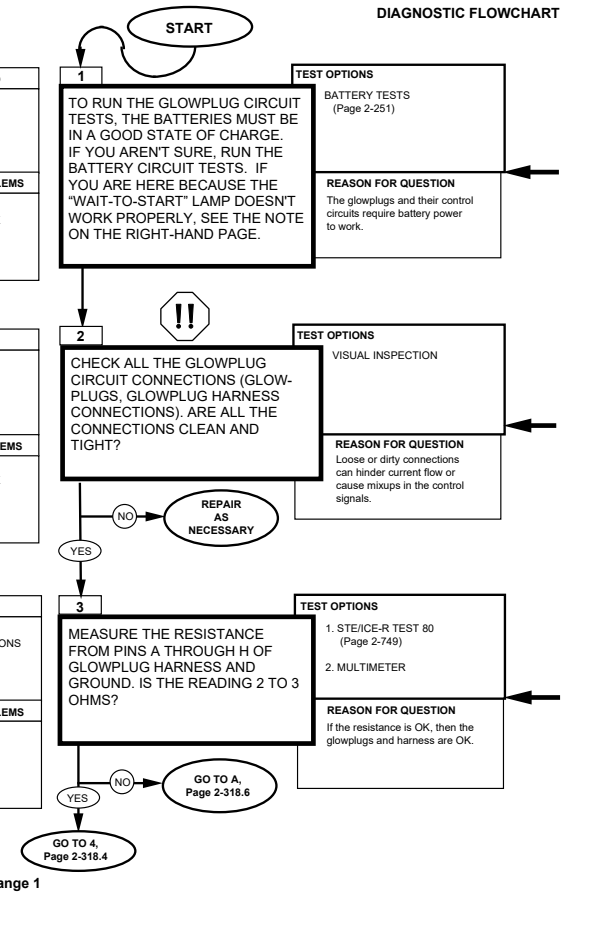

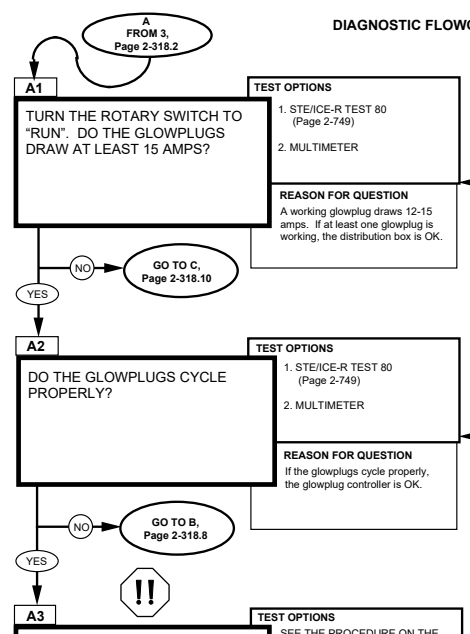

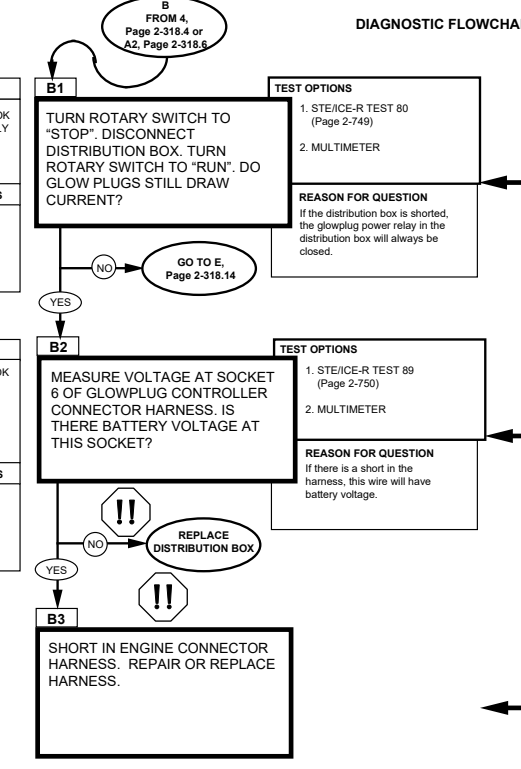

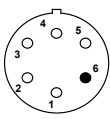

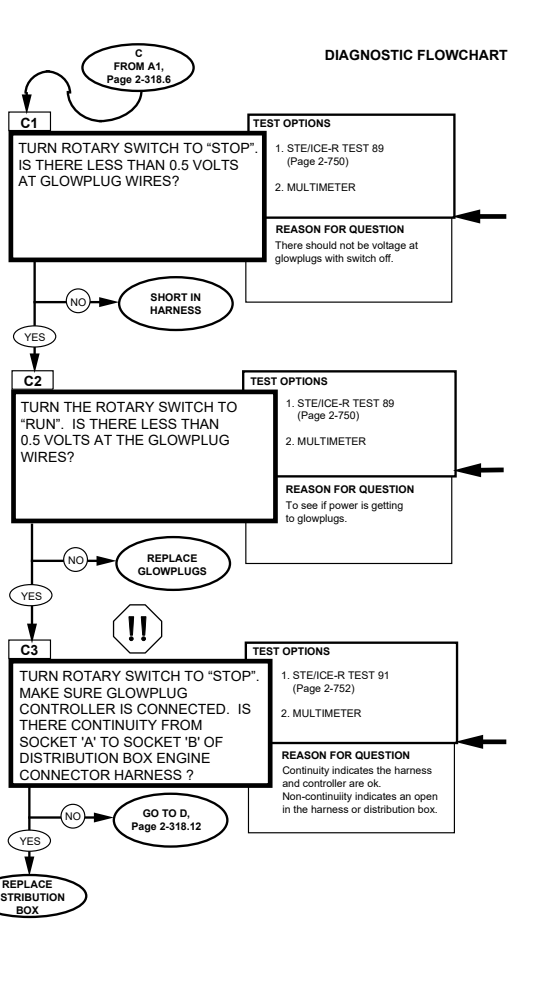

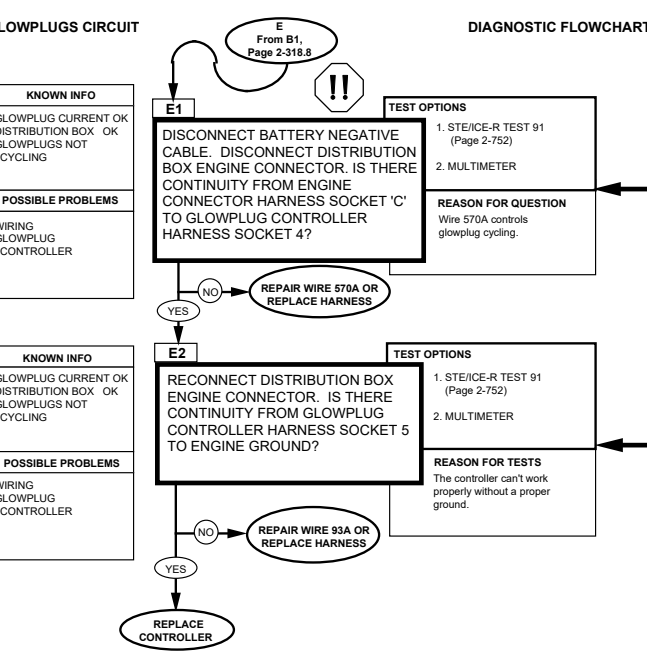

| 2-31 | 1. Glowplugs Circuit Tests (Distribution Box) |

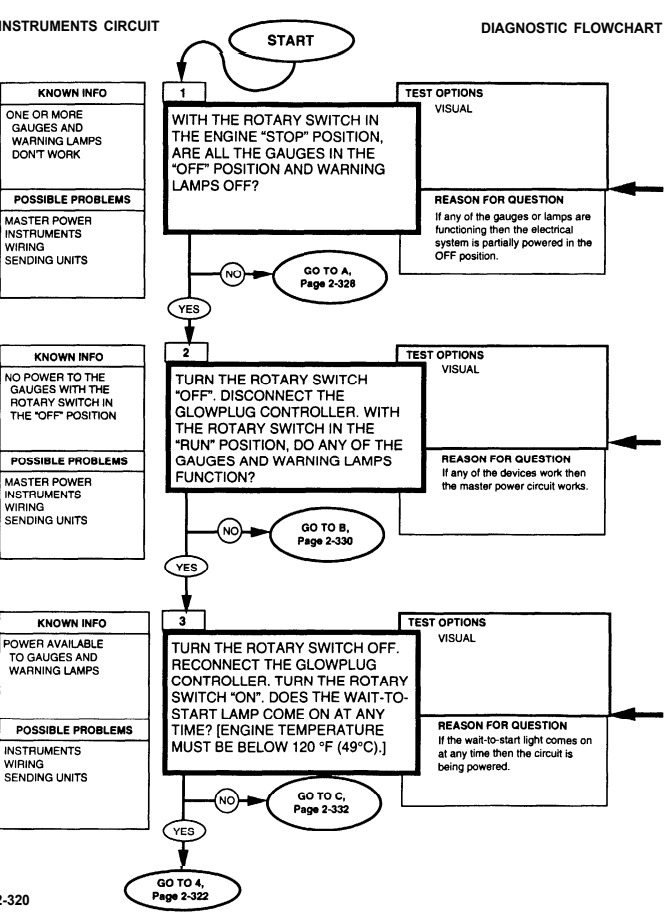

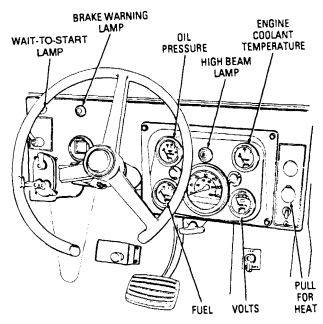

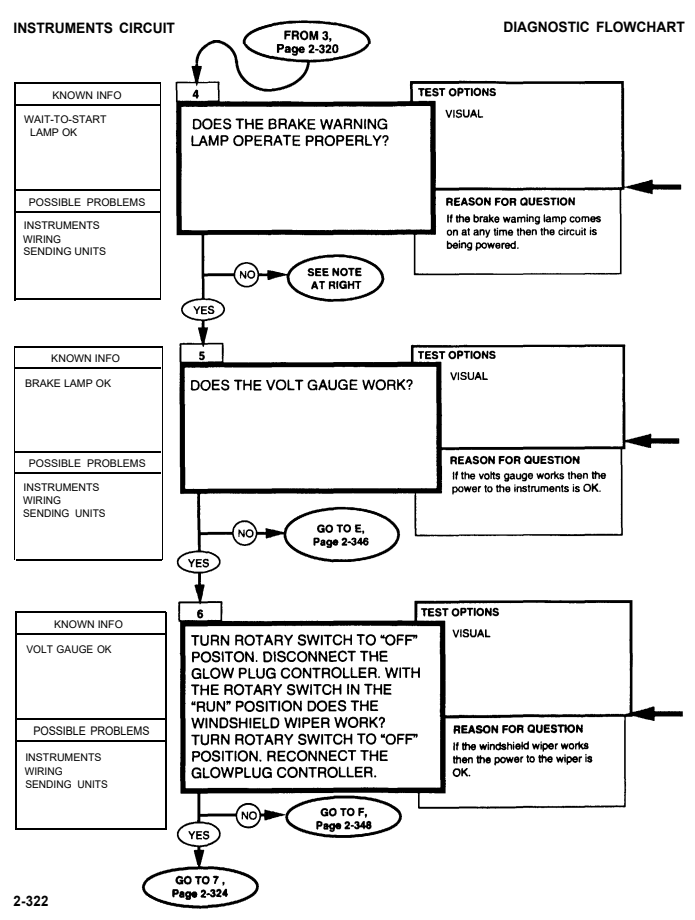

| 2-32 | Instrument Tests |

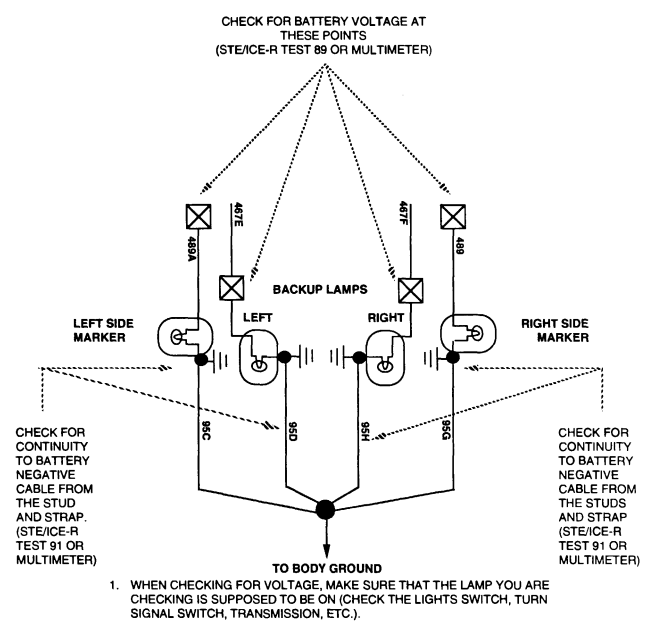

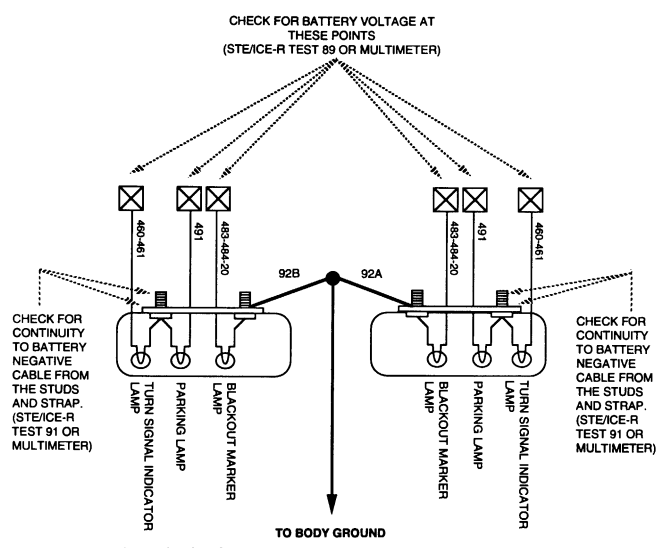

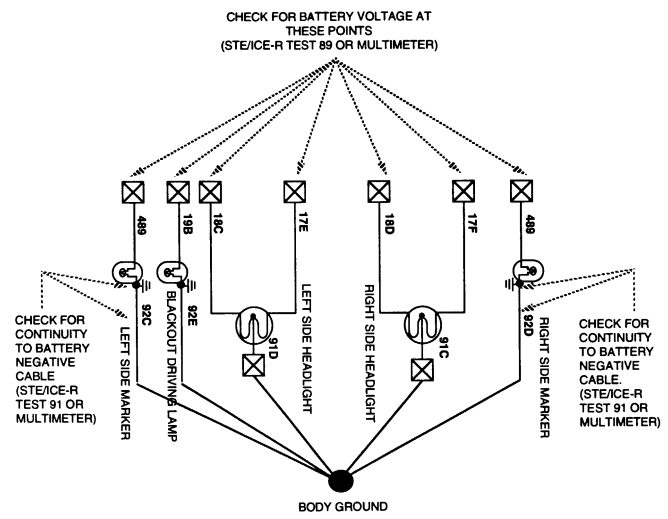

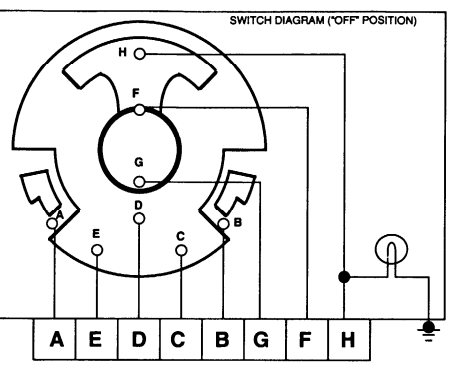

| 2-33 | Light Tests |

| 2-34 | Transmission System Tests (3L80) |

| 2-35 | Transmission System Tests (4L80-E) |

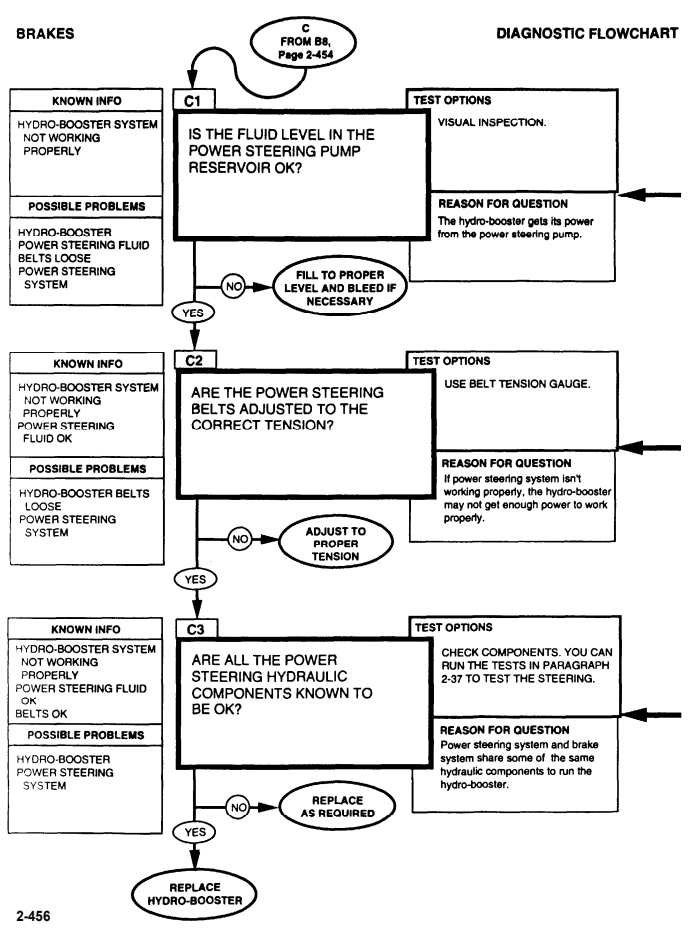

| 2-36 | Brake System Tests |

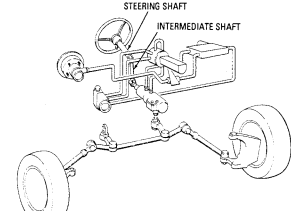

| 2-37 | Steering System Tests |

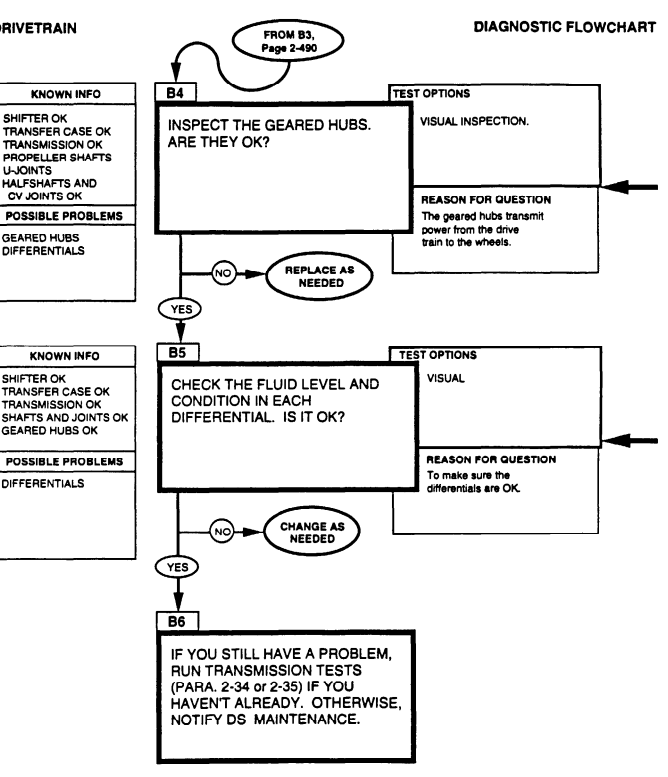

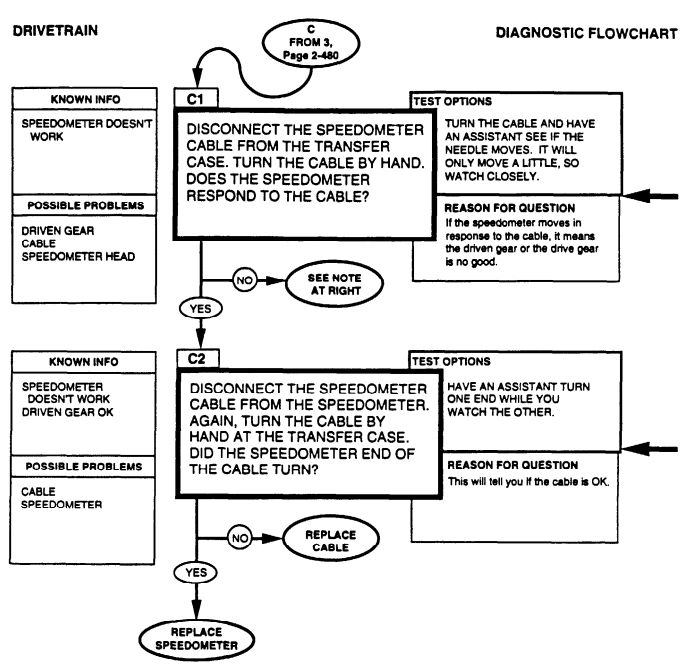

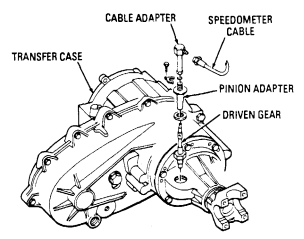

| 2-38 | Drivetrain Tests |

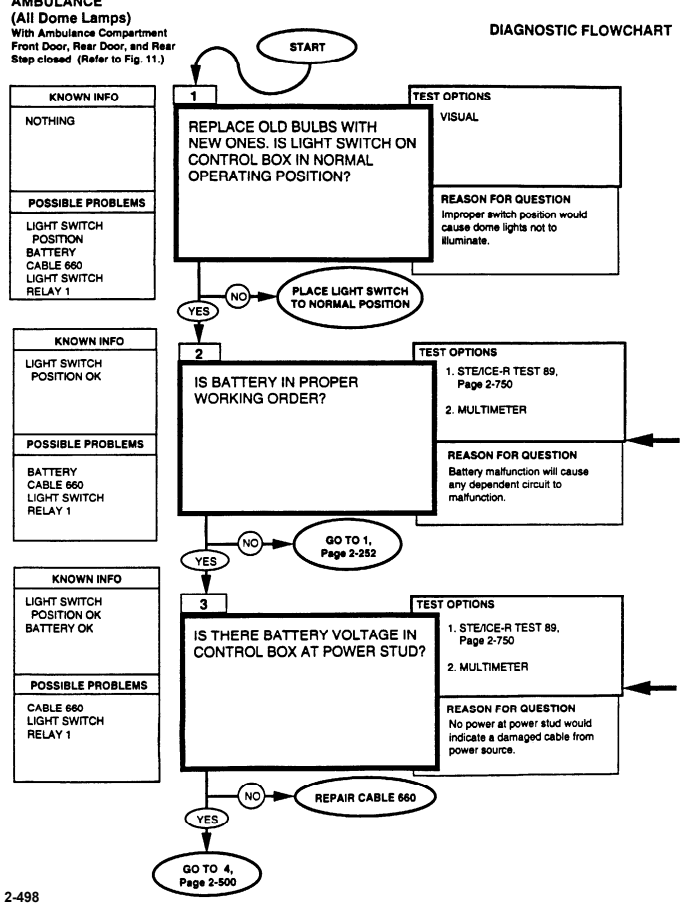

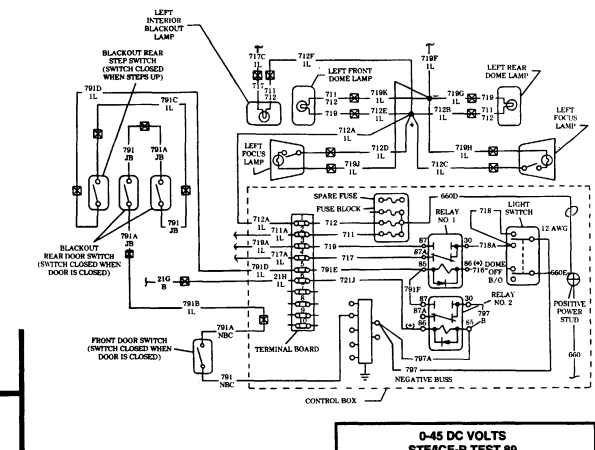

| 2-39 | Ambulance Electrical System Tests |

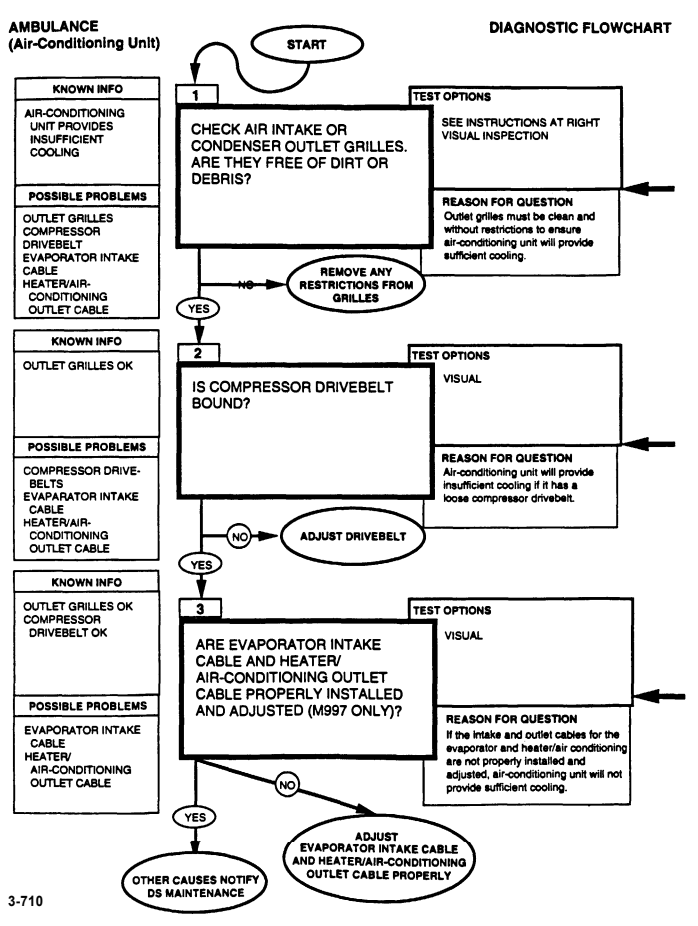

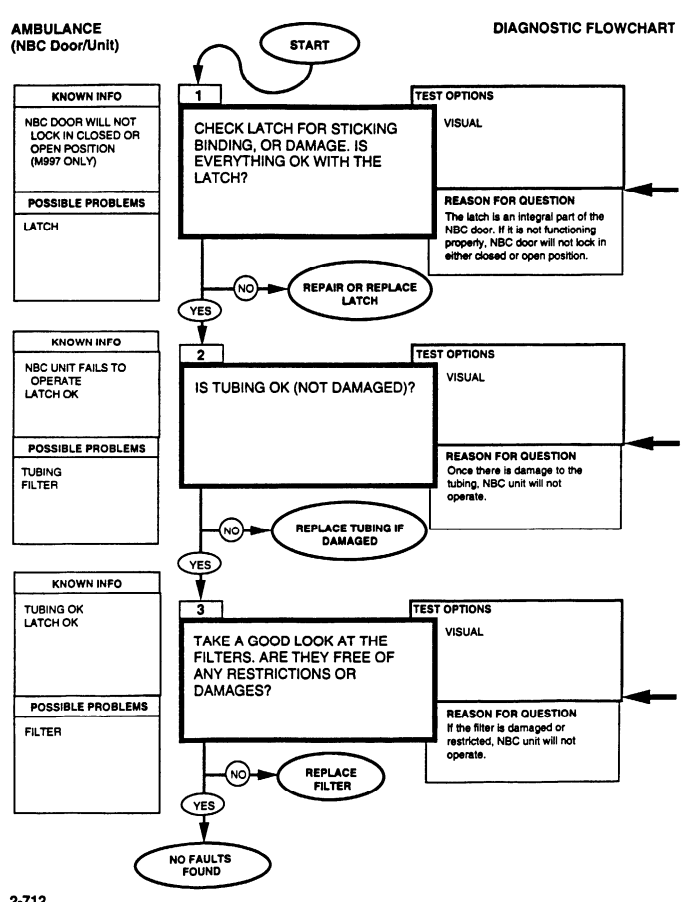

| 2-40 | Ambulance Mechanical System Tests |

| 2-41 | Winch System Tests |

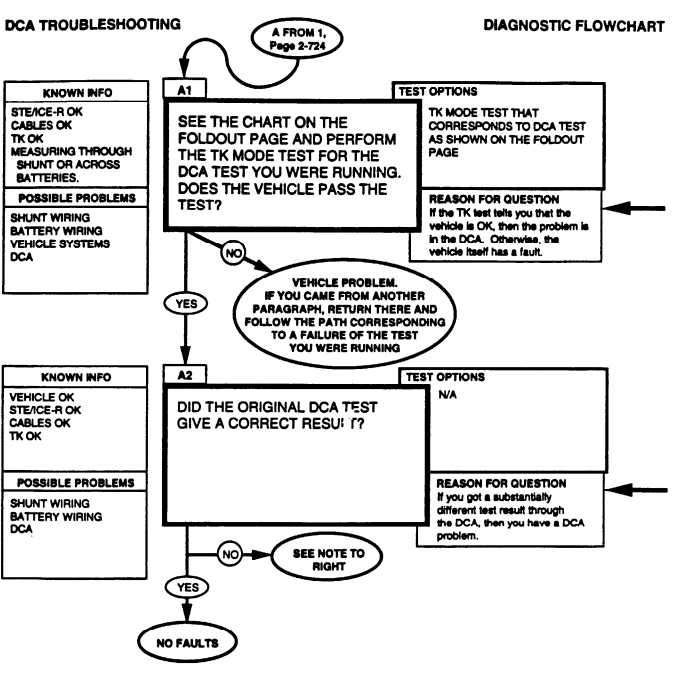

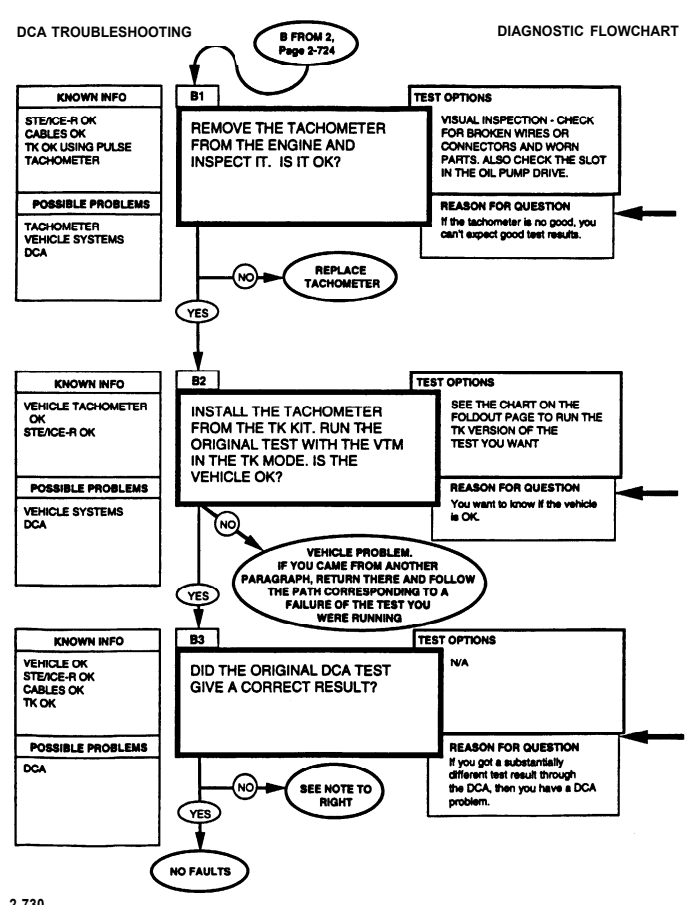

| 2-42 | Dca Troubleshooting |

| 2-43 | Ste/Ice-R Test Procedures |

| 2-44 | Vehicle Testing |

Section I. REPAIR PARTS, SPECIAL TOOLS, TEST, MEASUREMENT

DIAGNOSTIC EQUIPMENT (TMDE), AND SUPPORT EQUIPMENT

2-1. Common Tools And Equipment

For authorized common tools and equipment, refer to the Modified Table of Organization and Equipment (MTOE) applicable to your unit.

2-2. SPECIAL TOOLS, TMDE, AND SUPPORT EQUIPMENT

Special Tools, Test, Measurement, Diagnostic Equipment (TMDE), and Support Equipment used to maintain the vehicles covered in this manual can be found in TM 9-2320-280-24P.

2-3. REPAIR PARTS

Repair parts are listed and illustrated in TM 9-2320-280-24P.

Section II. Service Upon Receipt

2-4. General

a. Upon receipt of a new, used, or reconditioned vehicle, you must determine if the vehicle has been properly prepared for service. The following steps should be followed: 1. Inspect all assemblies, subassemblies, and accessories to be sure they are in proper working order. 2. Secure, clean, lubricate, or adjust as needed. 3. Check all Basic Issue Items (TM 9-2320-280-10) to be sure every item is present, in good condition, and properly mounted, or stowed. 4. Follow general procedures for all services and inspections given in TM 9-2320-280-10. b. The operator will assist when performing service upon receipt inspections. c. See TM 9-2320-280-10 when checking equipment for proper operation. d. Refer to TM 9-2320-280-10 for information concerning brake-in procedures.

2-5. General Inspection And Servicing Instructions

The following steps should be taken while performing general inspection and services: NOTE Cooler fin and engine protective covers can be used to prevent damage to the vehicle components during maintenance. Refer to Appendix D for fabrication instructions.

(1) Use TM 9-2320-280-10 as well as other sections of this manual, when servicing and inspecting equipment.

Warning

Drycleaning solvent is flammable and will not be used near an open flame. A fire extinguisher will be kept nearby when the solvent is used. Use only in well-ventilated places. Failure to do this may result in injury to personnel and/or damage to equipment.

(2) Clean all exterior surfaces coated with rust-preventive compounds. Use drycleaning solvent (Appendix C, Item 18).

(3) Clean fittings before lubrication. Clean parts with drycleaning solvent (SD), type II, or equivalent.

Dry before lubricating. Relubricate all items found contaminated after fording.

.Warning.

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with effective chip guarding and personal protective equipment such as goggles or shield, gloves, etc.

Note

Use compressed air to dry electrical components. Use sealing compound (Appendix C, Item 40) before reconnecting plugs.

(4) Inspect electrical connectors for corrosion and/or damage (i.e., bent pins). Clean and repair damage. Clean electrical components with clean cloth dampened with drycleaning solvent. Care must be taken not to damage protective insulation.

(5) Read "Processing and Deprocessing Record of Shipping, Storage, and Issue of Vehicles and Spare Engines," tag (DD Form 1397) and follow all precautions listed. This tag should be attached to steering wheel, steering column, or rotary switch.

2-6. Specific Inspection And Servicing Instructions

The following steps should be taken while performing specific inspections and services: (1) Do the Semiannual (S) preventive maintenance checks and services listed in Section III in this chapter.

(2) Lubricate the vehicle. Do not lubricate gear cases and engine unless processing tag states that the oil is unsuitable for 500 mi (805 km) operation. If oil is suitable, just check level.

(3) Schedule semiannual service on DD Form 314 (Preventive Maintenance Schedule and Record Card). (4) If vehicle is delivered with a dry charged battery, activate it according to TM 9-6140-200-14. (5) Check vehicle coolant level and determine if solution is proper for climate (refer to TB 750-651 for preparation of antifreeze solutions).

(6) Remove towing brackets from their stowed position behind the bumper and install them in their proper location (para. 9-2, 9-3, or 9-4).

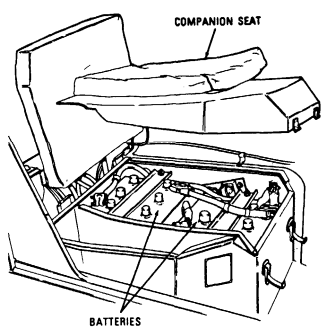

(7) Remove front lifting shackles from stowed position under passenger seat and install on towing brackets (para. 9-13).

Section Iii. Preventive Maintenance Checks And Serv I C E S

2-7 . G E N E R A L

The best way to maintain vehicles covered by this manual is to inspect them on a regular basis so minor faults can be discovered and corrected before they result in serious damage, failure, or injury. All intervals are based on normal operation. Hard time intervals may be shortened if your lubricants are contaminated or if you are operating the equipment under adverse conditions, including longer-than-usual operating hours. Hard time intervals may be extended during periods of low activity, though adequate preservation precautions must be taken. This section contains systematic instructions of inspection, adjustment, lubrication, and correction of vehicle components to avoid costly repairs or major breakdowns. This is Preventive Maintenance Checks and Services (PMCS).

2-8 . I N T E Rva L S

a. Unit maintenance, assisted by operator/crew, will perform checks and services contained in Table 2-1 at the following intervals: (1) Semiannually (S). Every 6 months or 3,000 miles (4,800 km), whichever comes first. (2) Annually (A). Every 12 months or 6,000 miles (9,654 km), whichever comes first. (3) Biennially (B). Every 24 months or 12,000 miles (19,308 km), whichever comes first.

b. Refer to following steps when performing lubrication checks and services: (1) Intervals. Lubrication services coincide with the vehicle's Semiannual (S) Preventive Maintenance Service. For this propose, a 10% tolerance (variation) in specified lubrication point mileage is permissible. Those vehicles not accumulating 1,000 mi (1,609 km) in a 6-month period will be lubricated at the time of (S) Preventive Maintenance Service.

(2) Army Oil Analysis Program (AOAP). HMMWV engines and transmissions are enrolled in the Army Oil Analysis Program (AOAP). The sampling interval for the engine is every six months or 3,000 miles, or 100 hours (if hour meter is installed) of operation. For the transmission, the sampling interval is every 12 months or 6,000 miles, or 300 hours (if hour meter is installed) of operation.

(3) For Operation of Equipment in Protracted Cold Temperatures Below -15°F. (-26°C).

Remove lubricants prescribed in lubrication table for temperatures above -15°F (-26°C). Relubricate with lubricants specified in lubrication table for temperatures below -15°F (-26°C). If OEA lubricant is required, see the temperature ranges prescribed in the lubrication table. OEA lubricant is to be used in place of OE/HDO 10 lubricant for all temperature ranges where OE/HDO 10 is specified in the lubrication table.

c. Perform all (S) inspections in addition to (A) inspections at the time of the annual inspection. Perform all (A) and (S) inspections in addition to (B) inspections at the time of the biennial inspection.

2-9 . R E P O Rting Repa I R S

All vehicle shortcomings will be reported on DA Form 2404 Equipment Inspection and Maintenance Worksheet or DA Form 5988-E (automated) (DA Pam 738-750) immediately after the PMCS, and before taking corrective action. All vehicle deficiencies will be reported in the equipment record.

2-10 . General Service And Inspection Procedures

a. While performing specific PMCS procedures, make sure items are correctly assembled, secure, not worn, serviceable, not leaking, and adequately lubricated as defined below.

(1) An item is CORRECTLY ASSEMBLED when it is in proper position and all parts are present. (2) When wires, nuts, washers, hoses, or attaching hardware cannot be moved by hand, or wrench, they are SECURE.

(3) An item is WORN if there is too much play between joining parts or when marking data, warning, and caution plates are not readable.

(4) An item is UNSERVICEABLE if it is worn beyond repair and is likely to fail before the next scheduled inspection.

(5) LEAKS. TM 9-2320-280-10 contains definitions of Class I, II, and III leaks and their effect on vehicle operation.

(6) If an item meets the specified lubrication requirements, then it is ADEQUATELY LUBRICATED.

b. Where the instruction "tighten" appears in a procedure, you must tighten with a wrench to the given torque value even when the item appears to be secure.

.Warning.

Drycleaning solvent is flammable and will not be used near an open flame. A fire extinguisher will be kept nearby when the solvent is used. Use only in well-ventilated places. Failure to do this may result in injury to personnel, and/or damage to equipment.

c. Where the instruction "clean" appears in a procedure, you must use drycleaning solvent (Appendix C, Item 18) to clean grease or oil from metal parts. After the item is cleaned, rinsed, and dried, apply a light grade of oil to unprotected surfaces to prevent rusting.

d. Clean rubber and plastic materials with soap and water. Refer to TM 9-2320-280-10 for general vehicle cleaning instructions.

2-11. Specific Pmcs Procedures

a. The preventive maintenance for which you are responsible is provided in Table 2-1. The checks and services listed are arranged in logical order requiring minimal time and effort on your part.

b. The following columns read across on the PMCS schedule: (1) Item Number. Provides logical order of PMCS performance and is used as a source number for DA Form 2404, on which your PMCS results will be recorded.

(2) Intervals. Shows the interval next to each item number to indicate when that check is to be performed. The interval will be repeated when consecutive item numbers are to be inspected during the same interval. Interval columns include: (a) Semiannual (six month) checks; (b) Annual (yearly) checks; and (c) Biennial (every two years) checks.

(3) Item To Be Inspected. Lists the system, common name, or location of the item to be inspected. (4) Procedures. Provides instructions for servicing, inspection, lubrication, replacement, or adjustment, and in some cases, having item repaired at a higher level.

Note

Always do your preventive maintenance checks and services in the order prepared. Once it gets to be a habit, you will be able to spot anything wrong in a hurry.

(5) Not Fully Mission Capable. If vehicle meets criteria in this column, vehicle is not mission capable (NMC).

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV

| ( C o n t ' d ) |

|---|

| ITEM | INTERVAL | ITEM TO BE | PROCEDURES | NOT FULLY MISSION |

|---|---|---|---|---|

| NO. | INSPECTED | CAPABLE IF: | ||

| 1 | Semi- Annual | Pre-Service Checks | h. Bring vehicle to full stop. Engage parking brake while transmission is | h. Parking brake doesn't hold vehicle |

| (Cont'd) | still in "D" (drive) or "(D)" (overdrive) | stationary. | ||

| for A2 series vehicles. Vehicle should | ||||

| remain stationary. | ||||

| i. Observe vehicle response to road | ||||

| shock. Side sway or continuous bouncing | ||||

| indicates a malfunction. | ||||

| AFTER ROAD LEST | ||||

| 2 | Semi- | Body | a. Make sure the vehicle has been | |

| Annual | cleaned of mud, gravel, etc., from the | |||

| underbody, outside, and crew com- partment area. | ||||

| b. Thoroughly wash all underbody | ||||

| sheet metal panels and corners. | ||||

| NOTE | ||||

| Lubricate vehicle in accordance with | ||||

| Lubrication Table. | ||||

| c. Inspect for loose rivets, cracks, loose or | c. Any body damage that | |||

| missing bolts and general body damage. | would hinder vehicle | |||

| operation. | ||||

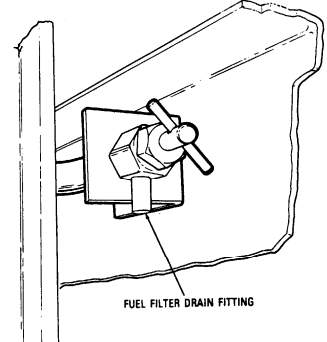

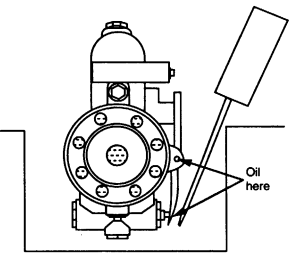

| 3 | Semi- | Fuel | a. Inspect fuel filter/water separator | a. Any class III fuel |

| Annual | System | assembly for dents and cracks that | leak. | |

| could cause leaks. | ||||

| b. Inspect fuel injection pump, | b. Any class III leak. | |||

| nozzle lines, and fittings for leaks and | Any nozzle loose or | |||

| damage. | damaged. | |||

| c. Inspect rear fuel injector nozzle | c. Rubber cap missing | |||

| rubber cap for presence and | or damaged. | |||

| condition. | ||||

| FUEL/WATER | ||||

| SEPARATOR |

Table 2-1. Unit Level Preventive Maintenance Checks and Semites HMMWV (Cont'd)

| Table 1-1. Differences Between Models | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Equipment/ | Function | |||||||||||

| Personnel/Cargo | x | x | x | Operations | ||||||||

| TOW Launcher | x | x | x | x | Mounting | |||||||

| Armament Mounting | x | x | x | x | ||||||||

| S250 Shelter | x | x | x | Configuration | ||||||||

| Ambulance: | ||||||||||||

| Two Litter Patients | x | x | ||||||||||

| Four Litter Patients | x | |||||||||||

| Eight Ambulatory | x | Patients | ||||||||||

| Six Ambulatory | x | Patients | ||||||||||

| Two Litter and Four | x | Ambulatory Patients | ||||||||||

| One Litter and | x | Three Ambulatory | ||||||||||

| Patients | ||||||||||||

| Vehicle Winch | x | x | x | x | x | x | ||||||

| Communications: | ||||||||||||

| AN/GRC-160 | x | x | x | x | x | x | x | x | x | x | x | x |

| AN/VRC-12 Series | x | x | ||||||||||

| Collective NBC Protection | x | x | ||||||||||

| Basic Armor | x | x | x | x | x | x | ||||||

| Supplemental Armor | x | x | x | x | ||||||||

| Howitzer Prime Mover | x |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

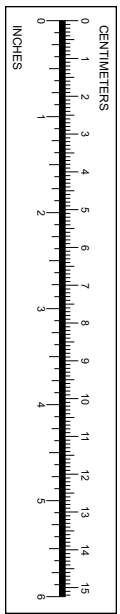

| Vehicle performance data for the M998 series vehicles is listed in table 1-2. This information includes only | |

|---|---|

| that data applicable to unit maintenance. Information not covered can be found in TM-9-2320-280-10. | |

| Table 1-2. Tabulated Data | |

| NOTE | |

| Standard and metric measurements will be used in this table. | |

| A list of their abbreviations is provided below. | |

| TABULATED DATA ABBREVIATIONS | |

| MEASUREMENT ABBREVIATION MEASUREMENT ABBREVIATION | |

| Pint pt Fahrenheit F | |

| Quart qt Celsius C | |

| Gallon gal. Liters L | |

| Inch in. Centimeter cm | |

| Miles Per Hour mph Kilometers Per Hour kph | |

| Miles Per Gallon mpg KiloPascal kPa | |

| Pounds Per Square Inch psi Maximum max | |

| Revolutions Per Minute rpm Minimum min | |

| Kilometers Per Liter km/L Kilogram kg | |

| Pound-Feet lb-ft Newton-Meter N•m | |

| Gallon Per Minute gpm Millimeter mm | |

| Volt V Ampere A | |

| Horsepower hp KiloWatt kW | |

| Liters Per Minute l/m | |

| STANDARD METRIC | |

| 1. PAYLOAD | |

| 1,135 kg | M998, M998A1, M1038, and M1038A1 2,50 0 lb |

| M1097, M1123, "A1" and "A2" Series 4,40 0 lb 1,998 kg | |

| 2. CAPACITIES* | |

| Cooling System 26 qt 24.6 L | |

| Engine | |

| Crankcase Only 7 qt 6.6 L | |

| Crankcase and Filter 8 qt 7.6 L | |

| Fuel Tank 25 gal. 94.6 L | |

| Differential (each) 2 qt 1.9 L | |

| Transmission (3L80): | |

| Drain and Refill 6 qt 5.7 L | |

| W/Dry Converter 11 qt 13.2 L | |

| Transmission (4L80-E): | |

| Drain and Refill 7.7 qt 7.3 L | |

| W/Dry Converter 13.5 qt 12.8 L | |

| Transfer Case (model 218) 3.5 qt 3.3 L | |

| Transfer Case (model 242) 3.35 qt 3.17 L | |

| Geared Hub 1 pt 0.47 L | |

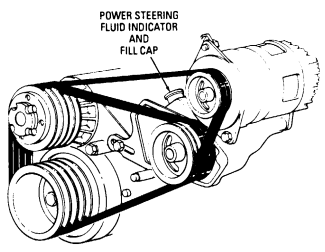

| Steering Hydraulic System 1 qt 0.95 L | |

| Steering Hydraulic System with Steering Cooler 1.25 qt 1.18 L | |

| Brake Hydraulic System (All except M1097, M1123, "A1" and "A2" series). . 1.2 pt 0.57 L | |

| Brake Hydraulic System (M1097, M1123, "A1" and "A2" series) 1.63 pt 0.77 L | |

| Brake Master Cylinder (All except M1097, M1123, "A1" and "A2 series). . . 0.69 pt 0.33 L | |

| Brake Master Cylinder (M1097, M1123, "A1" and "A2" series) 1.12 pt 0.53 L | |

| Windshield Washer Reservoir 1 qt 0.95 L | |

| *ALL HYDRAULIC SYSTEMS AND ALL FUEL CAPACITIES | |

| ARE CALCULATED APPROXIMATIONS |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

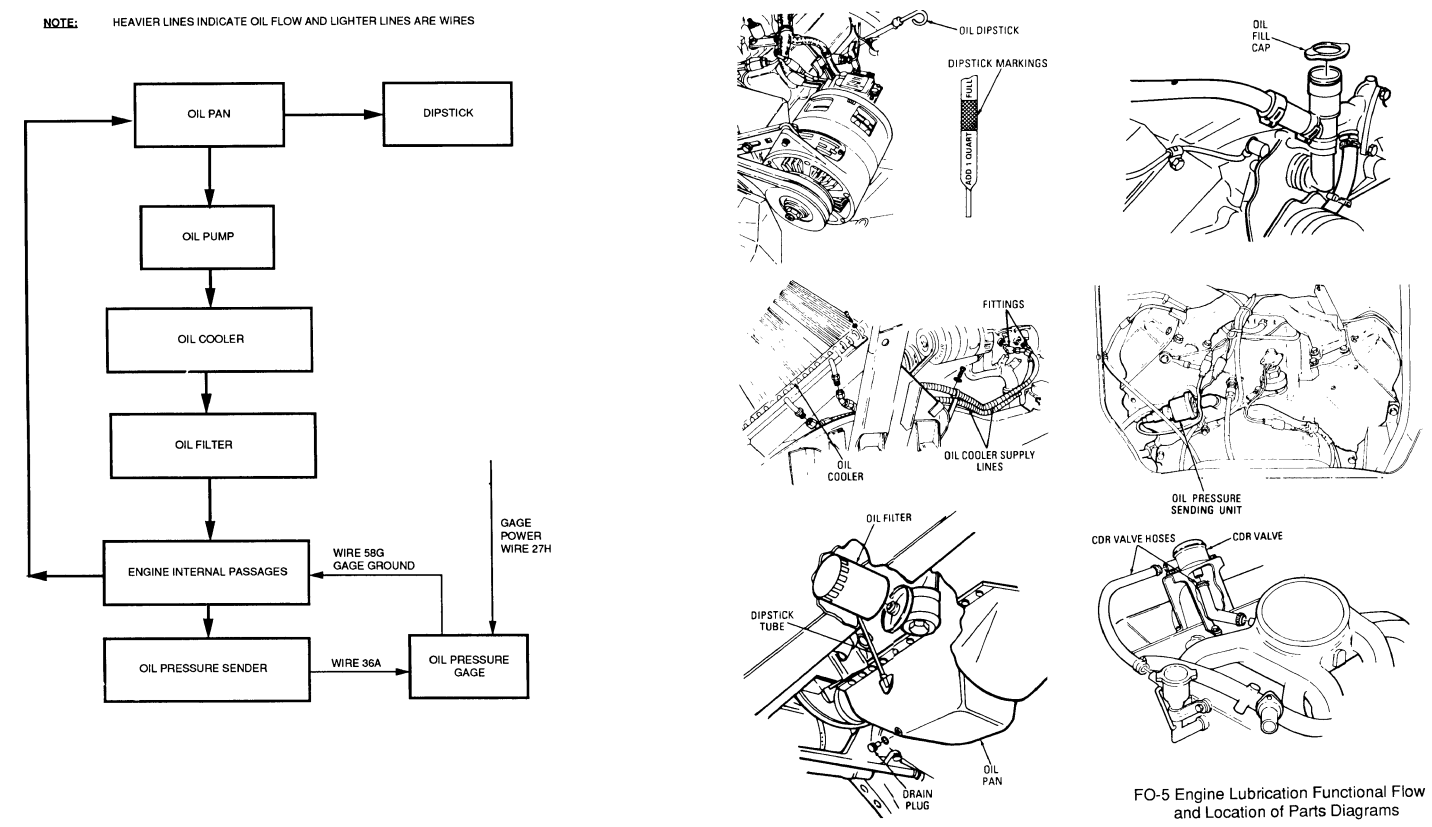

| 3. | ENGINE | |

|---|---|---|

| Model DDA 6.2 L | ||

| Type Diesel, Naturally Aspirated Liquid-Cooled, V8 | ||

| Brake Horsepower 150 hp @ 3,600 rpm | 111.9 kW @ 3,600 rpm | |

| Idle Speed 650 ± 25 rpm | ||

| Operating Speed 1,500-2,300 rpm | ||

| Oil Pressure: @ Idle 10 psi | 69 kPa | |

| @ Operating Speed 40-50 psi | 276-345 kPa | |

| 4. | ENGINE | |

| Model DDA 6.5 L and 6.5 L Detuned | ||

| Type Diesel, Naturally Aspirated, Liquid-Cooled, V8 | ||

| Brake Horsepower 160 hp @ 3,400 rpm | 119.4 kW @ 3,400 rpm | |

| Idle Speed 700 ± 25 rpm | ||

| Operating Speed 1,500-2,300 rpm | ||

| Oil Pressure | ||

| @ Idle 10 psi | 69 kPa | |

| @ Operating Speed 40-50 psi | 276-345 kPa | |

| 5. | FUEL SYSTEM | |

| Fuel Pump (Mechanical): | ||

| Type Cam-Driven Diaphragm | ||

| Fuel Filter | ||

| Type Fuel/Water Separator | ||

| Air Cleaner: | ||

| Type Dry Element | ||

| Glowplug: | ||

| Type Fast Start | ||

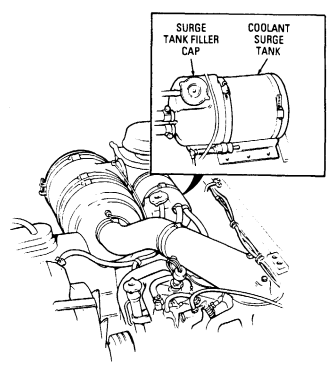

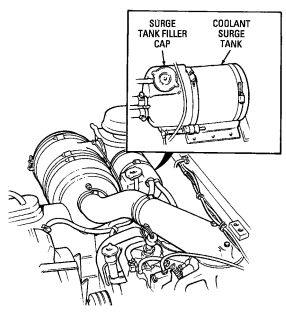

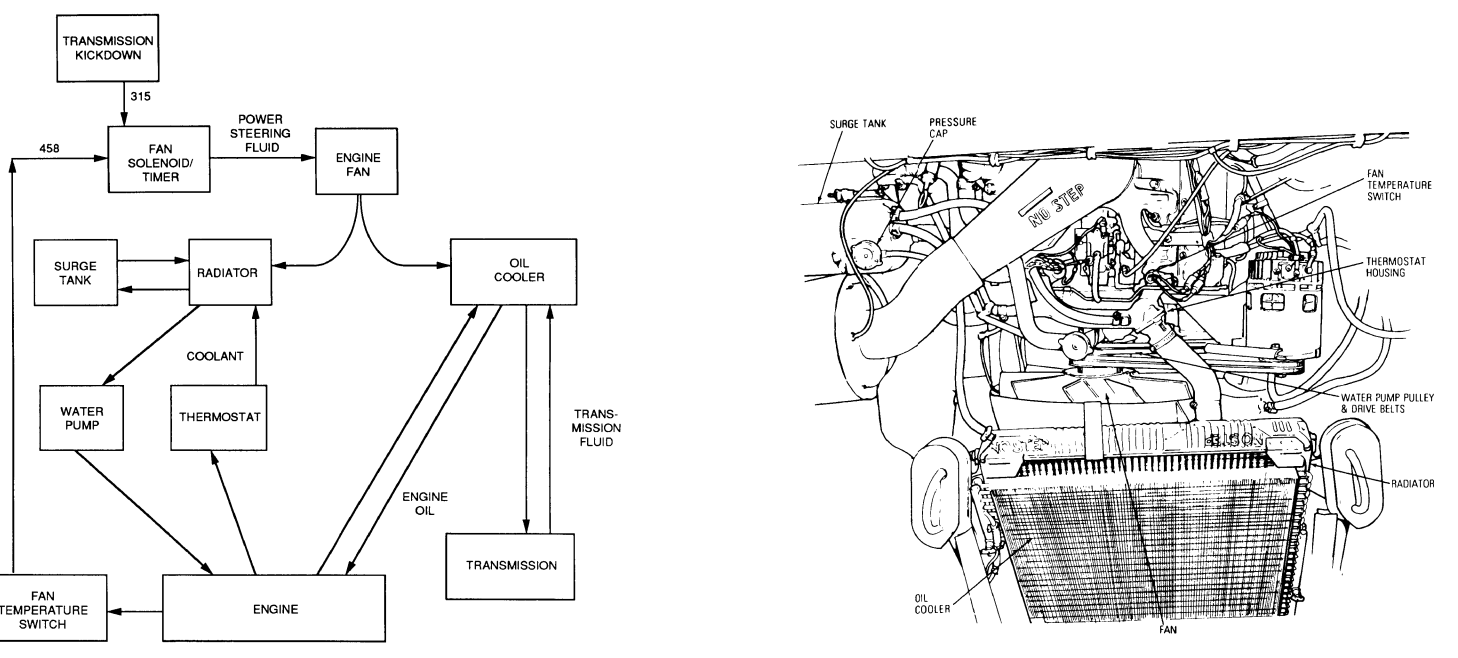

| 6. | COOLING SYSTEM | |

| Surge Tank Cap Pressure 15 psi | 103 kPa | |

| Thermostat: | ||

| Starts to Open 190°F | 88°C | |

| Fully Open 212°F | 100°C | |

| Radiator: | ||

| Type Downflow | ||

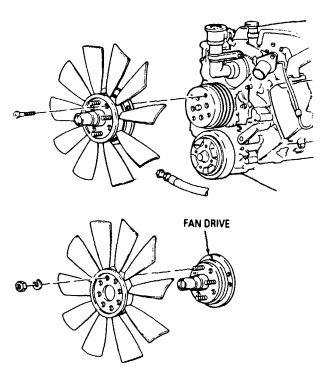

| Fan: | ||

| Type Ten Blade | ||

| Diameter 19 in. | 48.26 cm | |

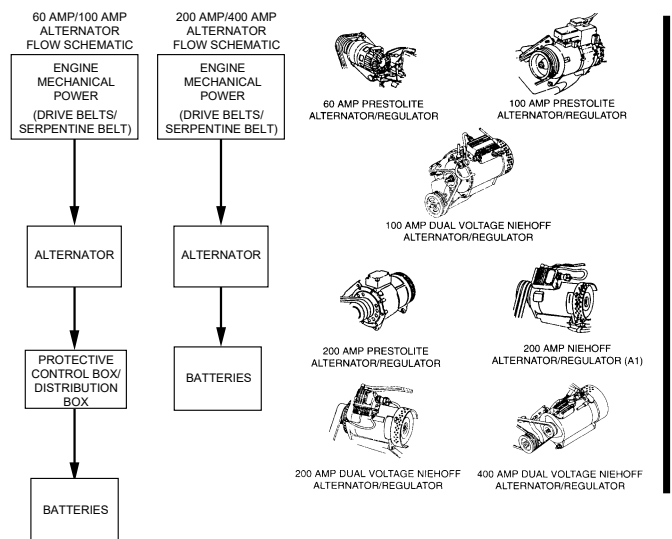

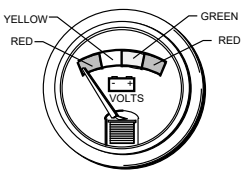

| 7. | ELECTRICAL SYSTEM | |

| Alternator: | ||

| 60 Ampere 60 A @ 28 V | ||

| 100 Ampere 100 A @ 28 V | ||

| 200 Ampere 200 A @ 28 V | ||

| 400 Ampere 400 A @ 28 V | ||

| Starter: | ||

| Voltage 14 V | ||

| Batteries (2): | ||

| Voltage 12 V |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| STANDARD | METRIC | ||

|---|---|---|---|

| 8. | TRANSMISSION | ||

| Model | 3L80 | ||

| Type | 3-Speed, Automatic | ||

| Oil Type | Dexron® II | ||

| Oil Pressure | 55-160 psi | 379-1,103 kPa | |

| 9. | TRANSMISSION | ||

| Model | 4L80-E | ||

| Type | 4-speed, Automatic Torque Converter Stall Ratio and | ||

| Direct Drive w/Lock Up Clutch | |||

| Gear Ratios | |||

| First 2.48:1 | |||

| Second | 1.45:1 | ||

| Third | 1.00:1 | ||

| Fourth | 0.75:1 | ||

| Reverse 2.08:1 | |||

| Oil Type | Dexron® III | ||

| Oil Pressure | 35-324 psi | 241-2,234 kPa | |

| 10. | TRANSFER CASE | ||

| Model | NPG 218 w/Cooler | ||

| NPG 242 w/Cooler | |||

| Type 2-speed | |||

| Oil Type | Dexron® II | ||

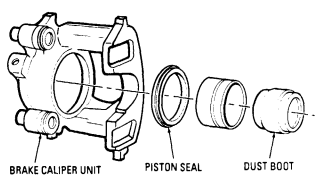

| 11. | SERVICE BRAKE CALIPER (FRONT) | ||

| Manufacturer Kelsey-Hayes | |||

| Piston Diameter 2.6 in. | 66 mm | ||

| 12. | SERVICE/PARKING BRAKE CALIPER (REAR) | ||

| Manufacturer Kelsey-Hayes | |||

| Piston diameter | 2.6 in. | 66 mm | |

| 13. | SERVICE BRAKE ROTOR (FRONT) | ||

| Manufacturer Kelsey-Hayes | |||

| A2 Manufacturer | Kelsey-Hayes | ||

| Diameter | 10.5 in. | 267 mm | |

| A2 Diameter | 12 in. | 305 mm | |

| Thickness | 0.87 in. | 22.1 mm | |

| A2 Thickness | 1.02 in. | 26 mm | |

| 14. | SERVICE/PARKING BRAKE ROTOR (REAR) | ||

| Manufacturer Kelsey-Hayes | |||

| A2 Manufacturer | Kelsey-Hayes | ||

| Diameter | 10.5 in. | 267 mm | |

| A2 Diameter | 12 in. | 305 mm | |

| Thickness | 0.87 in. | 22.1 mm | |

| A2 Thickness | 1.02 in. | 26 mm |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

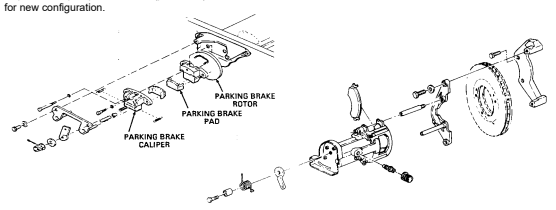

| 15. | PARKING BRAKE (VEHICLES SERIAL NUMBERS 1 THROUGH 44824) | ||

|---|---|---|---|

| Type Rod and Cable Actuated, Caliper | |||

| Rotor Diameter 8 in. | 203 mm | ||

| Brake Pad: | |||

| Type Bonded Minimum thickness 0.125 in. | |||

| Lever Type Over-Center | 3.2 mm | ||

| 16. | WHEELS AND TIRES | ||

| Tire size (Bias ply) 36 in. x 12.5 in. x 16.5 in. | 91.4 cm x 31.75 cm | ||

| x 41.9 cm | |||

| Tire size (Radial) 37 in. x 12.5 in. x 16.5 in. | 93.98 cm x 31.75 cm | ||

| x 41.9 cm | |||

| Wheels: | |||

| Type Offset Disc | |||

| Runflat Insert: | |||

| Type 2-Piece Magnesium | |||

| 17. | STEERING SYSTEM | ||

| Steering Gear: | |||

| Manufacturer Saginaw | |||

| Type Variable Ratio | |||

| Ratio 13/16:1 | |||

| Power Steering Pump: | |||

| Model Saginaw 125 | |||

| Output Pressure (max) 1,450 psi | 9,998 kPa | ||

| Flow Rate (max) 3.5 gpm | 13.2 l/m | ||

| Tow-In (Front/Rear @ curb weight): | |||

| M998, M998A1, M1025, M1025A1, M1025A2, M1026, M1026A1, | |||

| M1035, M1035A1, M1035A2, M1038, M1038A1, M1043, M1043A1, | |||

| M1043A2, M1044, M1044A1, M1097, M1097A1, | |||

| M1097A2, and M1123 0.438 in. ± 0.125 in. | 11 mm ± 3.2 mm | ||

| M966, M966A1, M996, M996A1, M997, M997A1, M997A2, | |||

| M1036, M1037, M1042, M1045, M1045A1, M1045A2, M1046, M1121, | |||

| and M1046A1 0.312 in. ± 0.125 in. | 8 mm ± 3.2 mm | ||

| 18. | WINCH | ||

| Model W6000D25 | |||

| Type | Electric Drive, Thermal Cutoff Switch | ||

| Capacity 6,000 lb | 2,724 kg | ||

| 19. | WINCH | ||

| Model MIL-9000 | |||

| Type Electric Drive, Thermal Cutoff Switch | |||

| Capacity 9,000 lb | 4,086 kg | ||

| 19.1.WINCH | |||

| Model 983-75-50050 | |||

| Type | Hydraulic | ||

| Capacity 10,500 lb | 4,767 kg | ||

| 20. | AIR-CONDITIONING COMPRESSOR | ||

| Manufacturer Sanden |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| ITEM | INTERVAL | ITEM TO BE | PROCEDURES | NOT FULLY WISSION |

|---|---|---|---|---|

| NO. | INSPECTED | CAPABLE IF: | ||

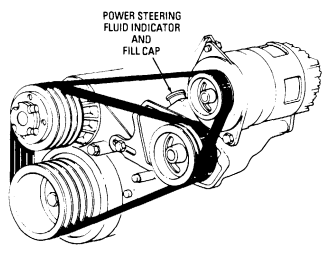

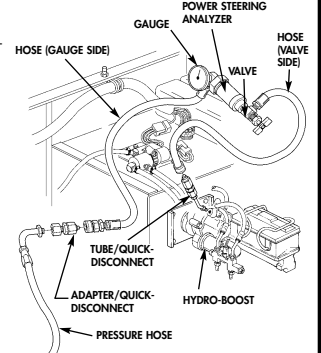

| 10 | Semi- | Suspension | g. Inspect power steering pump. | g. Any class III leak |

| Annual | and Steering | power steering gear, hydraulic | Any component damaged. | |

| System | control valve, hoses, lines, and | |||

| (Cont'd) | fittings for leaks or damage. | |||

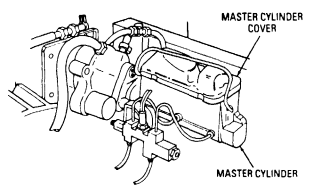

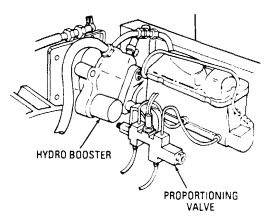

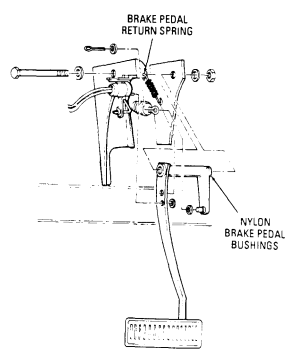

| 11 | Semi- | Brake | a. Inspect master cylinder, | a. Any leak. Plugged. |

| Annual | System | hydro-boost, lines, and fittings for | broken, or damaged | |

| leaks and damage. | lines and fittings. | |||

| MASTER CYLINDER | MASTER CYLINDER | |||

| HYDRO-BOOST | ||||

| NEW CONFIGURATION | ||||

| CAUTION | ||||

| · Use MIL-B-46176, Silicone Brake | ||||

| Fluid (BFS), for filling master brake cylinder. Failure to use BFS will | ||||

| cause damage to brake cylinder. | ||||

| · Throughly clean exterior of master | ||||

| cylinder cover before removing cover | ||||

| (table 2-1). Dirt, water, or grease will | ||||

| contaminate brake fluid causing | ||||

| brake system damage. | ||||

| · Do not use screwdriver to remove | ||||

| cover. Damage to bail wire will result. | ||||

| · To prevent excessive fluid spillage, | ||||

| ensure that rubber diaphragm is | ||||

| completely seated before installing cover to master cylinder. | ||||

| NOTE | ||||

| Remove cover from brake master | ||||

| cylinder by moving bail wire using | ||||

| thumb pressure only. | ||||

| b. Check master brake cylinder fluid | b. Level below 1/8 inch | |||

| level. Level should be 1/8 inch | (3.2 mm) from top of | |||

| (3.2 mm) from top of master cylinder | master cylinder reservoir. | |||

| reservoirs. Fill with BFS as necessary. |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| G E N E R A L | ||

|---|---|---|

| This section explains how components of the M998 series vehicles work together. The systems (functional | ||

| groups) covered are listed in the Principles of Operation Reference Index, paragraph 1-17. | ||

| PRINCIPLES OF OPERATION REFERENCE INDEX | ||

| S Y S T E M | P A G E | |

| P A R A . | N O . | |

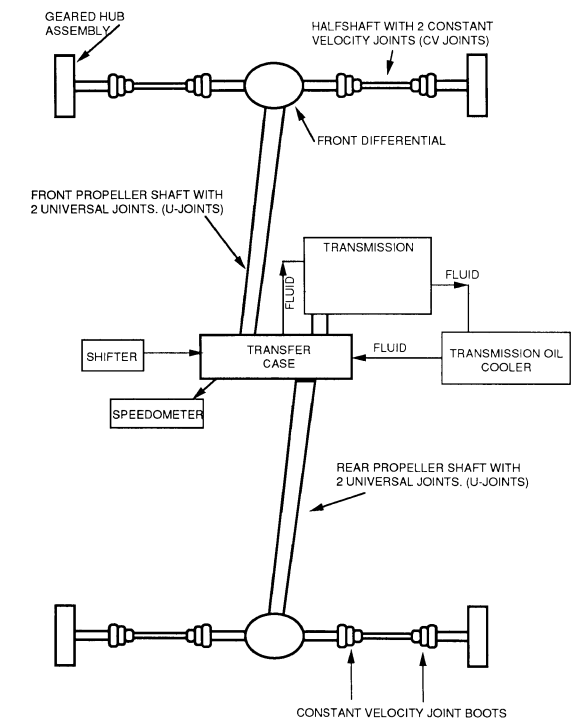

| Drivetrain Operation | 1-36 | |

| Fuel System Operation | 1-37 | |

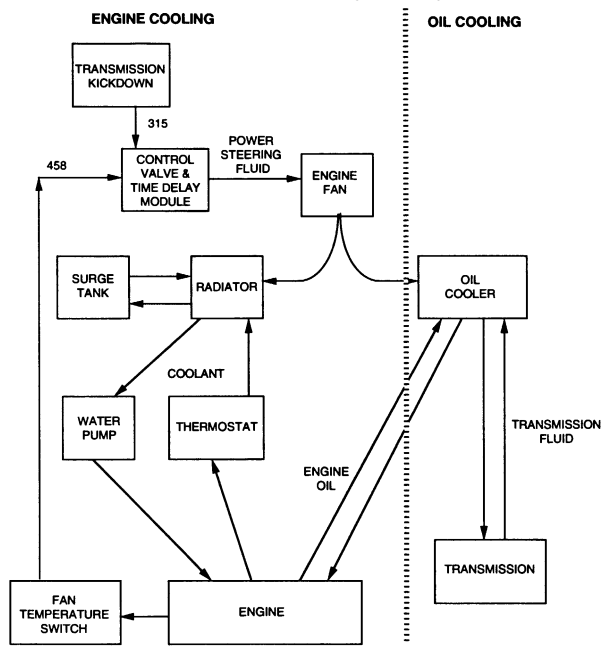

| Cooling System Operation | 1-38 | |

| Starting System Operation | 1-40 | |

| Generating System Operation | 1-41 | |

| Generating System Operation (200 Ampere Alternator) | 1-42 | |

| 1-23.1. | Generating System Operation (100 Ampere Dual Voltage | |

| Alternator) | 1-42.1 | |

| Generating System Operation (200 Ampere Dual Voltage | ||

| Alternator) | 1-42.2 | |

| Generating System Operation (400 Ampere Dual Voltage | ||

| Alternator) | 1-42.3 | |

| Battery System Operation | 1-43 | |

| Windshield Wiper/Washer System Operation | 1-44 | |

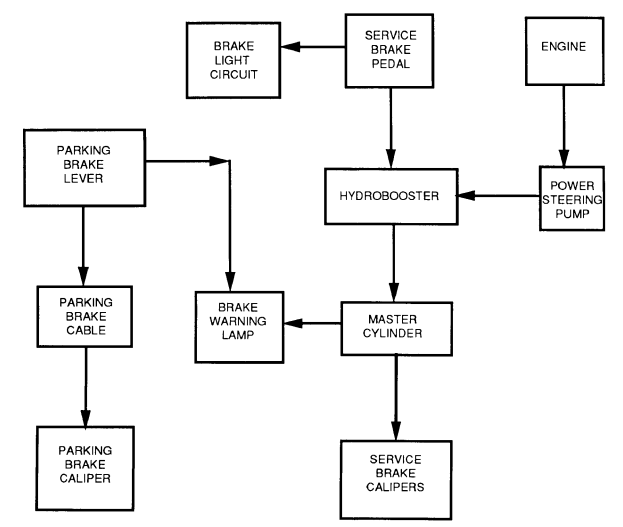

| Parking Brake System Operation | 1-45 | |

| Service/Parking Brake System Operation | 1-46 | |

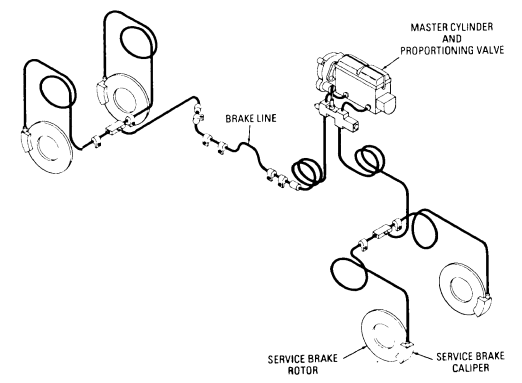

| Service Brake System Operation | 1-47 | |

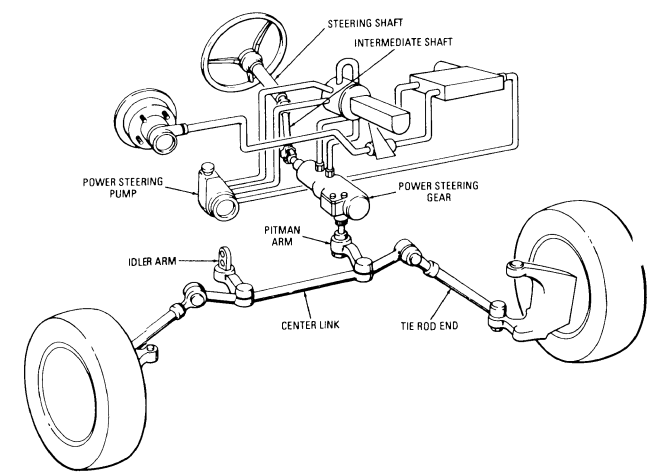

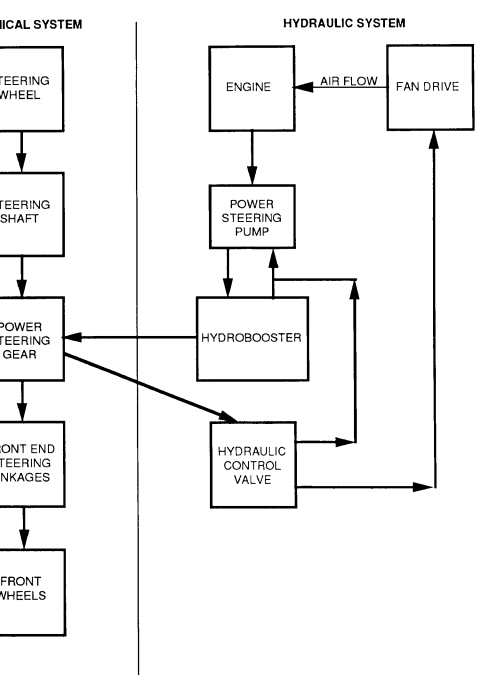

| Steering Control System Operation | 1-49 | |

| Suspension System Operation | 1-51 | |

| Ambulance Patient Compartment Fuel Burning Heater | 1-53 | |

| System Operation | ||

| M997, M997A1, and M997A2 Ambulance Air-Conditioning | 1-54 | |

| System Operation | ||

| Stowage Racks and Tiedown Straps | 1-55 | |

| 200 Ampere Umbilical Power Cable | 1-58 | |

| 1 - 1 6 . 1 - 1 7 . R E F . 1-18. 1-19. 1-20. 1-21. 1-22. 1-23. 1-23.2. 1-23.3. 1-24. 1-25. 1-26. 1-27. 1-28. 1-29. 1-30. 1-31. 1-32. 1-33. 1-34. |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| I T E M | I N T E RVA L | ITEM TO BE | P R O C E D U R E S | NOT FULLY MISSION |

|---|---|---|---|---|

| N O . | I N S P E C T E D | C A PABLE IF: | ||

| PRIOR TO ROAD TEST | ||||

| Ensure Operator/Crew has | ||||

| performed PMCS listed in TM 9- | ||||

| 2320-280-10. | ||||

| ROAD TEST | ||||

| Maintenance personnel will be with | ||||

| vehicle operator to assist in perform | ||||

| ing PMCS checks and verify pre | ||||

| service checks. | ||||

| 1 | Semi- | Pre-Service | a. Notice if starter engages smoothly | a. Starter inoperative or |

| Annual | Checks | and turns the engine at normal | makes excessive grinding | |

| cranking speed. | sound. | |||

| b. Listen for unusual noise at idle, | b. Engine knocks, rattles, | |||

| at operating speed, and under | or smokes excessively. | |||

| acceleration. Be alert for excessive | ||||

| vibration and the smell of oil, fuel, | ||||

| and exhaust. | ||||

| c. Check for transmission response to | c. Transmission shifts | |||

| shifting and for smoothness of | improperly, does not shift, | |||

| operation in all gear ranges. Be alert | or makes excessive noises. | |||

| for unusual noises and difficulty in | ||||

| shifting in any speed range. | ||||

| NOTE | ||||

| If desired range cannot be selected, | ||||

| turn engine off, select range, and re | ||||

| start engine. | ||||

| d. Check for transfer response to | d. Lever inoperable or | |||

| shifting and for smoothness of | does not engage in all | |||

| operation in all gear ranges. Be | ranges with engine not | |||

| alert for unusual noises and difficulty | running. | |||

| in shifting in any gear range. | ||||

| e. Test for response to accelerator | e. Pedal sticking or | |||

| feed. Observe for sticking pedal. | binding. | |||

| f. With vehicle speed approximately 5 | f. Steering binds, grabs, | |||

| mph (8 kph) turn steering wheel to | wanders, or has excessive | |||

| left, then right, to detect hard steering, | freeplay. | |||

| steering backlash, or shimmy. Vehicle | ||||

| should respond instantly. With vehicle | ||||

| moving on straight, level terrain, lightly | ||||

| hold steering wheel to check for pull | ||||

| and wandering. | ||||

| g. Apply brake pedal with steady force. | g. Brakes chatter, pull | |||

| Vehicle should slow and stop without | to one side, or inoperative. | |||

| pulling to one side or jerking. Release | Brakes will not release. | |||

| brake pedal. The brakes should release | ||||

| immediately and without difficulty. |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| Table 2-1. Unit Level Preventive Maintenance Checks and Semites HMMWV (Cont'd) |

|---|

| NOTE |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| I T E M | I N T E RVA L | ITEM TO BE | P R O C E D U R E S | NOT FULLY MISSION |

|---|---|---|---|---|

| N O . | I N S P E C T E D | C A PABLE IF: | ||

| 3 | Semi- | Fuel | d. Inspect all fuel lines for loose con- | d. Any class III leak. |

| Annual | System | nections, splits, cracks, and bends that | ||

| (Cont'd) | could leak. | |||

| e. Disconnect leads from each | e. Continuity is not | |||

| glow plug (paragraph 3-38) and check | present. | |||

| for resistance between glow plug ter | ||||

| minal and ground. Continuity should | ||||

| be present. | ||||

| f. Check each glow plug for looseness | f. Glow plugs are loose | |||

| and damage. Tighten each plug to | or damaged. | |||

| 8-12 lb-ft (11-16 N•m). | ||||

| g. Check locknut on body mounts. | g. Body mounts loose. | |||

| Proper torque 90 lb-ft (122 N•m). | ||||

| h. Check the fuel tank for propeller | h. Any class III fuel leak | |||

| shaft rub marks and damage. Ensure | or tank strap improperly | |||

| straps are properly installed in fuel | installed or loose. | |||

| tank slots. Tighten strap locknuts | ||||

| to 23-27 lb-in. (2.6 - 3 N•m). | ||||

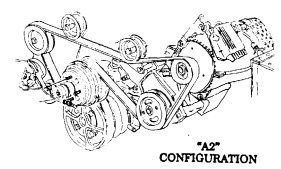

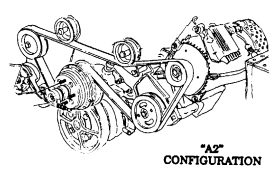

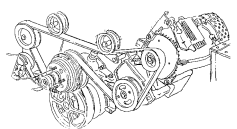

| 4 | Semi- | Engine | a. Check for missing, broken, cracked, | a. Any drivebelt is miss |

| Annual | Accessory | and frayed drivebelts. Ensure | ing, broken, frayed, or | |

| Drive and | serpentine drivebelt has not moved | dry-rotted. Belt fiber has | ||

| B e l t | Serpentine | out of place on pulley. | more than one crack 1/8 in. (3.2 mm) in depth or 50% of | |

| belt thickness) or has frays | ||||

| more than 2 in. (51 mm) | ||||

| long. Serpentine belt has | ||||

| moved out of place on | ||||

| p u l l e y s . | ||||

| b. (All models except M1123 and "A2" | b. Tension below 70 lbs | |||

| vehicles). Check all drivebelts tension | (311 N), or greater than | |||

| using belt tension gauge. Belt tension | 110 lbs (489 N) new belt | |||

| should be 70 lbs (311 N) minimum. If | and 95 lbs (422 N) | |||

| belt tension is not at least 70 lbs (311 N), | old belts. | |||

| adjust drivebelts (paragraph 3-82). Te n s i o n | ||||

| should not be greater than 110 lbs (489 N) | ||||

| for new belts; old belts 95 lbs (422 N). | ||||

| 5 | Semi- | Protective | a. Inspect four nuts for security of | a. Mounting not secure, |

| Annual | Control Box | mounting. | four nuts loose. | |

| b. Ensure cannon plugs are securely | ||||

| connected to box. |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd) | |||||||

|---|---|---|---|---|---|---|---|

| INTERVAL | ITEM TO BE | NOT FULLY MISSION | ITEM | PROCEDURES | INSPECTED | NO. | CAPABLE IF: |

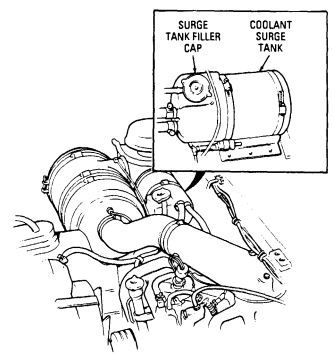

| Cooling | 6 | Semi- | WARNING | Annual | System | If vehicle has been operating, use | |

| extreme care to avoid being burned | when removing cooling system | ||||||

| radiator cap. Use heavy rags or gloves | to protect hands. Turn radiator cap | ||||||

| only one-half turn counterclockwise | and allow pressure to be released | ||||||

| before fully removing cap. | |||||||

| NOTE | Ž Coolant level is correct when coolant | ||||||

| recovery tank is full TM 9-2320-280-10). | Ž Use MIL-A-46153 in temperatures | ||||||

| above 0°F (-18°C) and MIL-A-11755 in | temperature below 0°F (-18°C). | ||||||

| a. Check coolant condition. Test coolant | a. Coolant condition/ | testing shows draining | to see if draining is necessary | ||||

| is required. | (TB 750-651). | ||||||

| b. Any class III water | b. Inspect surge tank, radiator shroud, | power steering cooler, oil cooler, all | leak. Hoses cracked | ||||

| hoses, quick disconnects and fittings for | or dry rotted. | security of mounting, leaks, and | |||||

| deterioration. Inspect and clean as | necessary the radiator and oil cooler cores. |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd) | |||||||

|---|---|---|---|---|---|---|---|

| NOT FULLY MISSION | ITEM TO BE | INTERVAL | ITEM | PROCEDURES | CAPABLE IF: | INSPECTED | NO. |

| WARNING | If NBC exposure is suspected, all air | ||||||

| filter media should be handled by | protective | personnel | wearing | ||||

| equipment. Consult your unit NBC | officer or NBC NCO for appropriate | ||||||

| handling or disposal instructions. | |||||||

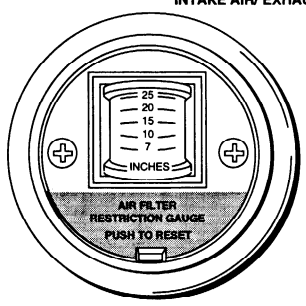

| Air-Intake | a. Inspect and clean air cleaner | Semi- | 7 | element and housing | Annual | System | |

| (para. 3-13). | |||||||

| b. CDR fails water | b. Check CDR valve oil saturation. | manometer vacuum test. | Disconnect CDR valve oil fill tube hose | ||||

| from CDR valve and inspect. Some oil | accumulation in the CDR valve is | ||||||

| acceptable. Correct CDR function is | determined by checking vacuum with a | ||||||

| water manometer. (para. 3-9a). | |||||||

| CAUTION | Do not clean CDR valve with solvent. | ||||||

| This will damage the diaphragm in | side the CDR valve. Wiping with a rag | ||||||

| is the only authorized method of | cleaning. | ||||||

| c. Remove and wipe off the CDR valve | and hoses with a rag. |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| ITEM TO BE | NOT FULLY MISSION | I T E M | P R O C E D U R E S | I N T E RVA L | I N S P E C T E D | C A PABLE IF: | N O . | ||

|---|---|---|---|---|---|---|---|---|---|

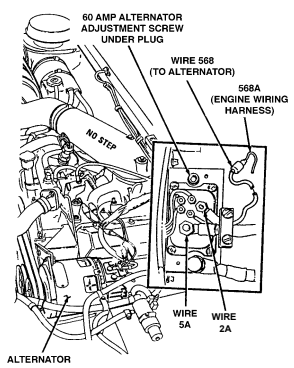

| 8 | Semi- | 60, 100, and | a. | Inspect alternator and voltage | a. Mounting bolts | Annual | 200 Amp | regulator (200 amp only) for condition, | missing or alternator |

| Alternators | proper installation, and security of | damaged. | mounting. | ||||||

| b. | Inspect electrical wiring for | b. | Wiring frayed, broken, | broken strands, frayed, cracked or worn | or loose connections. | ||||

| insulation, and loose connections. | |||||||||

| c. | Deleted | ||||||||

| d. | Check alternator mounting bolts | d. | Any alternator | for security of mounting. Tighten | mounting bolt is loose. | ||||

| bolts to 40 lb-ft (54 N•m). | |||||||||

| 9 | Semi- | Accelerator | Inspect for bends, excessive play, cracks, | Linkage damaged, bent, | Annual | Linkage | and damage that could cause failure. | or cracked. | |

| 10 | Semi- | Suspension | NOTE | Annual | and | If access to locknut is a problem, | |||

| Steering | remove geared hub from control arm | System | (para. 6-11 ) . | ||||||

| a. | Remove wheel and tire assembly | a. | Capscrews or locknuts | (para. 8-3). Check front and rear | are finger or hand | ||||

| lower ball joint mounting. For M996, | turnable. | M997, M1042, M1037, M1097, M1123, | |||||||

| and "A1" and "A2" series vehicles, | tighten rear lower ball joint to lower | ||||||||

| control arm locknuts to 60 lb-ft (81 N•m) | and front to 35 lb-ft (48 N•m). All other | ||||||||

| models, tighten front and rear lower | ball joint to lower control arm locknuts | ||||||||

| to 35 lb-ft (48 N•m) and ensure cotter | pin is present. Tighten ball joint slotted | ||||||||

| nut to 73 lb-ft (99 N•m) and ensure | cotter pin is present. | ||||||||

| b. | Check front and rear upper ball joint | b. | Capscrews or locknuts | mounting. Tighten upper ball joint to | are finger or hand | ||||

| upper control arm locknuts to 21 lb-ft | turnable. | 29 (N•m). Tighten upper control arm to | |||||||

| control arm bracket locknuts to 260 lb-ft | (353 N•m) . Tighten ball joint slotted | ||||||||

| nut to 65 lb-ft (88 N•m) and ensure cotter | pin is present. | NOTE | |||||||

| Do not over lubricate ball joints, one | or two shots is adequate. | ||||||||

| c. | Lubricate front and rear upper | ball joints with GAA. |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| ITEM | INTERVAL | ITEM TO BE | PROCEDURES | NOT FULLY WISSION |

|---|---|---|---|---|

| NO. | INSPECTED | CAPABLE IF: | ||

| । ਰੇ | Semi- Annual | Tires (Cont'd) | b. Inspect tires for uneven wear and | b. Tires exhibit excessive |

| balance (paragraph 8-9). For normal wear, rotate tires as shown in rotation | or uneven wear or balance. | |||

| diagram. The vehicle's wheel alignment is optimumly designed for GVW | ||||

| operation. Operating the vehicle without | ||||

| a load can cause excessive wear on the | ||||

| outer edge of the tread pattern. If this | ||||

| pattern develops, turn tires around | ||||

| on the rim (para. 8-4). | ||||

| c. Rotate tires as diagram shows. | ||||

| ROTATION DIAGRAM | ||||

| d. Tighten wheel lug nuts to 90-110 lb-ft (122-149 N·m) in | d. Any broken studs, loose or missing lug nuts. | |||

| tightening sequence shown. | ||||

| TIGHTENING SEQUENCE | ||||

| -9 | ||||

| গু 0 | ||||

| 0 0 | ||||

| 0 ਉ | ||||

| ତି |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| ITEM TO BE | NOT FULLY MISSION | I T E M | P R O C E D U R E S | I N T E RVA L | I N S P E C T E D | C A PABLE IF: | N O . |

|---|---|---|---|---|---|---|---|

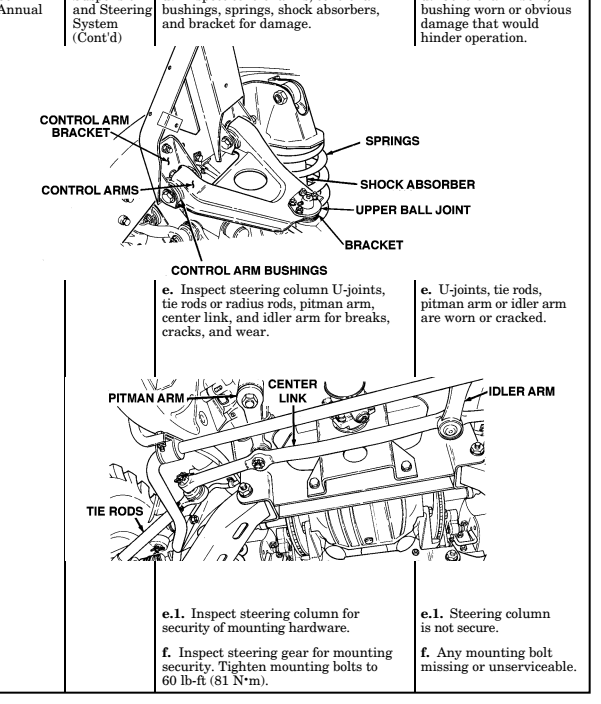

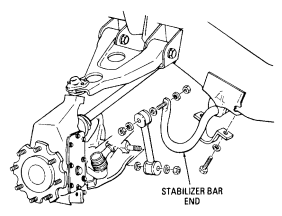

| NOTE | Do not lubricate shock absorber | ||||||

| bushings, radius rod bushings, | stabilizer bar bushing, or suspension | ||||||

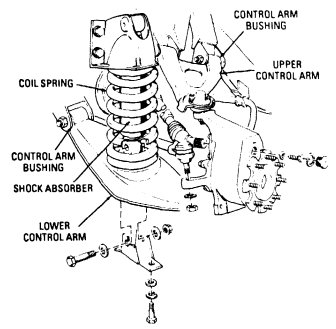

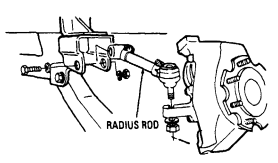

| arm pivot bushing. | 10 | Semi- | Suspension | d. | Inspect control arms, control arm | d. | Control arm bent, |

| Annual | and Steering | bushings, springs, shock absorbers, | bushing worn or obvious | System | and bracket for damage. | damage that would | |

| (Cont'd) | hinder operation. | ||||||

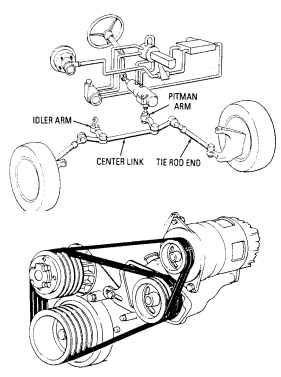

| e. | Inspect steering column U-joints, | e . | U-joints, tie rods, | tie rods or radius rods, pitman arm, | pitman arm or idler arm | ||

| center link, and idler arm for breaks, | are worn or cracked. | cracks, and wear. | |||||

| e.1. | Inspect steering column for | e.1. | Steering column | security of mounting hardware. | is not secure. | ||

| f. | Inspect steering gear for mounting | f. | Any mounting bolt | security. Tighten mounting bolts to | missing or unserviceable. | ||

| 60 lb-ft (81 N•m). |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd) Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd) | |

|---|---|

| CAUTION | MIL-B-46176 |

| table 2-1 | |

| NOTE |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| ITEM | INTERVAL | ITEM TO BE | PROCEDURES | NOT FULLY MISSION |

|---|---|---|---|---|

| NO. | INSPECTED | CAPABLE IF: | ||

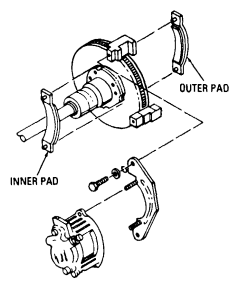

| 11 | Semi- | Brake | c. Inspect service brake pads and | c. Service brake pads less |

| Annual | System (Cont'd) | rotor disks for wear (para. 7-11). | than 1/8 inch (3.2 mm). | |

| d. Inspect parking brake pads and | d. Parking brake pads | |||

| rotor disk for wear (para. 7-3). | less than 1/8 inch (3.2 mm). | |||

| d.1. Inspect brake calipers and mounting | d.1. Brake calipers are | |||

| hardware for damage or loose hardware. | damaged or mounting | |||

| bolts are loose. | ||||

| e. Inspect dual service/park brake | e. Brake pads less than | |||

| pads and rotor for wear (para. 7-21). | 1/8 inch (3.2 mm). |

| ITEM TO BE | NOT FULLY MISSION | I T E M | P R O C E D U R E S | I N T E RVA L | I N S P E C T E D | C A PABLE IF: | N O . | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 11 | Semi- | Brake | f. | Inspect parking brake cable, cable | f. | Parking brake binding | Annual | System | clip, lever, spring, and pushrod/guide | or cable frayed or broken. |

| (Cont'd) | pin for binding and loose components. | Spring or cable clip | missing. | |||||||

| g. | On vehicles equipped with a single | parking brake assembly mounted | ||||||||

| between the rear prop shaft and rear | differential, lubricate parking brake | |||||||||

| lever, parking brake cam, parking | brake push pins, and parking brake | |||||||||

| guide pins with WTR. On vehicles | equipped with a left and right parking/ | |||||||||

| service brake assembly mounted between | the rear axle half-shafts and rear | |||||||||

| differential, lubricate the parking brake | lever with WTR. The parking/service | |||||||||

| brake assembly needs no lubrication. | ||||||||||

| h. | Inspect rear parking brake cables for | h. | Parking brake binding | damage and/or chaffing in the area of | or cable frayed or broken. | |||||

| the control arm. If cables are damaged, | replace cables (paragraph 7-23 or 7-24). | |||||||||

| i. | Inspect for presence of, or damage to, | parking brake cable clamps. | ||||||||

| 12 | Semi- | Engine and | a. | Inspect engine mounts and insu- | a. Engine mounts or | Annual | Transmis- | lators for loose, worn, and damaged | insulators cracked, | |

| sion Mounts | condition. | damaged, loose, or worn. | ||||||||

| b. | Check for loose or missing engine | b. | Capscrews or locknuts, | mount capscrews and locknuts. If | loose or missing. | |||||

| engine mount capscrews or locknuts are | loose or missing, notify DS maintenance. |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd) Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| ITEM TO BE | NOT FULLY MISSION | I T E M | P R O C E D U R E S | I N T E RVA L | I N S P E C T E D | C A PABLE IF: | N O . | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 12 | Semi- | Engine and | c. | Using 3/4 inch torque adapter | c. | Transmission mount | Annual | Trans- | (reefer to Appendix B, Item 145), | loose, cracked, or |

| mission | tighten two capscrews securing | damaged. | Mount | transmission mount to adapter to | ||||||

| (Cont'd) | 65 lb-ft (88 N•m). Tighten two locknuts | securing transmission mount to | ||||||||

| crossmember to 28 lb-ft (38 N•m). | ||||||||||

| 13 | Semi- | Starter | CAUTION | Annual | Disconnect negative cable. | |||||

| a. | Inspect starter for mounting | a. | Mounting bolt | security. Tighten mounting bolts to | missing or will not | |||||

| 40 lb-ft (54 N•m). | torque. | |||||||||

| b. | Inspect cables and studs for loose | b. | Stud nut loose. | nuts and damage. | ||||||

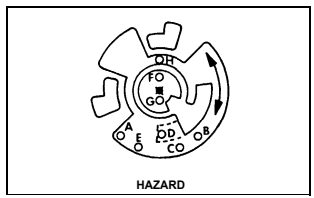

| 13.1 | Semi- | Neutral | WARNING | Annual | Start Safety | Ensure vehicle parking brake is set, | ||||

| Switch | wheels are chocked, and rotary | switch is in the ENG STOP position. | ||||||||

| Failure to comply may result in | injury to personnel and/or damage to | |||||||||

| e q u i p m e n t . | ||||||||||

| a. | Disconnect wires 14A and 14B from | Neutral start safety | wires 14 at neutral start safety | switch is malfunctioning. | ||||||

| switch. | ||||||||||

| b. | Check for continuity of neutral | start safety switch. | ||||||||

| (1) | With transmission shift lever in | N (neutral), or P (park) (for M1123, | ||||||||

| A2 series, and up-armor models only), | continuity should be present between | |||||||||

| wires 14 at neutral start safety | switch. |

| ITEM TO BE | NOT FULLY MISSION | I T E M | P R O C E D U R E S | I N T E RVA L | I N S P E C T E D | C A PABLE IF: | N O . | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 13.1 | Semi- | Neutral | (2) | Place transmission shift lever in | Annual | Start Safety | D (drive). There should be no | |||

| Switch | continuity present between wires 14. | (Cont'd) | If continuity is present, replace | |||||||

| neutral start safety switch (para. 5-6). | ||||||||||

| c. | Connect wires 14A and 14B to | wires 14 at neutral start safety | ||||||||

| switch. | ||||||||||

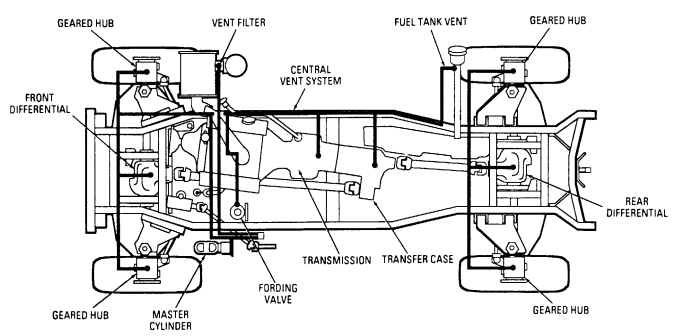

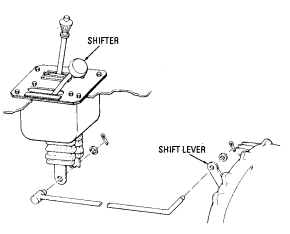

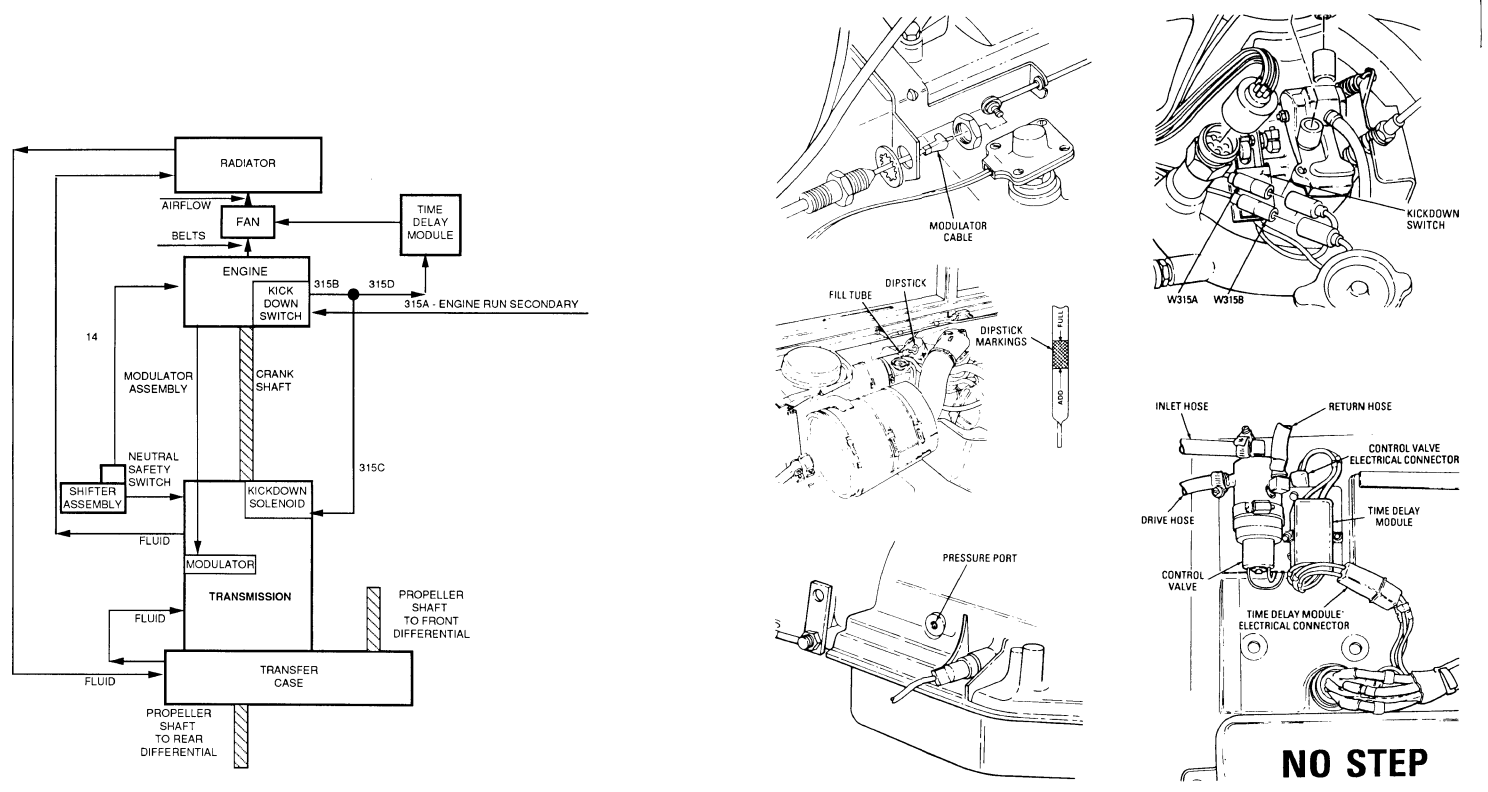

| 14 | Semi- | Trans- | a. | Inspect vent lines and connectors | a. | Vent line cracked, | Annual | mission | for security, cracks, and deterioration. | plugged, or missing. |

| b. | Inspect transmission shift linkage | b. | Shift linkage is | for bends, excessive play, cracks, and | unserviceable. | |||||

| damage that could cause failure. | ||||||||||

| 15 | Semi- | Transfer | a. | Inspect transfer case vent lines and | a. | Vent line cracked, | Annual | connectors for security, cracks, and | plugged or missing. | |

| deterioration. | Shift linkage is unserv | iceable. | ||||||||

| b. | Inspect transfer case shift linkage | for bends, excessive play, cracks, and | ||||||||

| damage that could cause failure. | ||||||||||

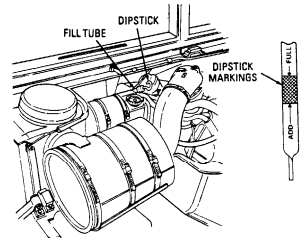

| CAUTION | Use Dexron® II | for filling transfer case. | ||||||||

| Failure to use Dexron® II | will cause | damage to transfer case. | ||||||||

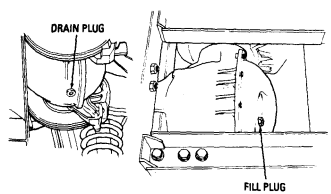

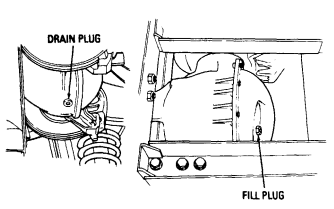

| c. | Check transfer case fluid level every | 3,000 (4,800 km) or semiannually, | ||||||||

| whichever occurs first. Remove fill plug | and gasket. Level should be within 1/2 in. | |||||||||

| (12.7 mm) of fill plug opening when vehicle | is on level ground. Install fill plug and | |||||||||

| gasket, and tighten to 35 lb-ft (47 N•m ) . |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| I T E M | I N T E RVA L | ITEM TO BE | P R O C E D U R E S | NOT FULLY MISSION |

|---|---|---|---|---|

| N O . | I N S P E C T E D | C A PABLE IF: | ||

| 15 | Semi- | Transfer | NOTE | |

| Annual | (Cont'd) | Do not overtorque retaining nuts. | ||

| d . Inspect oil cooler lines for leaks or | d . Any class III oil | |||

| damage. Check for loose oil cooler line | leak or damage to | |||

| nuts and damage to the spiral wrap on | spiral wrap. | |||

| the cooler line. If oil cooler line nuts are l o o s e, hold end of oil cooler stationary, and | ||||

| tighten line nuts to 194-212 lb-in. | ||||

| ( 2 2-24 N•m ) | ||||

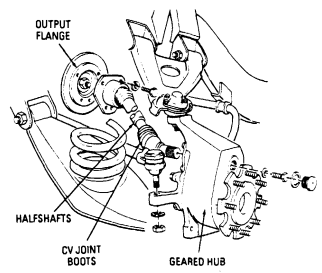

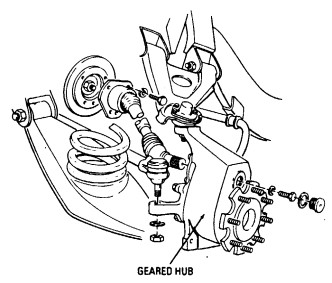

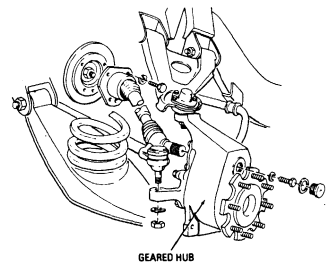

| 16 | Semi- Annual | Driveline Compo- | a. Inspect geared hub vent lines and connectors for security, cracks, and | a. Hub vent lines cracked, plugged, or |

| nents | deterioration. | missing. | ||

| b. Inspect geared hub for leaking | b. Class III leaks or | |||

| seals and damage. | damage. | |||

| CAUTION | ||||

| Change geared hub and differential | ||||

| lubricants when required by mainte | ||||

| nance repair action, contaminated by | ||||

| water or foreign material, or if | ||||

| lubricant appears by smell, feel, or | ||||

| visual indication to be overheated. | ||||

| NOTE | ||||

| •Fill each axle differential with 2 | ||||

| quarts (1.9 L) of GO. | ||||

| •Fill each geared hub with 1 pint | ||||

| (0.5 L) of GO. | ||||

| c. Adjust spindle bearing | c. Bearing damaged. | |||

| (paragraph 6-14). | ||||

| d. Inspect differential vent lines and | d. Differential vent line | |||

| connectors for security, cracks, and | has hole, plugged, or | |||

| deterioration. | cracked. | |||

| e. Inspect differentials for leaking | e. Class III leak. | |||

| seals and cracks. |

Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd)

| ITEM TO BE | NOT FULLY MISSION | ITEM | INTERVAL | PROCEDURES | INSPECTED | CAPABLE IF: | NO. | |

|---|---|---|---|---|---|---|---|---|

| 16 | Semi- | Driveline | f. M998, M998A1, and M1121 series | f. Lube level not within | Annual | Compo- | vehicles - Check differential lubricant | 1/4 inch (6.4 mm) of fill |

| nents | level semiannually or every (3,000 miles) | plug opening when cold | (Cont'd) | (4,830 km). M998A2 and M1123 series | or to plug level when hot. | |||

| vehicles - Change differential lubricant | semiannually or every 3,000 miles | |||||||

| (4,830 km). Differential level should be | within 1/4 inch (6.4 mm) of fill plug | |||||||

| opening when lubricant is cold or to plug | level when hot. |

SEMI-ANNUAL (3,000 MILE) PMCS PARTS LIST

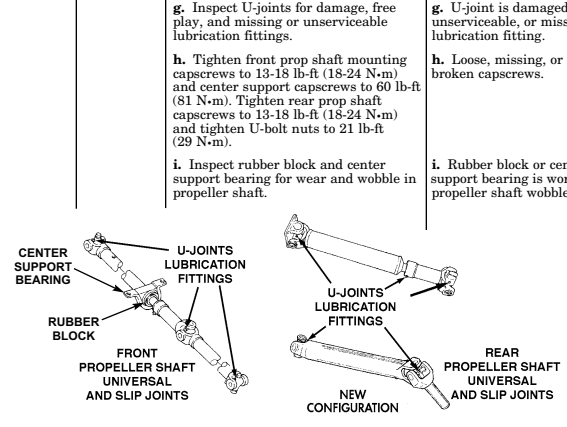

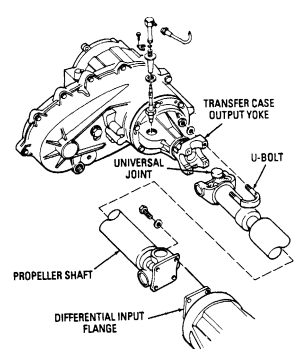

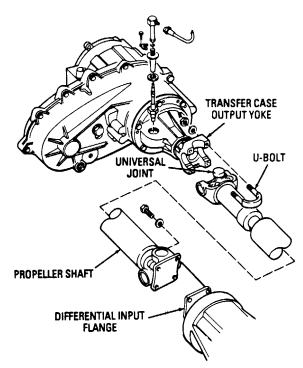

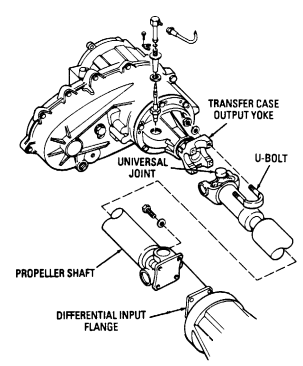

| g. Inspect U-joints for damage, free play, and missing or unserviceable | g. U-joint is damaged, unserviceable, or missing | |

|---|---|---|

| lubrication fittings. | lubrication fitting. | |

| h. Tighten front prop shaft mounting | h. Loose, missing, or | |

| capscrews to 13-18 lb-ft (18-24 N•m) | broken capscrews. | |

| and center support capscrews to 60 lb-ft | ||

| (81 N•m). Tighten rear prop shaft | ||

| capscrews to 13-18 lb-ft (18-24 N•m) | ||

| and tighten U-bolt nuts to 21 lb-ft | ||

| (29 N•m). | ||

| i. Inspect rubber block and center | i. Rubber block or center | |

| support bearing for wear and wobble in | support bearing is worn or | |

| propeller shaft. | propeller shaft wobbles. | |

| CENTER | ||

| SUPPORT | ||

| BEARING |

ANNUAL (6,000 MILE) PMCS PARTS LIST

| ITEM | INTERVAL | ITEM TO BE | PROCEDURES | NOT FULLY MISSION |

|---|---|---|---|---|

| NO. | INSPECTED | CAPABLE IF: | ||

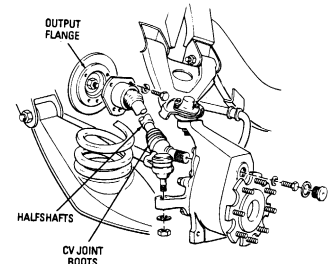

| 16 | Semi- | Driveline | j. Tighten halfshaft mounting bolts to | j. Loose, missing, or |

| Annual | Compo- | 48 lb-ft (65 N•m). | broken bolts. | |

| nents (Cont'd) | ||||

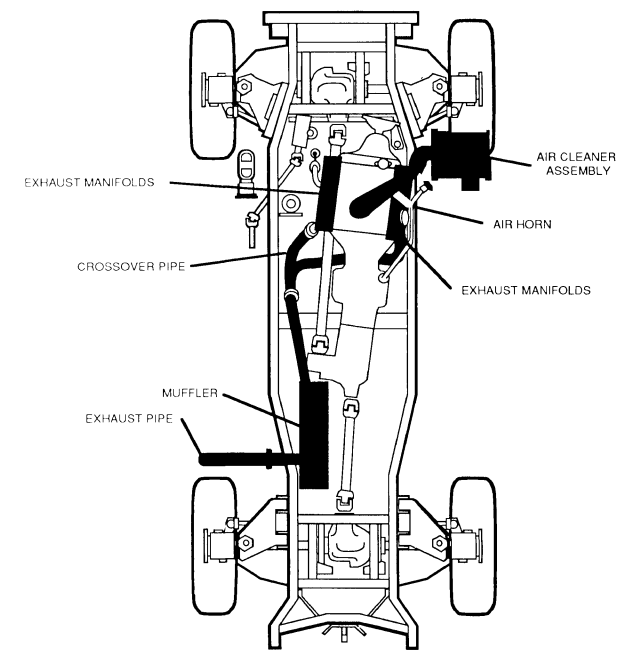

| 17 | Semi- | Exhaust | Inspect for cracked and loose pipes, | Cracked, loose, or holes in |

| Annual | Compo- | muffler, and hangers. Check for ex- | pipes or muffler. | |

| nents | haust leaks. | Exhaust leak. | ||

| 18 | Semi- | Frame and | a. Inspect frame side rails for cracks, | a. Any loose or missing |

| Annual | Cross- | breaks, bends, wear, deterioration, | fasteners, cracks, bends, | |

| members | and missing or loose fasteners. | or breaks in frame. | ||

| b. Inspect crossmembers for cracks, | b. Any loose or missing | |||

| breaks, bends, deterioration, and | fasteners. Cracks, bends | |||

| loose or missing fasteners. | (bends are defined as a | |||

| condition that would | ||||

| affect vehicle operation) | ||||

| or breaks in cross members. | ||||

| c. Inspect for missing, broken, bent, or loose bumper supports before | c. Any missing, broken, bent, or loose bumper | |||

| towing a trailer. | supports. | |||

| 19 | Semi- | Tires | WARNING | |

| Annual | - Changing tire pressures or wheel | |||

| alignment, out of the | ||||

| recommended specification, may | ||||

| adversely affect the vehicle's | ||||

| handling characteristics. Loss of vehicle control may result in | ||||

| serious injury or death and | ||||

| damage to equipment. | ||||

| - Radial and bias ply tires should not be mixed on the same vehicle. | ||||

| Injury to personnel and damage to | ||||

| equipment may result. | ||||

| NOTE | ||||

| Vehicle must be up on jack stands for | ||||

| the following checks. | ||||

| a. Check tread depth of tires with tire | a. Tread depth is less | |||

| gauge. If tread depth is less than 1/16 in. (1.59 mm), replace tire in approx | than 1/16 in. (1.59 mm). | |||

| imately 400 miles (644 km), bias tires | ||||

| will wear 1/32 in. (0.79 mm), radial tires | ||||

| will take approximately 1,300 miles | ||||

| (2092 km) to wear 1/32 in. (0.79 mm). If | ||||

| mission will require the vehicle to travel this distance within a month, replace tire | ||||

| if it measures 3/32 in. (2.38 mm). |

BIENNIALLY (12,000 MILE) PMCS PARTS LIST

OE/HDO 15/40 (Grade 15W-40) lubricant may be used when expected temperatures are above +5°F (-15°C). If OEA lubricant is required to meet the temperature ranges prescribed in the table, then the OEA lubricant is to be used in place of OE/HDO 10 lubricant for all temperature ranges. If operating conditions are severe or abnormal, service chassis lubrication points at 1,000 miles (1,600 kilometers).

| Table 2-1. Unit Level Preventive Maintenance Checks and Services HMMWV (Cont'd) |

|---|

| paragraph 8-9 |

| para. 8-4 |

Section IV. Electrical/Mechanical Systems Troubleshooting

2-12. General

a. This section provides information to diagnose and correct malfunctions of the electrical/mechanical system.

b. Principles of operation showing system operation can be found in chapter 1. It should be used as a reference when performing electrical/mechanical troubleshooting.

c. Each malfunction symptom given for an individual component or system is followed by step(s) you should take to determine the cause and corrective action you must take to remedy the problem.

d. Before taking any action to correct a possible malfunction, the following rules should be followed: (1) Question operator to obtain any information that might help you determine the cause of the problem. (2) Never over look the chance that the problem could be of simple origin. The problem could be corrected with minor adjustment. (3) Use all senses to observe and locate troubles. (4) Use test instruments or gauges to help you determine and isolate problem. (5) Always isolate the system where the malfunction occurs and then locate the defective component. (6) Use standard automotive theories and principles when troubleshooting the vehicles covered in this manual.

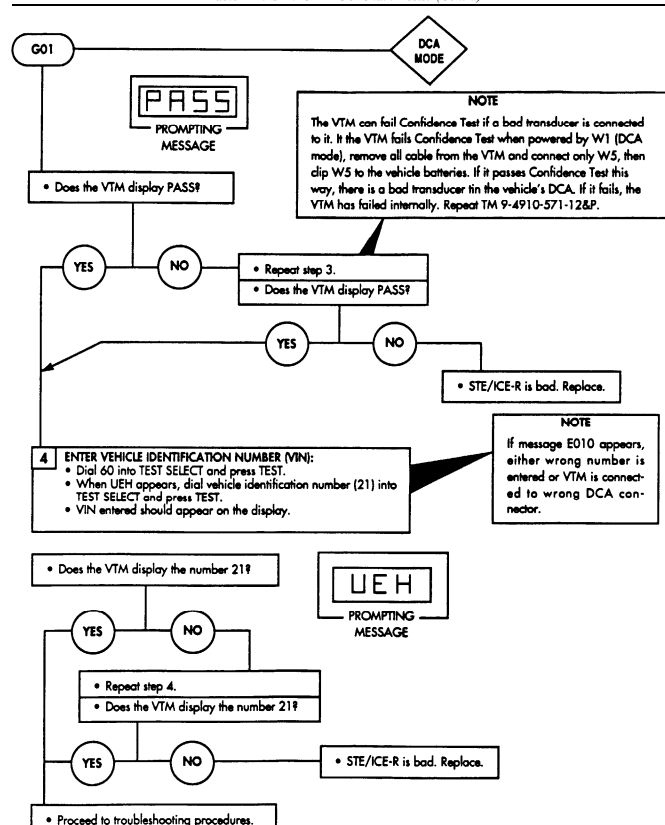

e. The STE/ICE-R is an integral part of these troubleshooting procedures. It should be used whenever possible, although other options are given, when available. The Vehicle Identification Number (VIN) assigned to the M998 series vehicles is 21 (14 is the temporary VIN). On page 2-753, you will find information on STE/ICE-R description and operation. Use this information to become familiar with STE/ICE-R operation and the equipment contained in the test set. On page 2-763 you will find STE/ICE- R setup and internal checks. These must be performed prior to performing tests.

2-13 . Electrical/Mechanical Systems Troubleshooting Electrical/Mechanical Troubleshooting

2-14. How To Use This Troubleshooting Guide

Note To The Recipient Of This Manual

There are 16 foldouts that are supplied with this manual. Take the foldouts and place them after the last page of diagnostics at the end of the paragraph. That way, the foldout will be with diagnostics for that system.

Use the cross-reference information listed below to guide you in the placement of the foldouts.

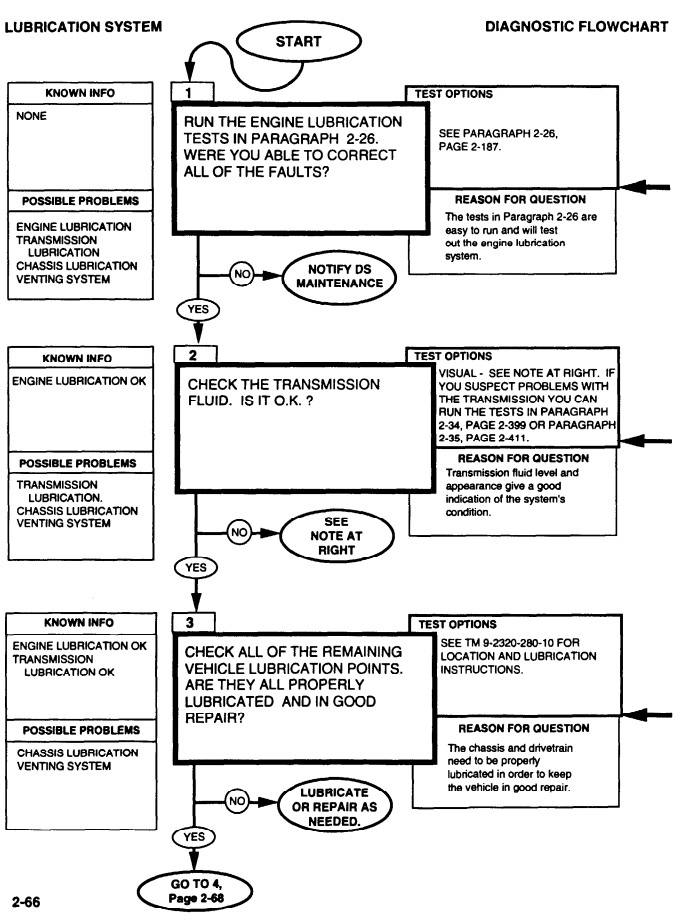

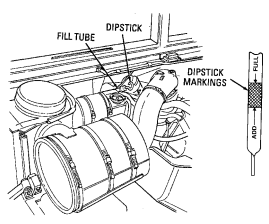

| If AOAP is not | b. Perform AOAP sample. |

|---|---|

| available, change oil and oil filter at | |

| 3,000 miles (4,800 km), or 100 hours (if | |

| hour meter is installed), or every six | |

| m o n t h s . | |

2-14. How To Use This Troubleshooting Guide (Cont'D)

2-14. How To Use This Troubleshooting Guide (Cont'D)

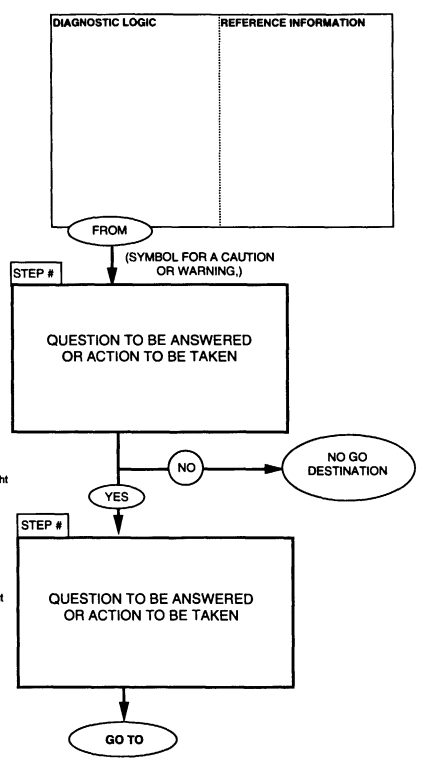

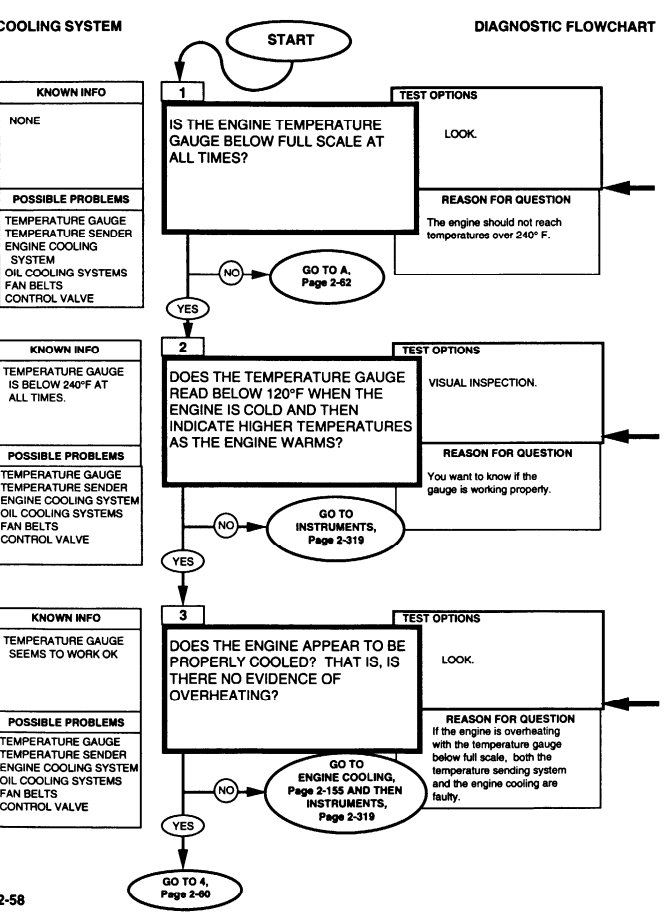

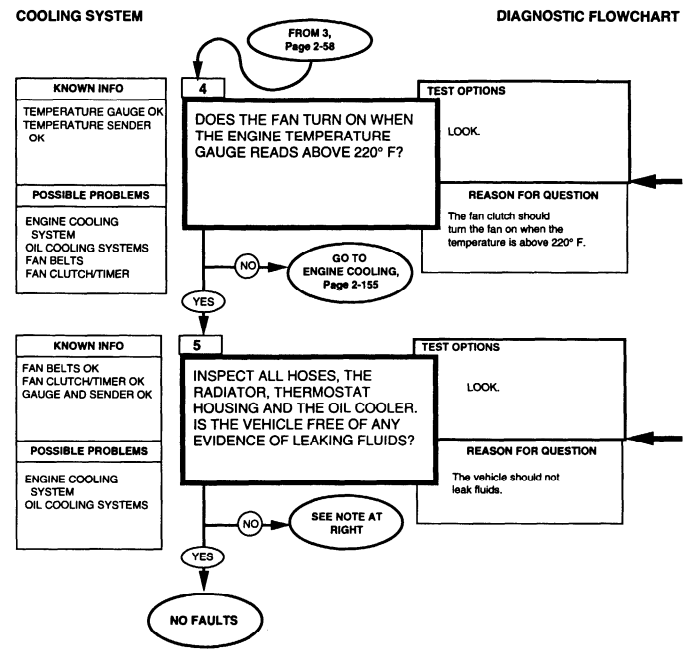

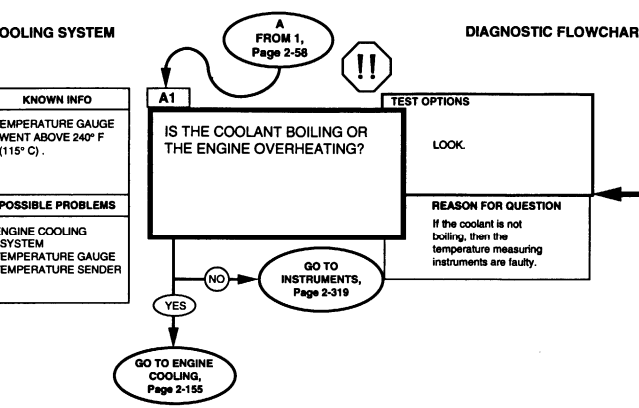

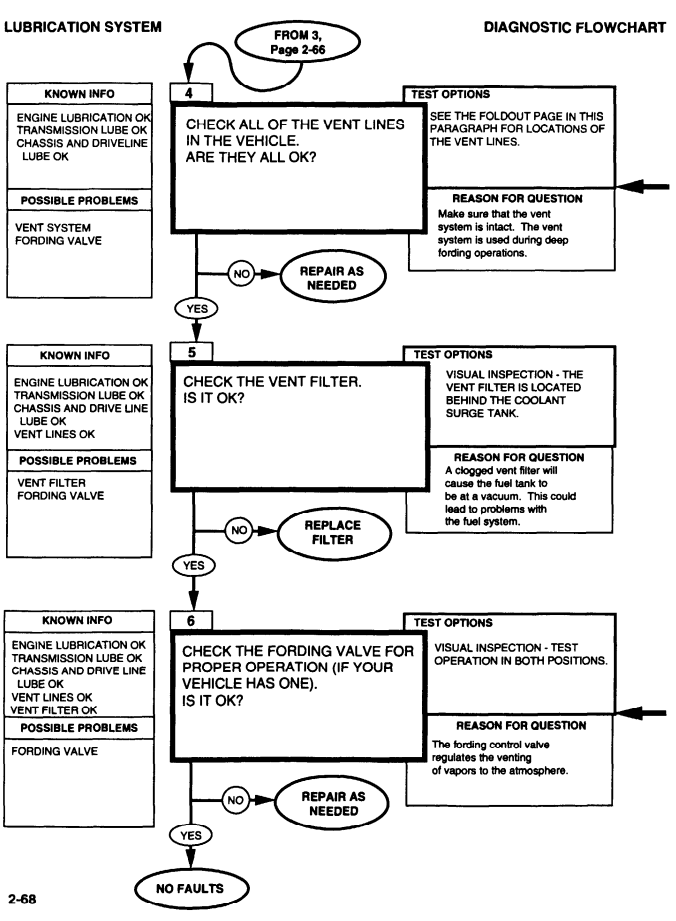

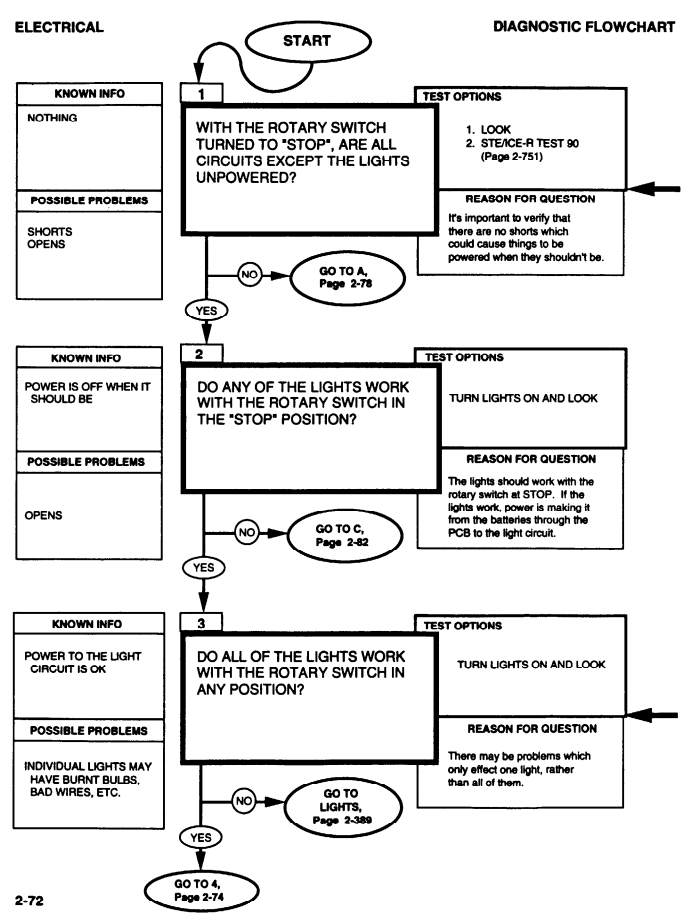

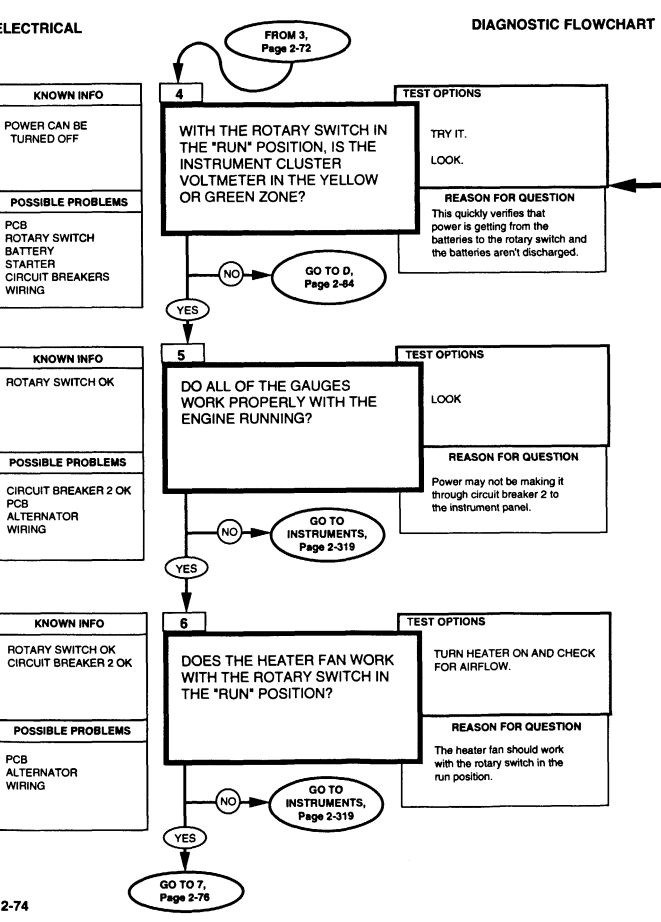

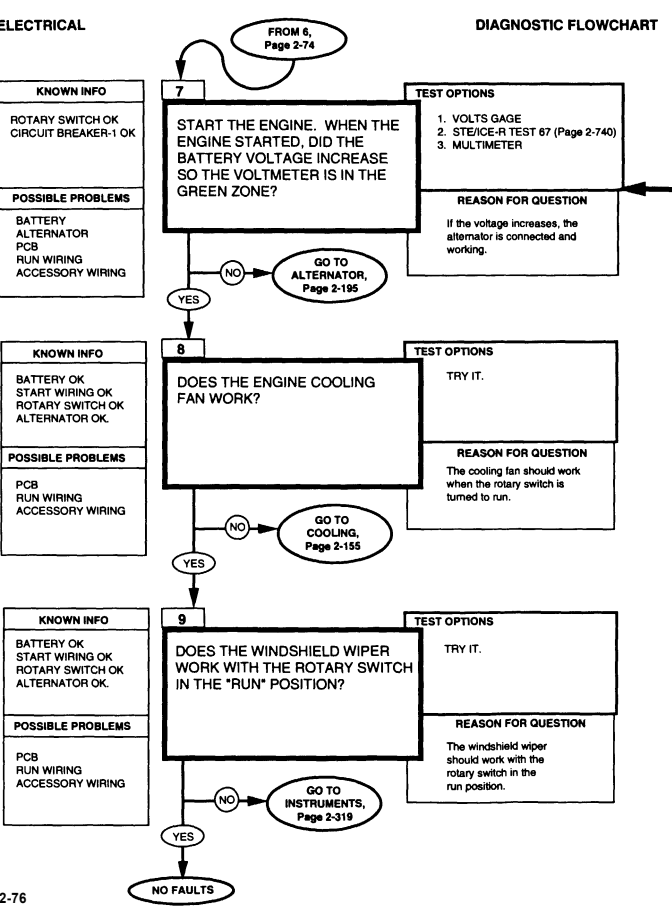

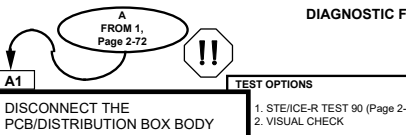

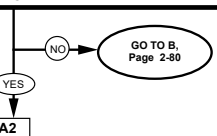

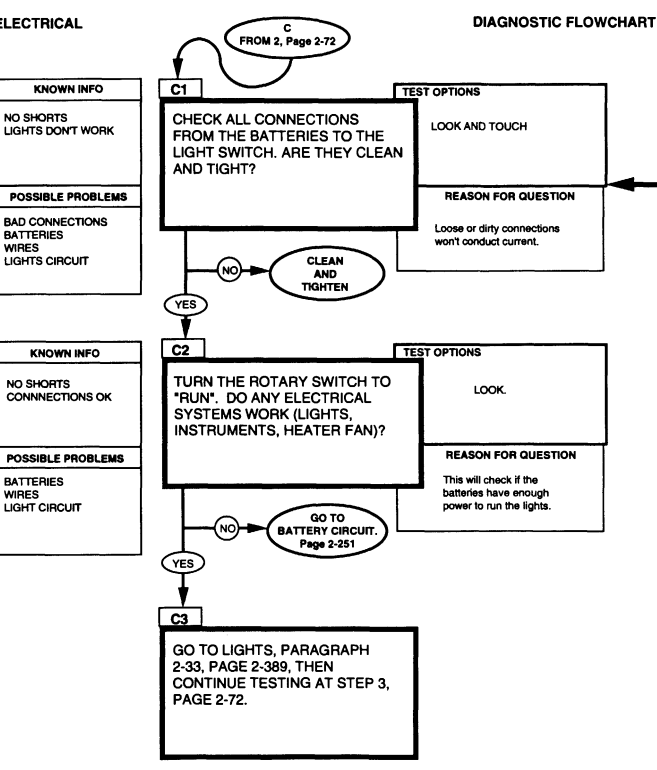

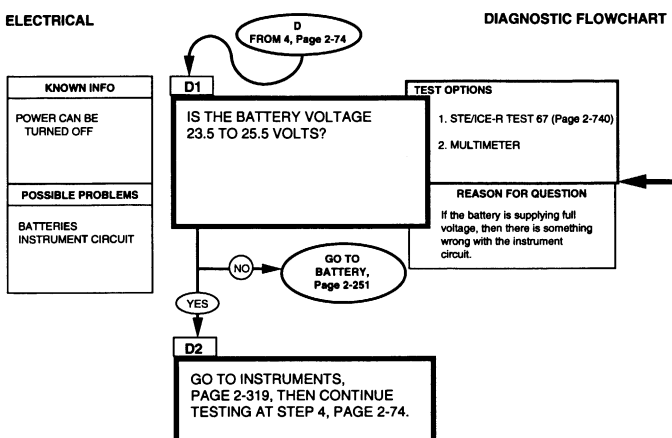

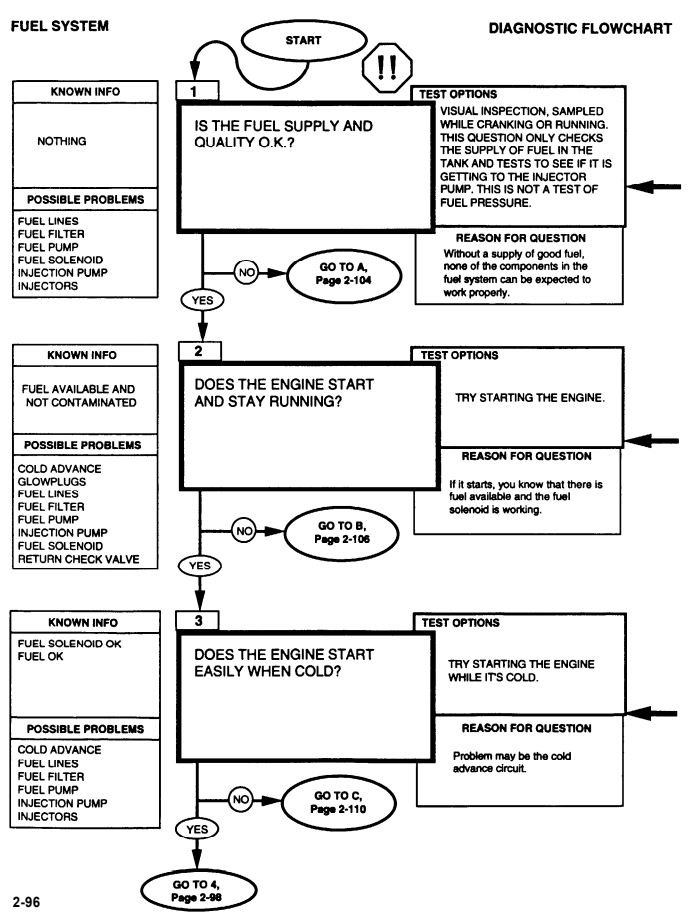

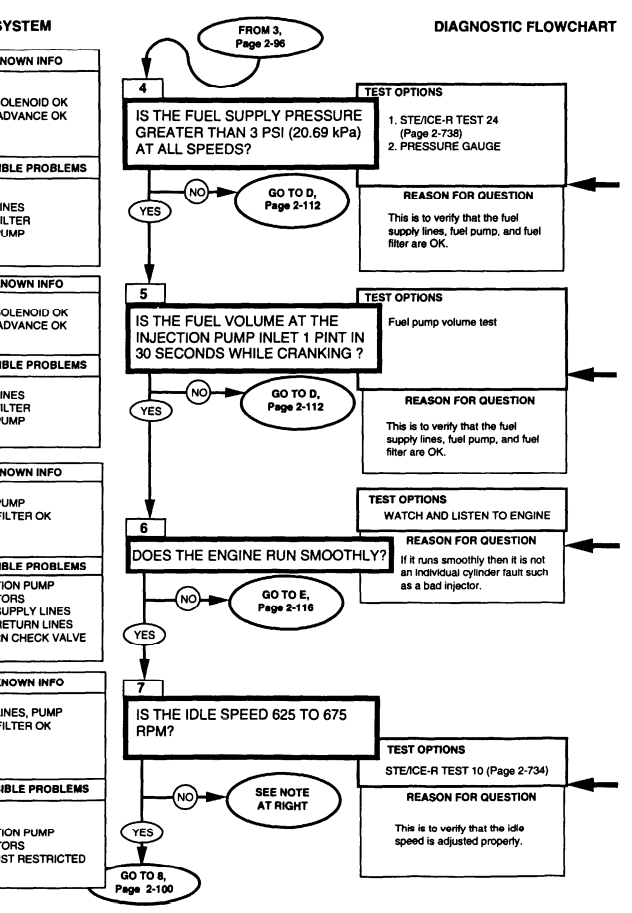

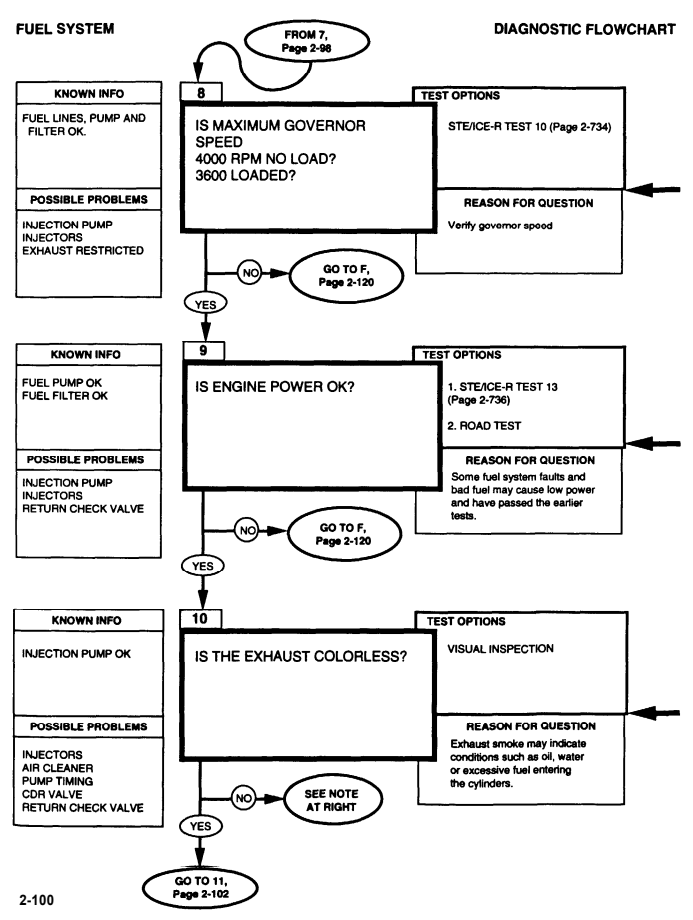

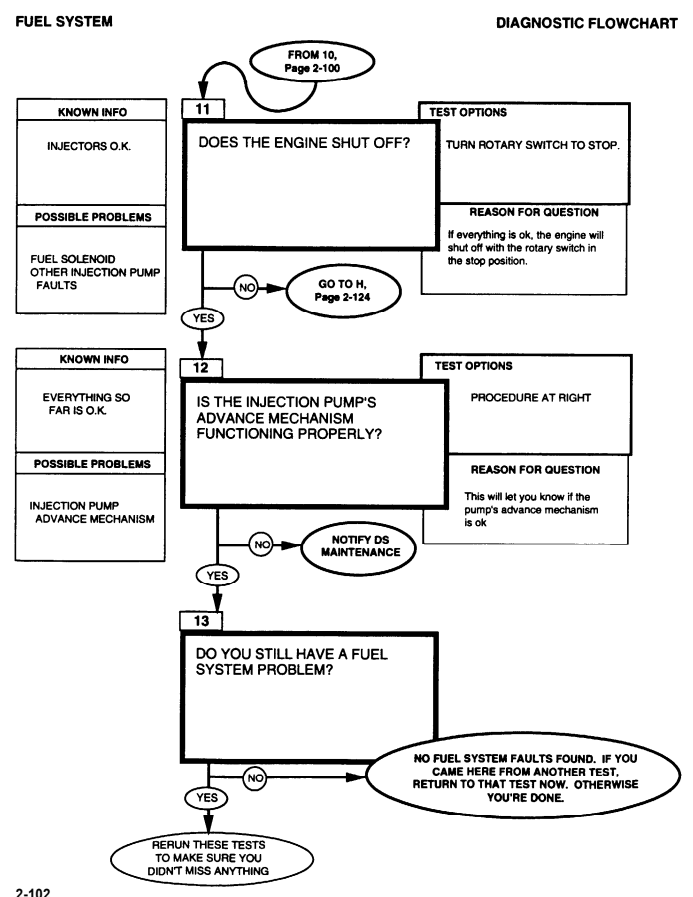

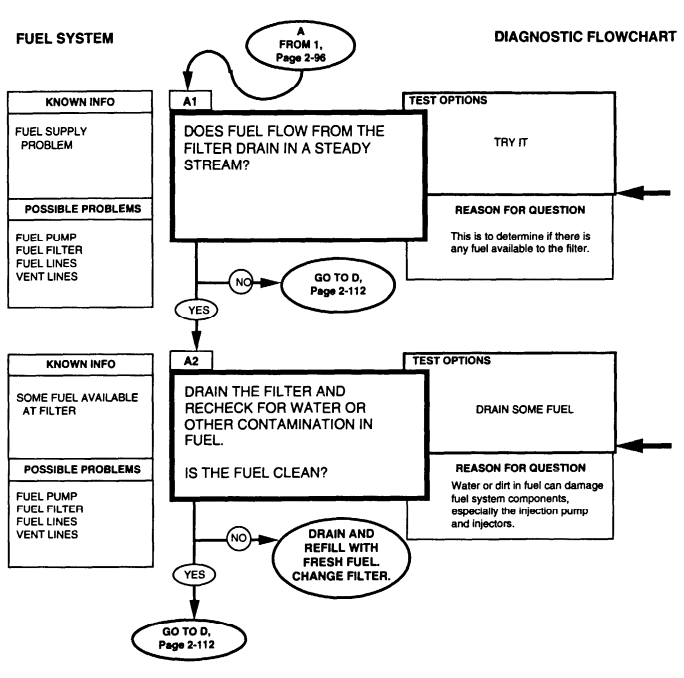

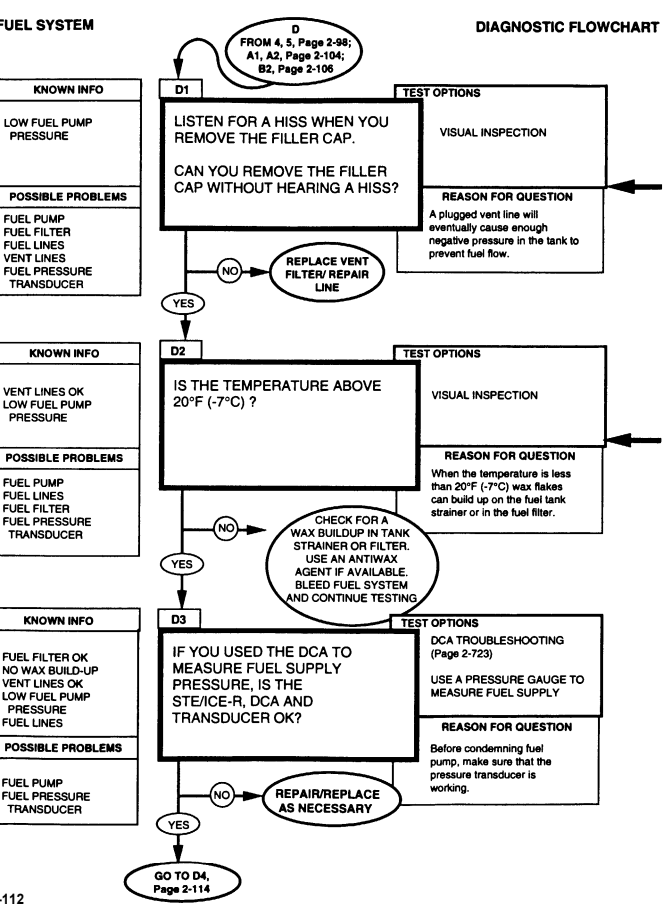

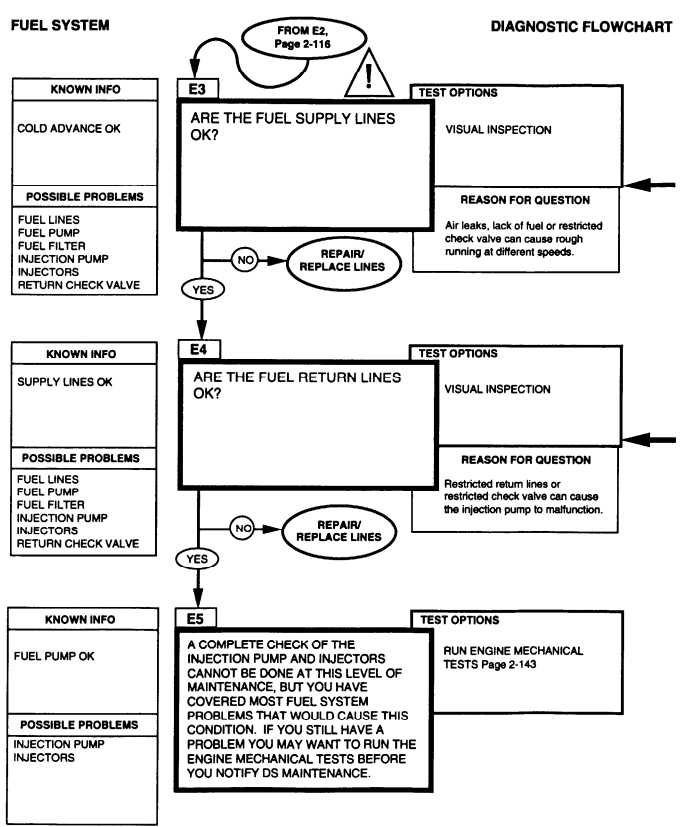

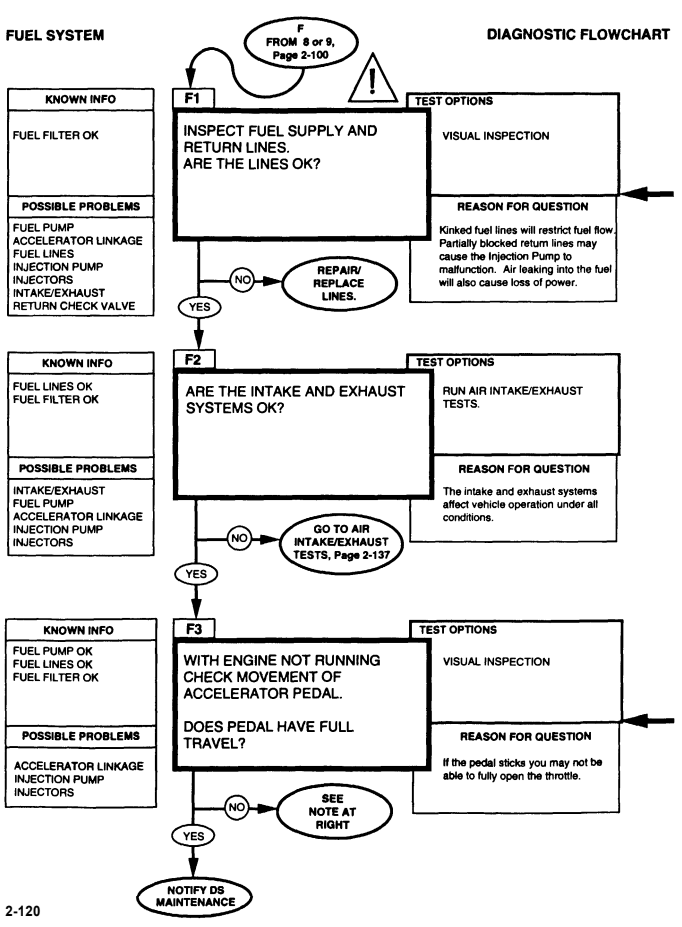

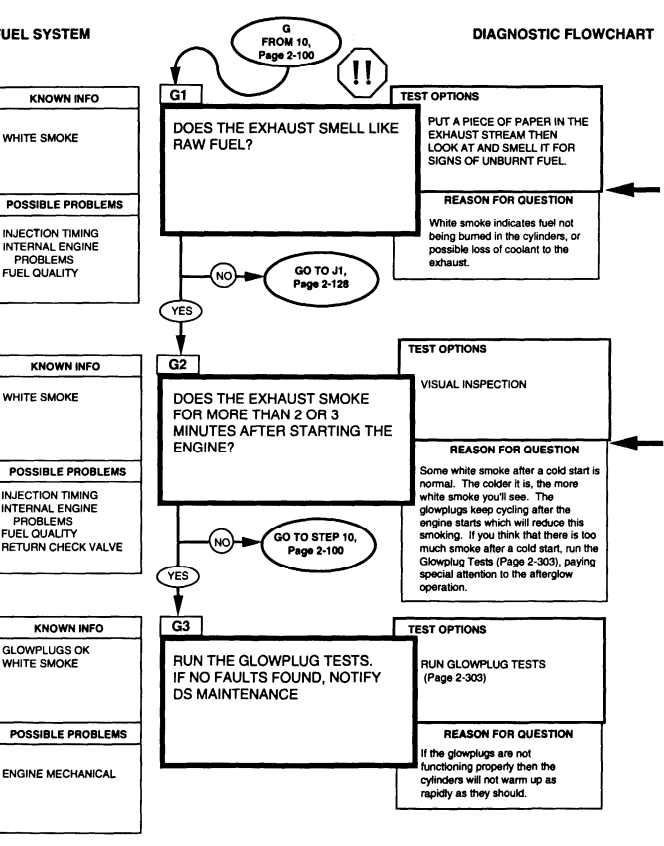

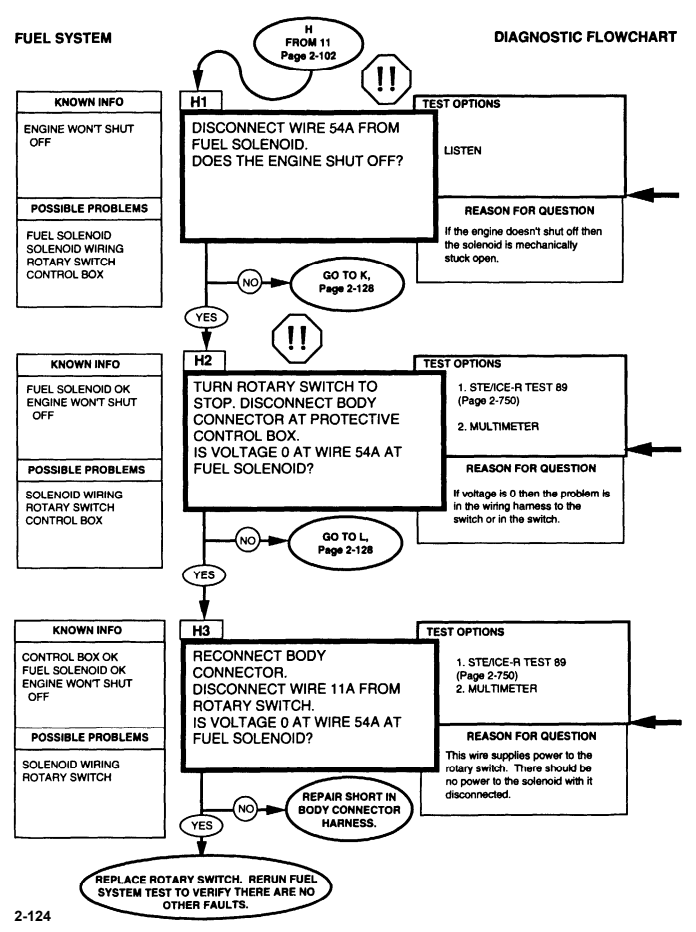

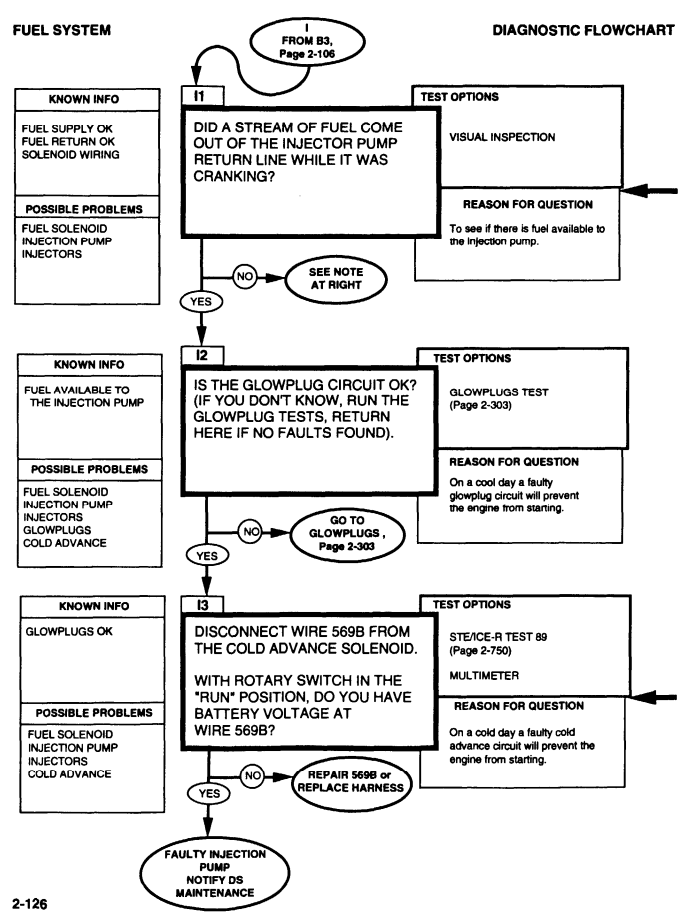

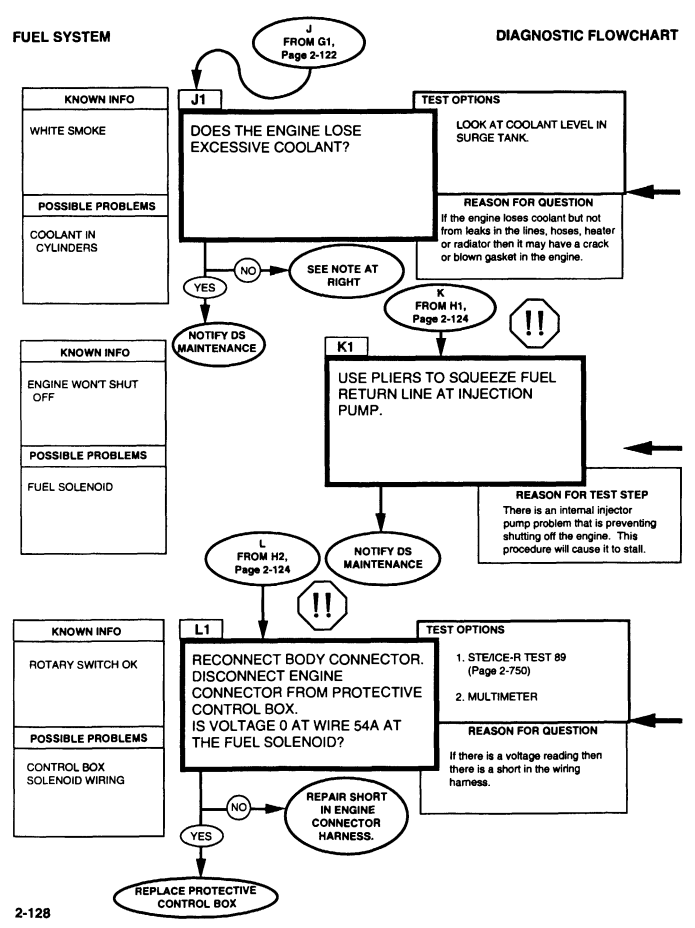

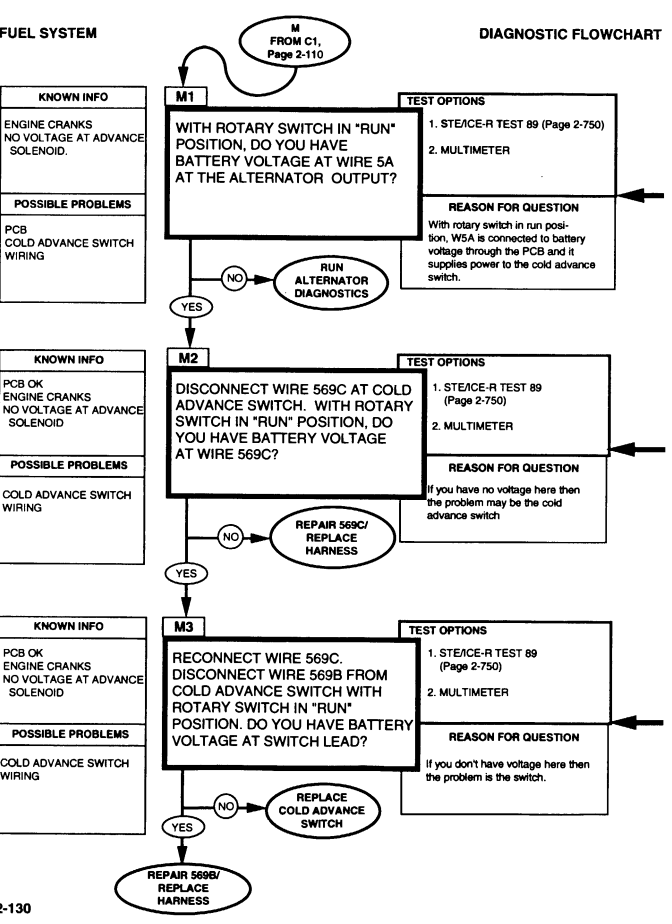

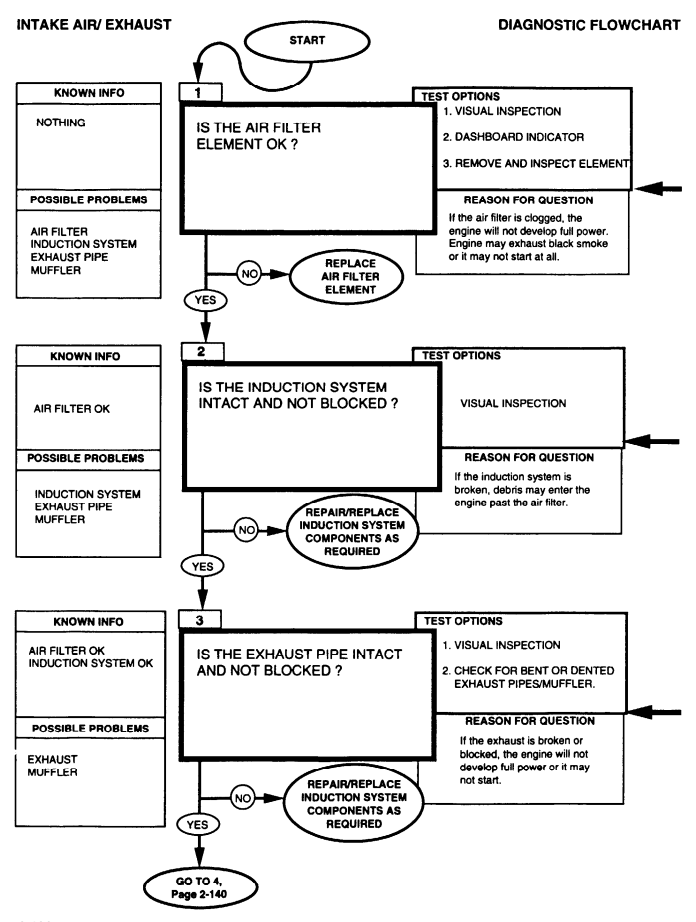

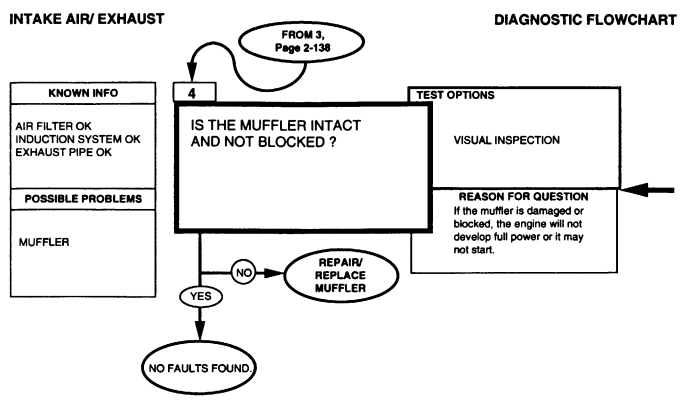

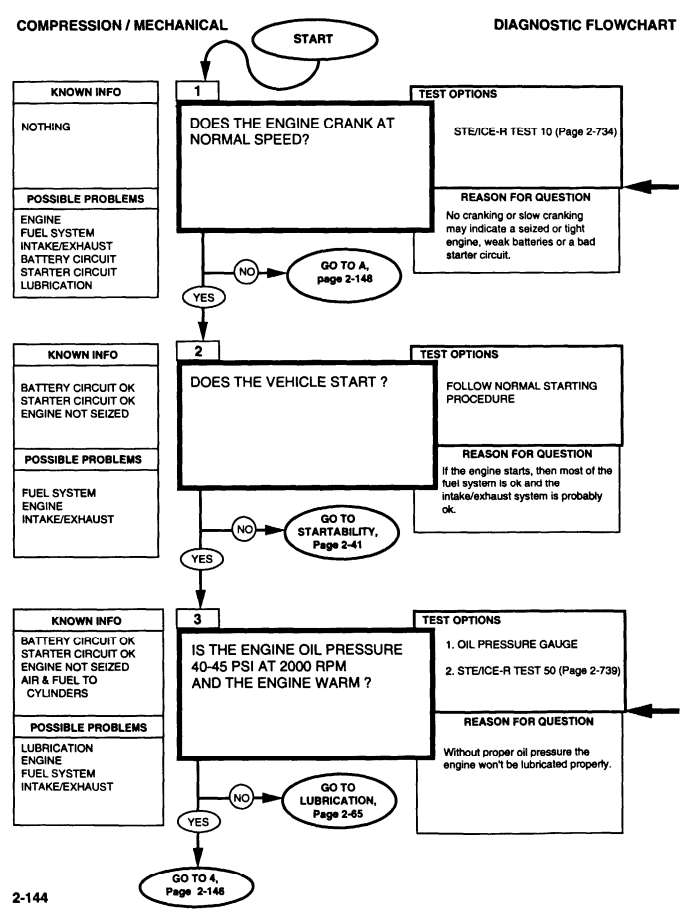

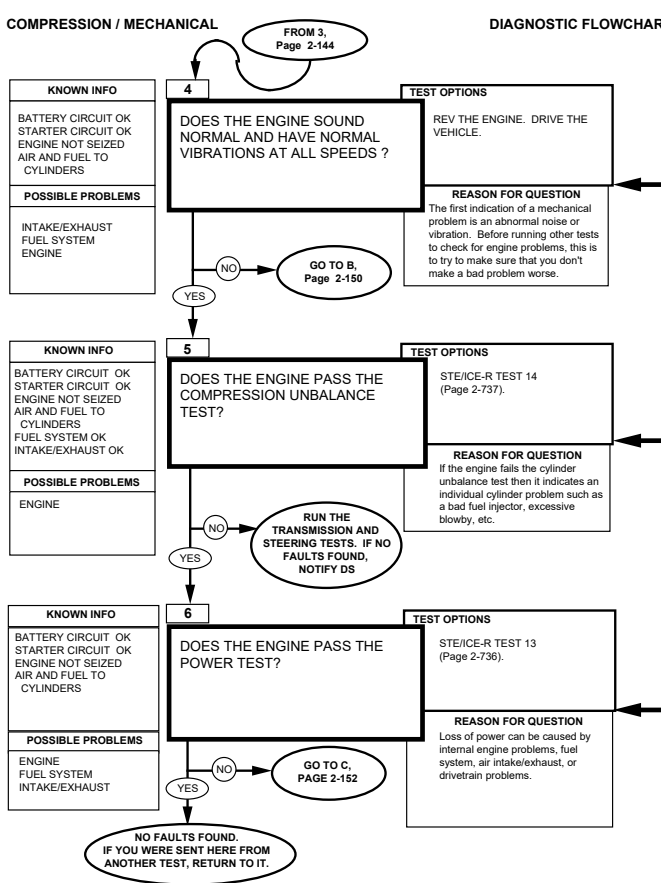

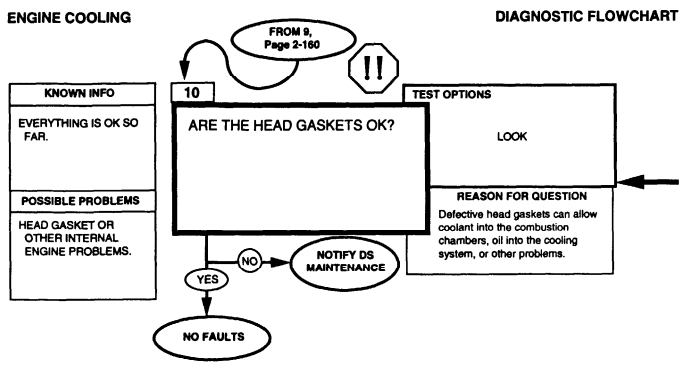

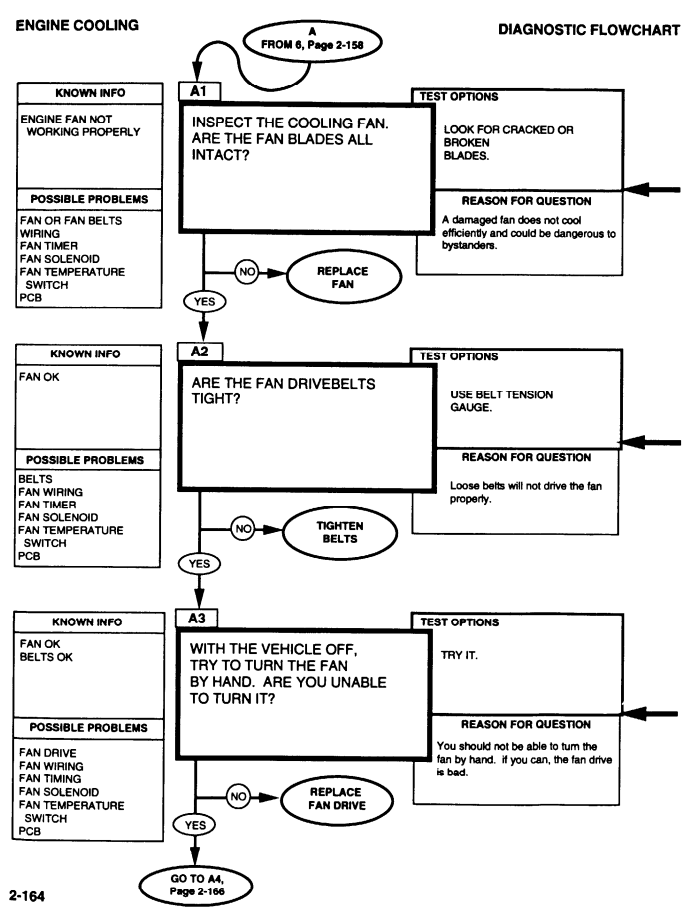

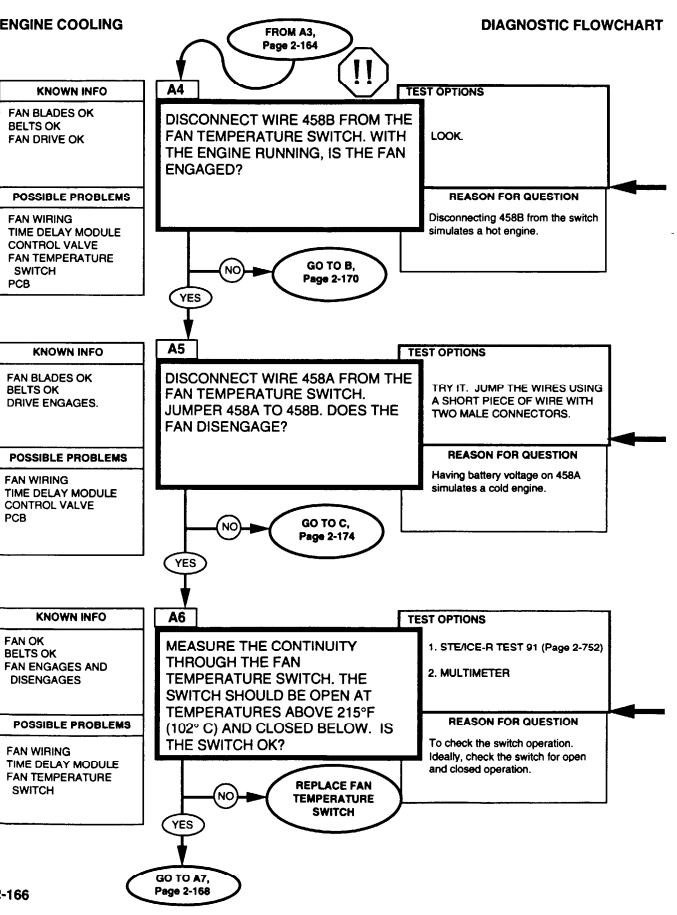

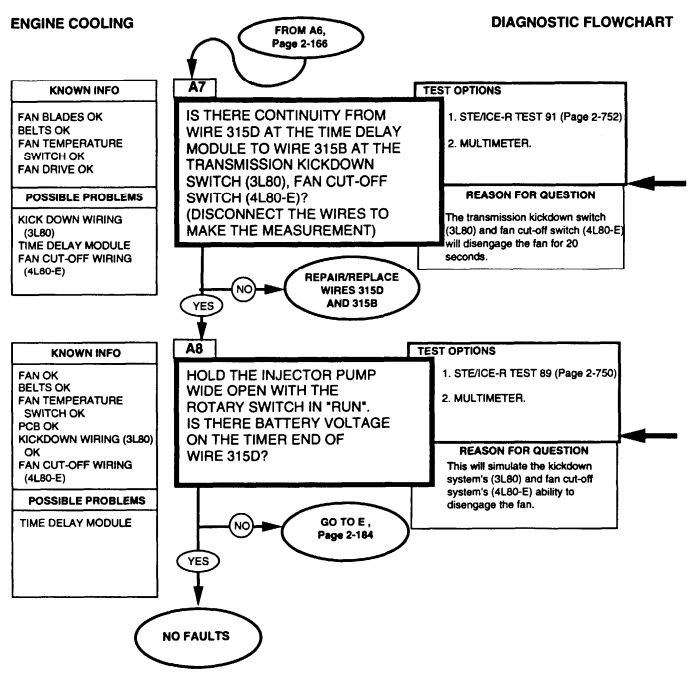

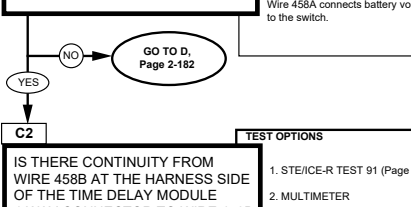

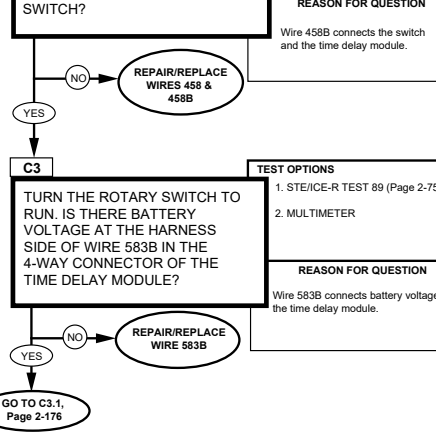

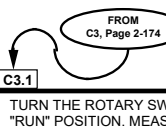

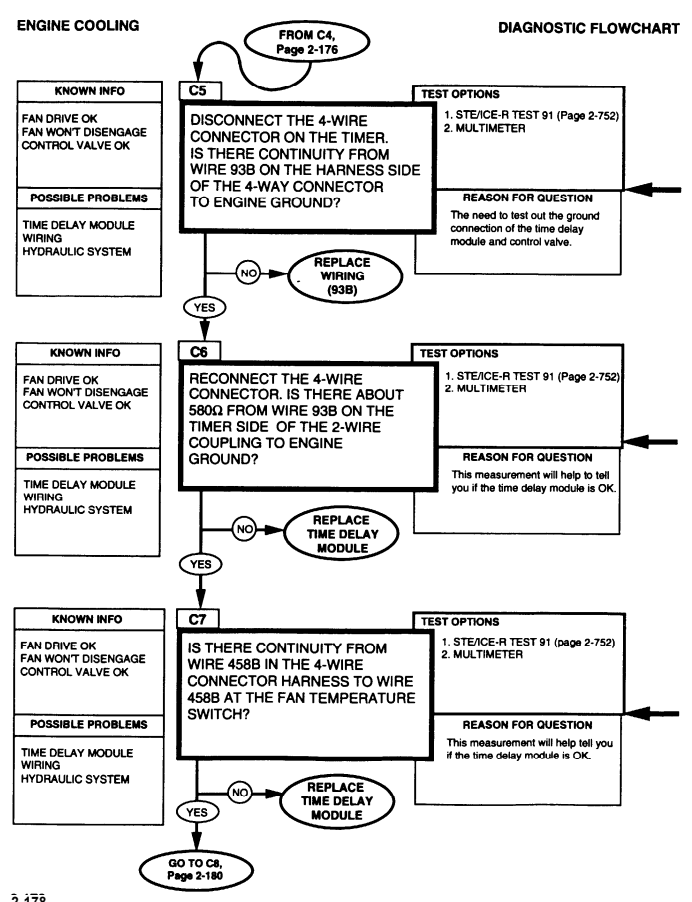

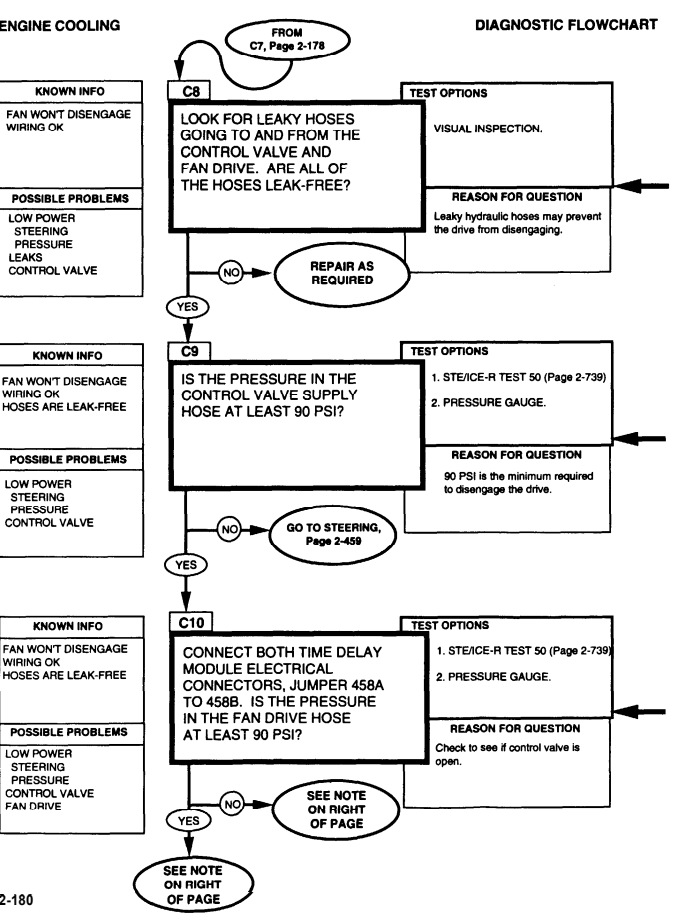

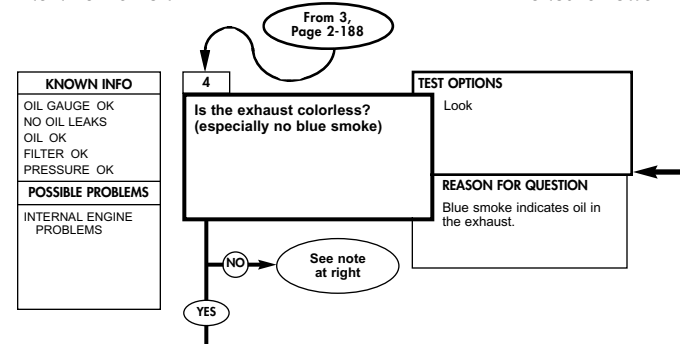

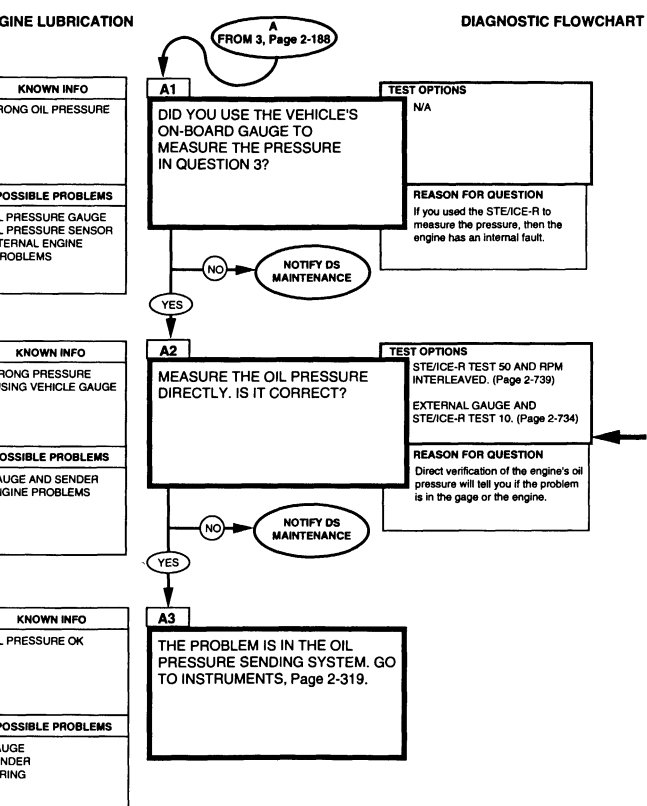

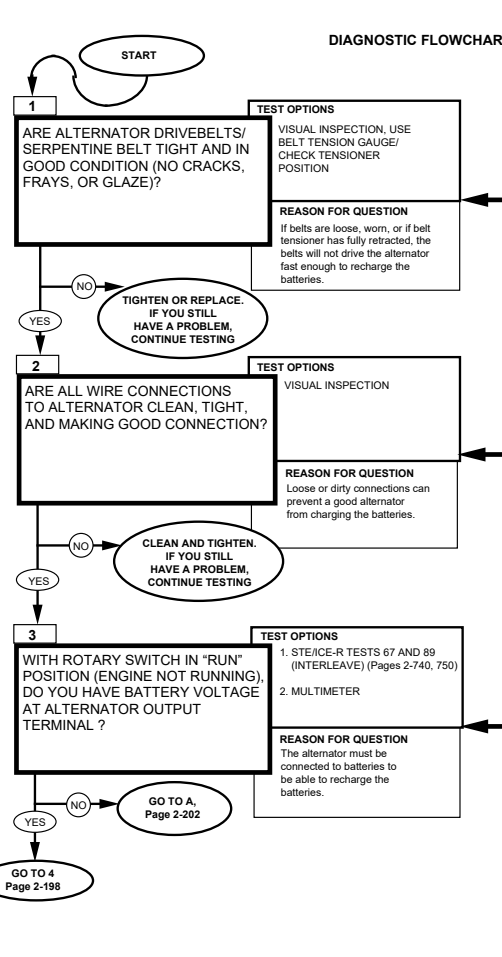

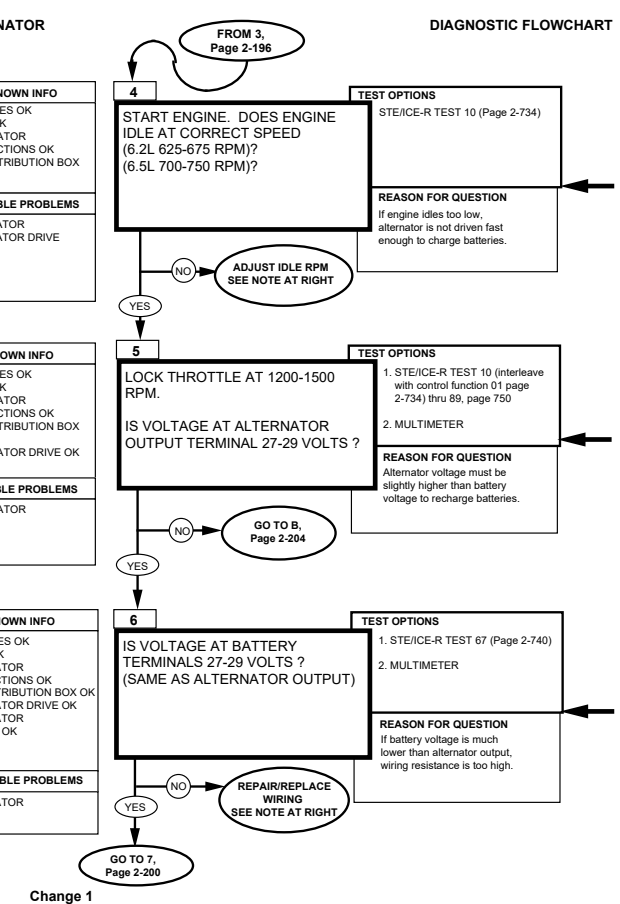

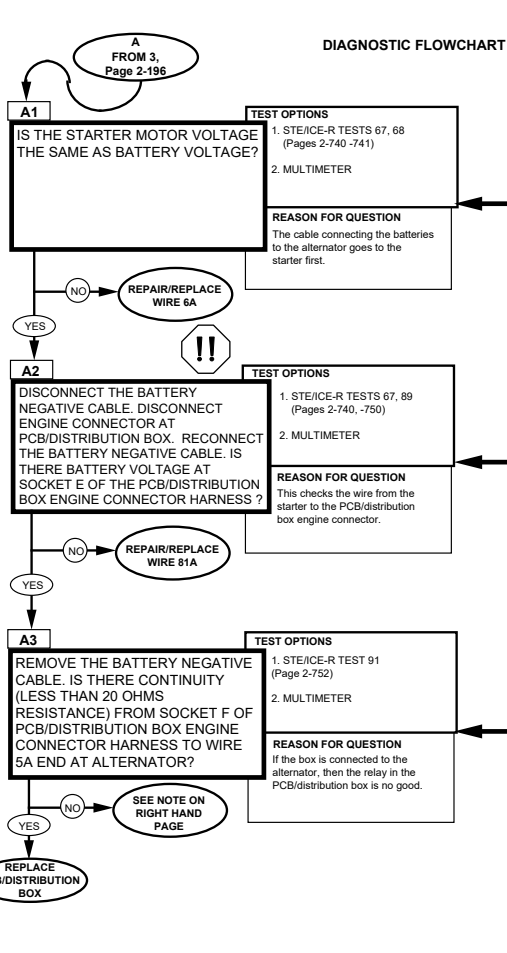

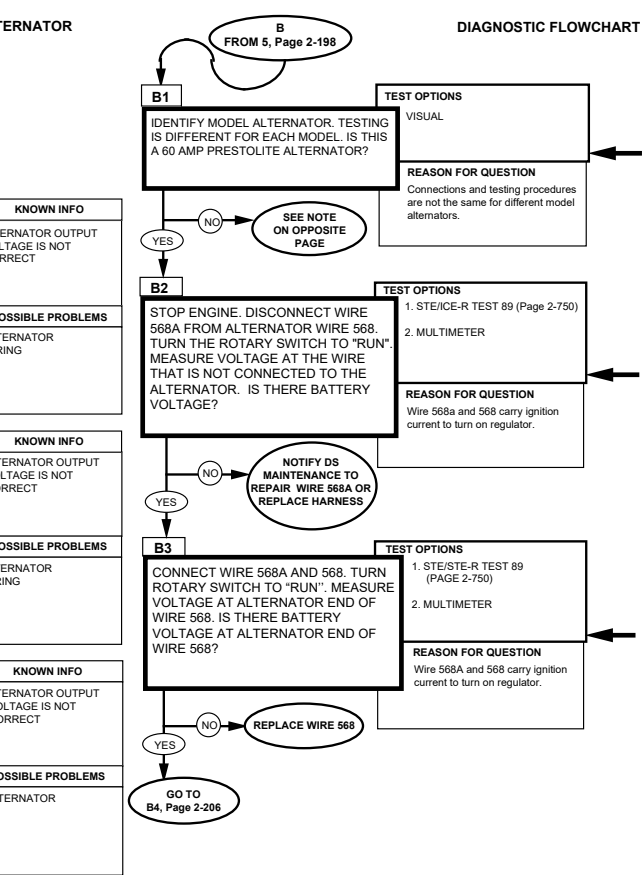

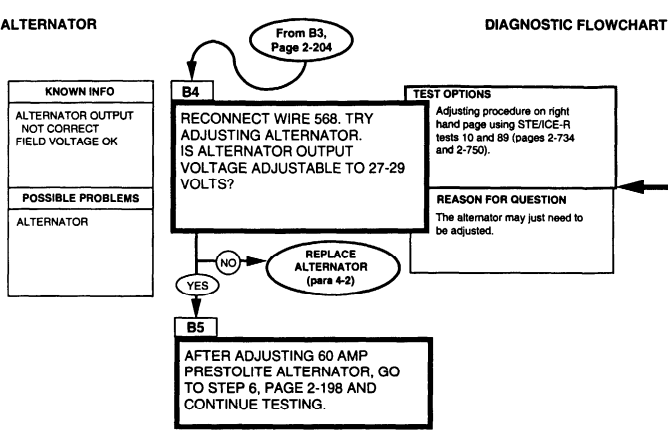

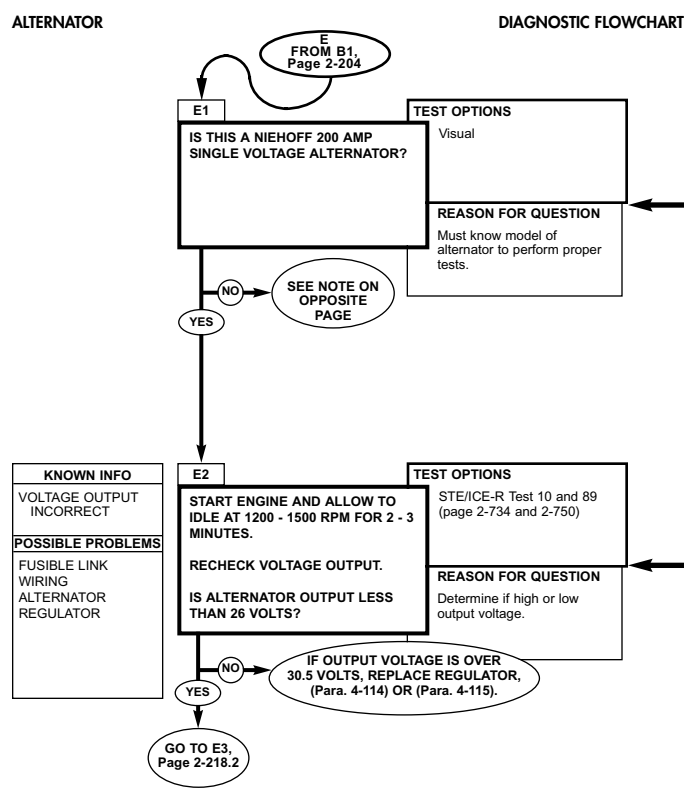

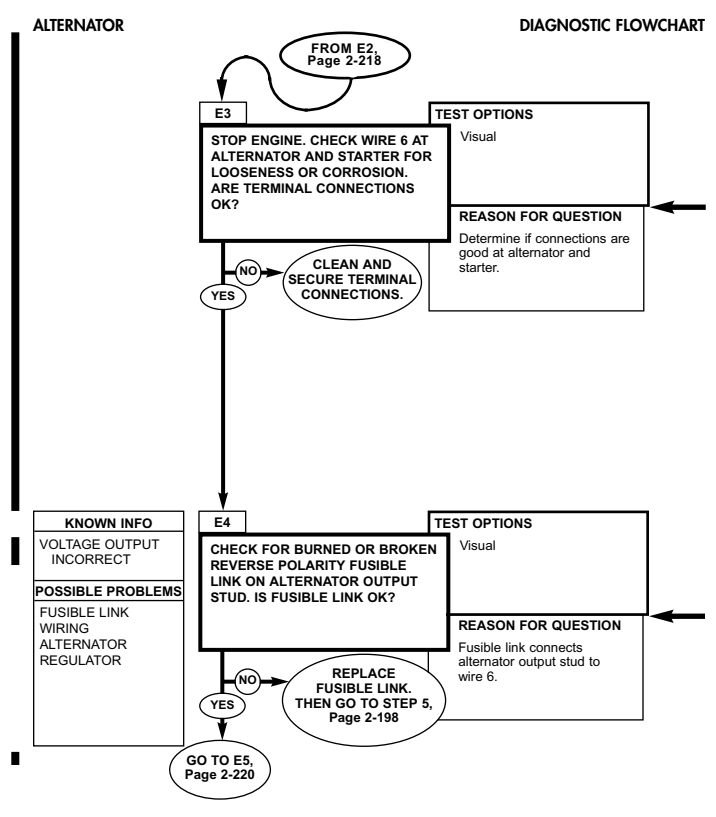

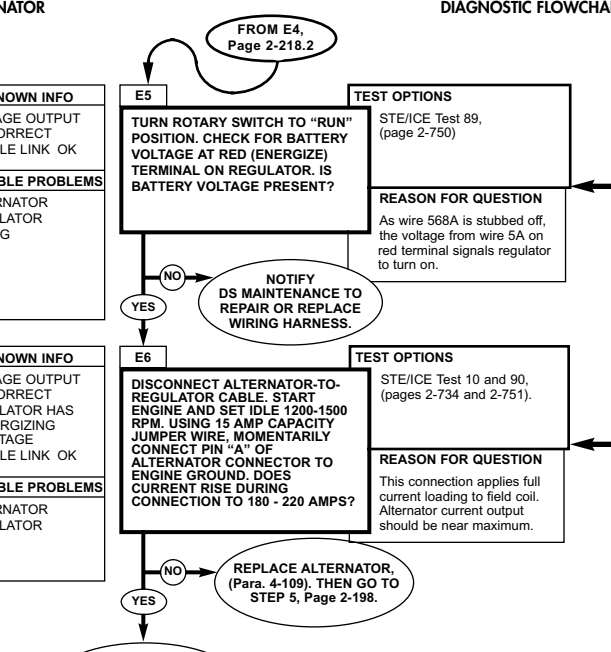

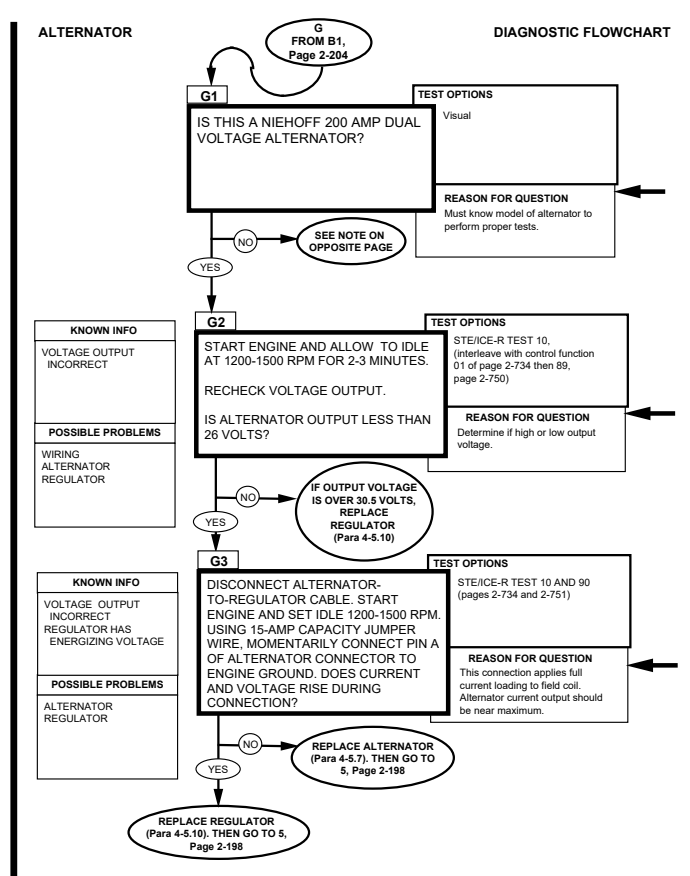

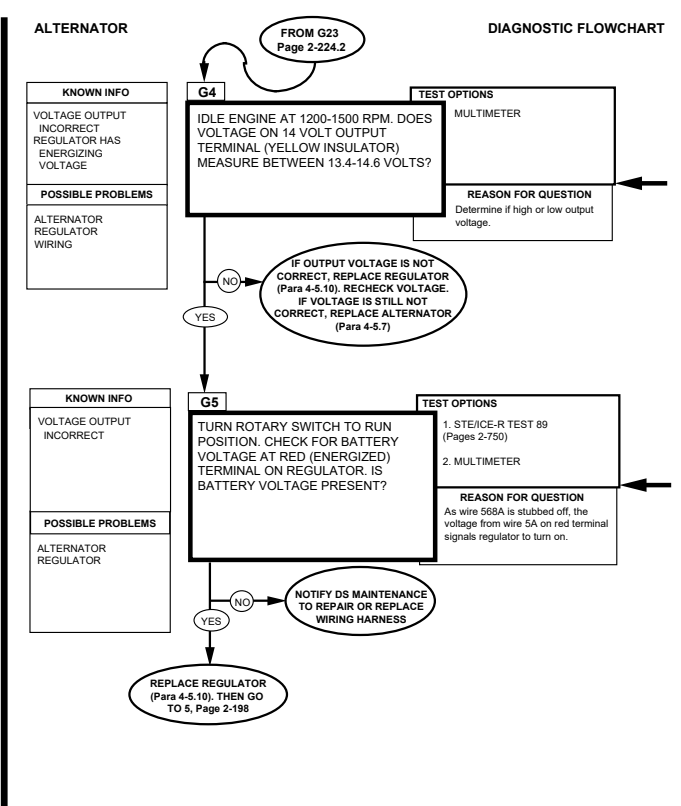

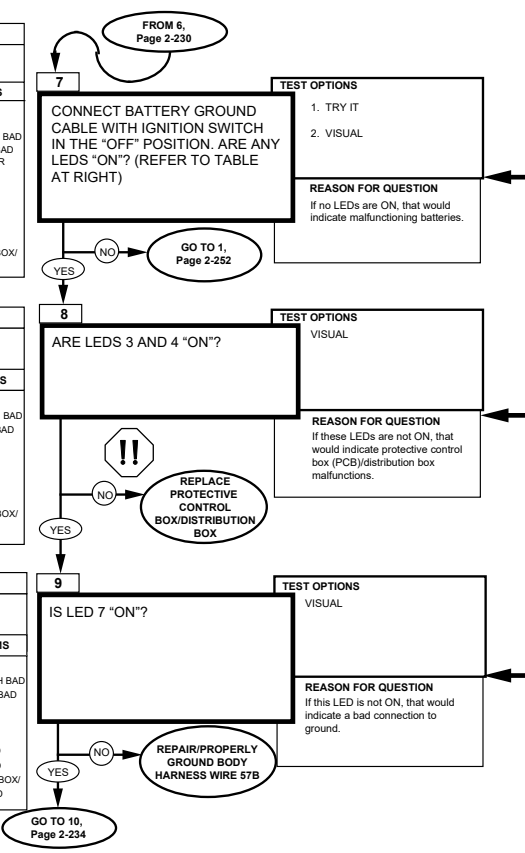

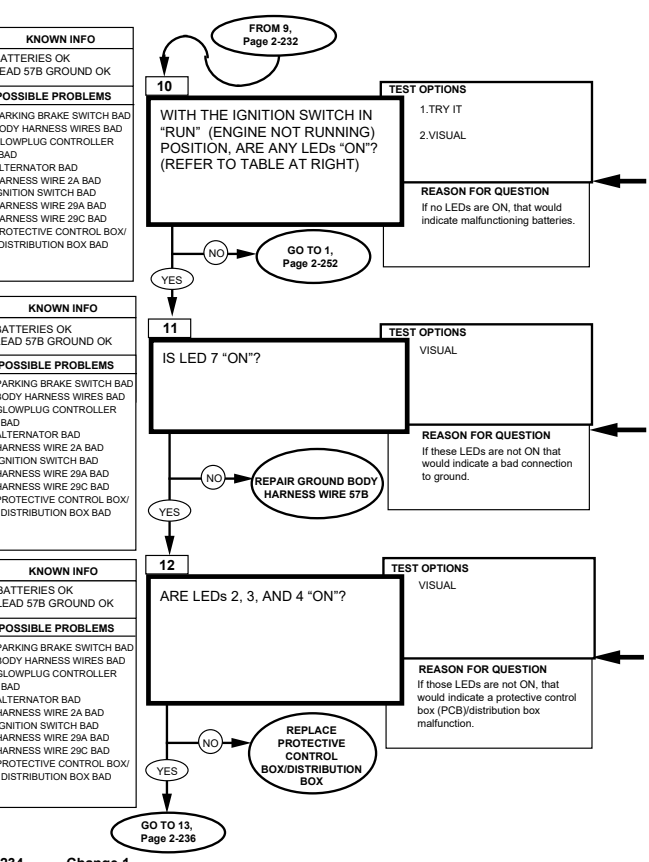

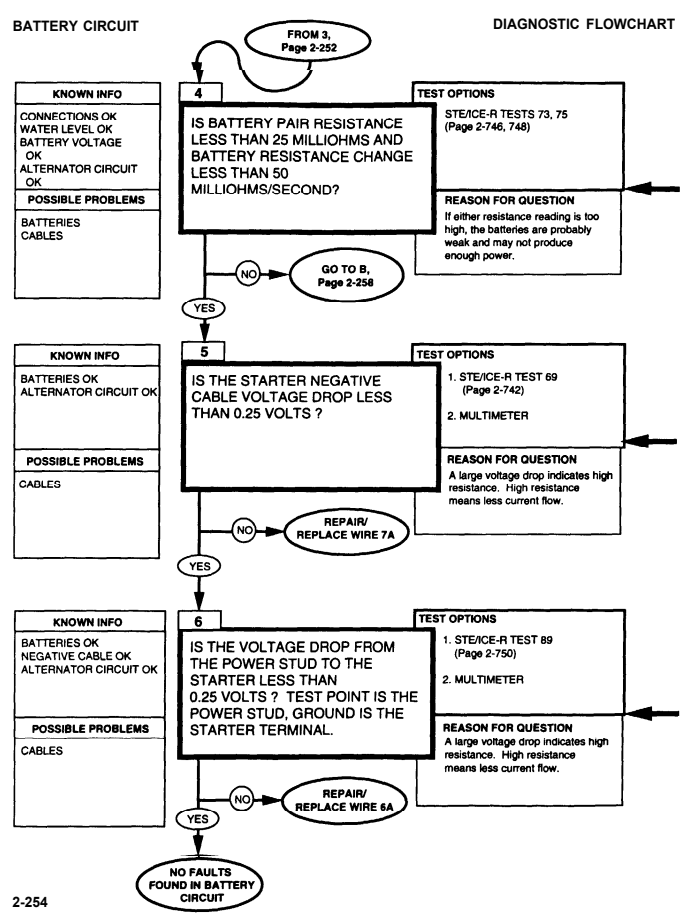

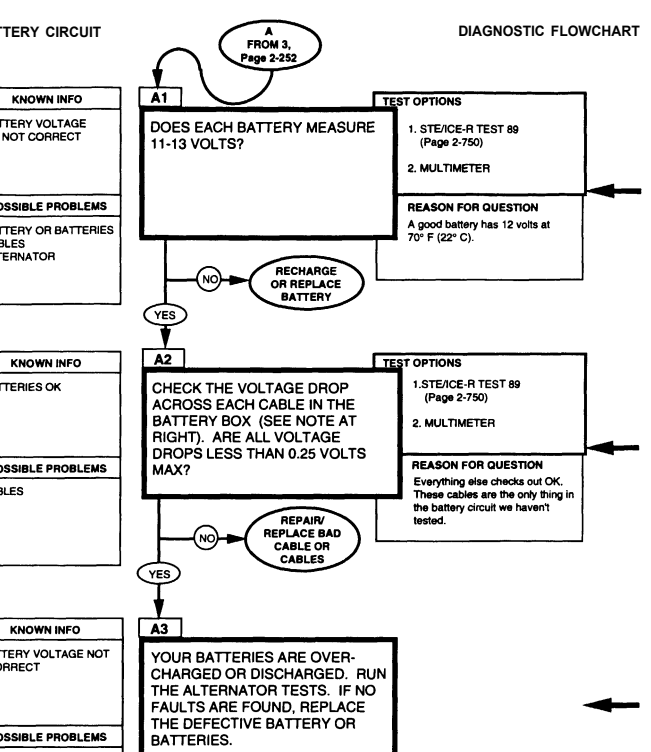

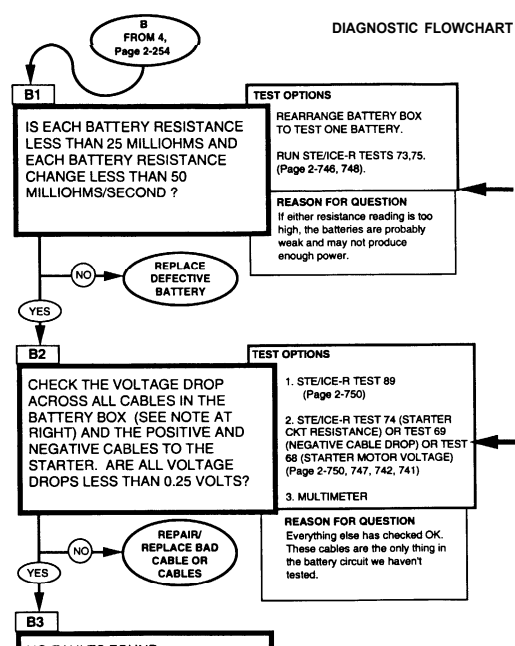

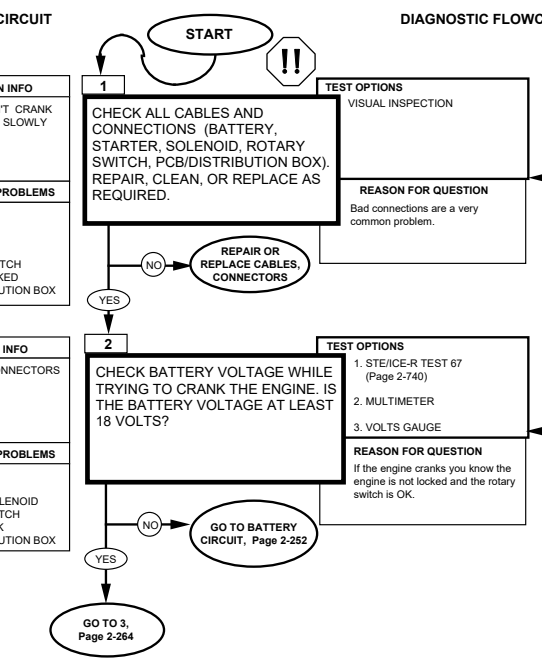

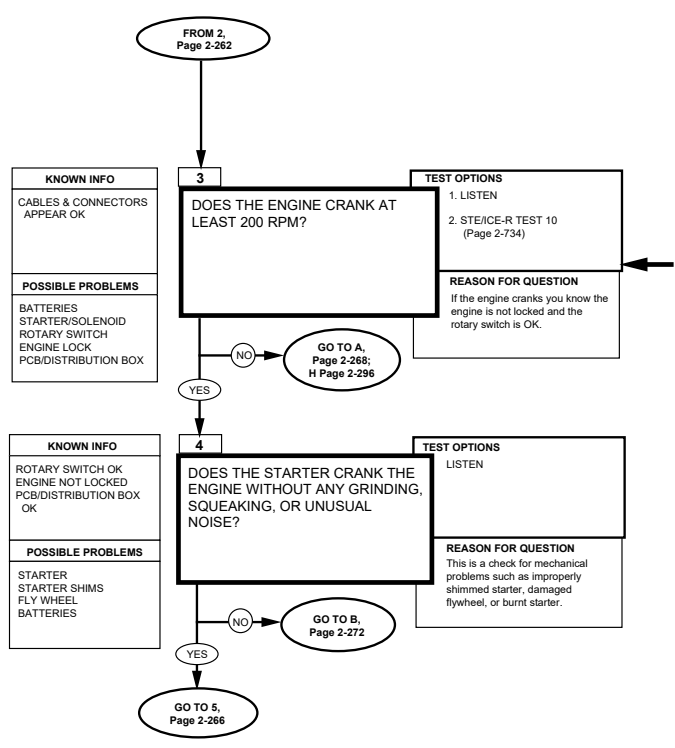

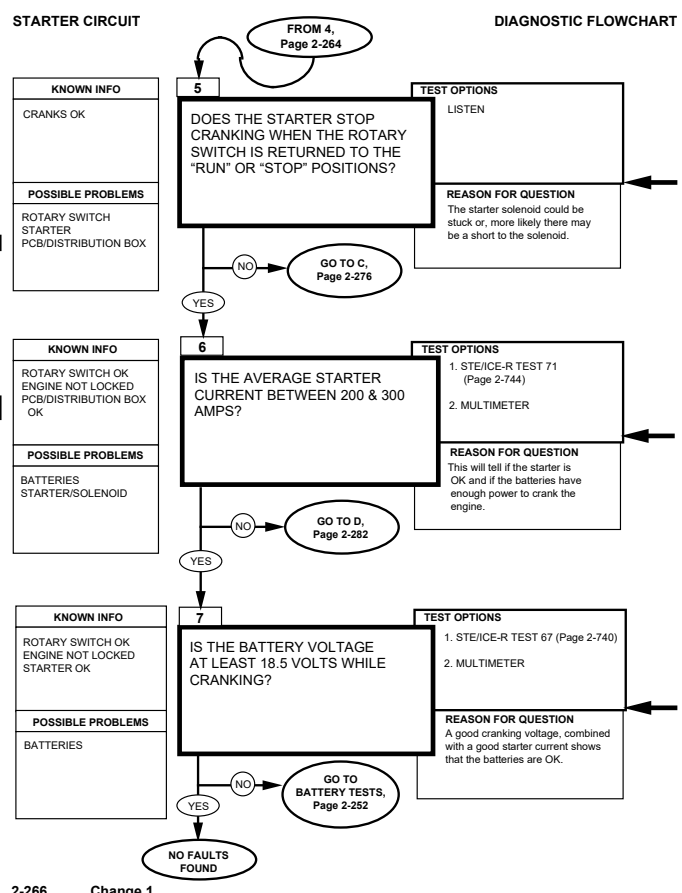

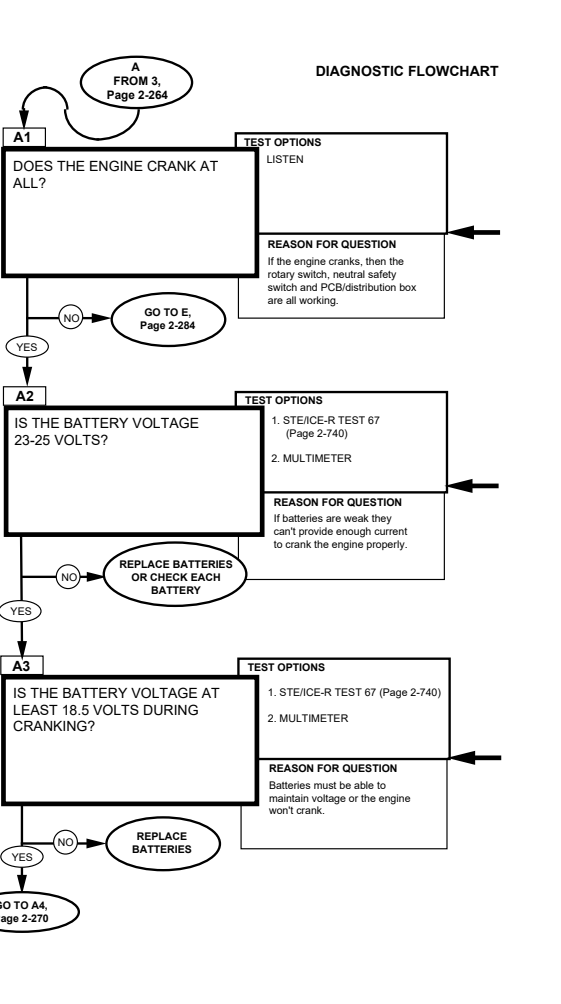

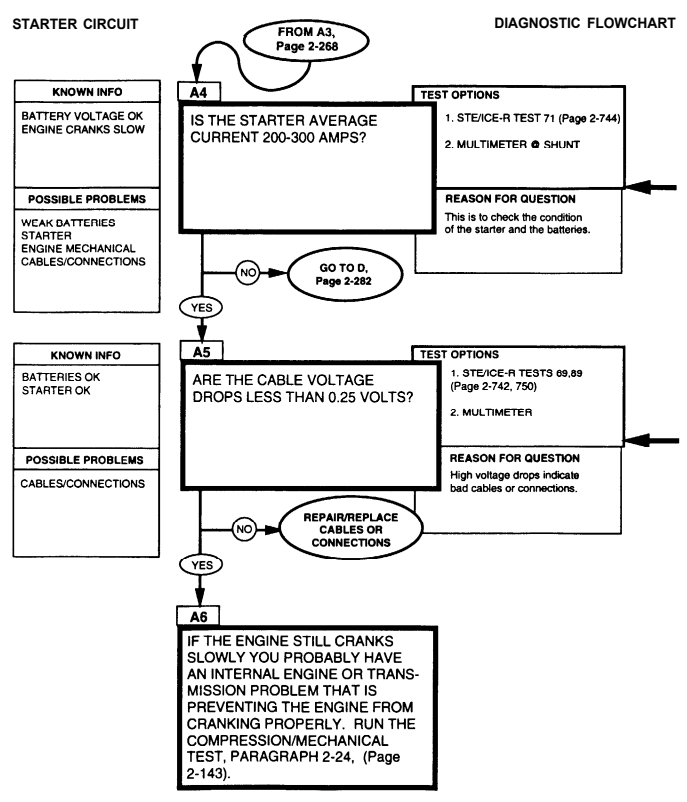

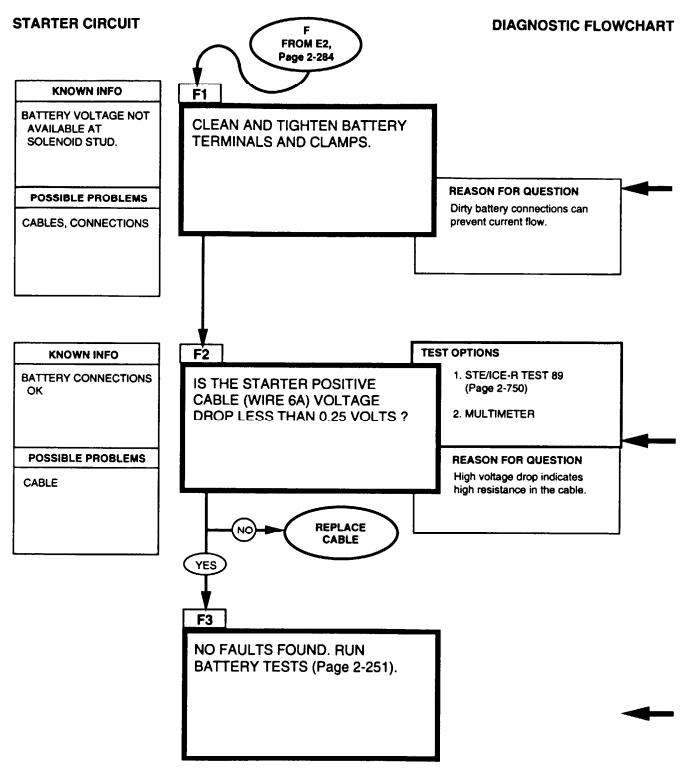

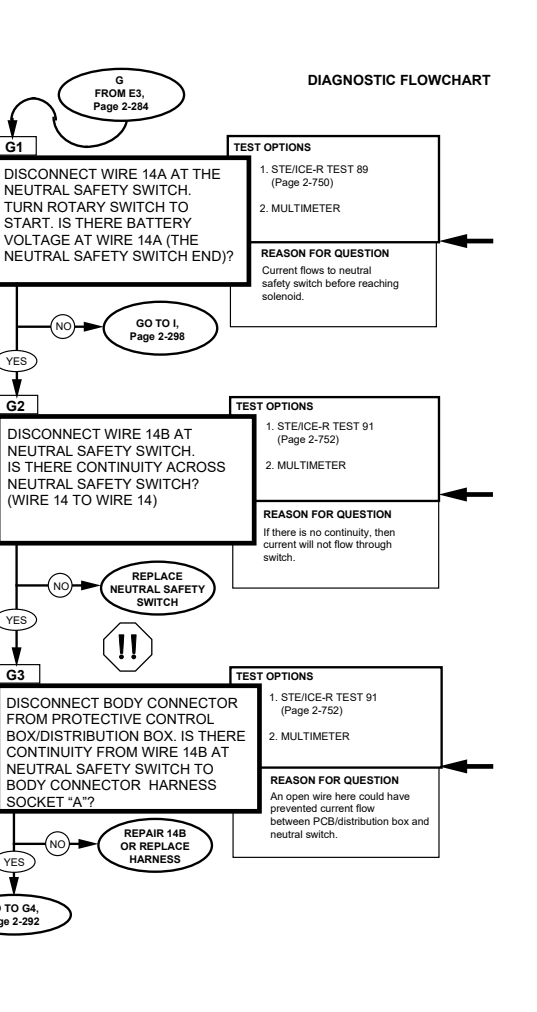

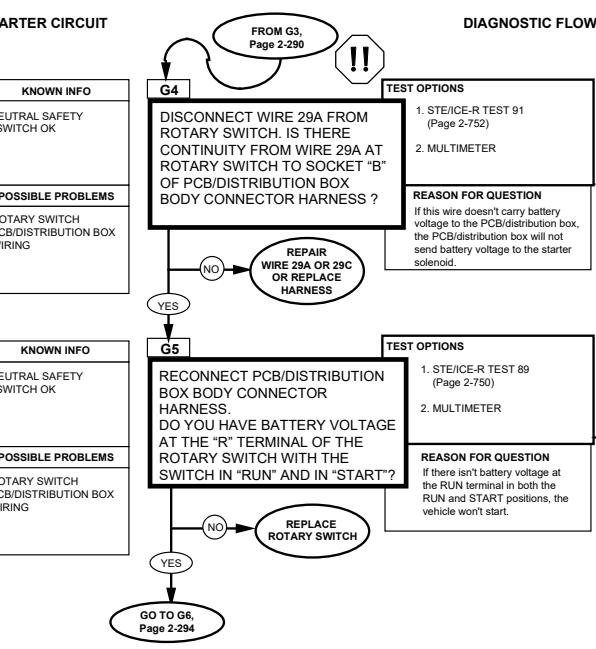

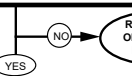

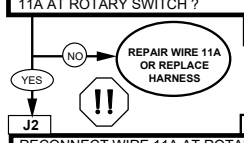

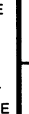

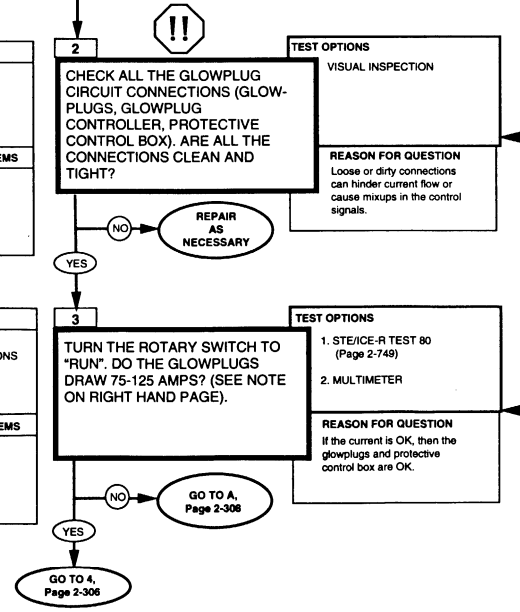

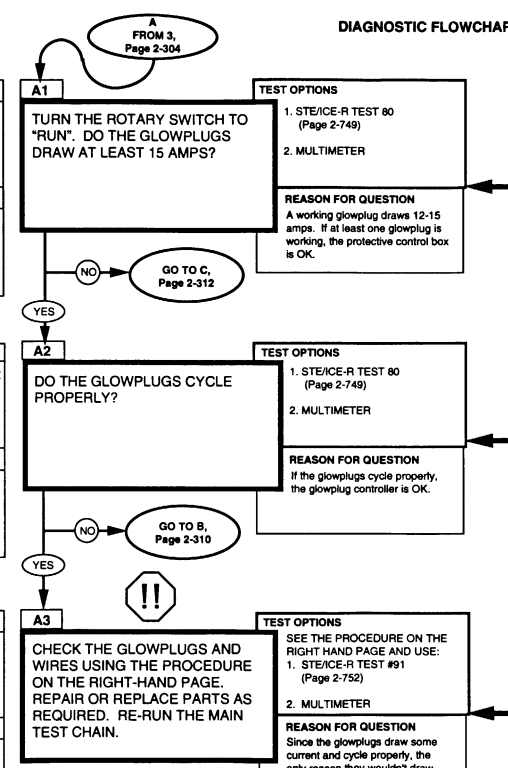

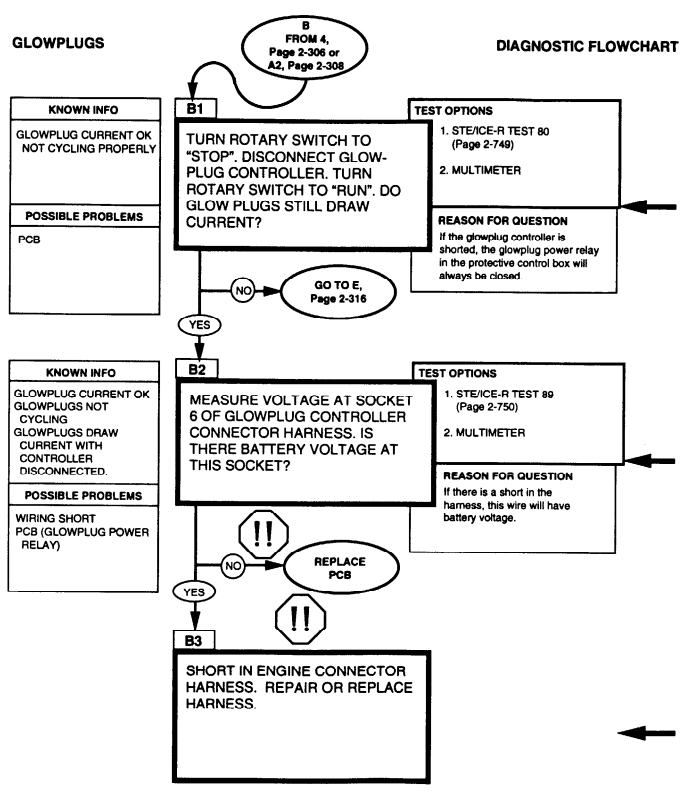

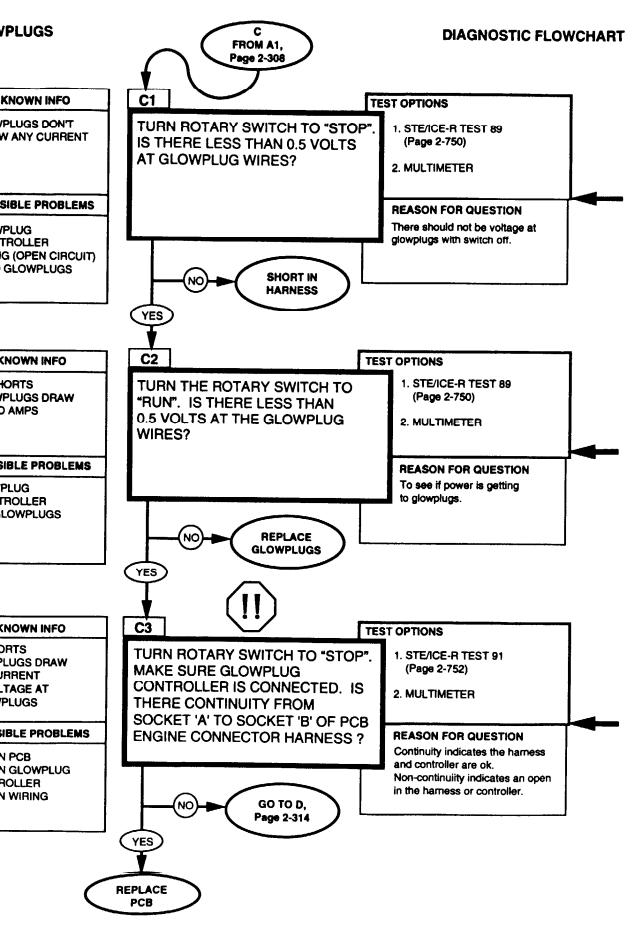

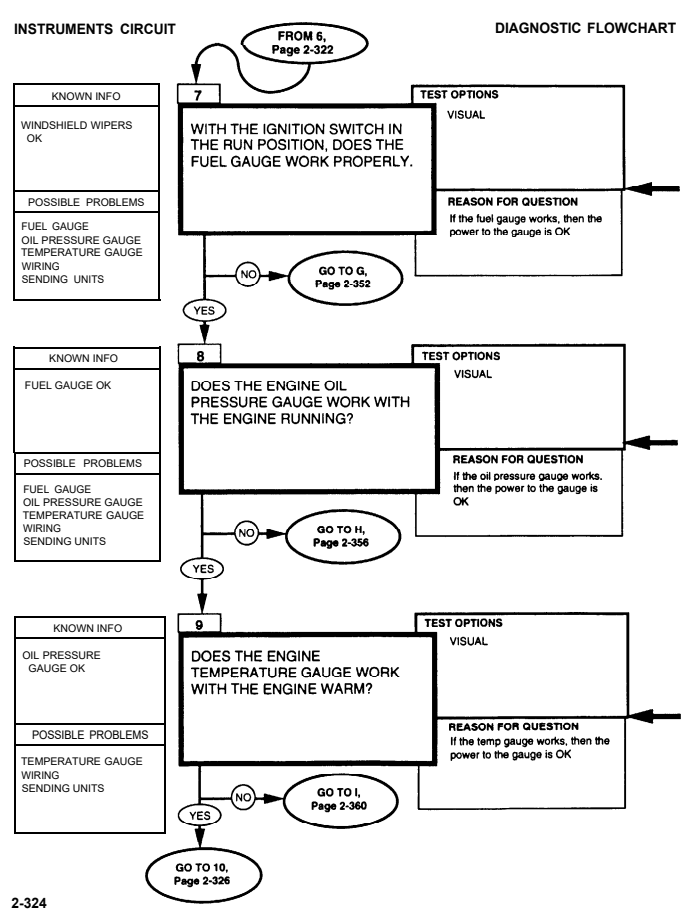

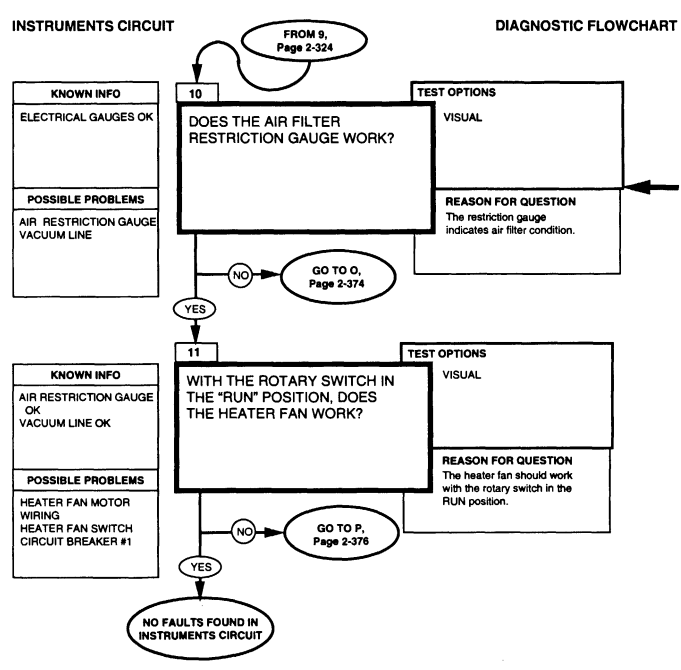

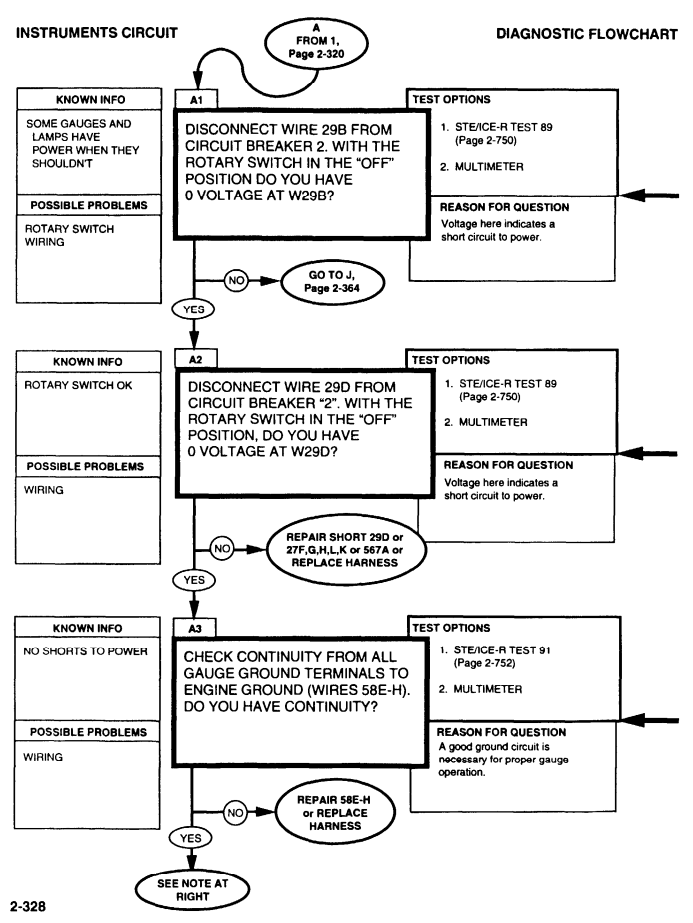

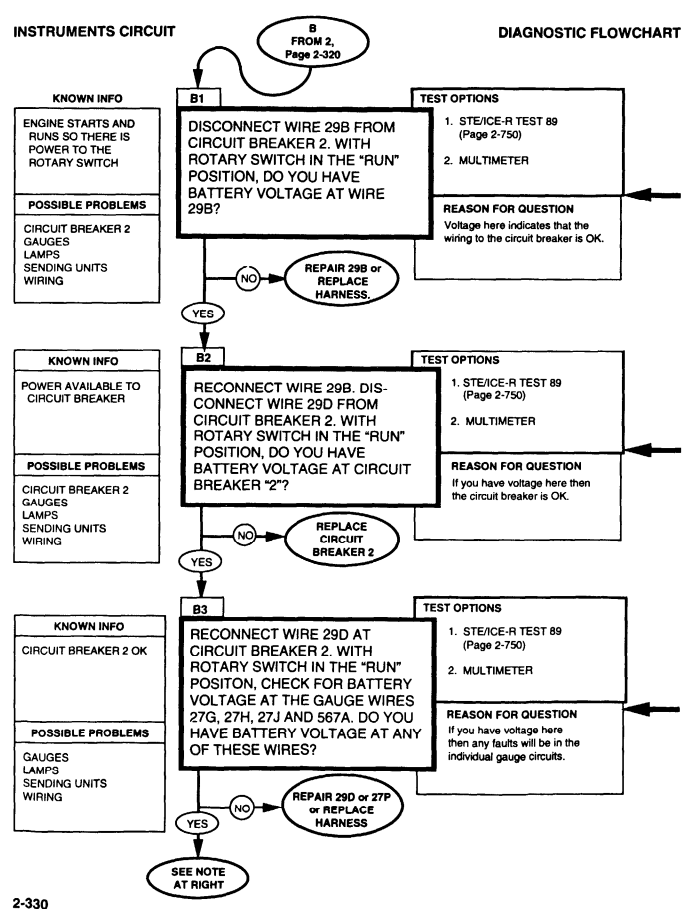

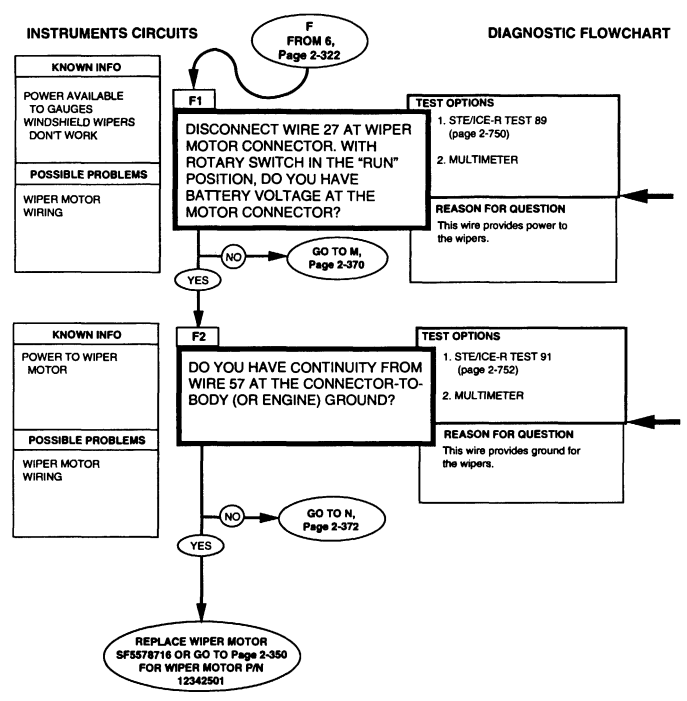

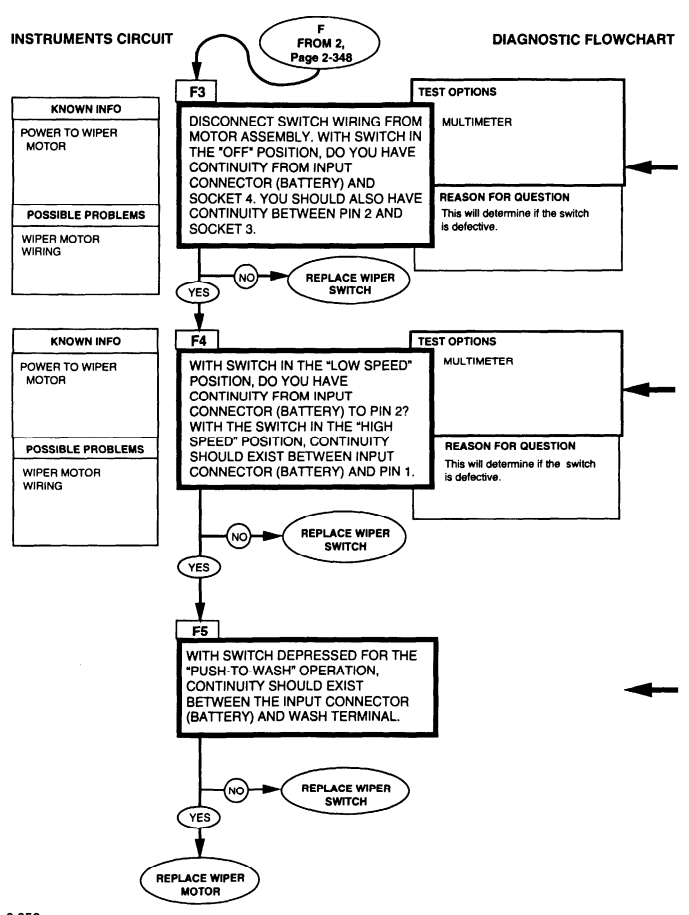

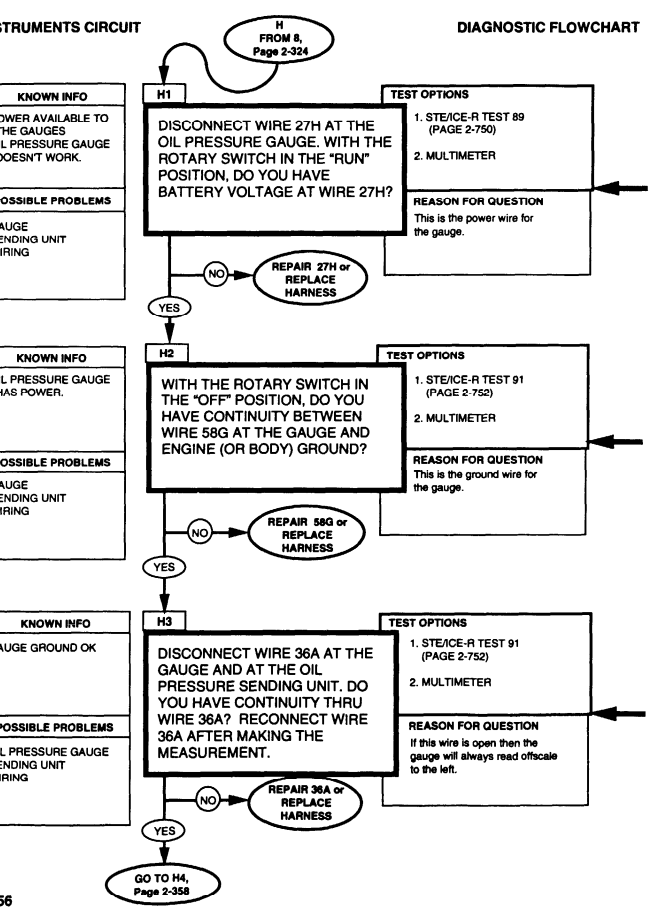

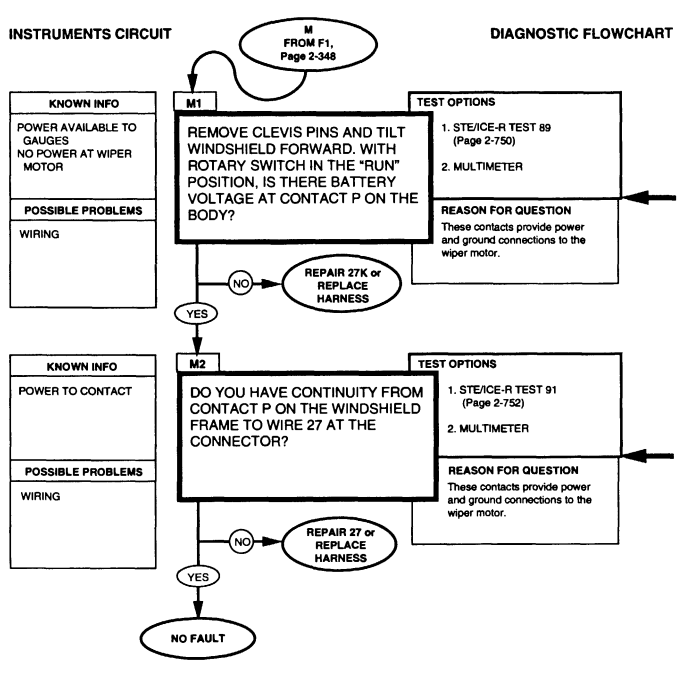

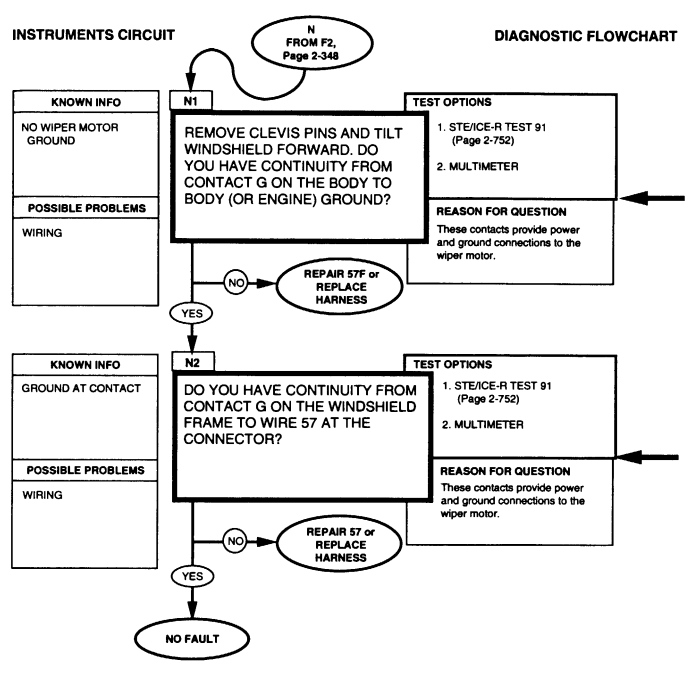

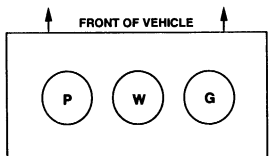

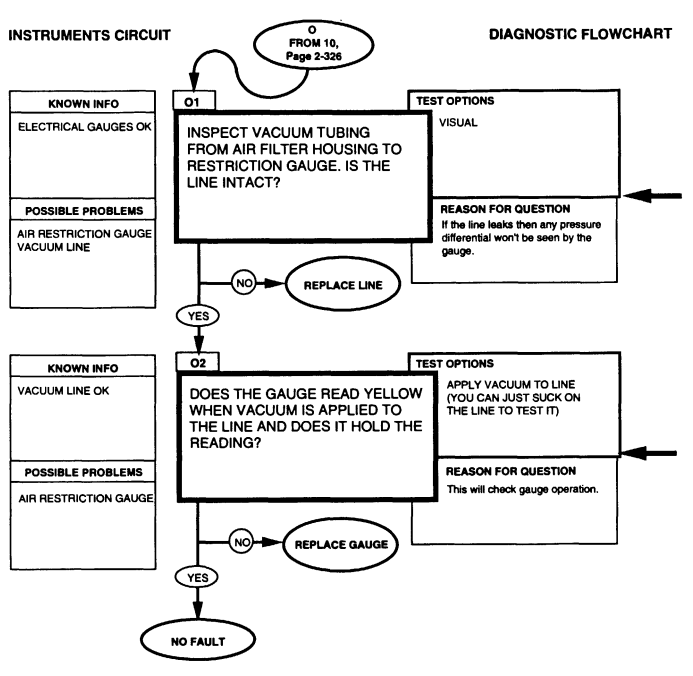

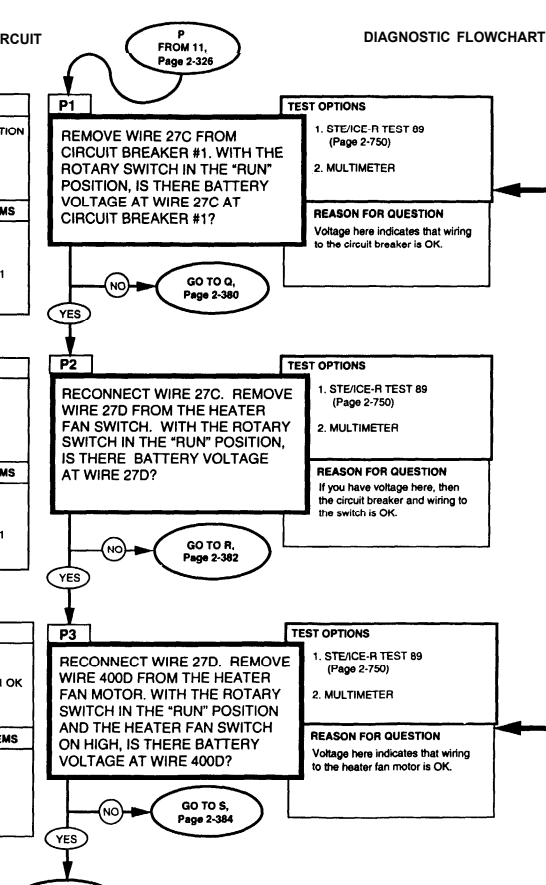

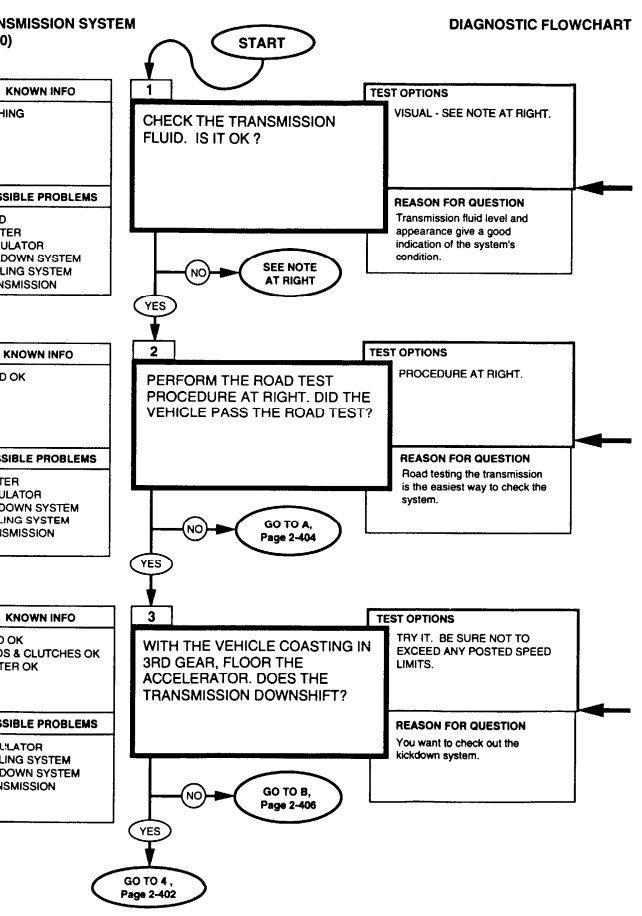

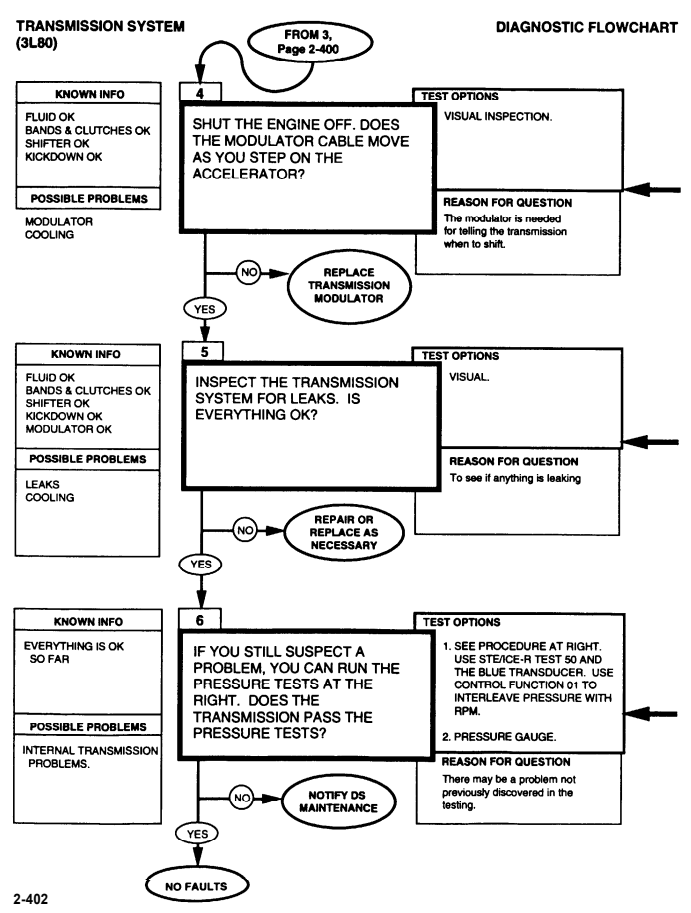

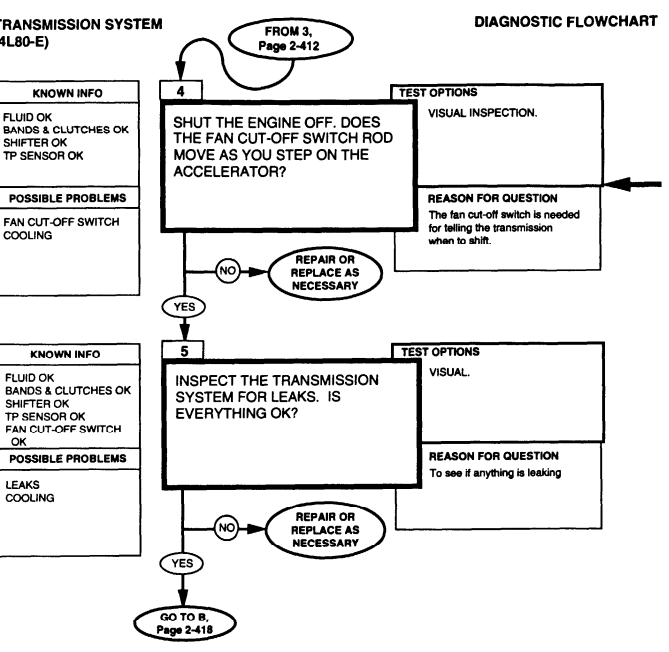

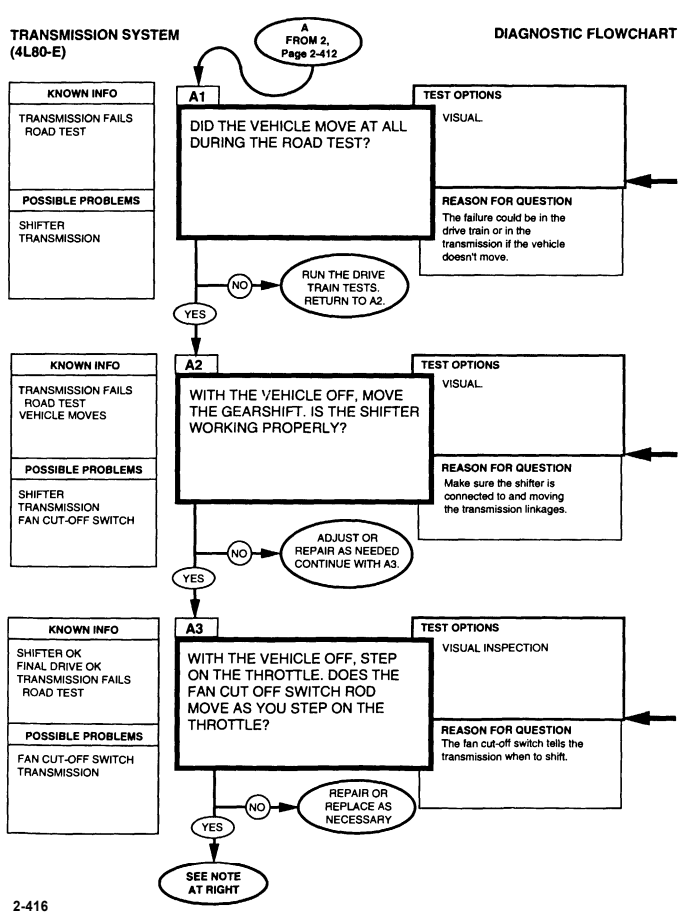

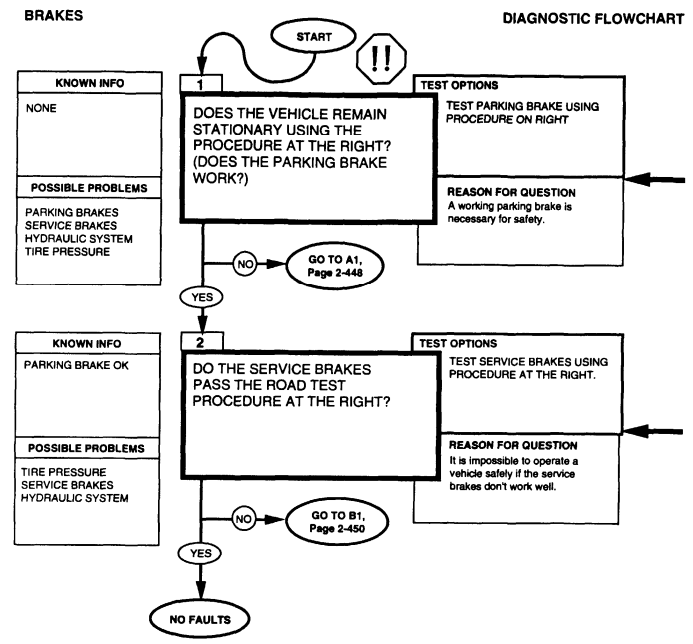

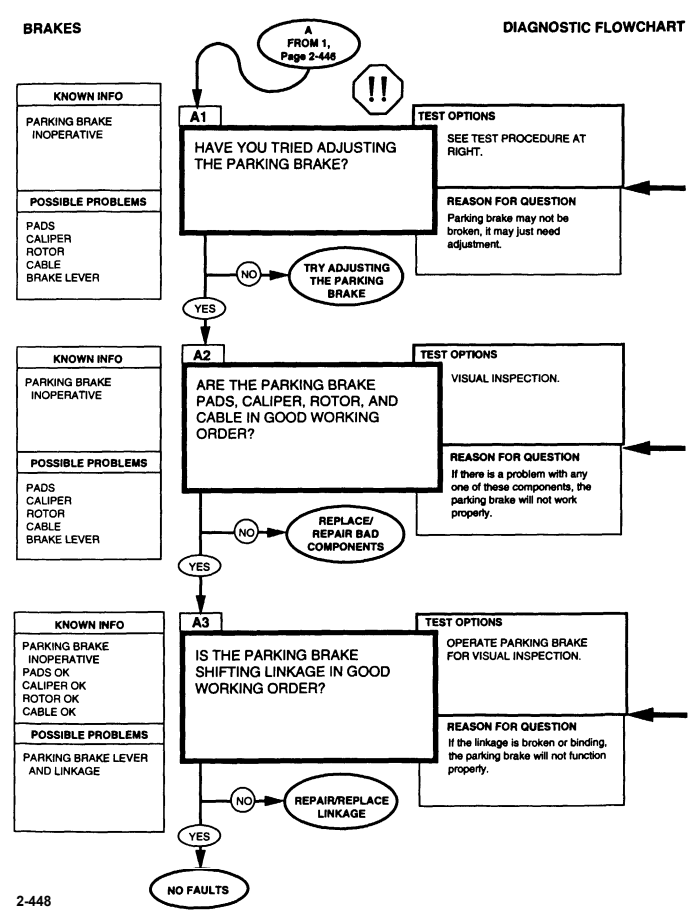

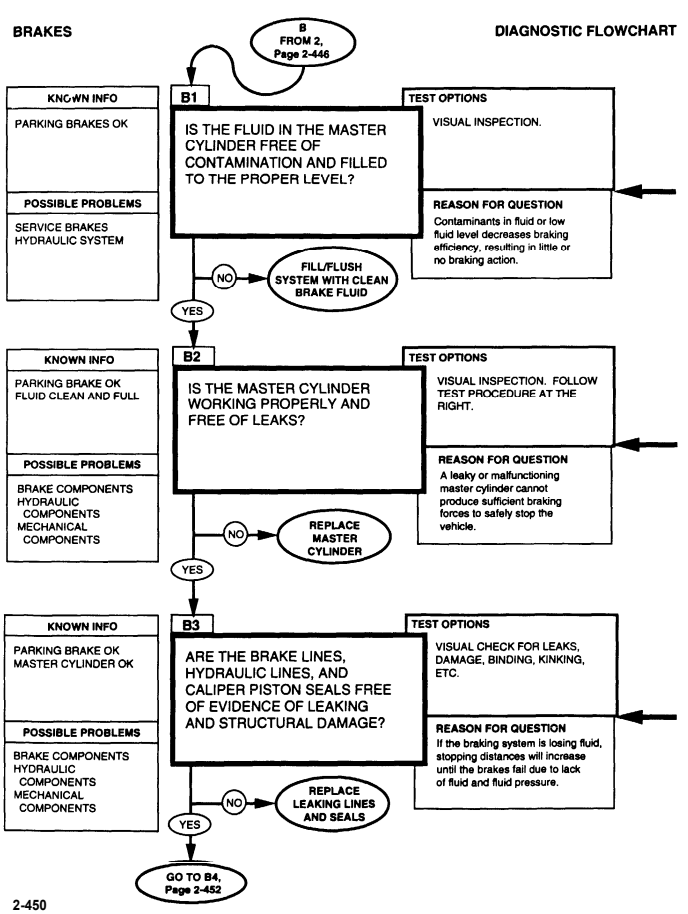

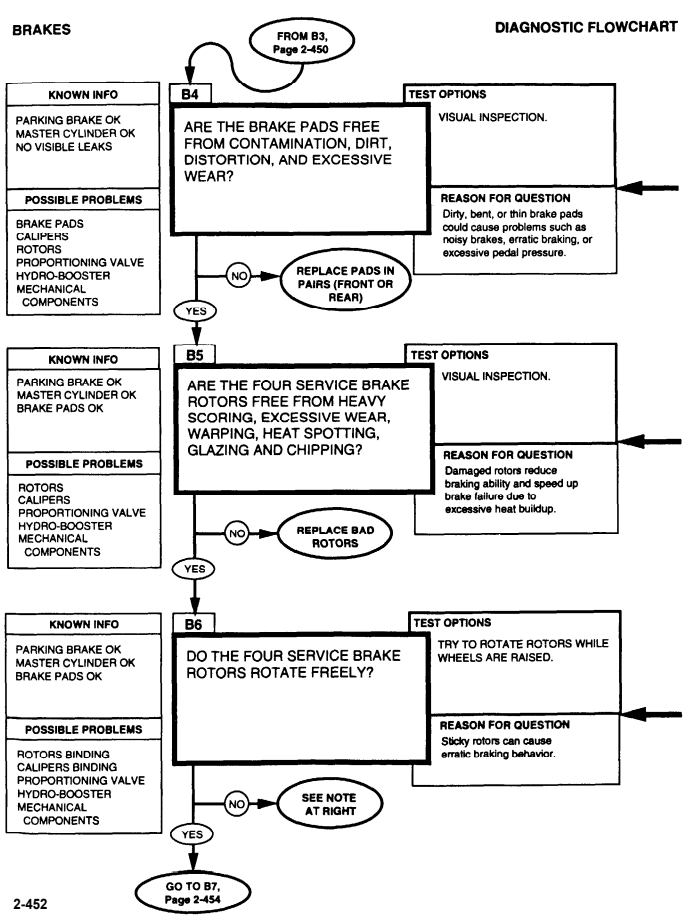

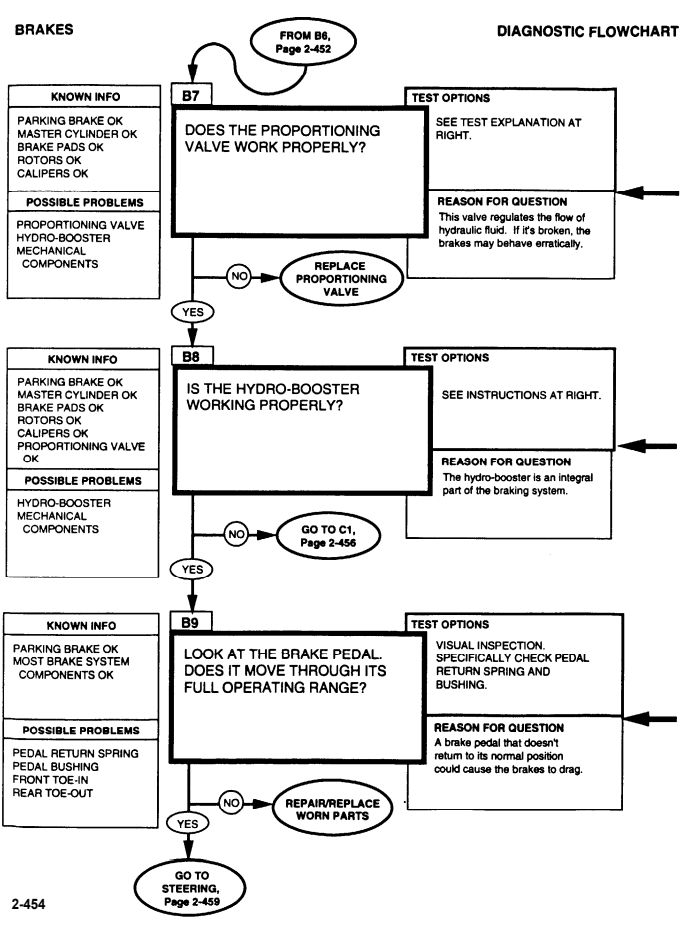

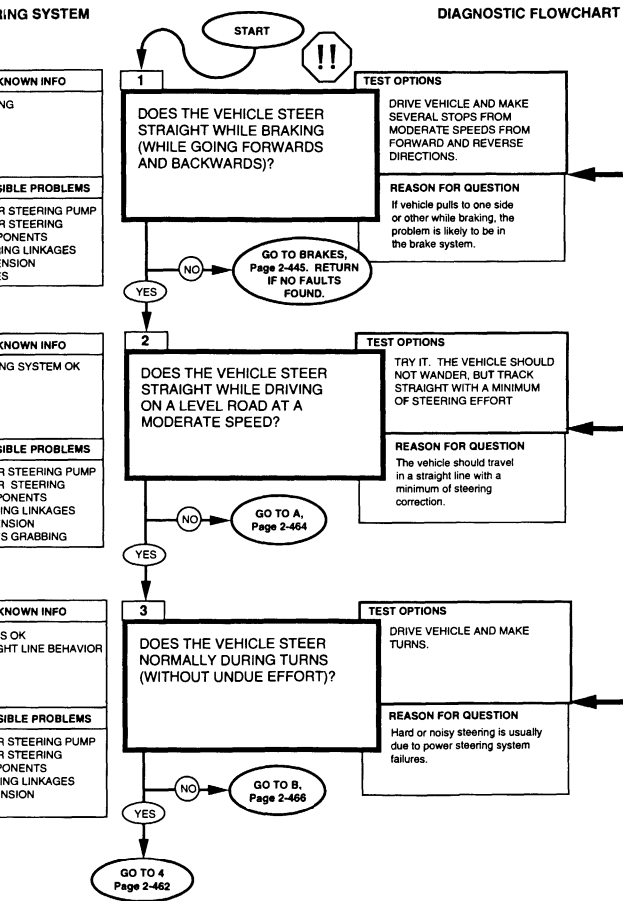

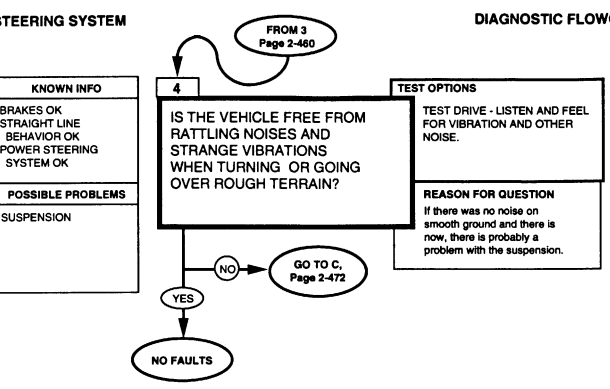

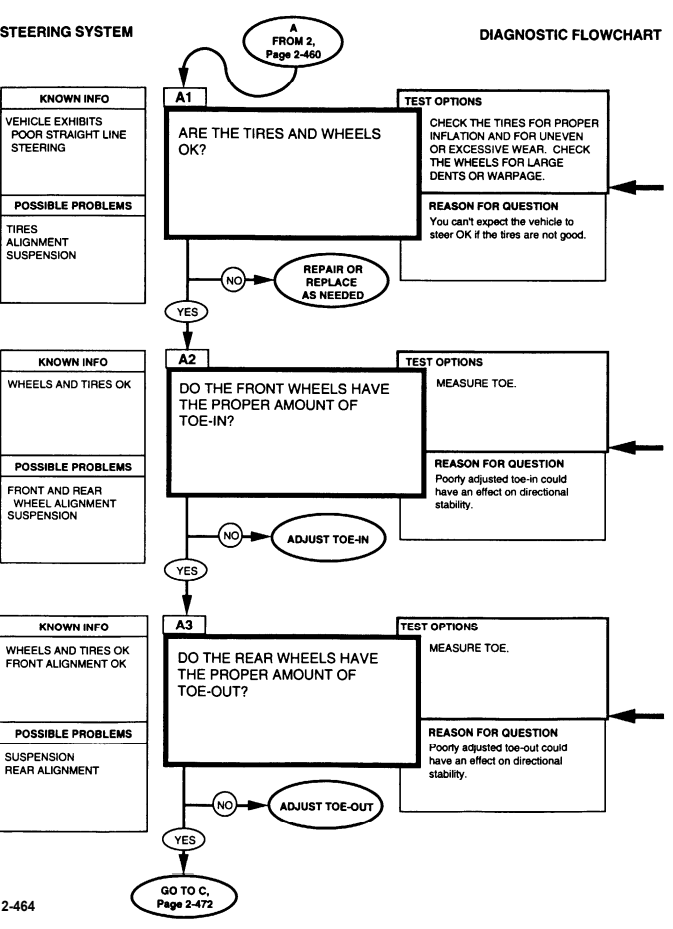

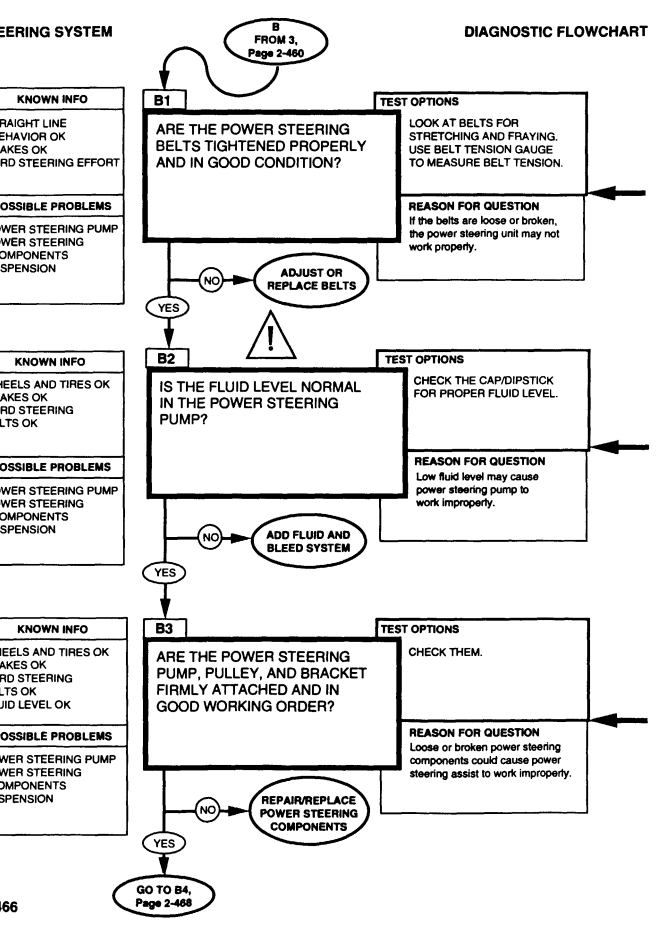

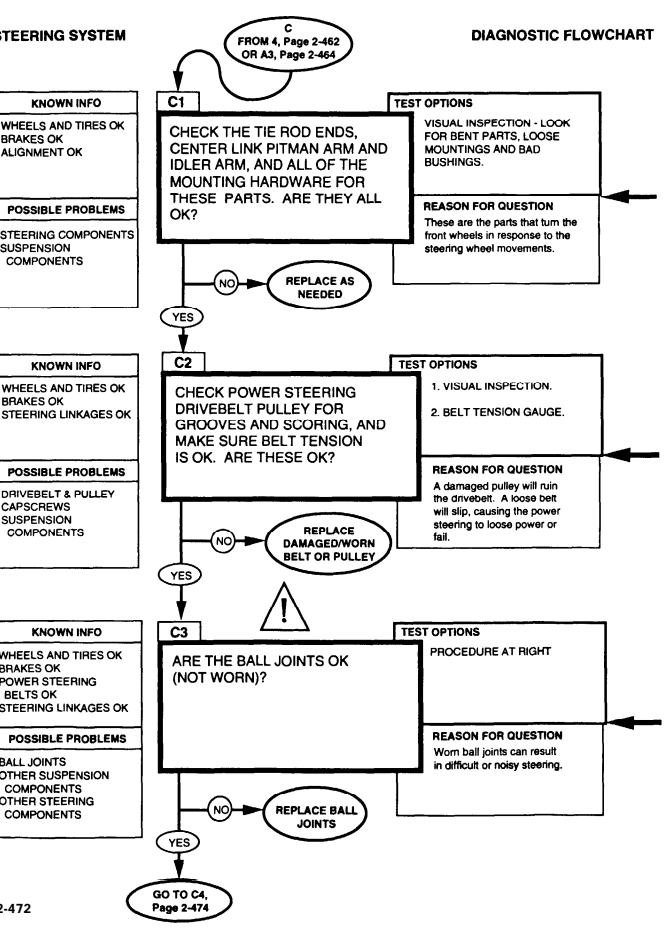

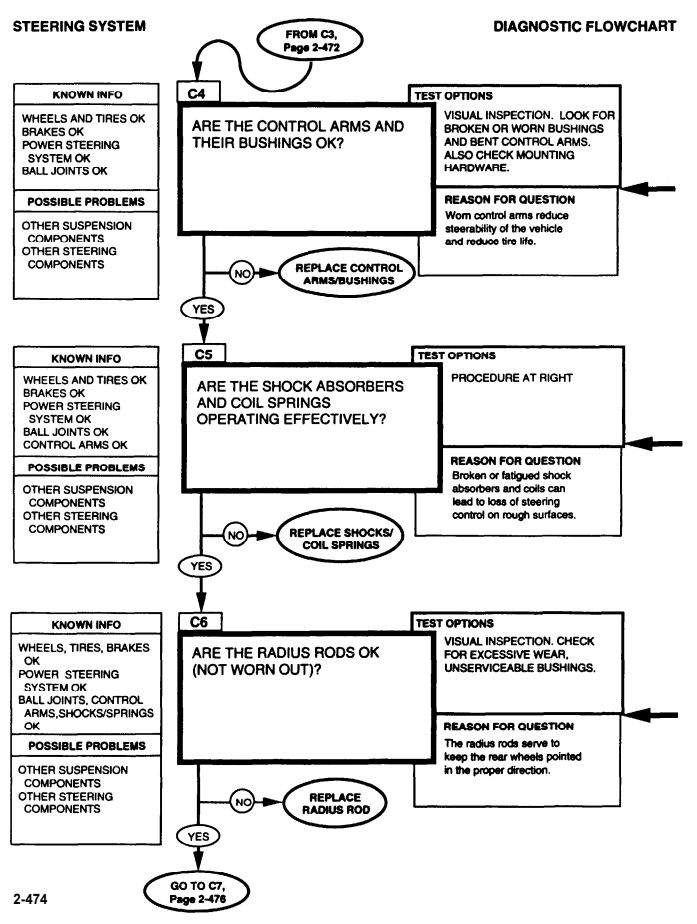

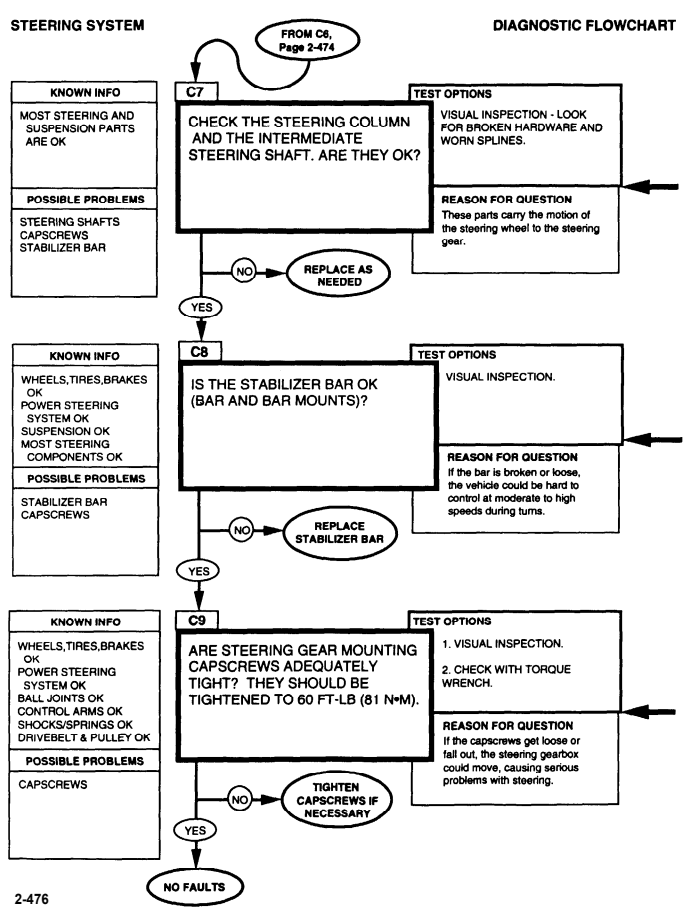

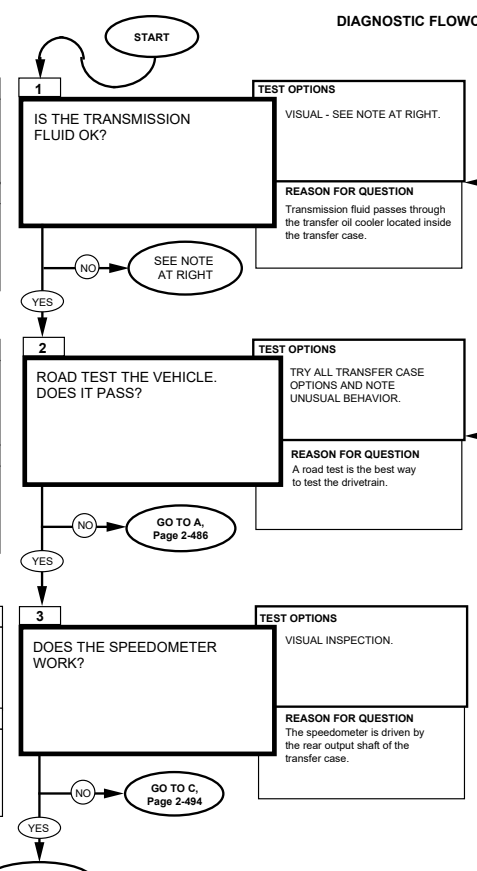

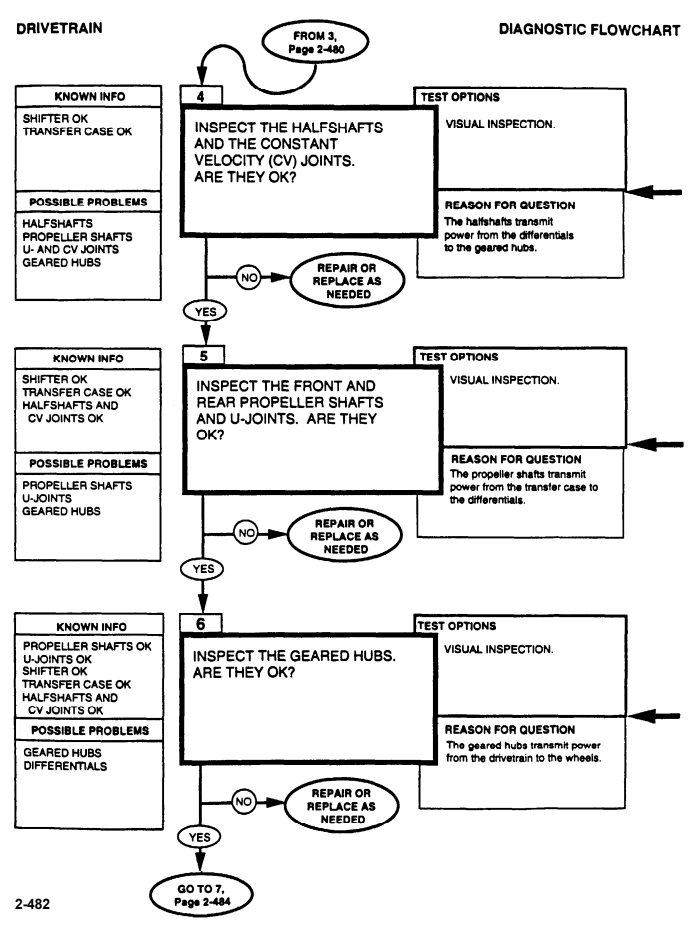

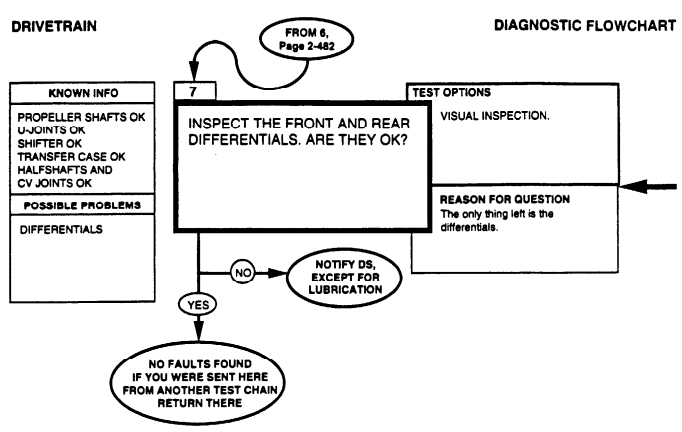

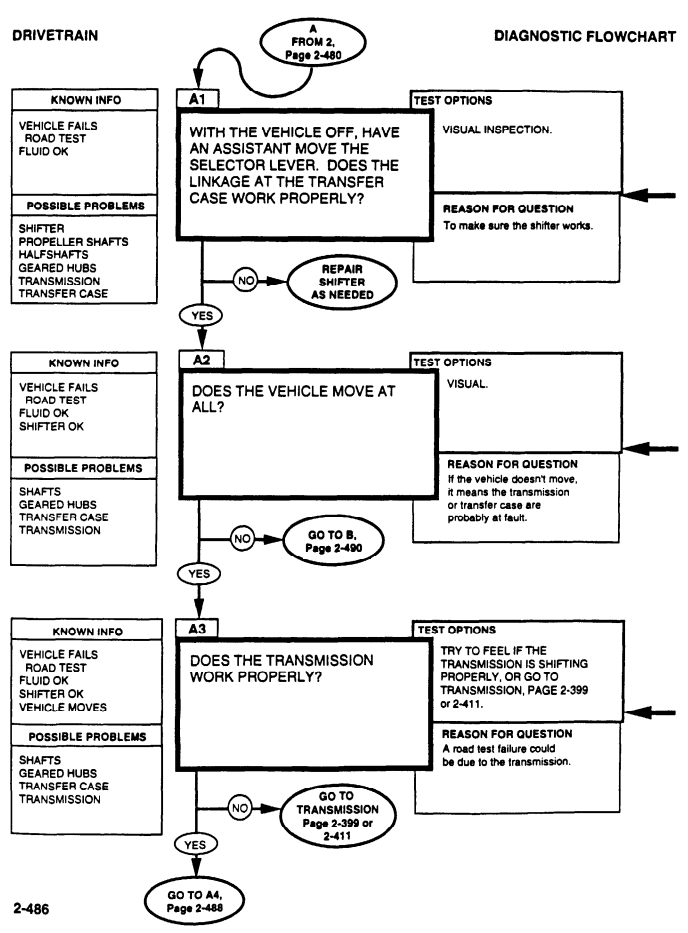

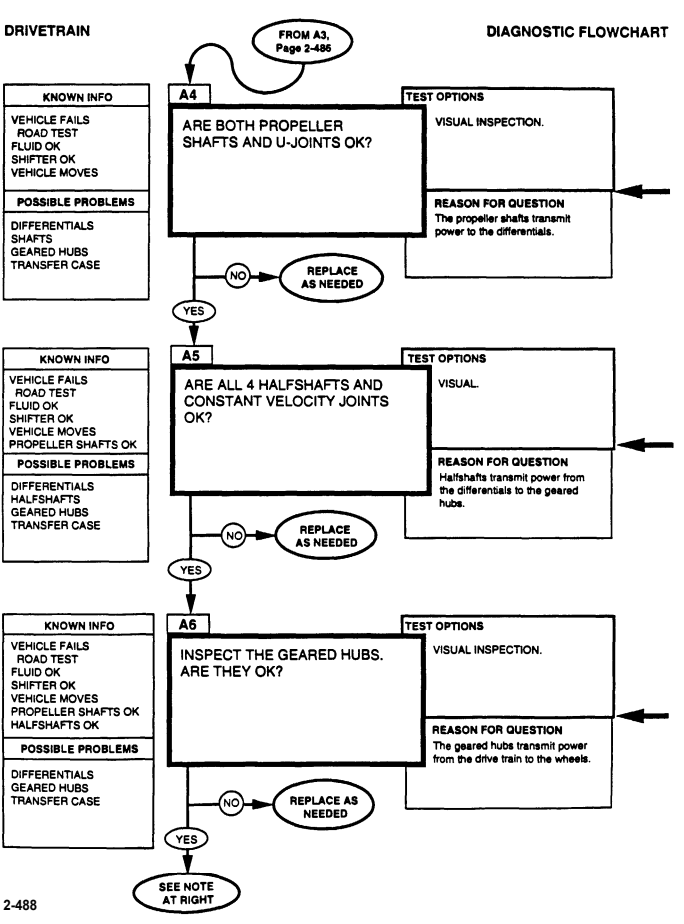

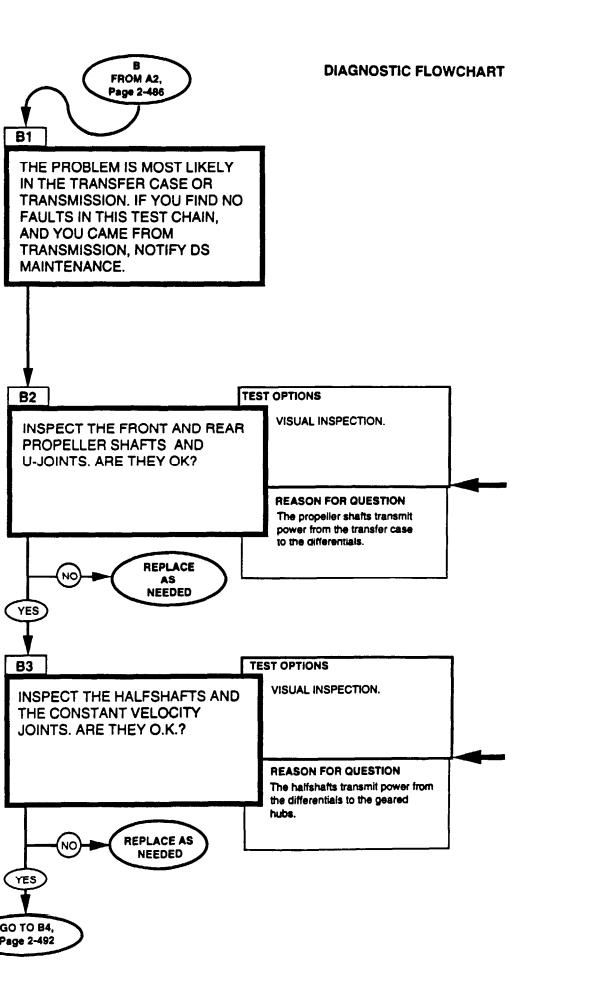

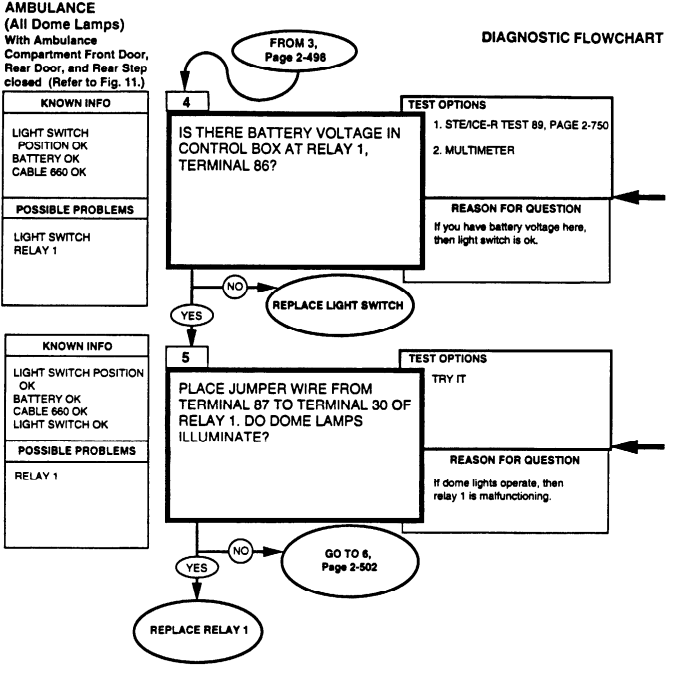

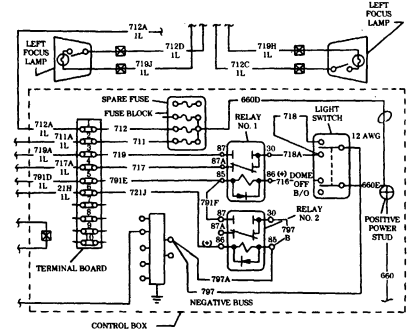

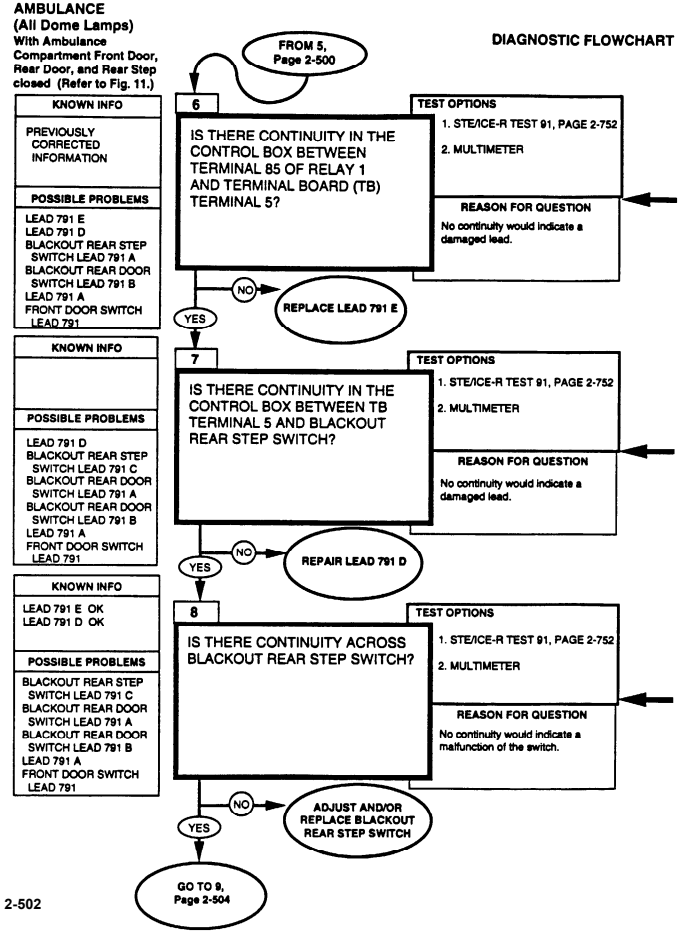

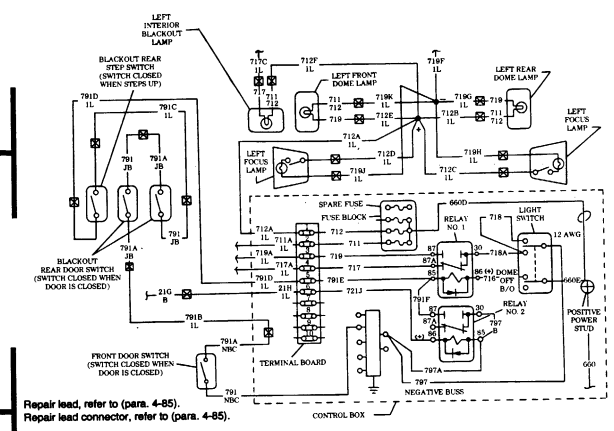

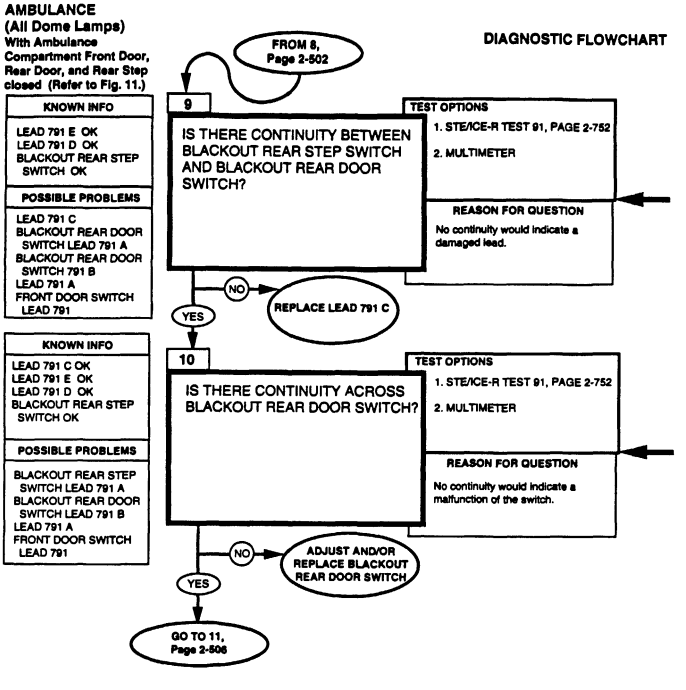

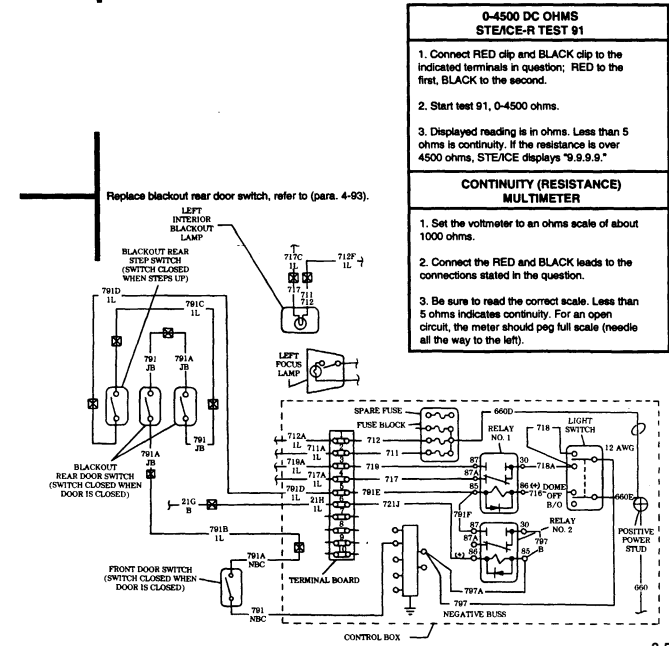

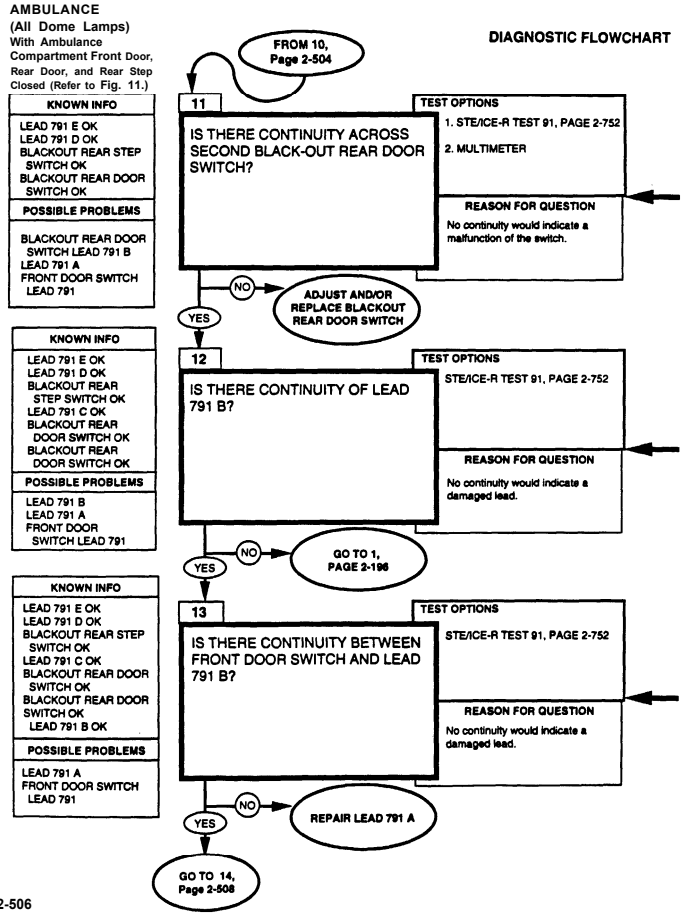

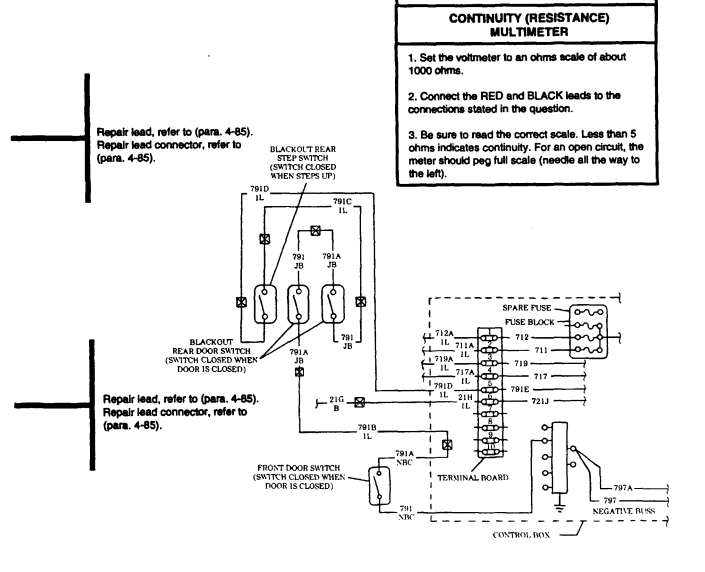

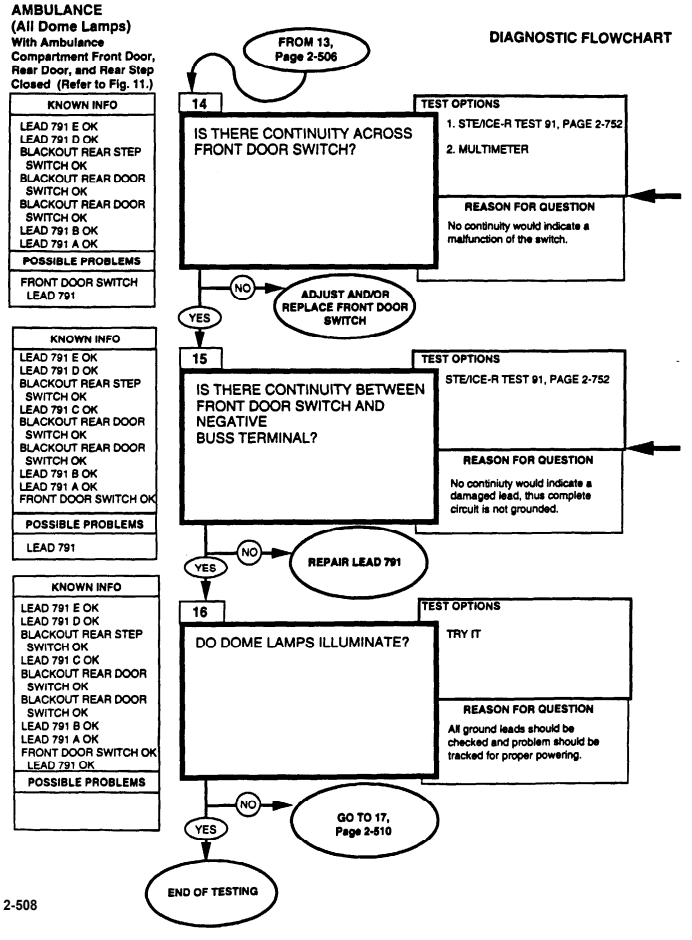

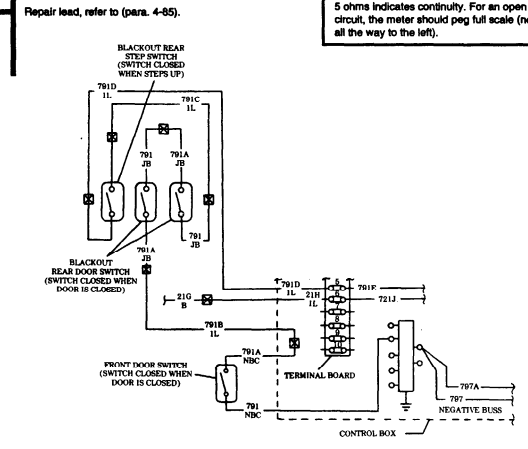

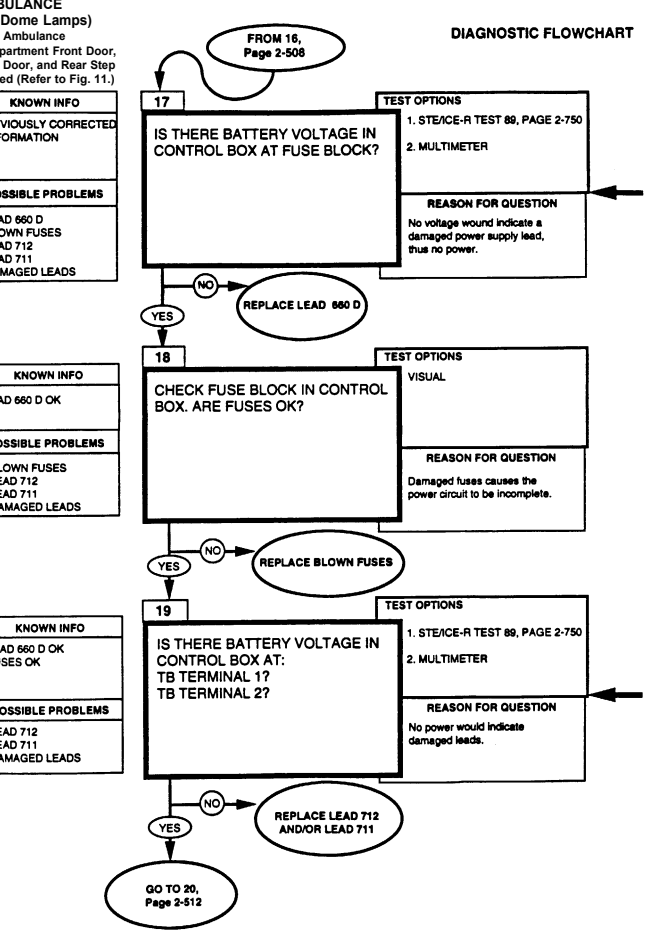

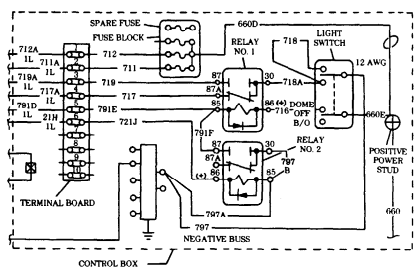

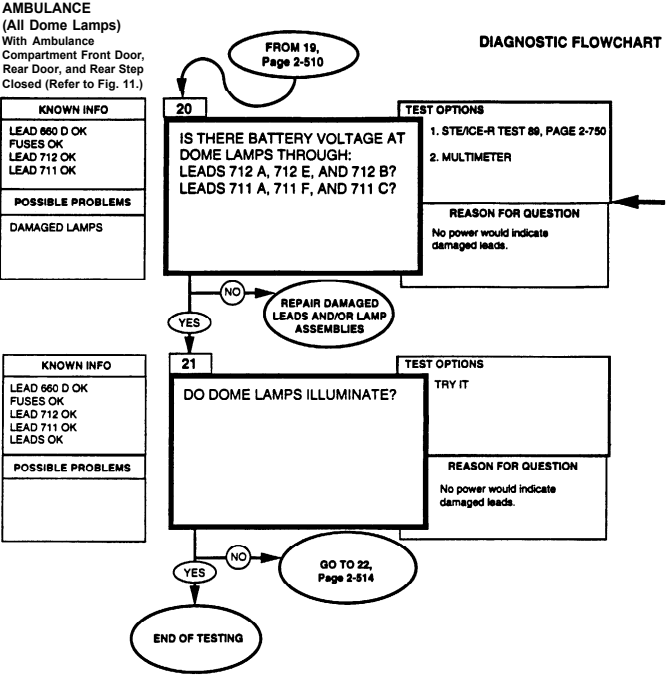

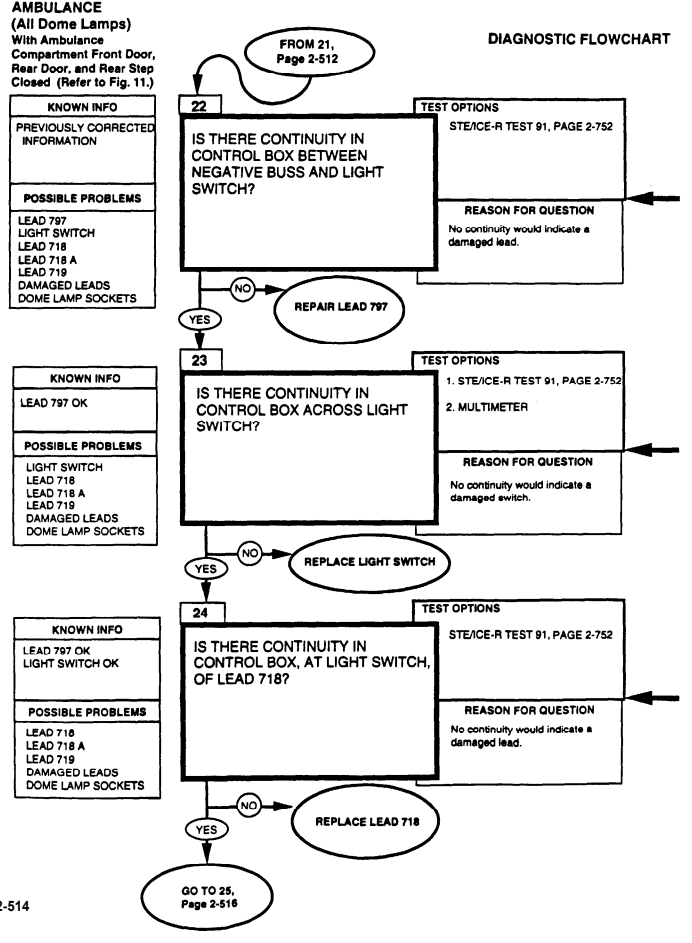

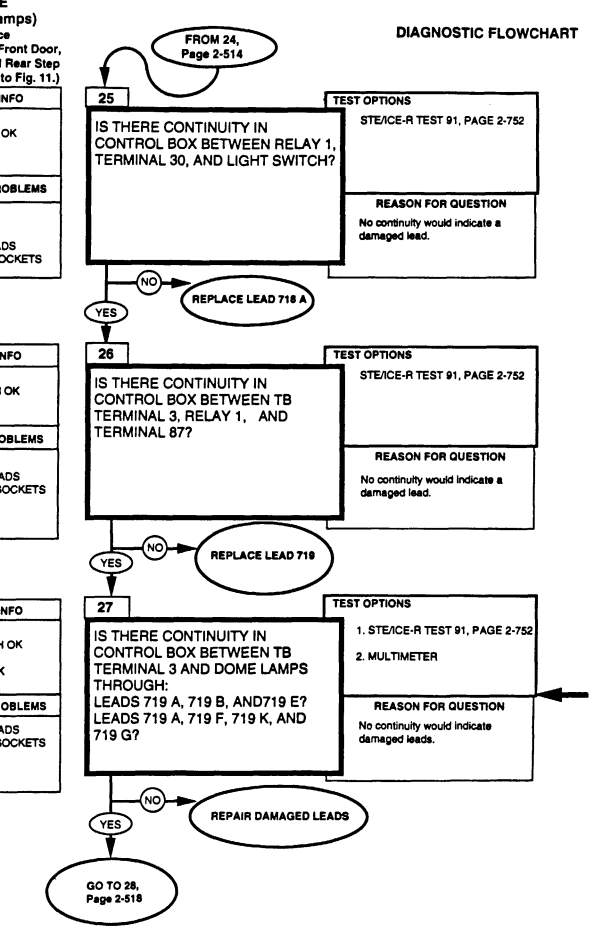

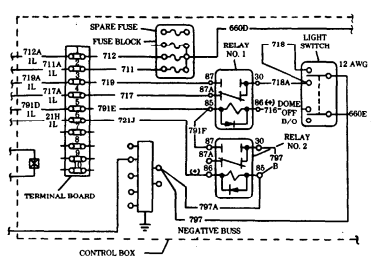

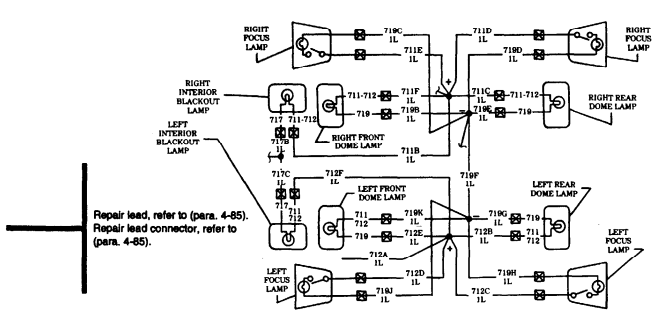

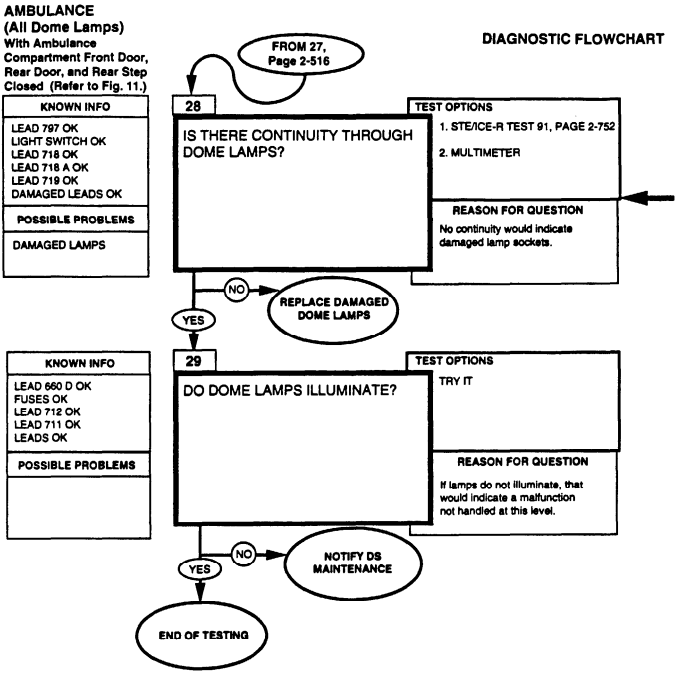

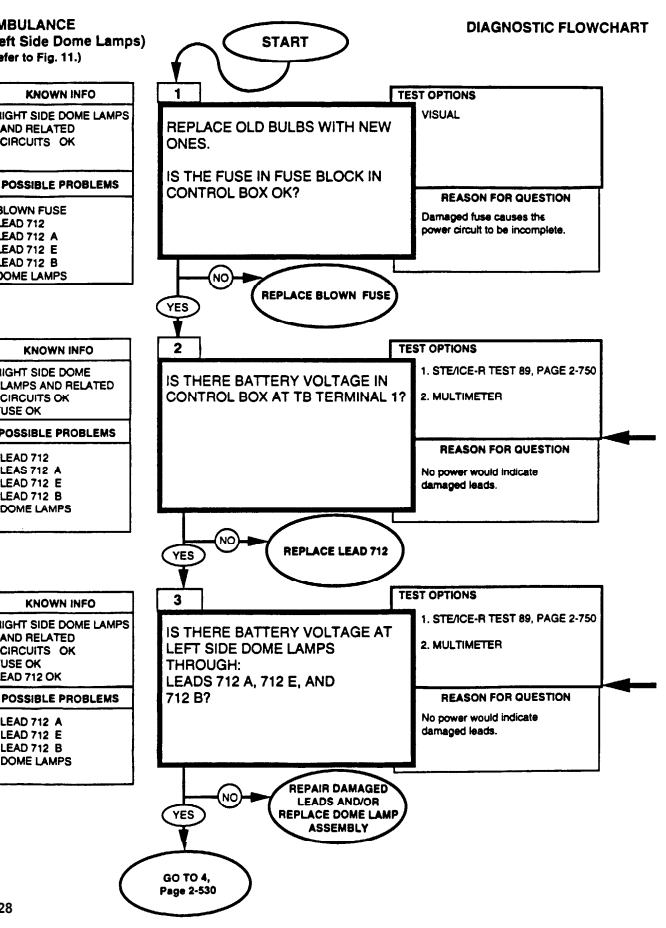

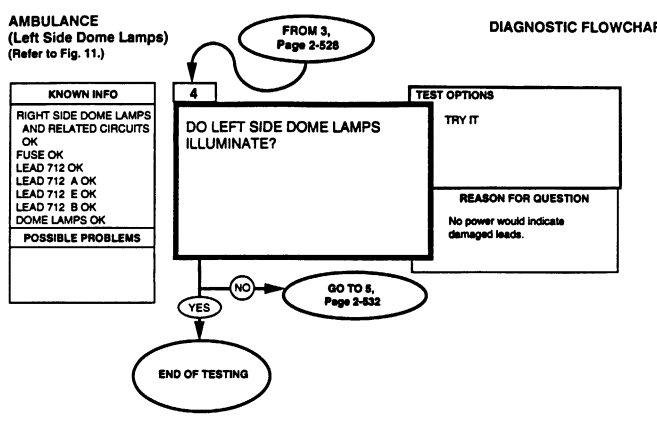

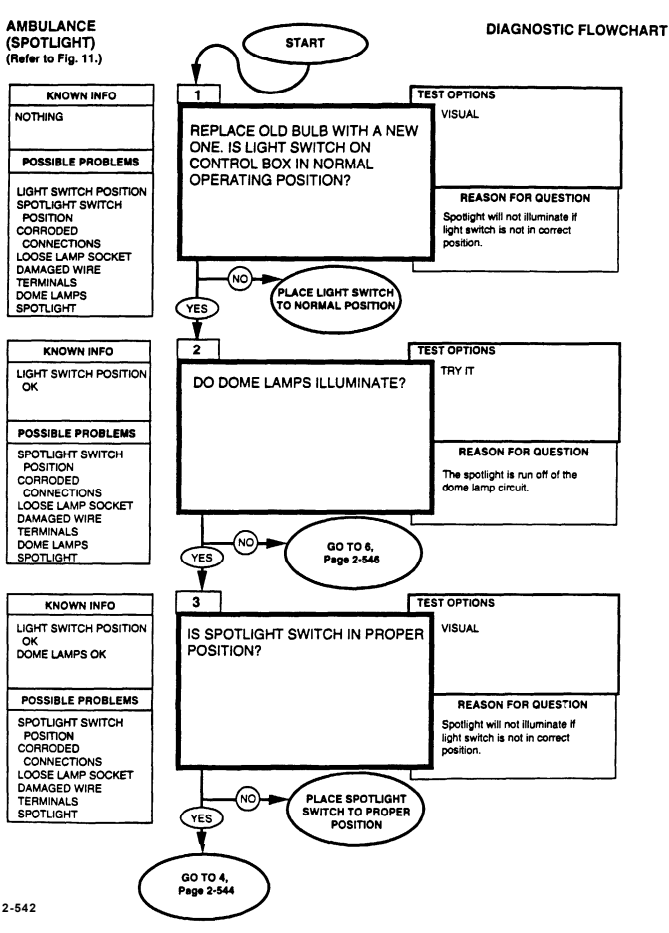

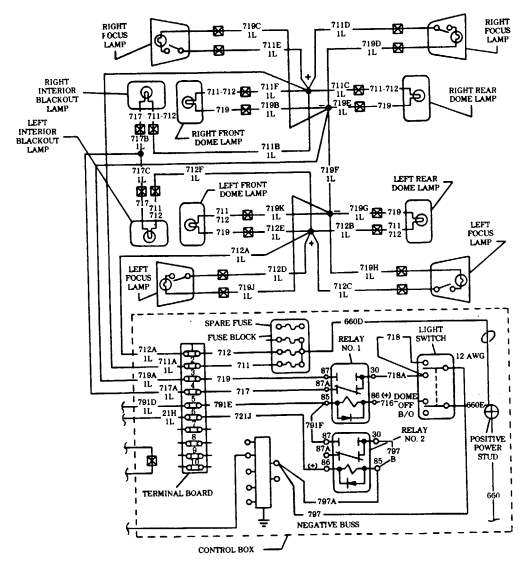

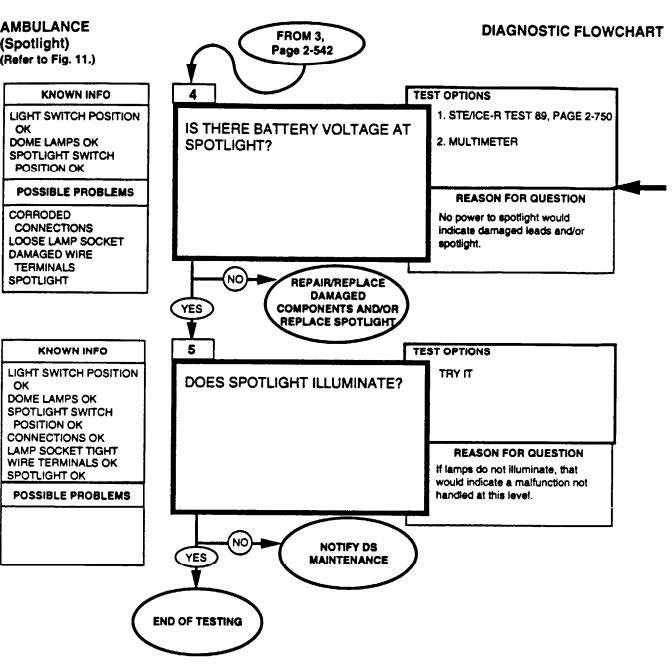

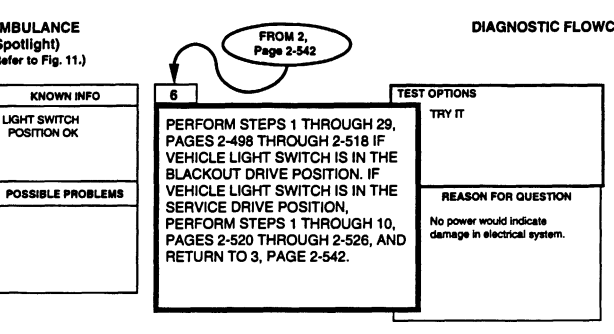

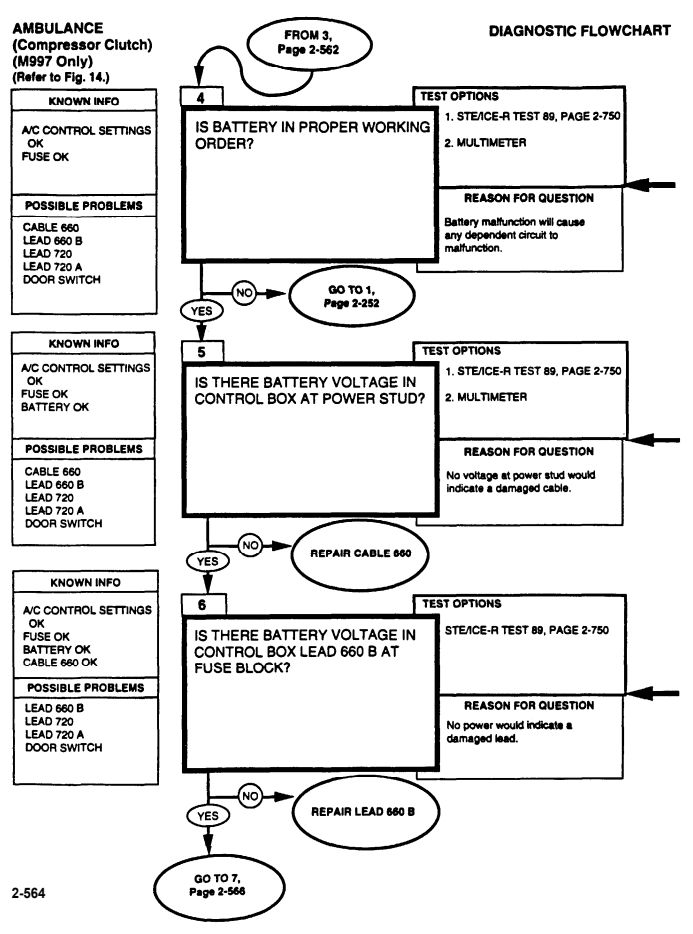

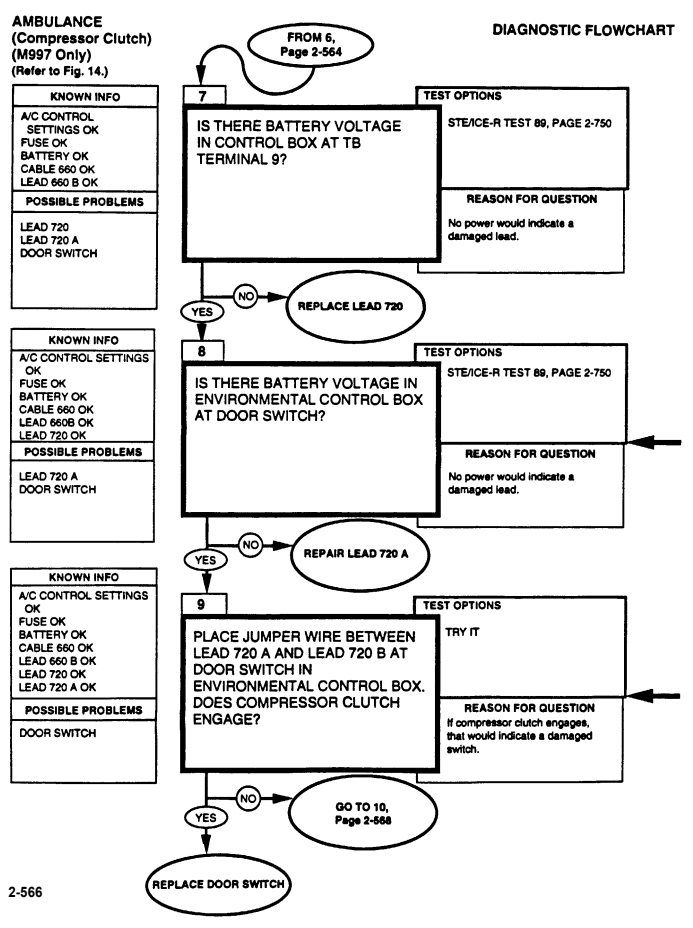

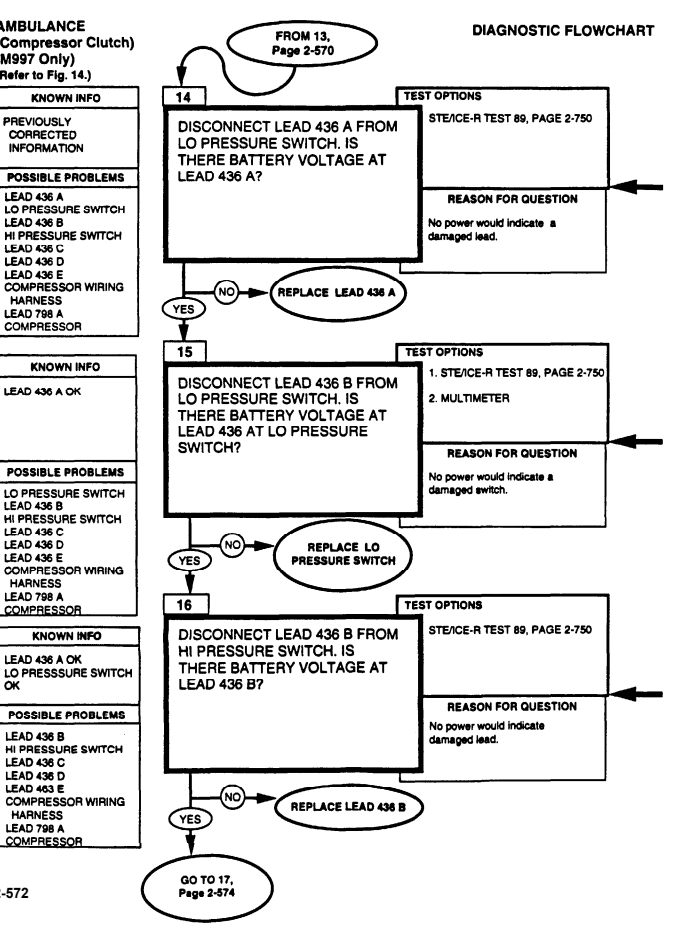

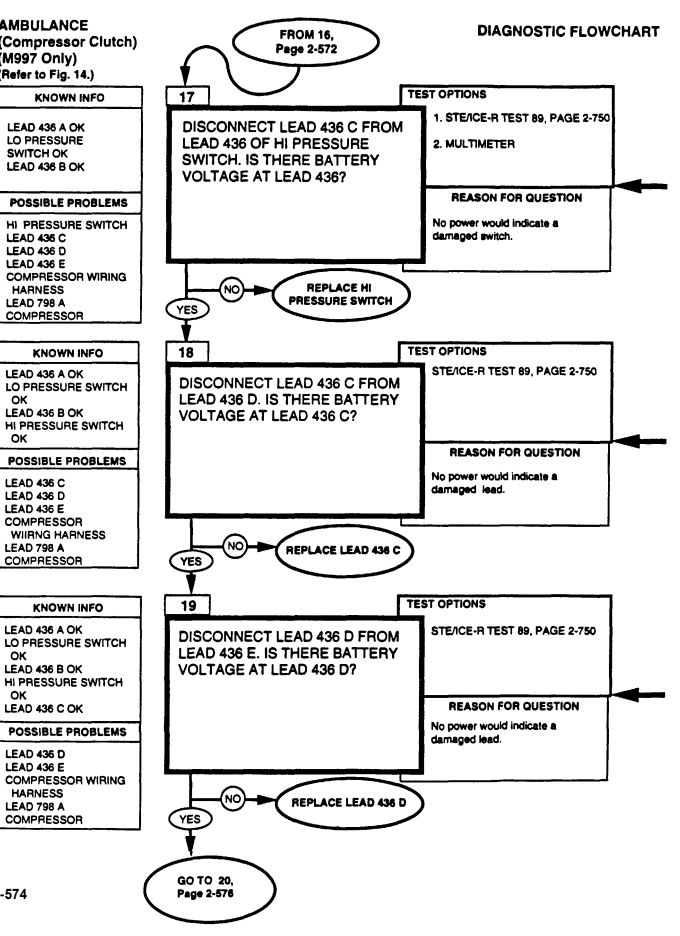

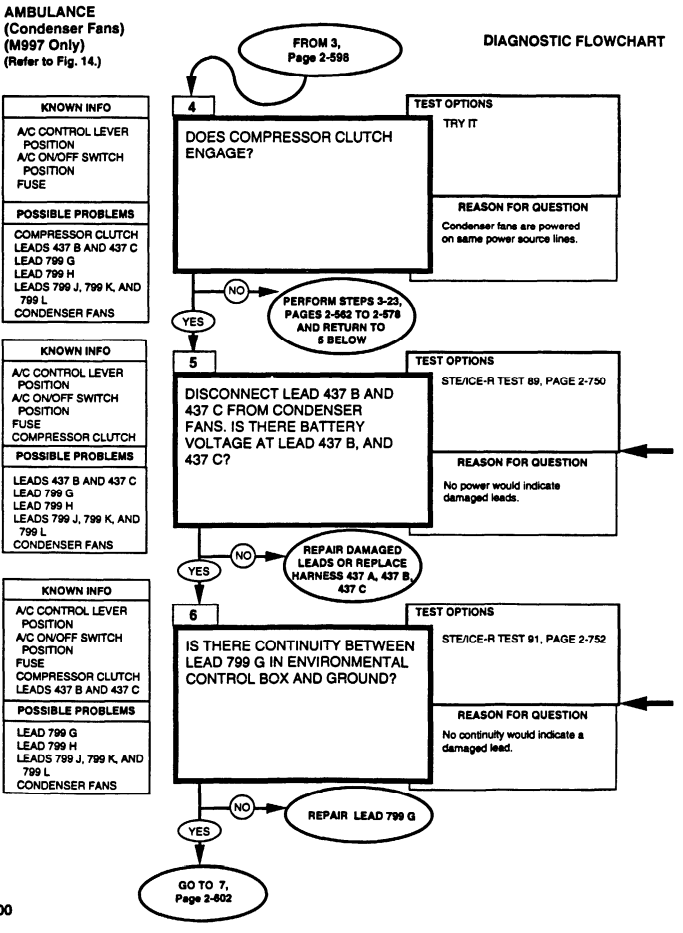

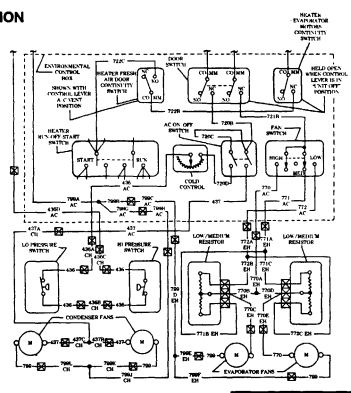

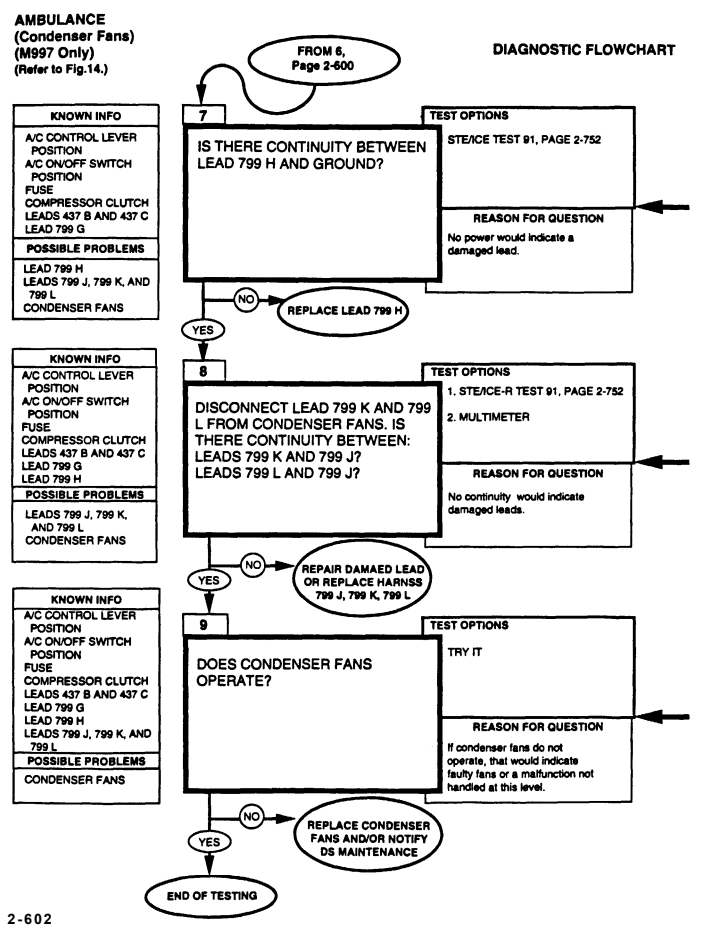

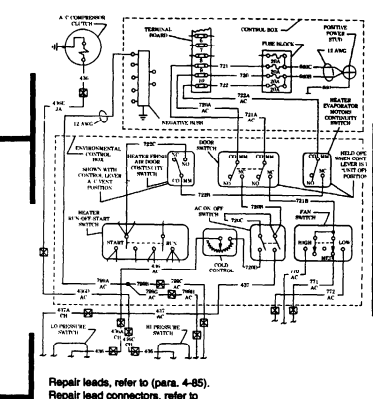

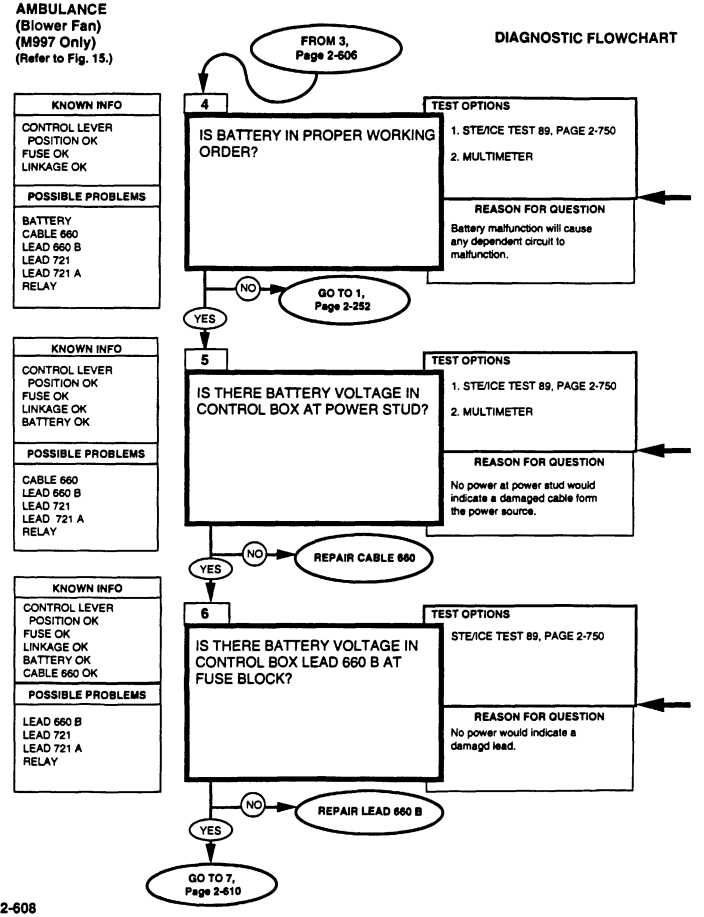

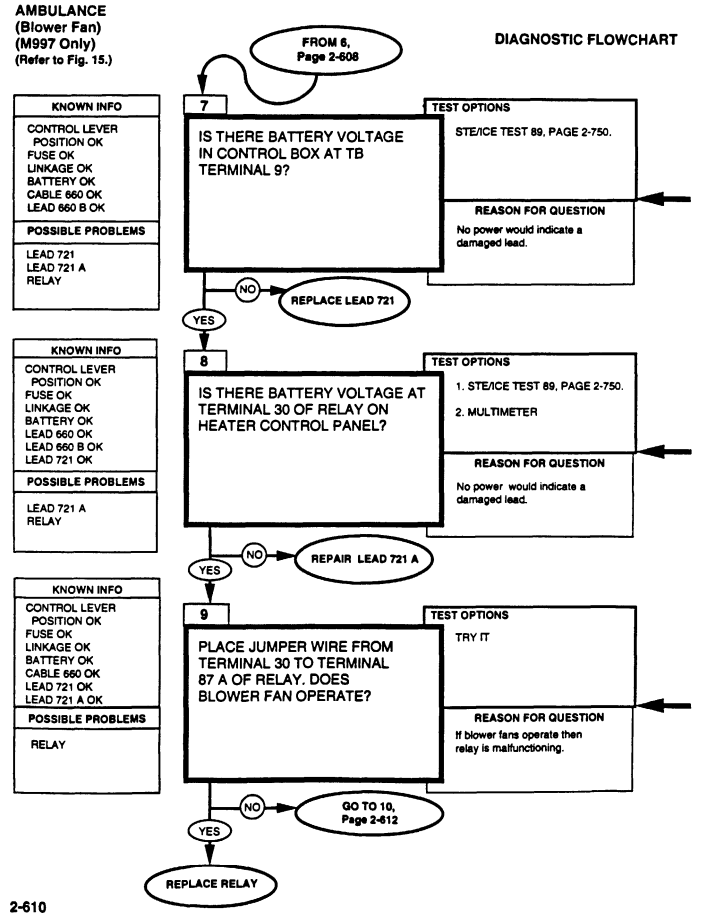

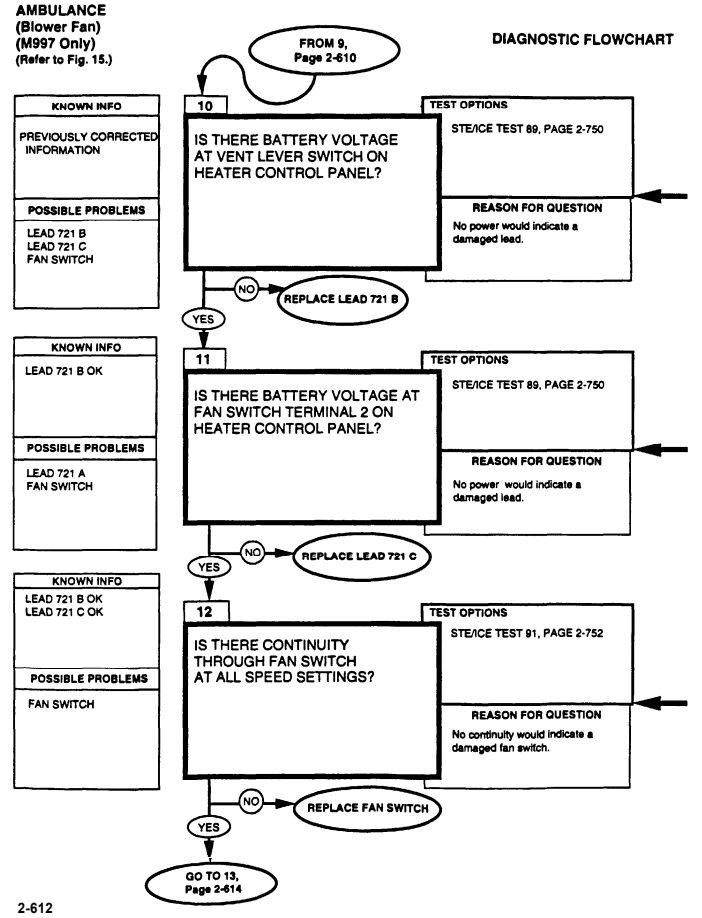

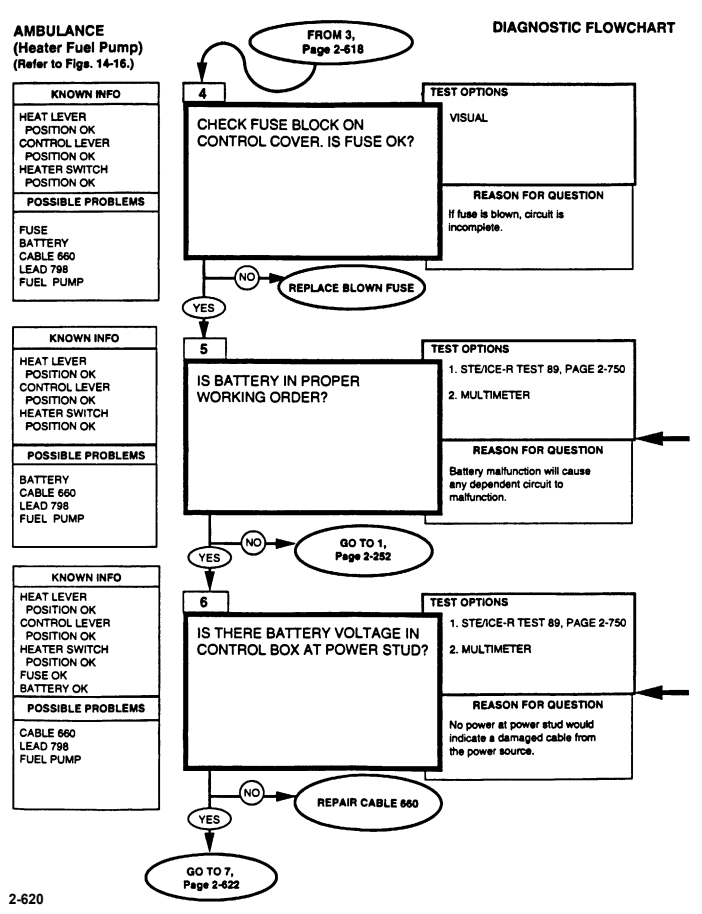

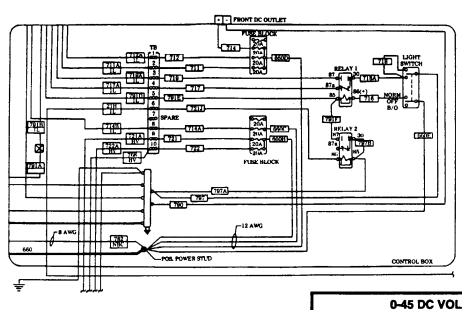

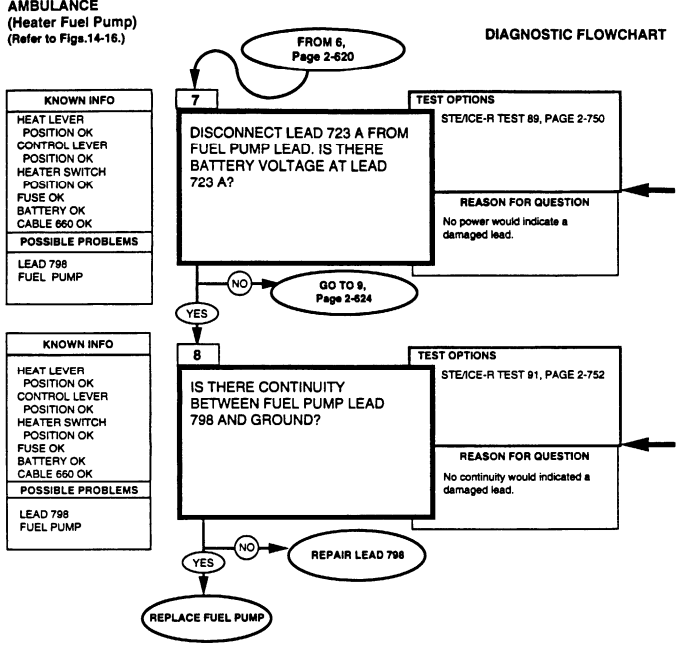

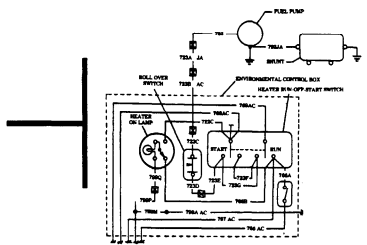

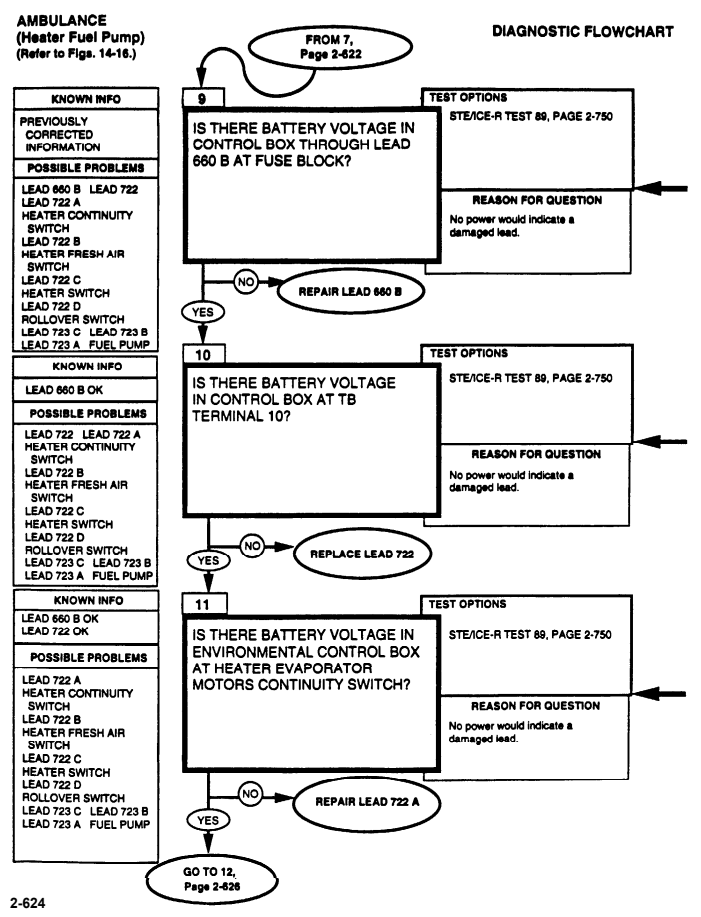

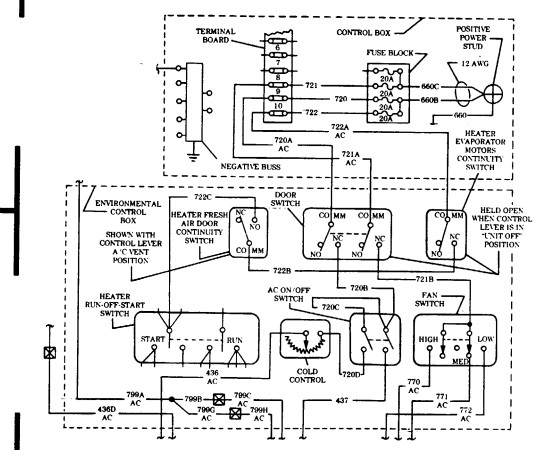

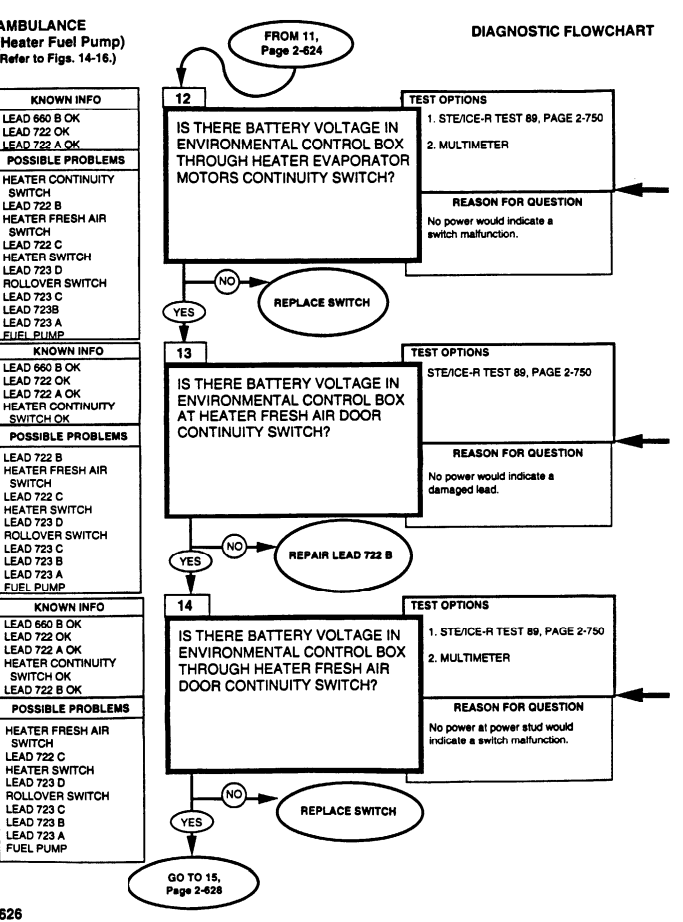

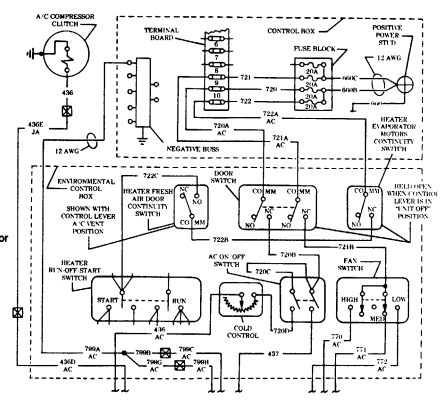

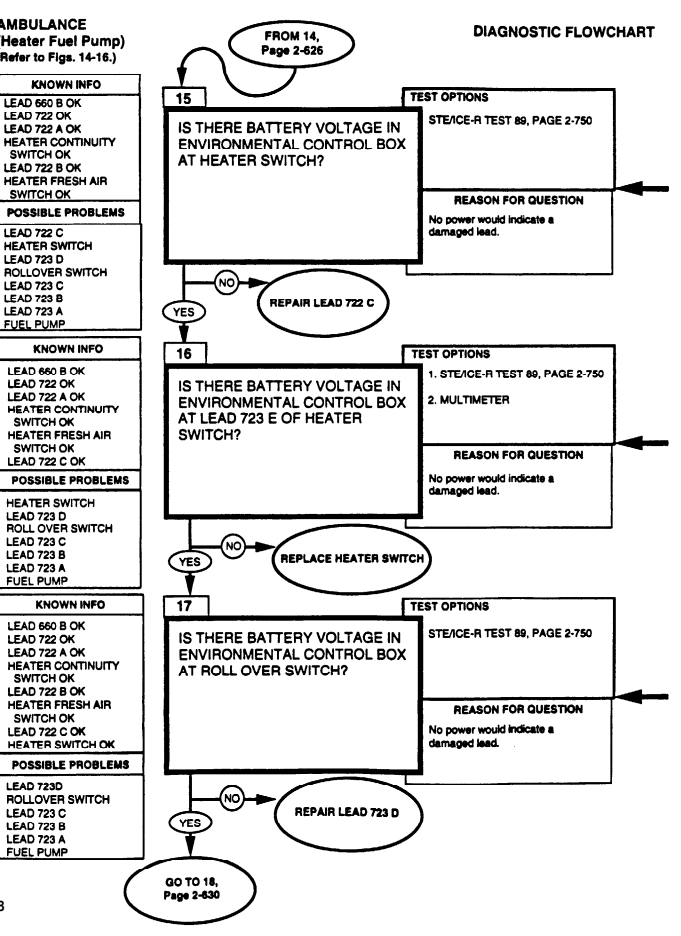

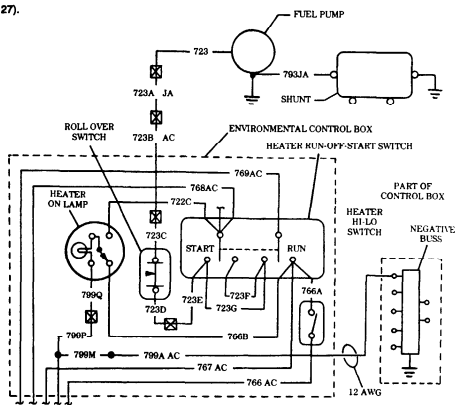

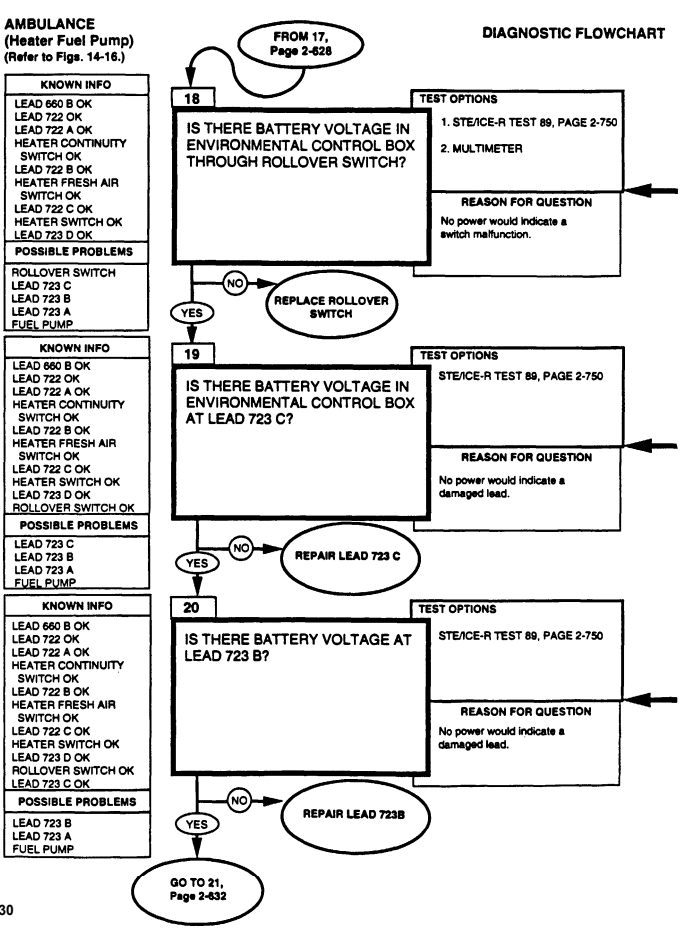

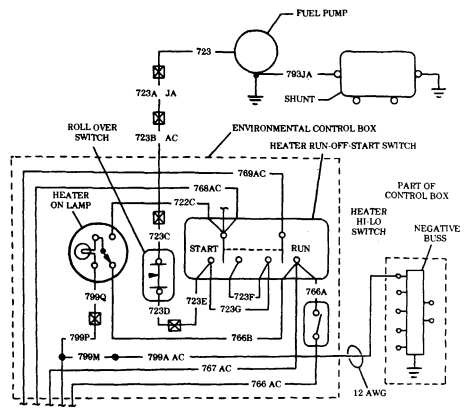

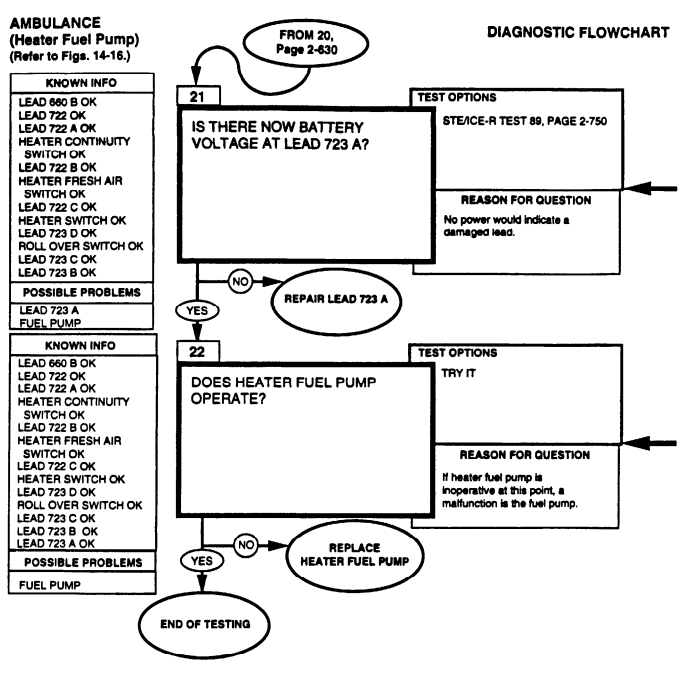

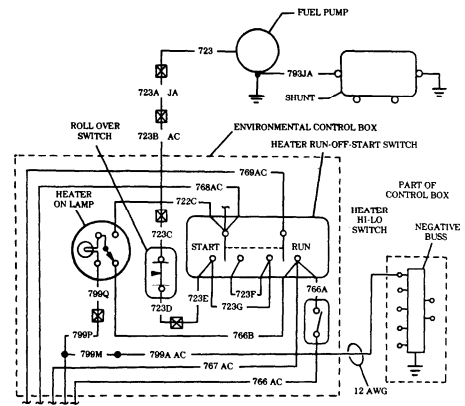

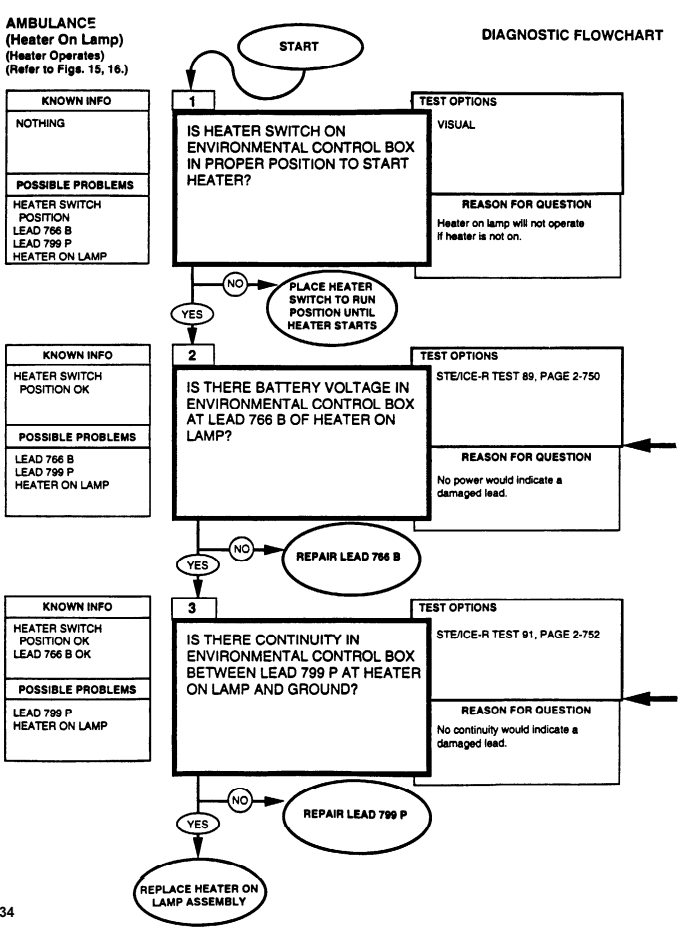

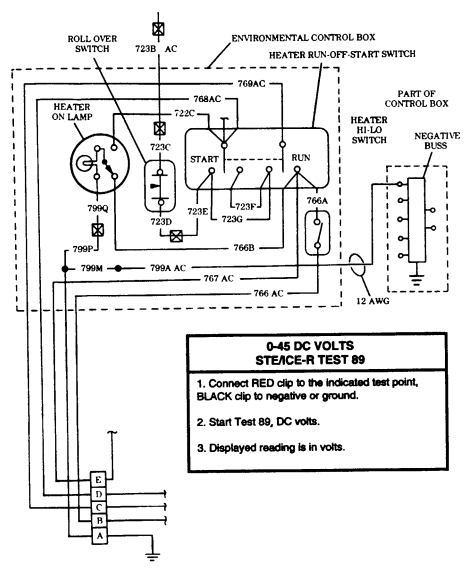

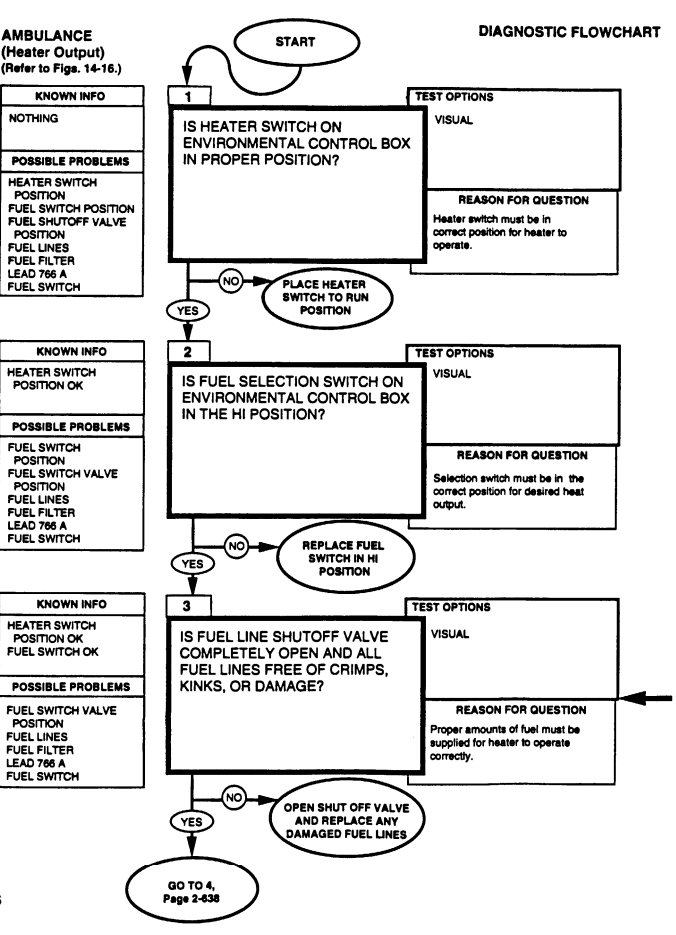

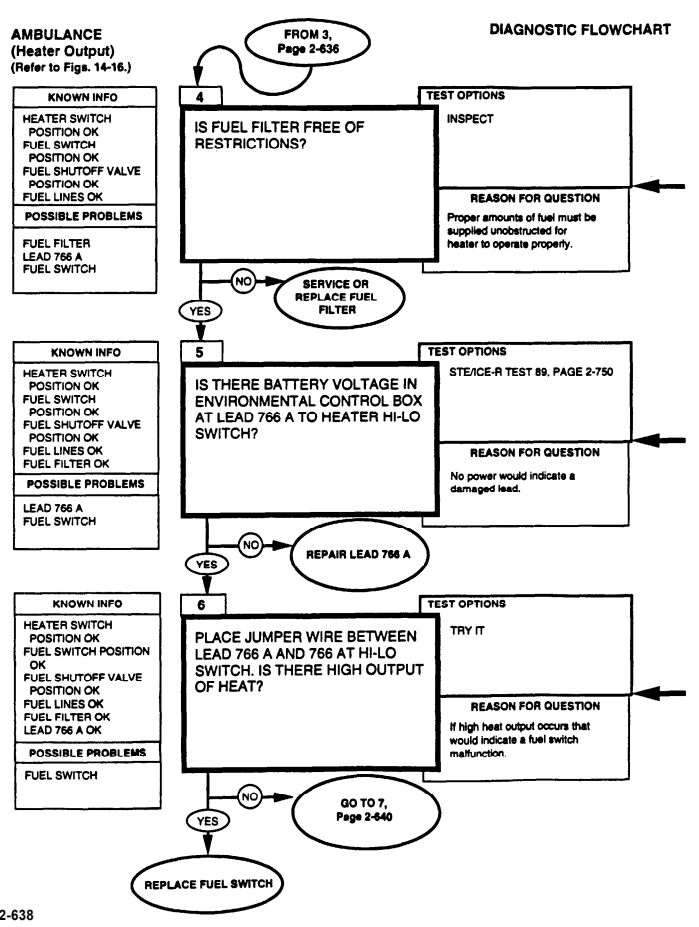

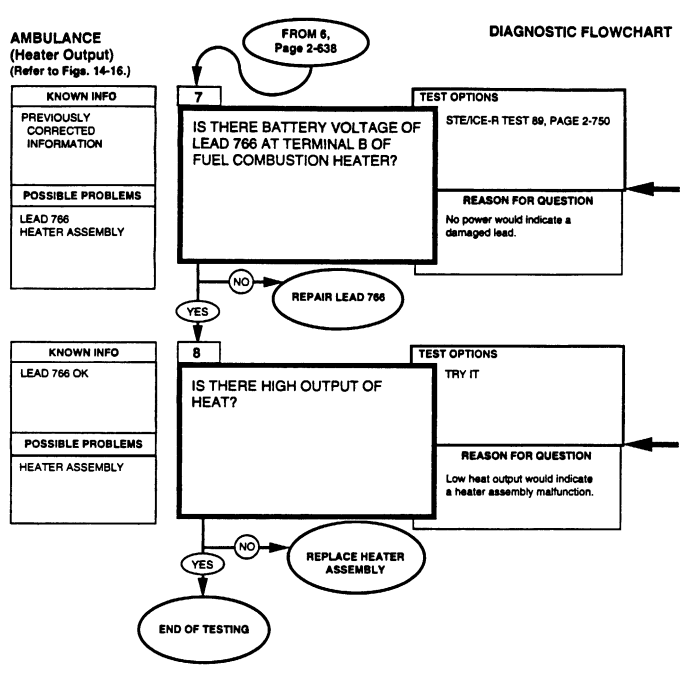

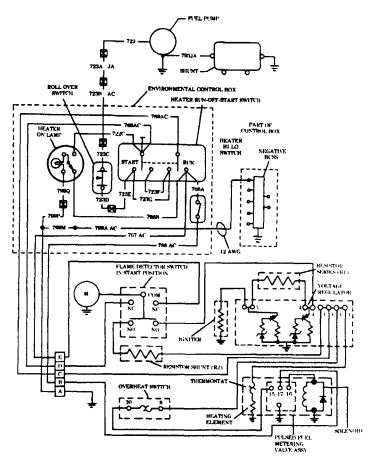

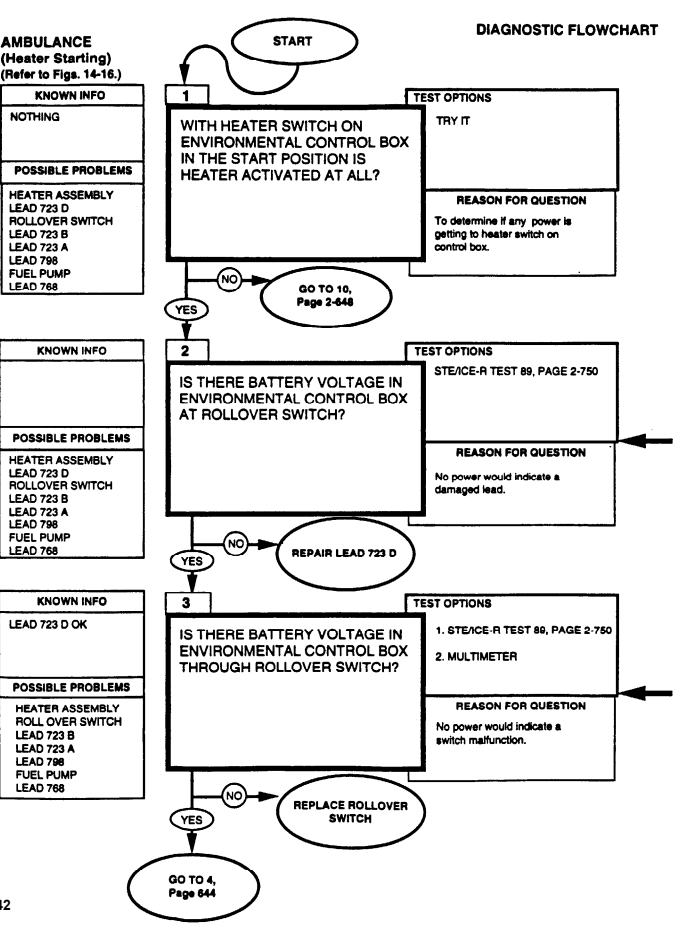

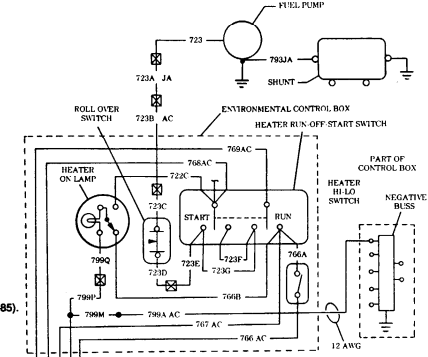

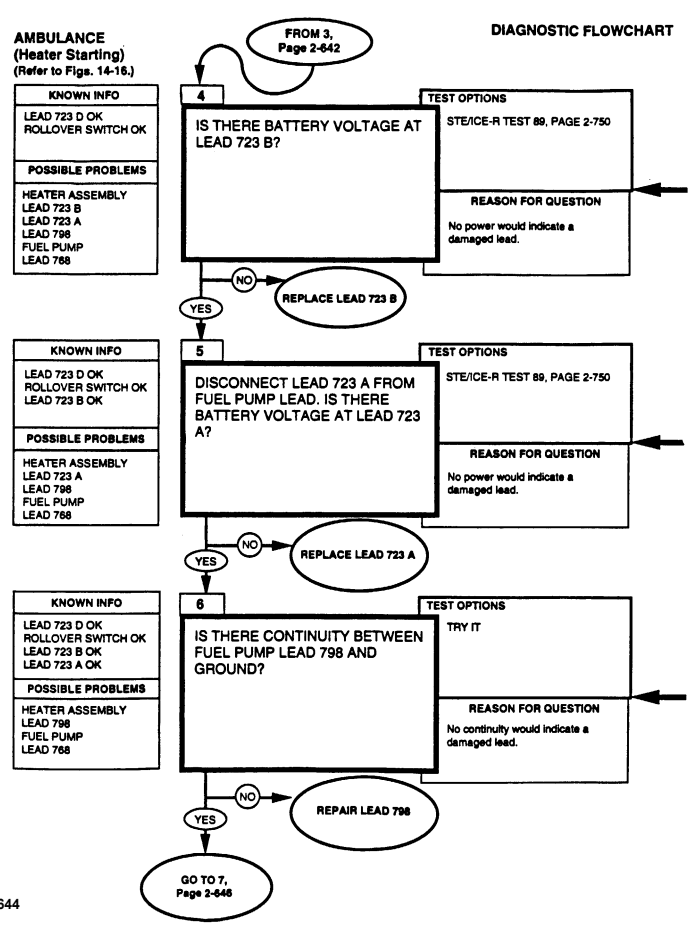

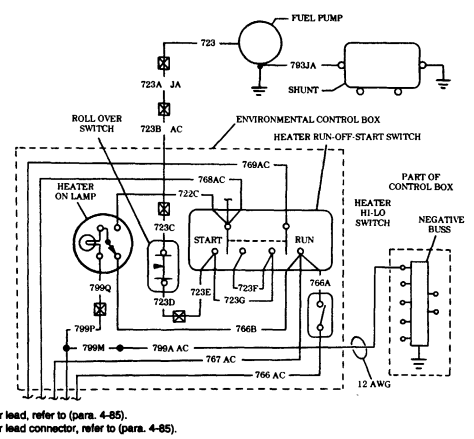

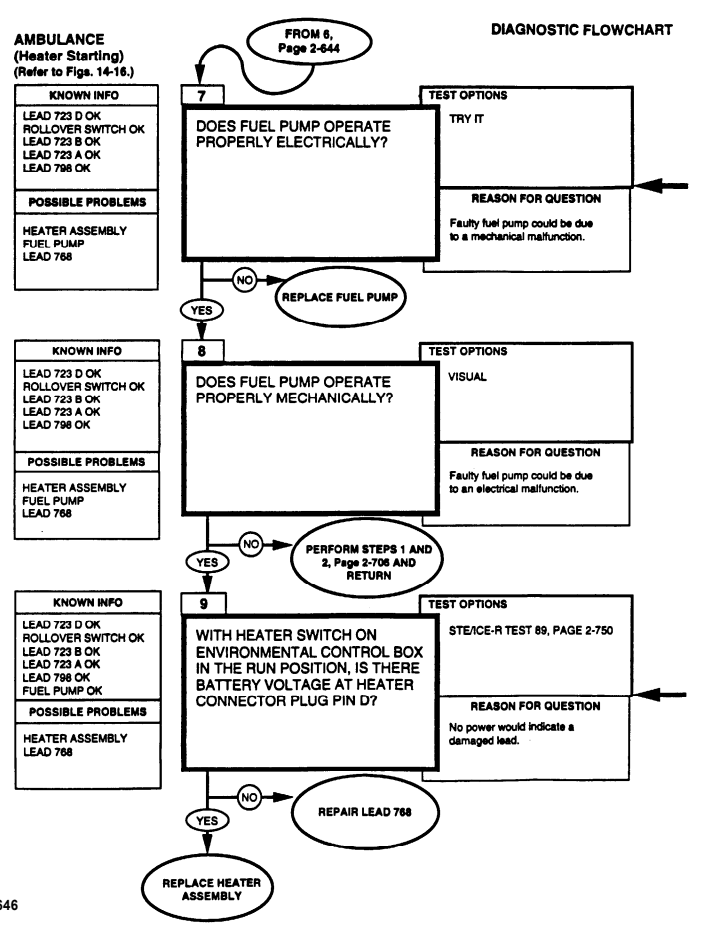

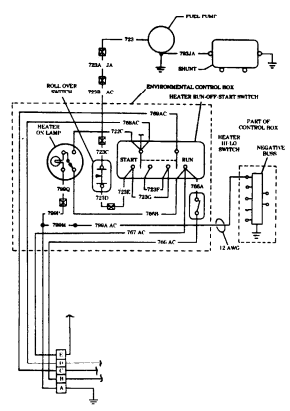

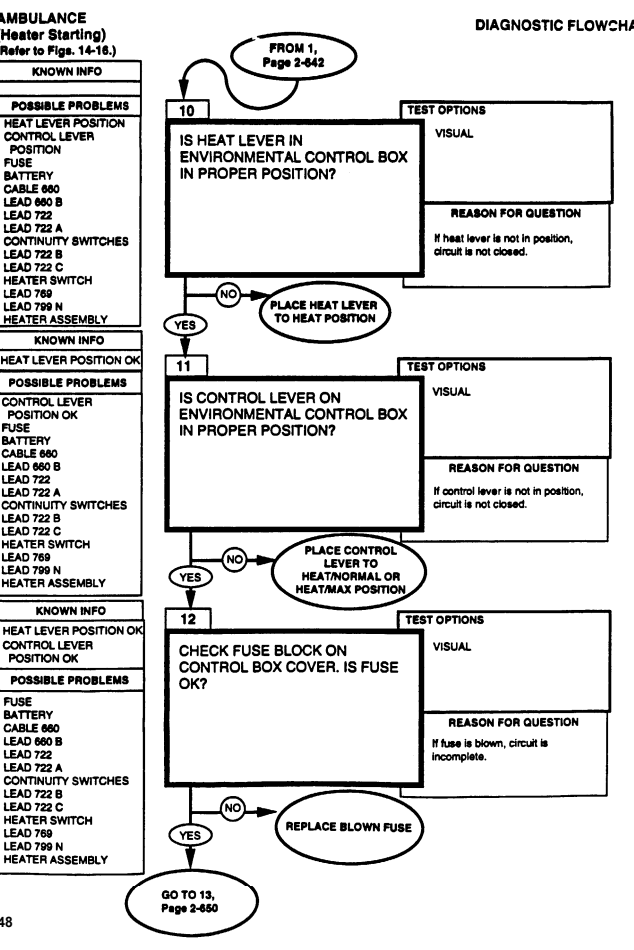

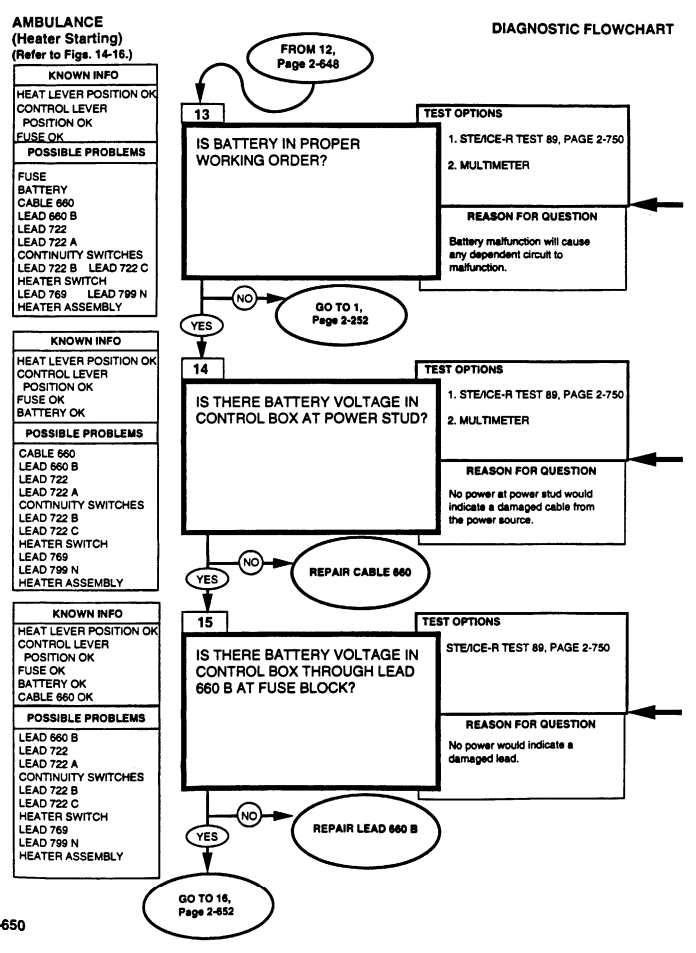

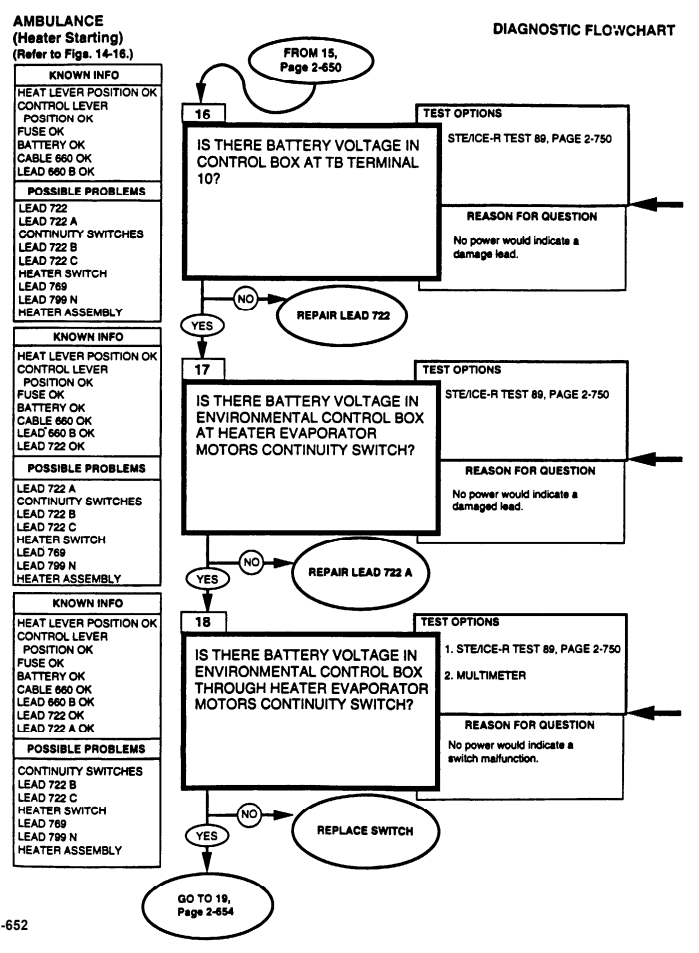

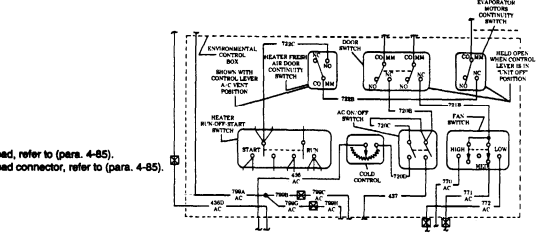

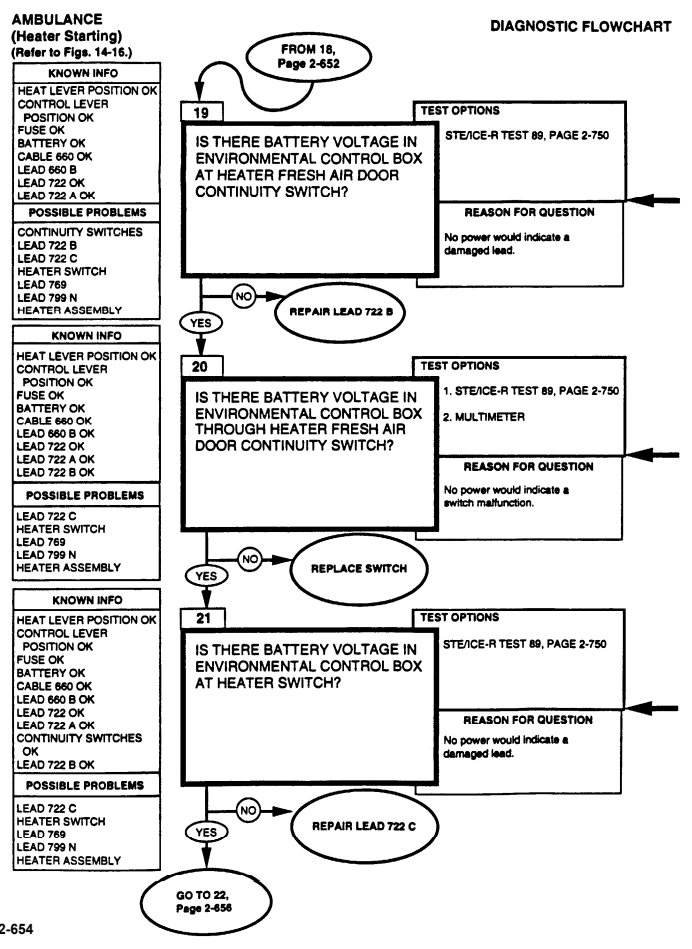

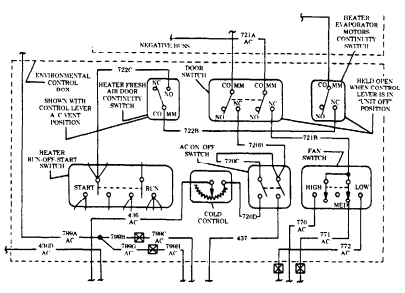

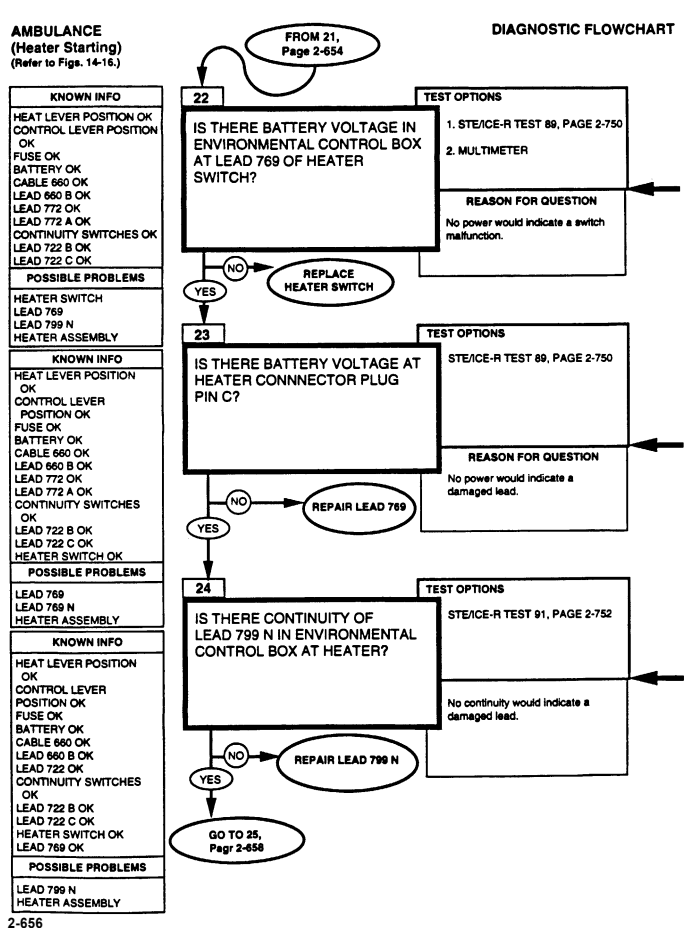

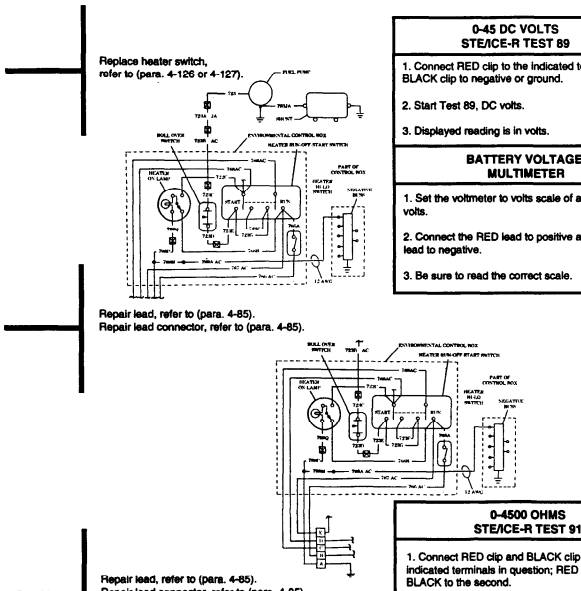

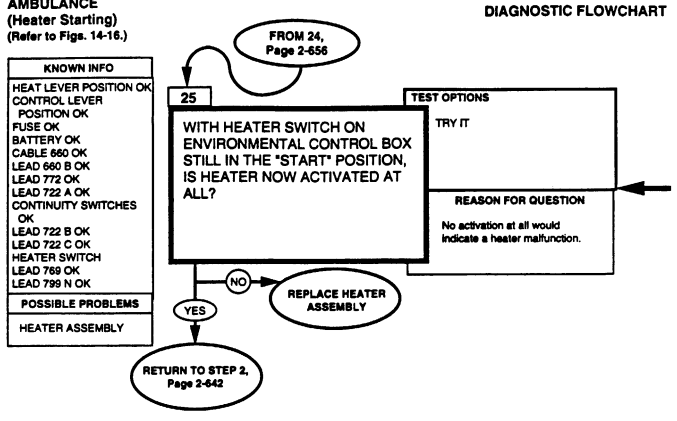

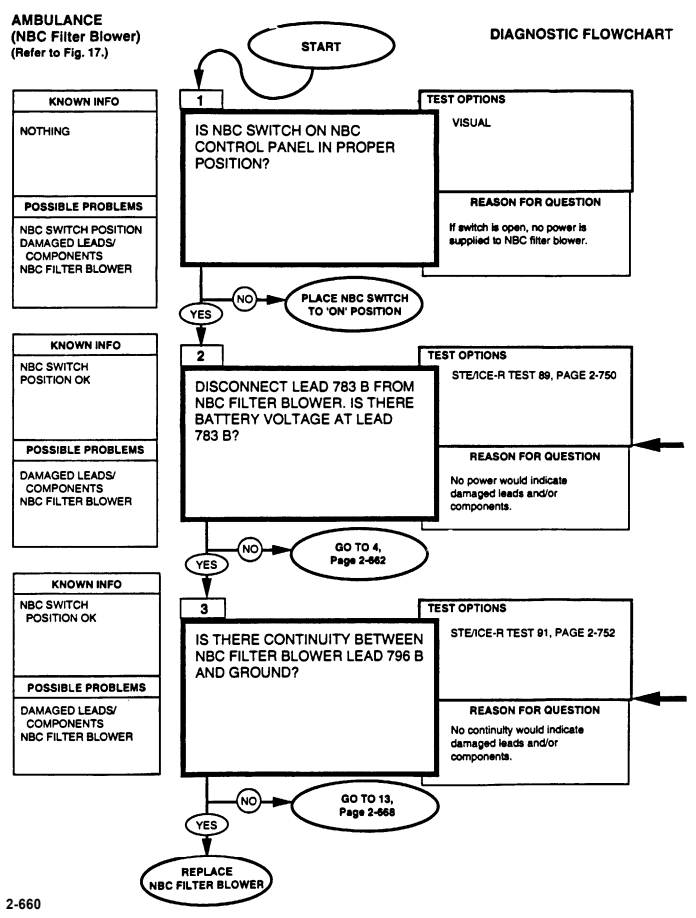

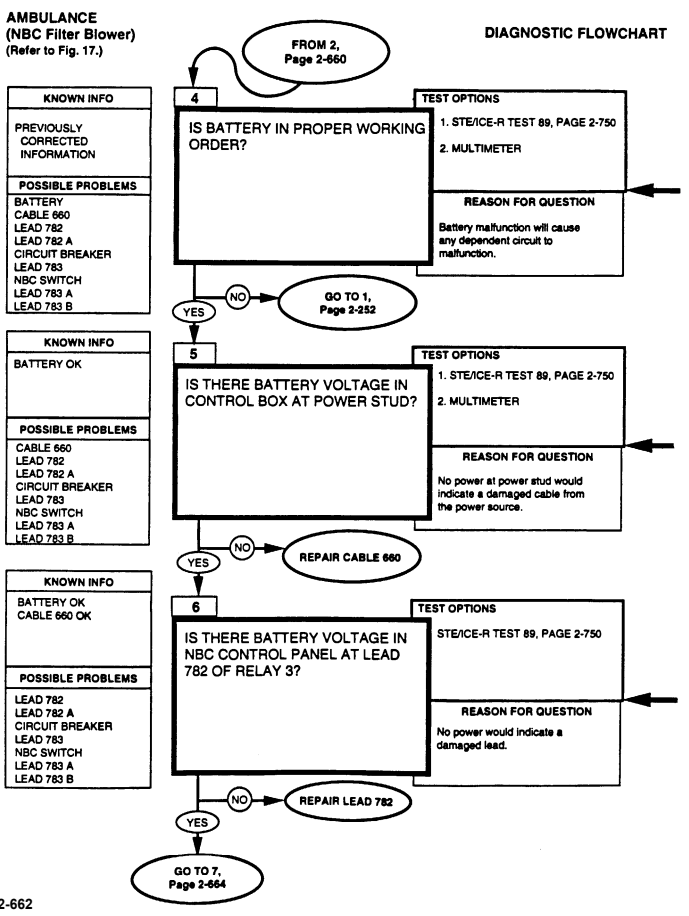

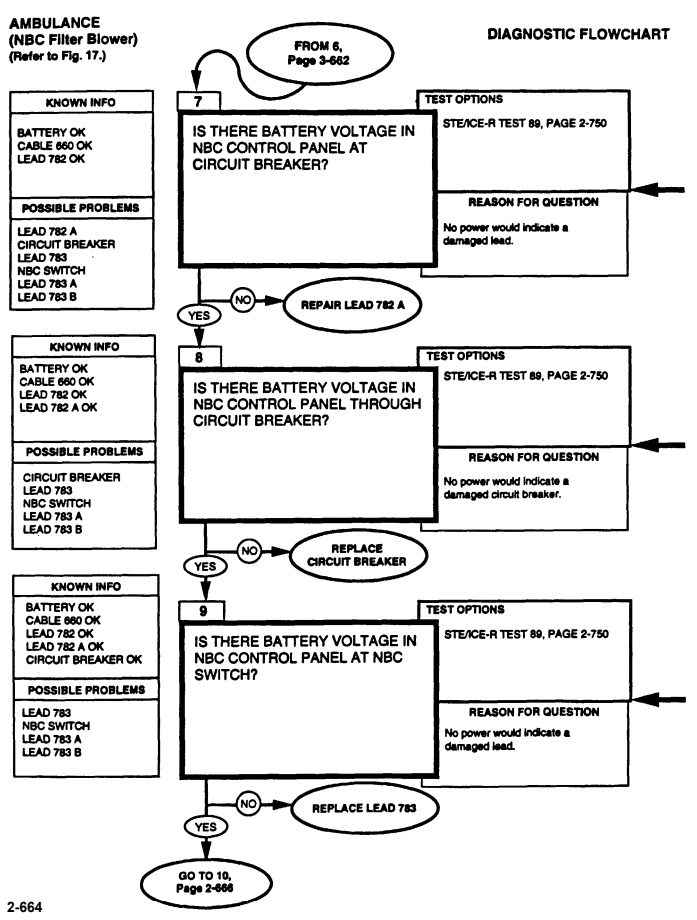

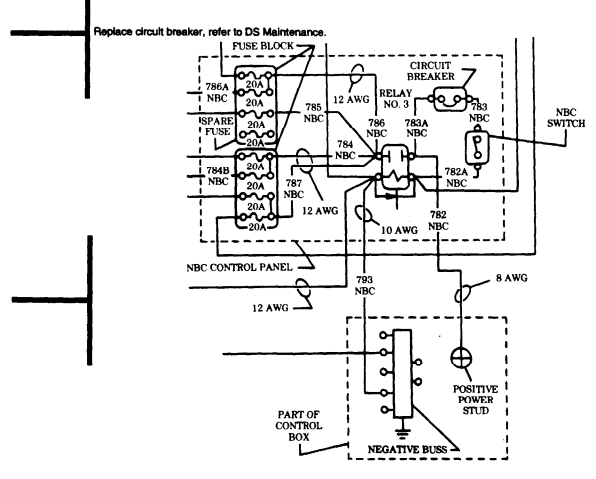

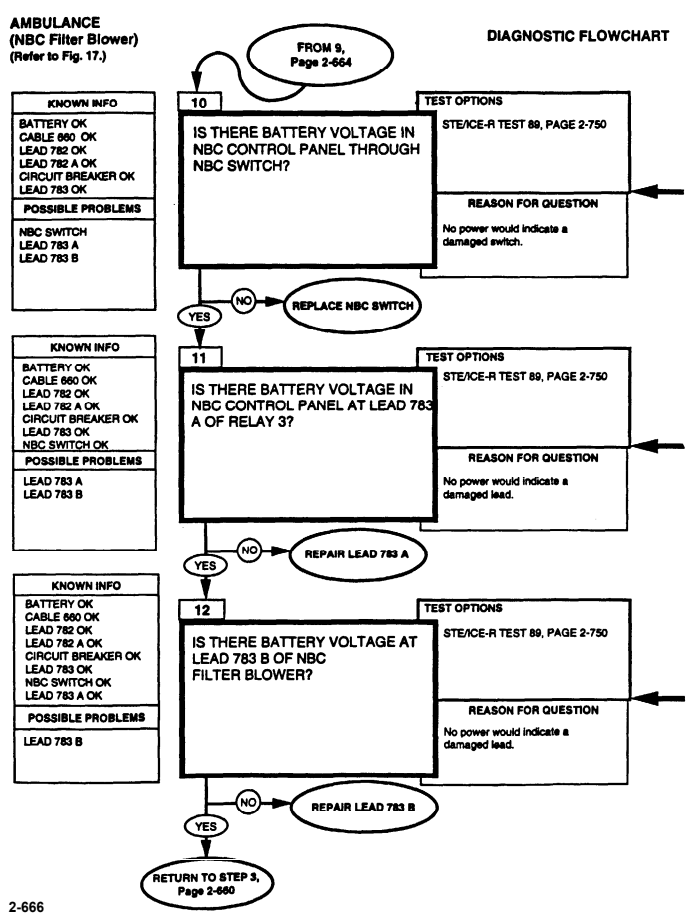

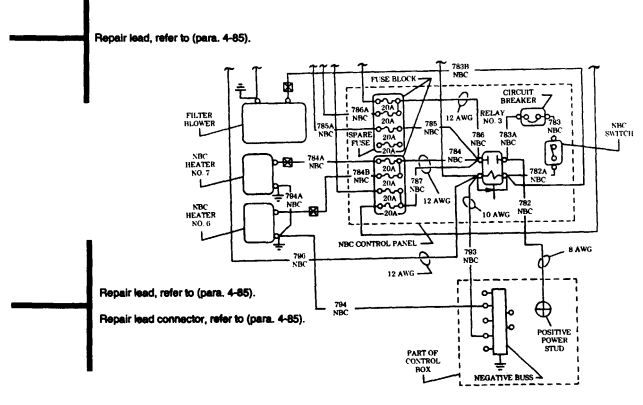

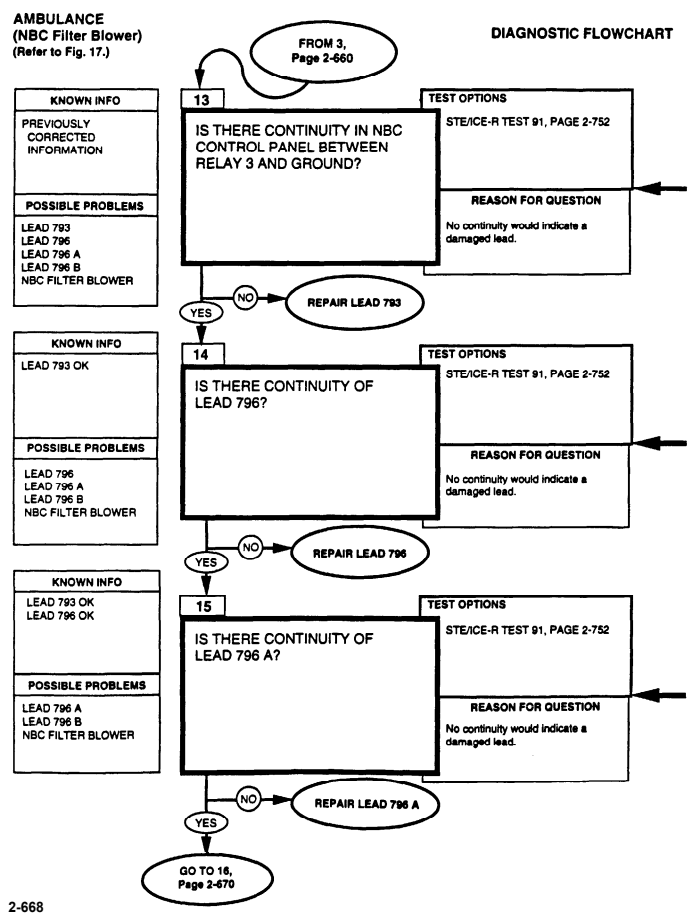

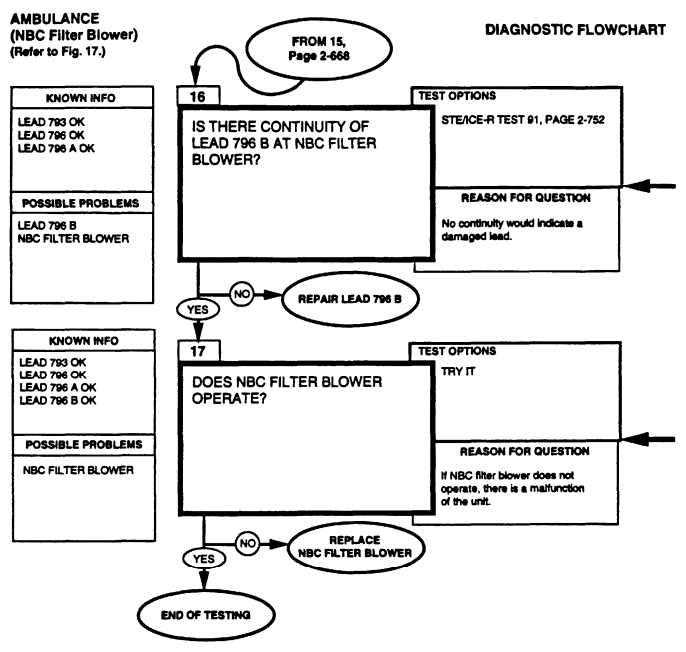

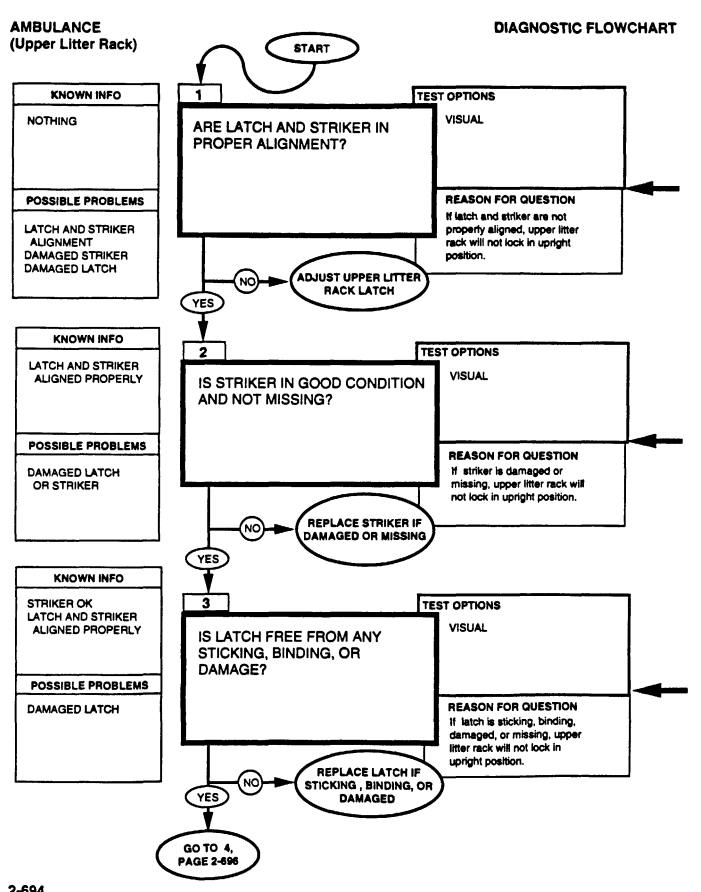

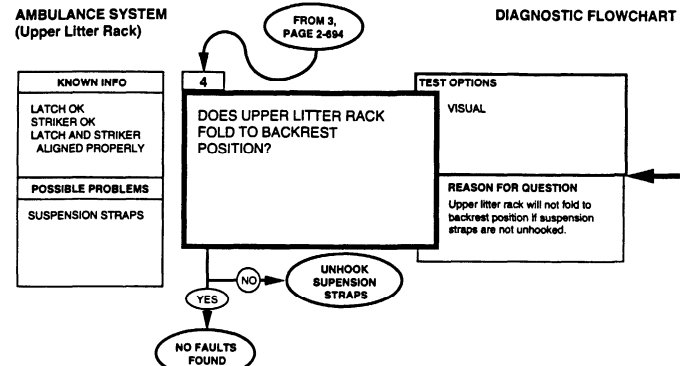

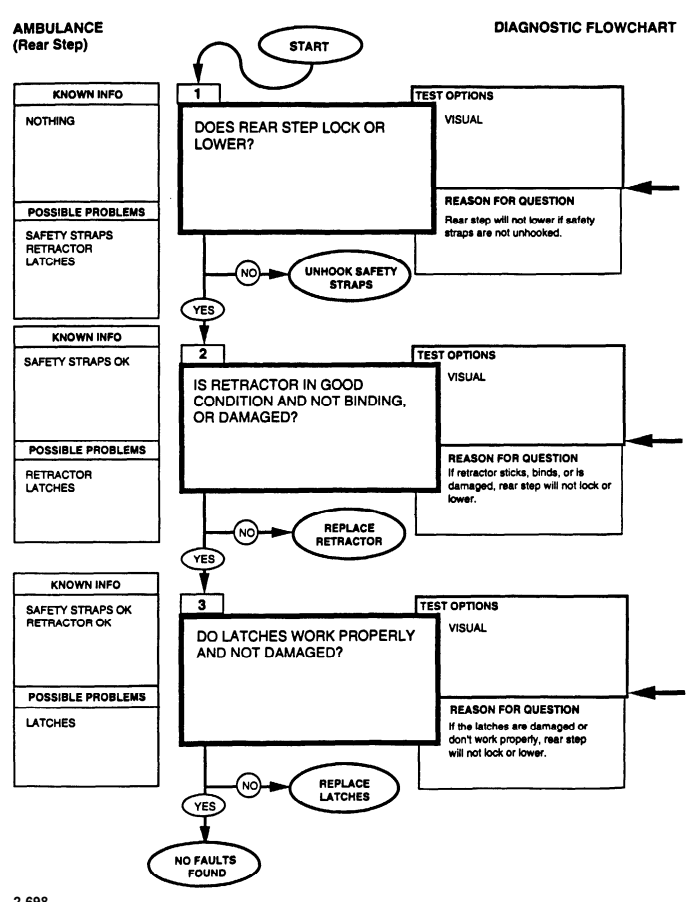

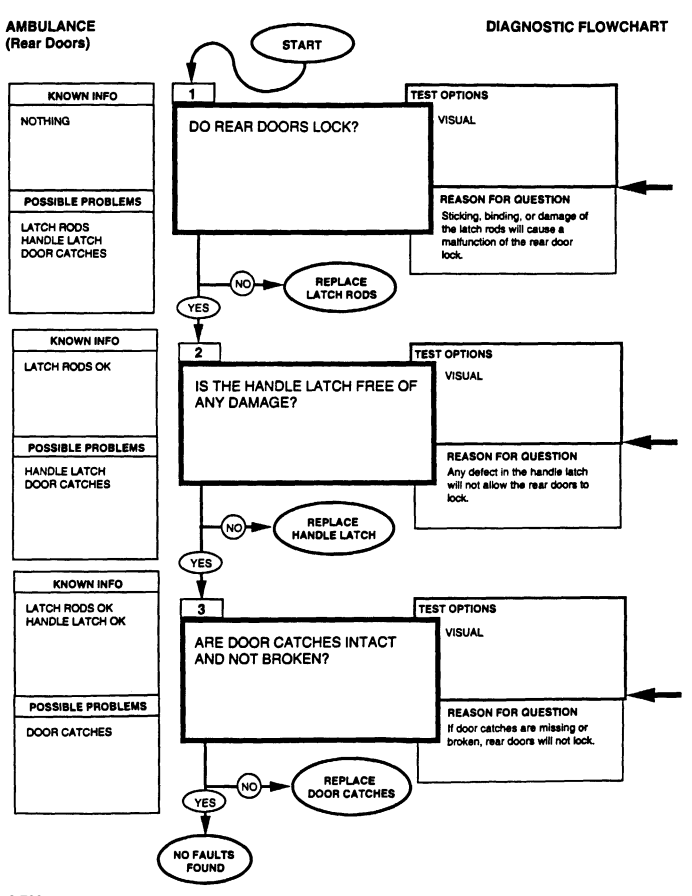

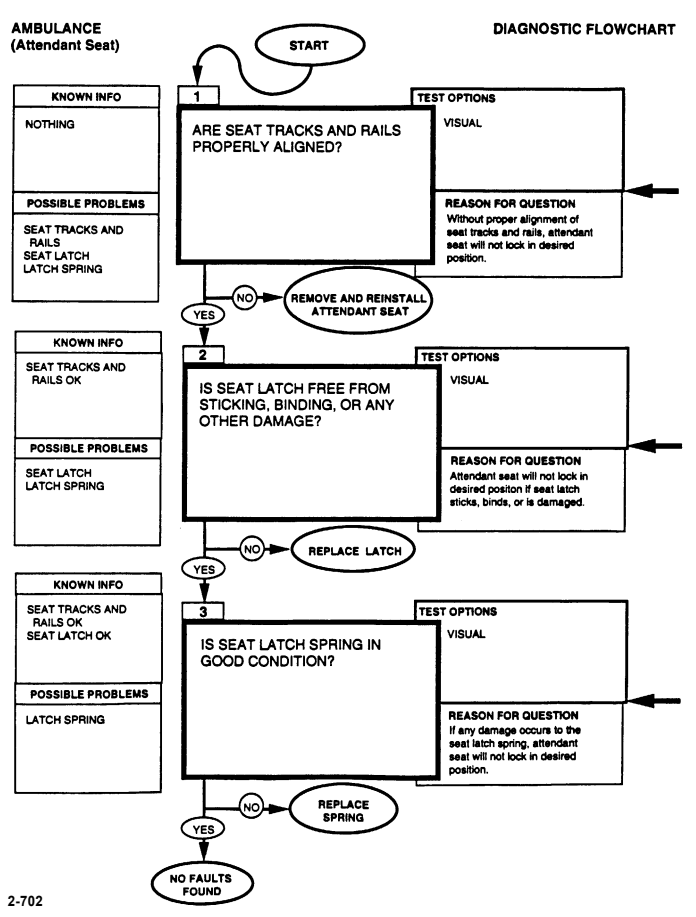

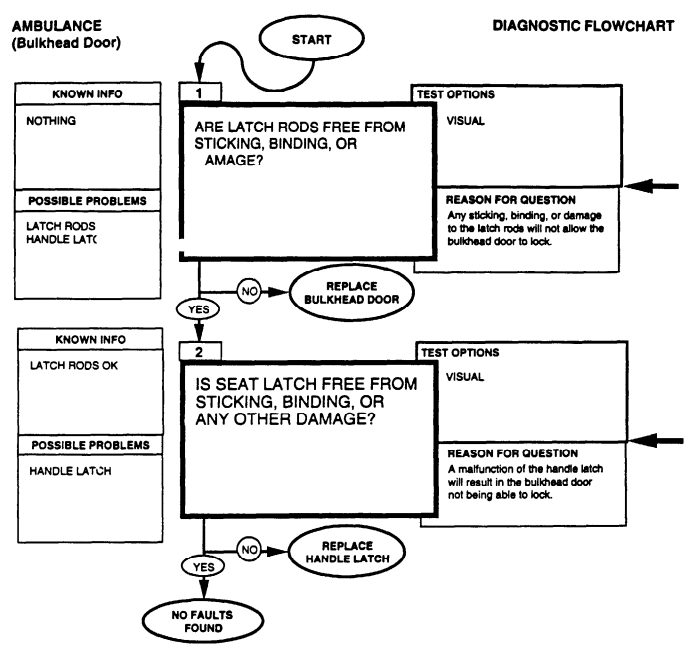

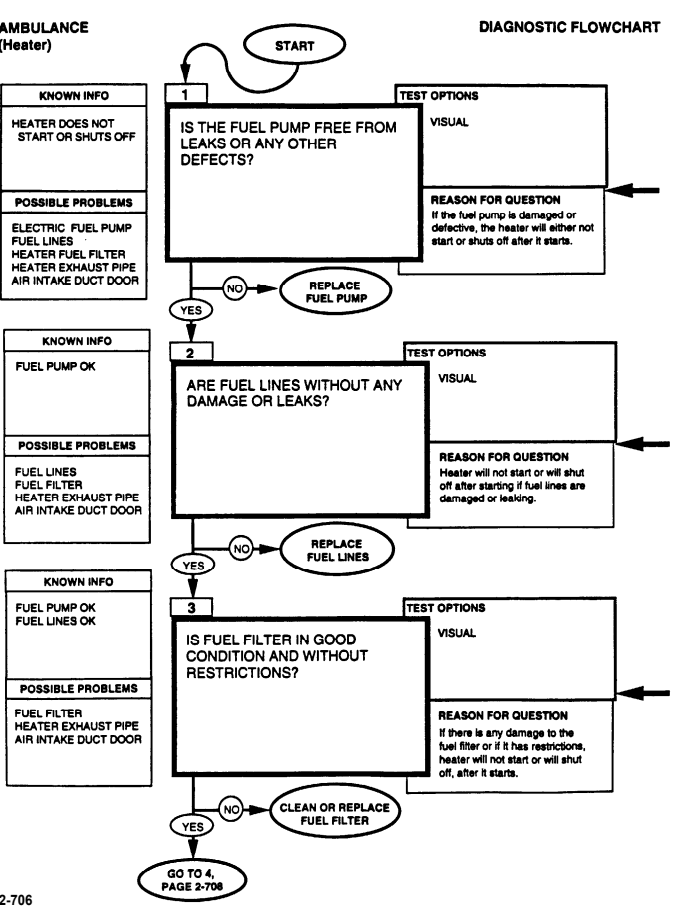

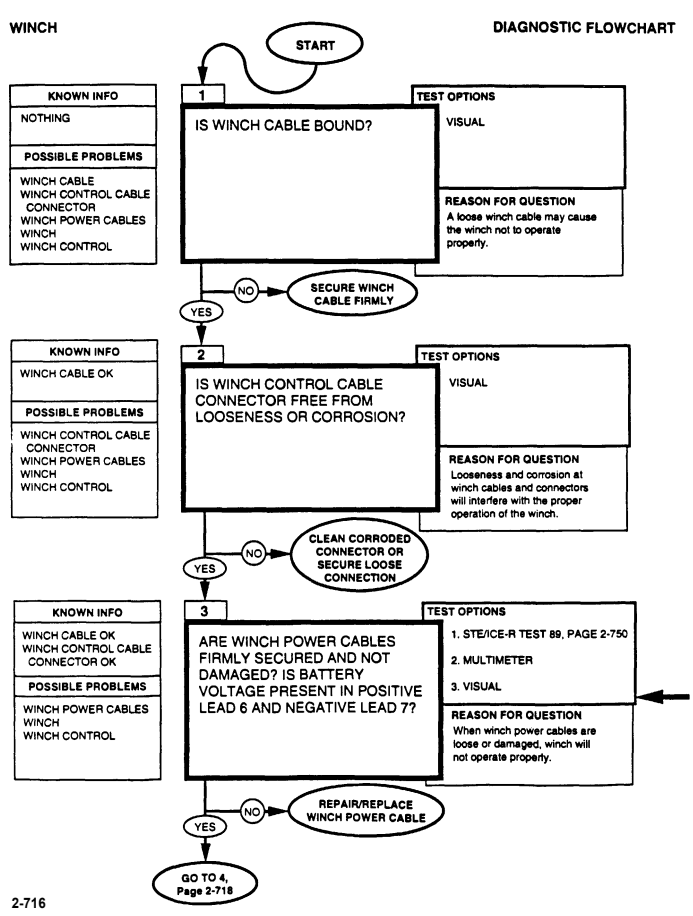

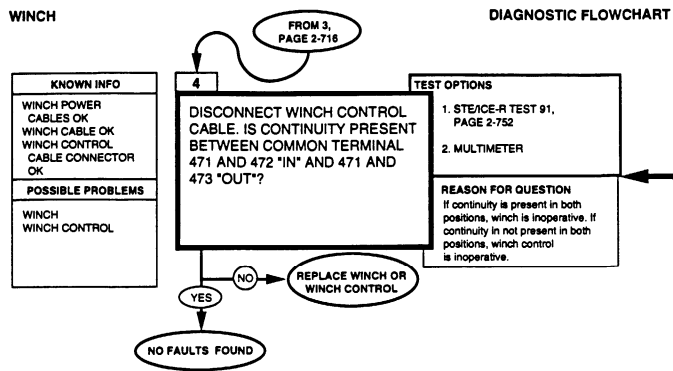

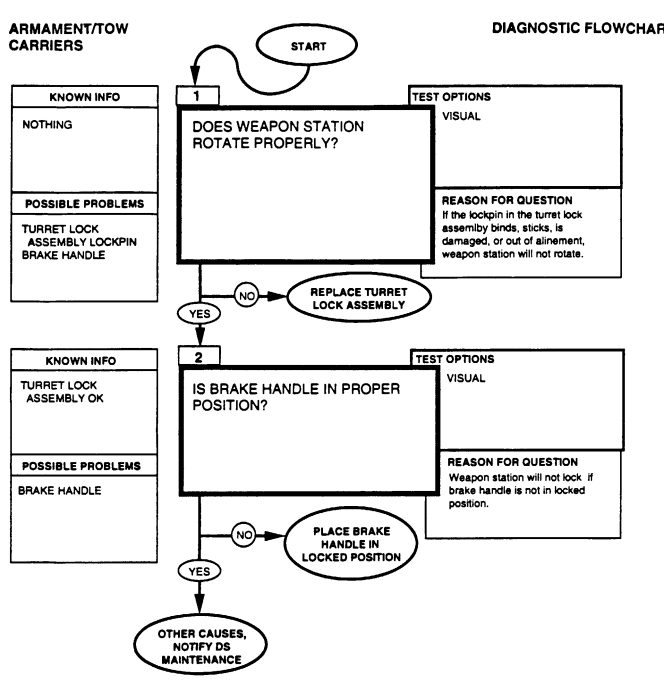

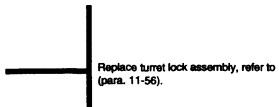

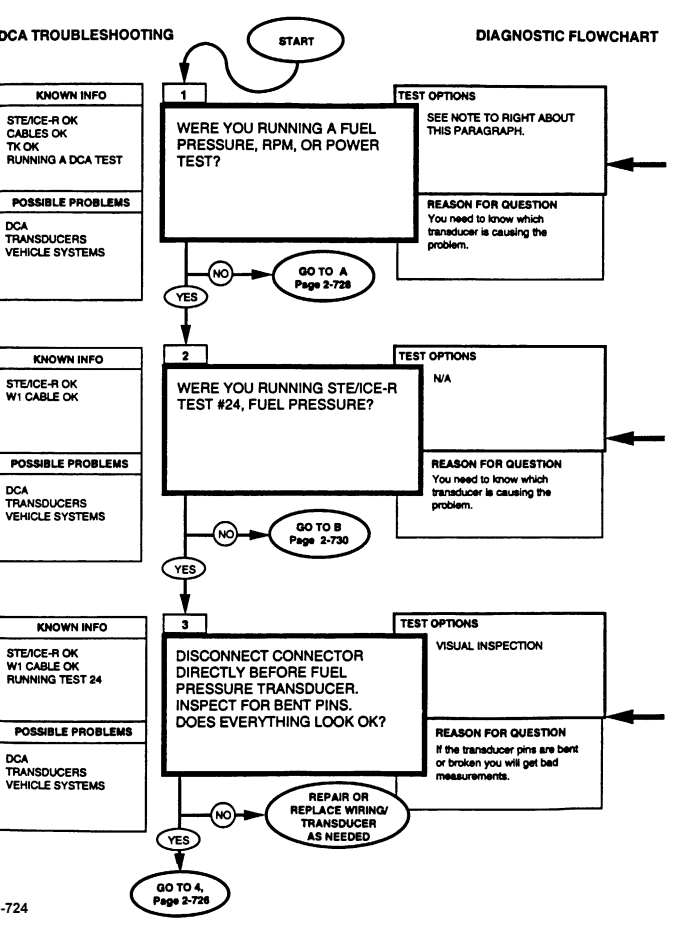

PAGE LAYOUT All diagnostic logic and flowcharts are on the left hand page, with supporting information, help, test, instructions and vehicle operation on the right.

Question number, so you know

where you are and where to go when entering or leaving a test chain.

where you are and where to go when entering or leaving a test chain.

Notes, warnings and cautions about a particular question. Instructions for how to perform a test or make a measurement, usually in a box.

Known info and possible problems with the system.

Reason for question; This is to help by telling you why it's being asked. This is especially helpful when something's just a little bit bad' and you're not sure if it passed or failed.

Test options; Mutible choice of methods you can use to obtain the answer to the question.

DIAGNOSTIC REFERENCE FLOWCHART INFORMATION

How To Troubleshoot

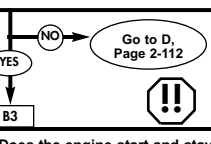

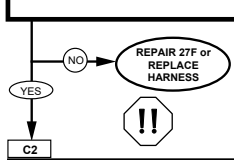

PICK THE TESTS: Select either a top level or a system level test. DIAGNOSTIC PROCEDURE Just answer the questions on the left hand page and follow the YES or NO path. Helpful information about the question is also on the right hand page. If you aren't sure about a question or procedure, look on the right page for notes, instructions and help.

2-14. How To Use This Troubleshooting Guide (Cont'D)

Page Layqut

Diagnostic logic is on the left hand page.

Related and helpful information is on the right hand page.

Diagnostic Procedure

Just answer the questions on the left hand page. Follow the YES or NO path to the next step.

Everything else on both pages is information to support the question. As a rule, the most important information (warnings, cautions, etc) is closest to the question, less important information is farther away.

Is the symbol for a WARNING

statement. If you see this symbol above a question, look on the right hand page for the text of the message. The WARNING message on the right hand page will also have the symbol above it.

statement. If you see this symbol above a question, look on the right hand page for the text of the message. The WARNING message on the right hand page will also have the symbol above it.

Is the symbol for a CAUTION

statement. If you see this symbol above a question, look on the right hand page for the text of the message. The CAUTION message on the right hand page will also have the symbol above it.

2-14. How To Use This Troubleshooting Guide (Cont'D)

Information About The Question Test Options:

This box lists at least one way of getting the answer to the question. When there is more than one way to get the answer, the different options will be given. Usually the easiest or best option is first.

REASON FOR QUESTION

Reason For Question:

If you know why the question is being asked, it should be easier to understand the diagnostic logic and easier to answer the question. This is especially helpful when a measurement is 'just a little bad'. Knowing why the question is being asked should help you decide if the answer should be 'YES' or 'NO'.

Information About The Diagnostic Logic Known Info

This box indicates what is known about the vehicle's condition.

As you follow a test chain, parts will be listed here after they have checked ok. Sometimes this box will indicate a fault that you know exists, such as a shorted or open circuit, or a component that doesn't work. DO NOT USE THIS BOX TO PICK A 'JUMP-IN' POINT. ALWAYS RUN A COMPLETE CHAIN WHEN INSTRUCTED TO DO SO.

Possible Problems

This box is the opposite of 'KNOWN INFO'. Possible causes of the problem are listed here until tested and shown to be ok.

2-14. How To Use This Troubleshooting Guide (Cont'D)

Information About The Question

All warnings and cautions are given next to (or as close as possible to) the arrow pointing to the particular question. Look for the symbol that is in the box for the question in order to locate the particular note. Helpful notes, test procedures, or other information related to the question are provided here. These notes are provided as supporting information only, you don't usually need them to answer the question.

The more skilled you become, the less you'll have to read these.

Any cross references to other manuals will be located in this area.

NOTES. WARNINGS AND

CAUTIONS ARE IN BOLD FACE TYPE.

Additional information, notes and/or suggestions are in normal type so as not to draw too much attention.

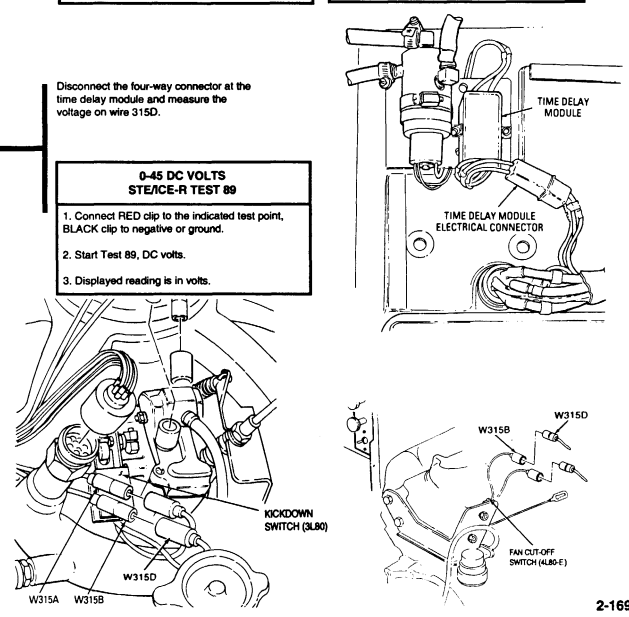

Test Procedures

These are special notes about how to make measurements with the test equipment. Ocassionally, if space is limited on a page, the easiest procedure will be listed with a page reference for the other procedures if you would rather use them. The procedures presume a basic working knowledge of the equipment to be used, but references are included for the less experienced operator.

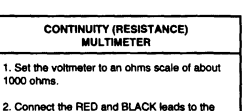

Type Of Measurement Type Of Equipment

Procedure for performing the measurement using the type of equipment listed above.

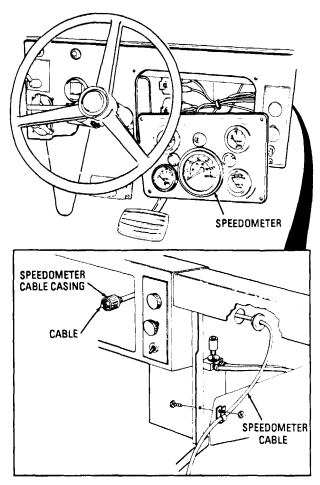

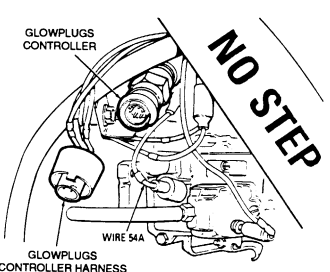

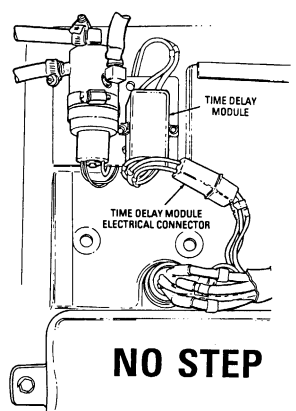

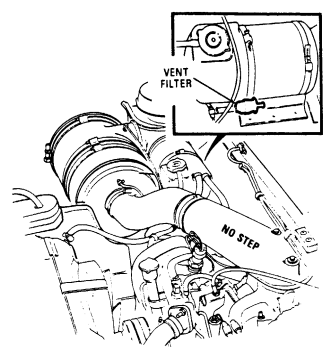

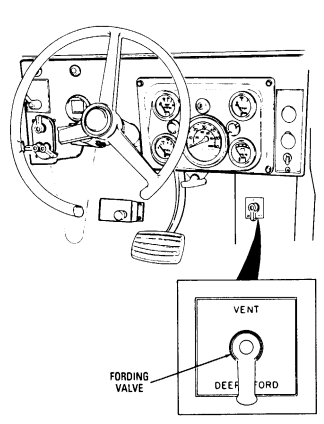

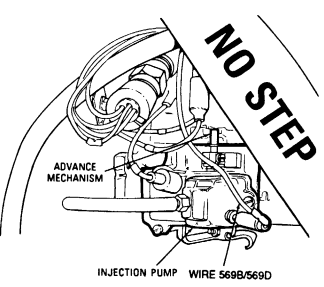

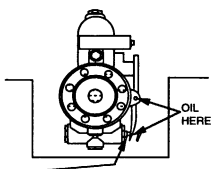

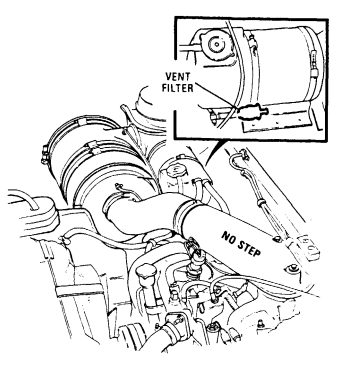

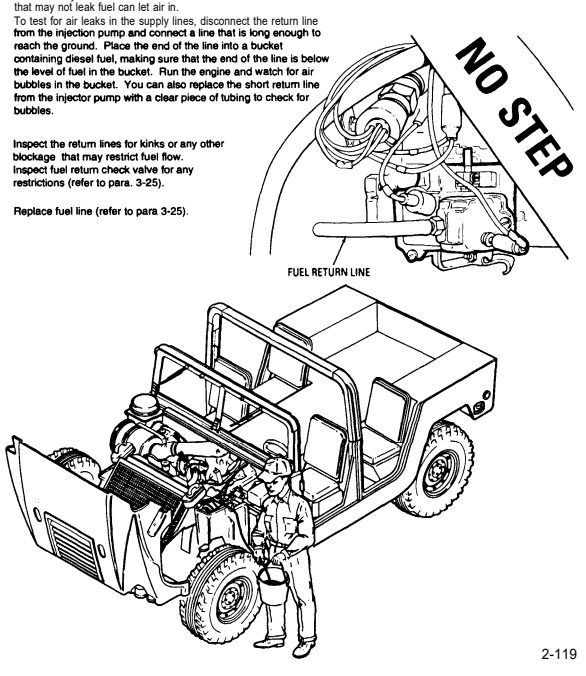

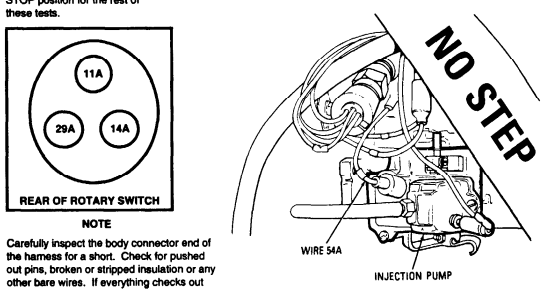

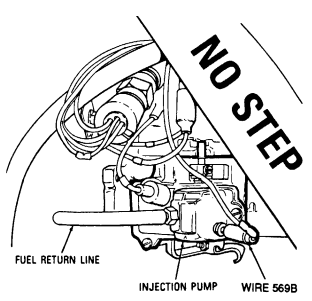

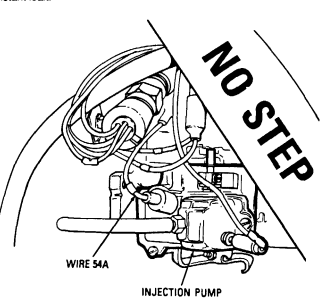

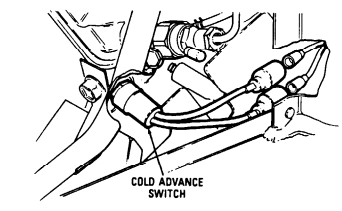

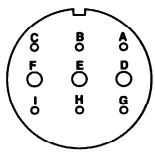

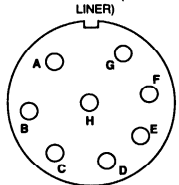

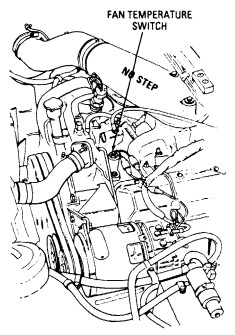

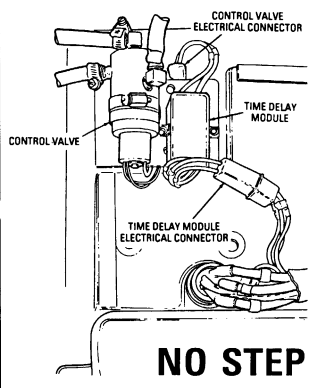

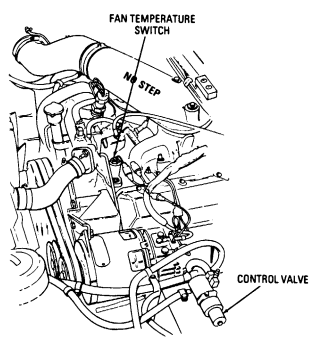

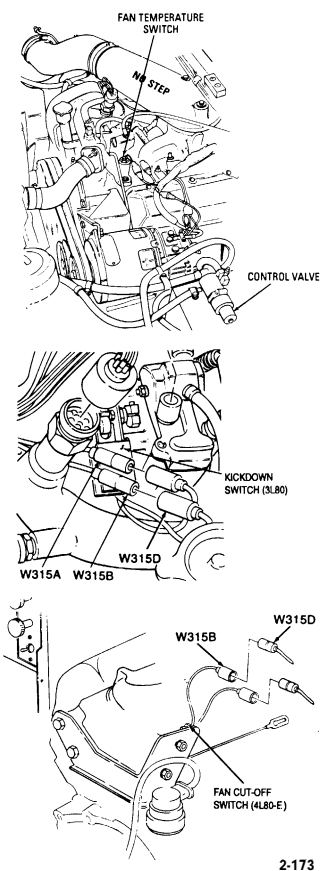

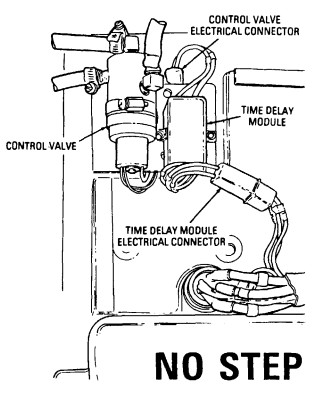

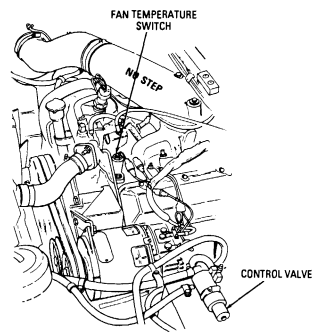

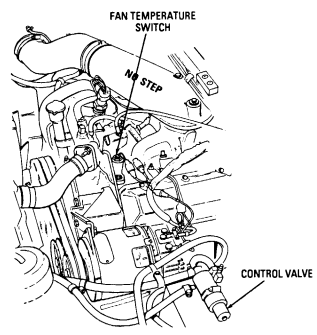

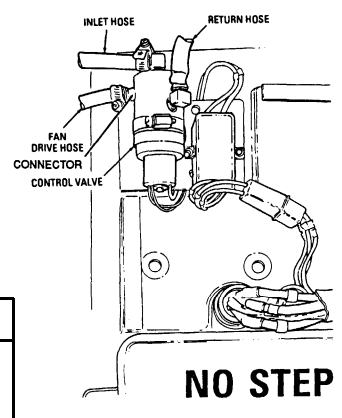

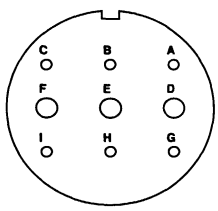

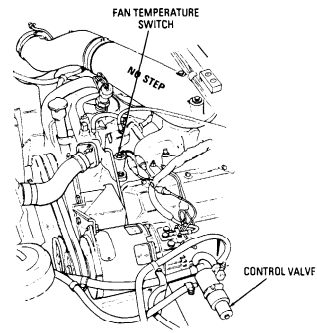

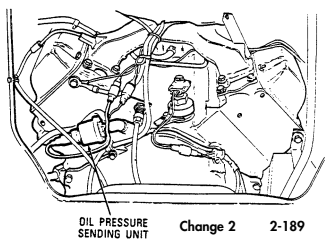

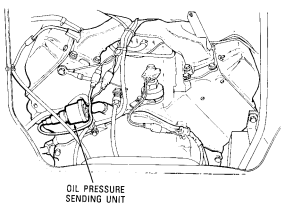

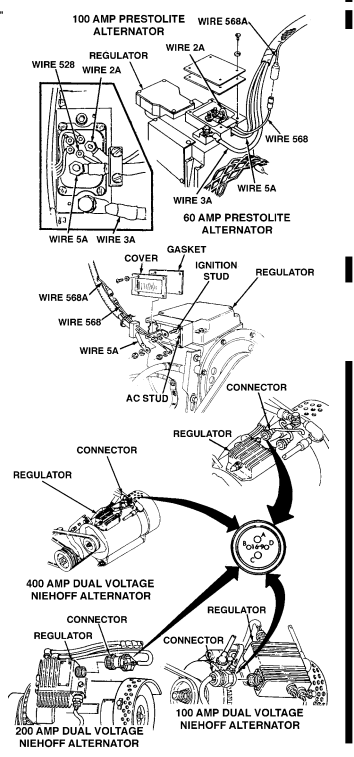

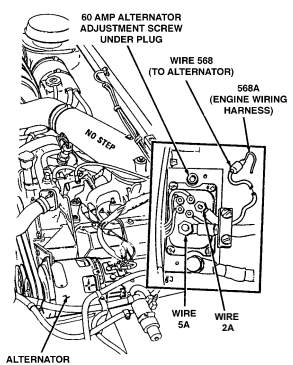

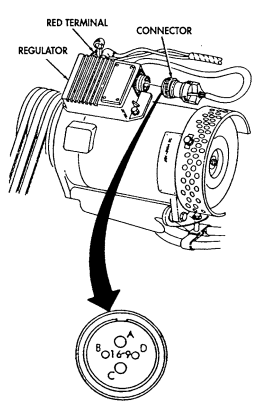

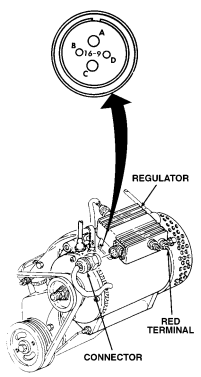

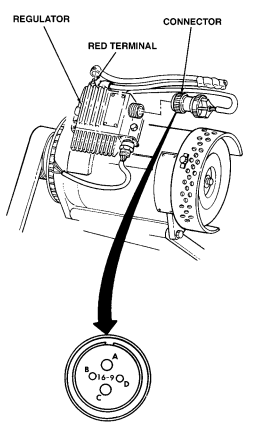

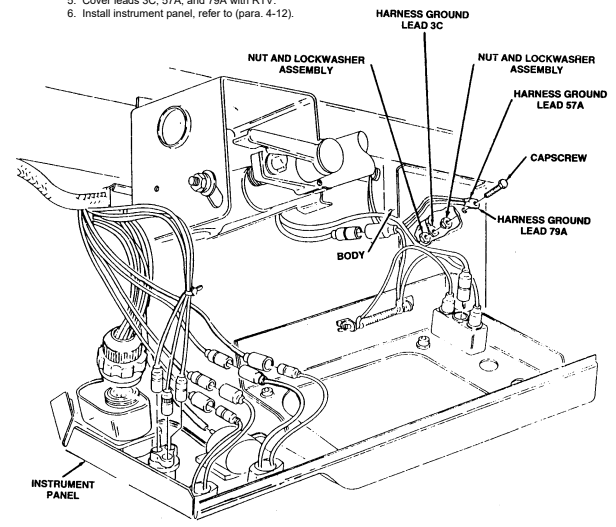

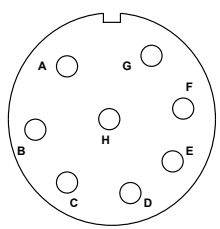

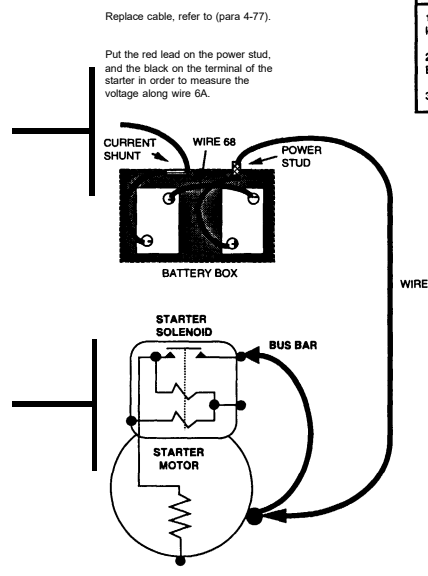

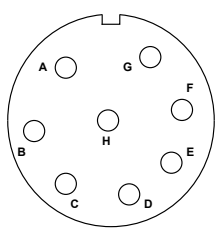

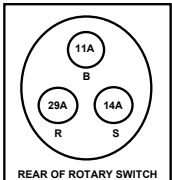

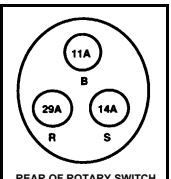

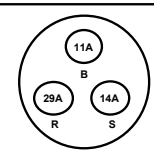

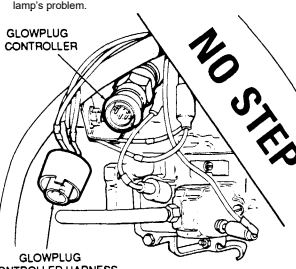

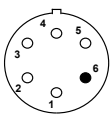

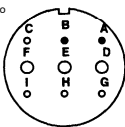

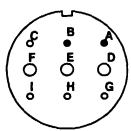

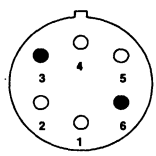

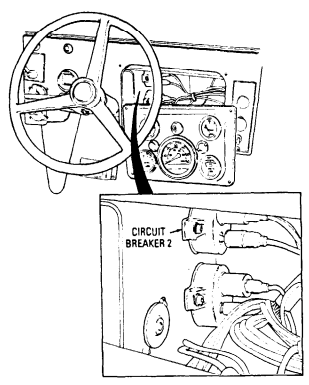

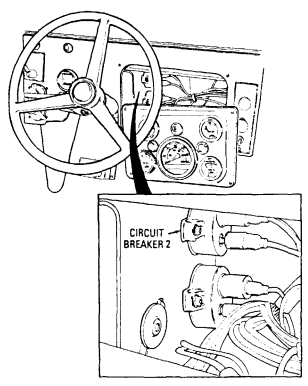

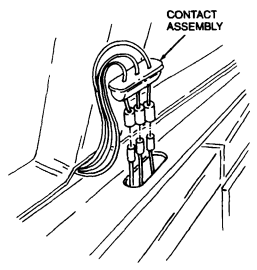

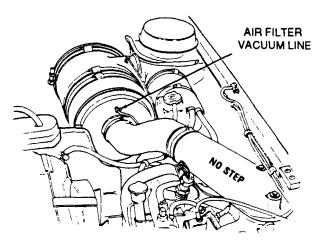

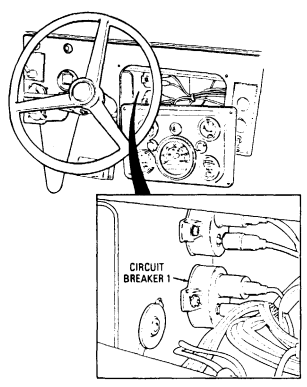

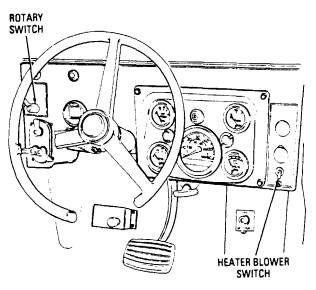

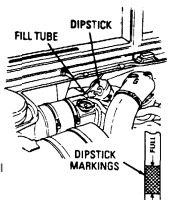

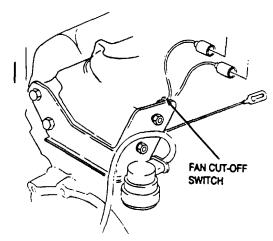

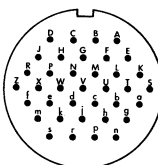

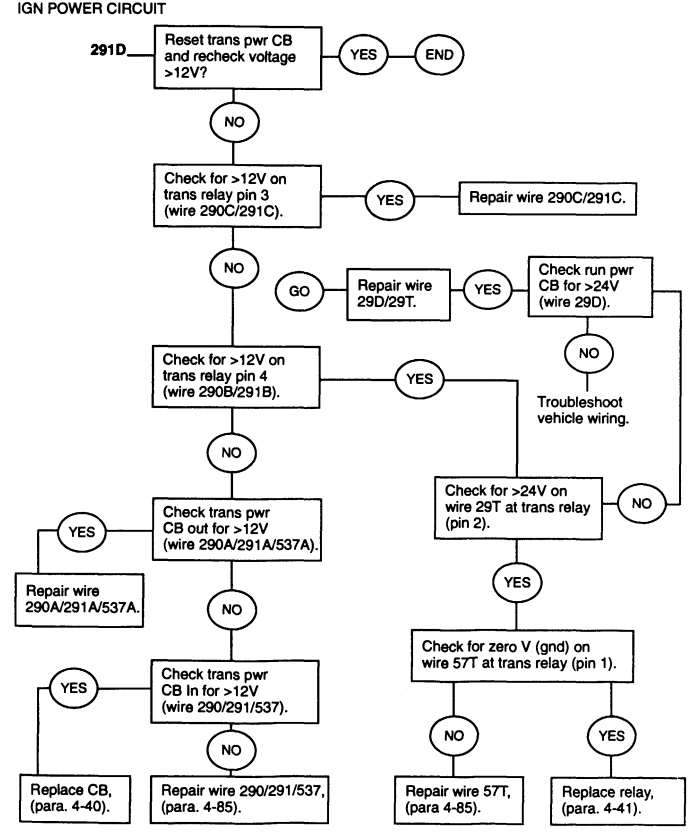

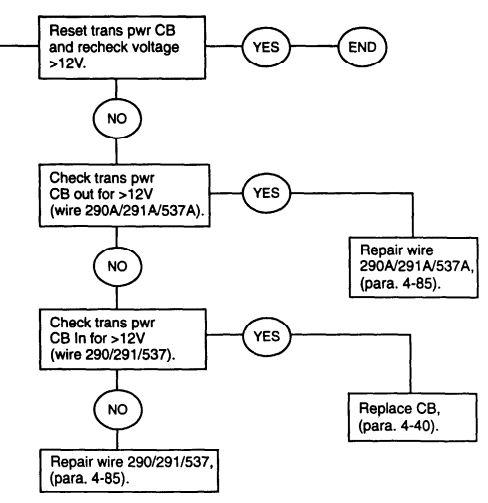

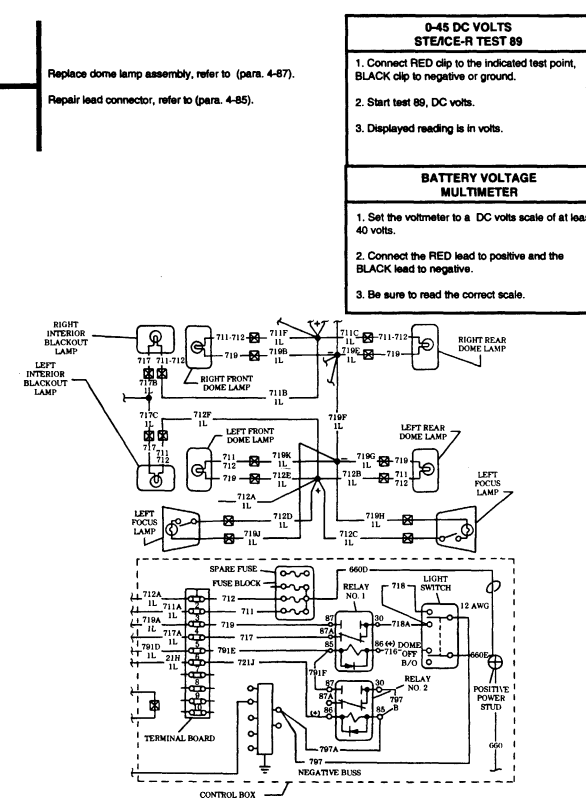

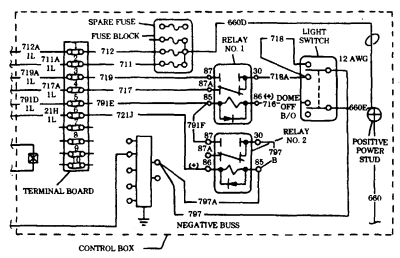

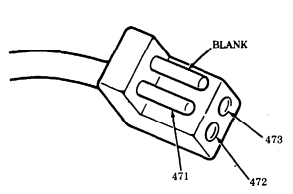

Pictures

The pictures are supposed to make it easier to find what you're looking for, such as a pin in a connector or a particular wire or component.

PICTURES ARE PROVIDED WHEREVER POSSIBLE.

2-15. Glossary Of Abbreviations And Commonly Used Terms

-

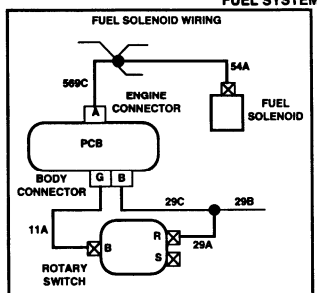

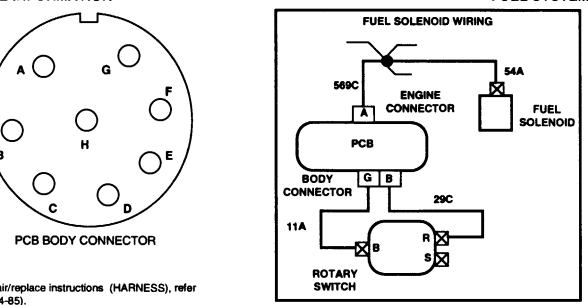

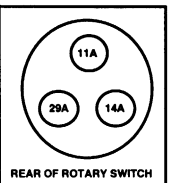

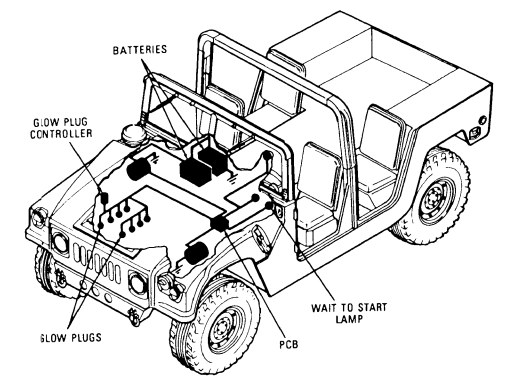

PCB - Protective Control Box, located on the firewall above the brake pedal.

-

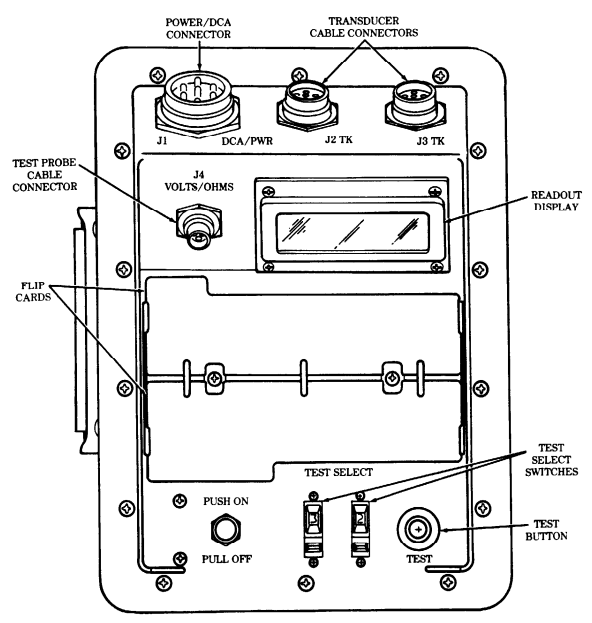

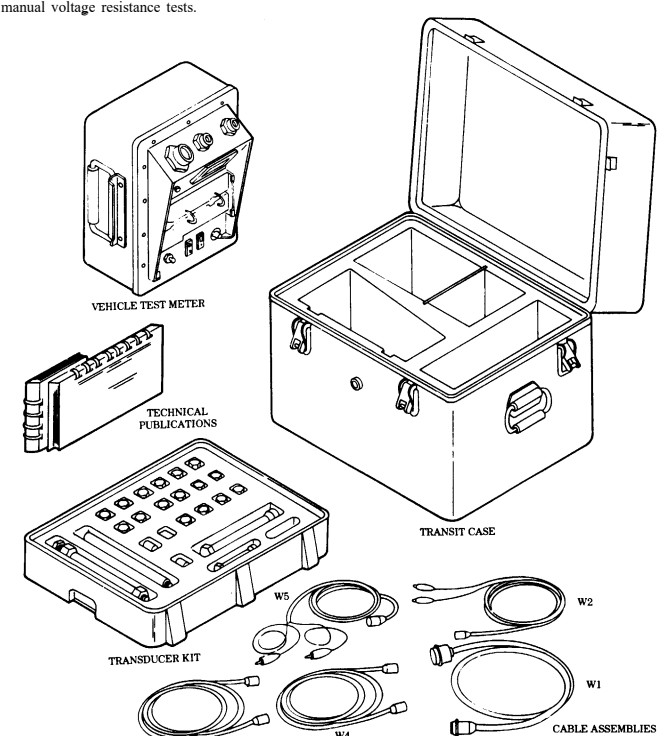

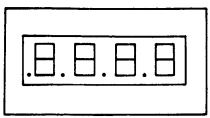

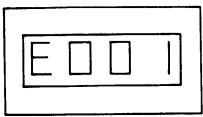

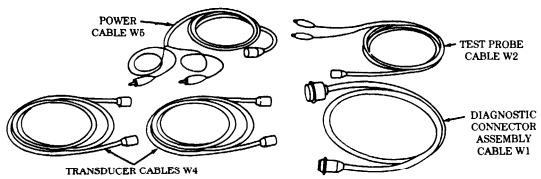

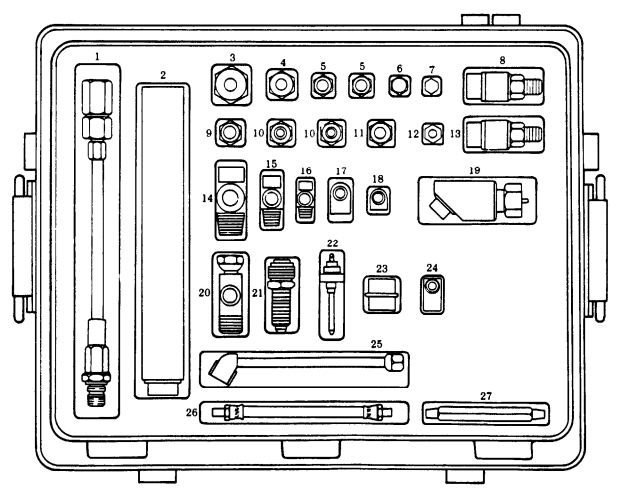

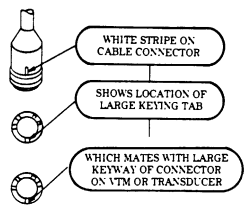

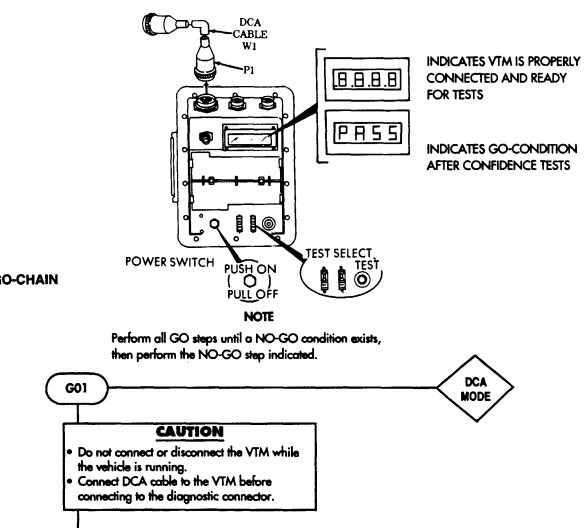

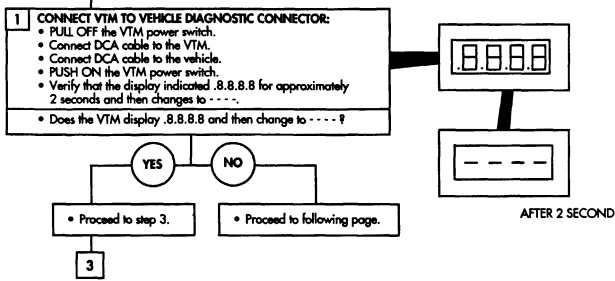

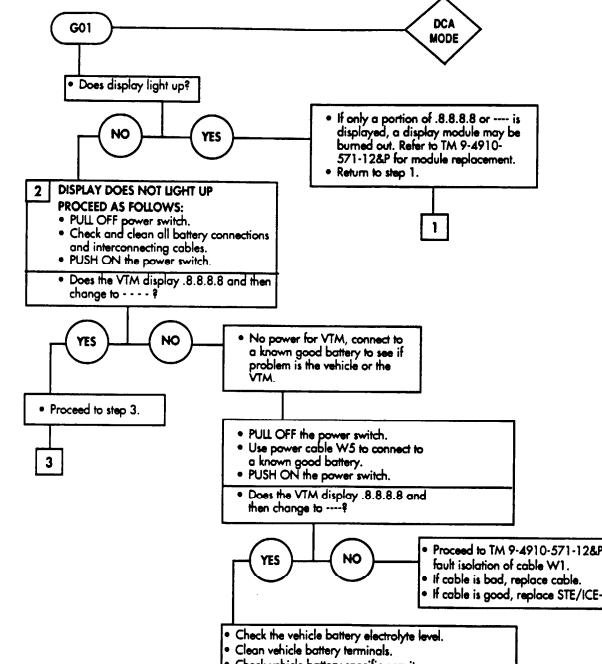

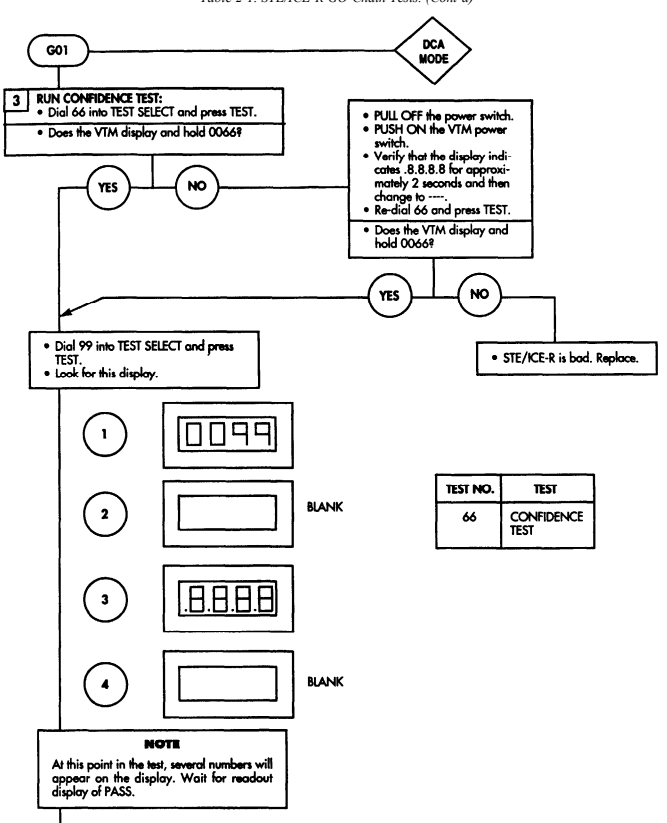

STE/ICE-R - Simplified Test Equipment for Internal Combustion Engines - Reprogrammable, a testing system used for performing tests and measurements on the vehicle. In addition to acting as a conventional digital multimeter to measure voltage, current and resistance, it is also capable of measuring pressure, speed, compression unbalance, engine power, and some specialized battery and starter evaluations. It is powered from the vehicle batteries. The complete system includes a vehicle test meter (VTM), a transducer kit (TK), cables, transit case and technical publications.

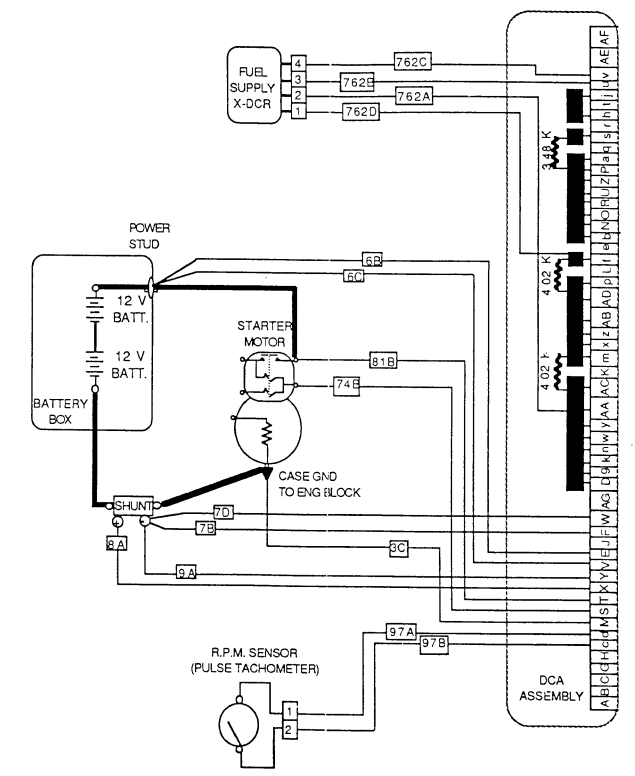

-

DCA - Diagnostic Connector Assembly, an electrical harness on the vehicle which allows the STE/ICE-R to be powered and to make measurements of key vehicle signals from a single connection. In addition to many basic electrical signals such as starter voltage and current, it includes engine speed and fuel supply pressure. The STE/ICE-R can make TK measurements at the same time that it is connected to the DCA.

-

VTM - Vehicle Test Meter, a box which performs the measurement and analysis functions of the STE/ICE-R systems.

-

TK (and TK mode) - Transducer Kit, a collection of transducers, adapters and fittings which permit the STE/ICE-R to be used as a general purpose measurement system for any application. This allows the STE/lCE-R to be used anywhere that you want to measure voltage, current, resistance, pressure, or speed. TK mode of operation is what you are doing when you use this kit (as opposed to DCA mode where you are using the vehicle's built-in sensors to make measurements).

-

Compression unbalance - A STE/ICE-R test that gives an indication of any engine cylinders that have lower compression then the average. It does this by monitoring the battery voltage during cranking. As each cylinder goes into compression, the extra load on the starter shows up as a drop in voltage. This works well for finding one or more cylinders that have a compression problem, but don't forget that it doesn't give the average compression. If all cylinders are low by the same amount, this test doesn't find it.

-

Troubleshooting - the process of making measurements and observing the operation of the vehicle to find out if anything is wrong with it and then to locate any problem that exists.

-

Diagnostics - Troubleshooting by following an exact procedure.

-

Test Chain - a series of tests to be followed in a particular order or sequence. It is referred to as a "chain" of tests because they are all connected one after another like the links of a chain.

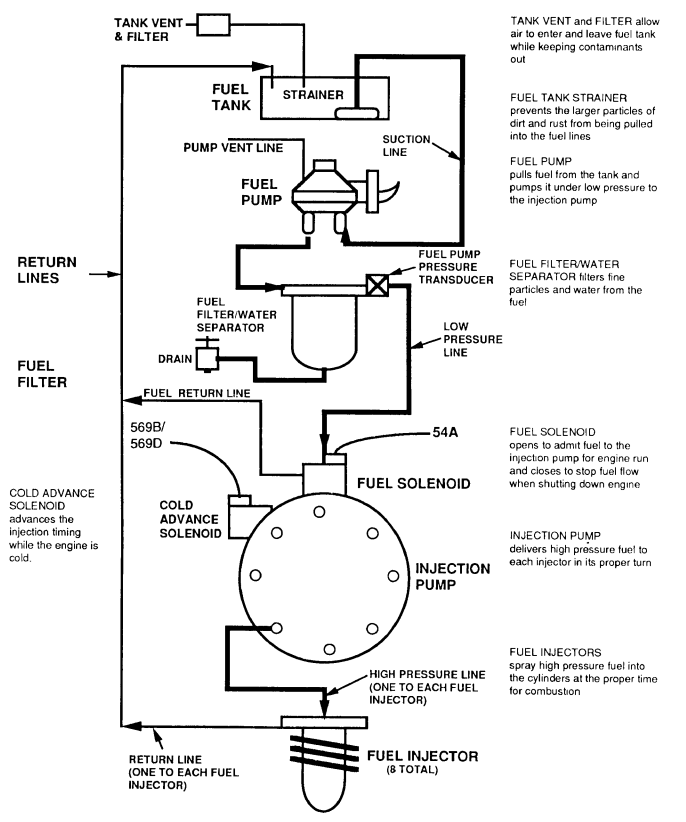

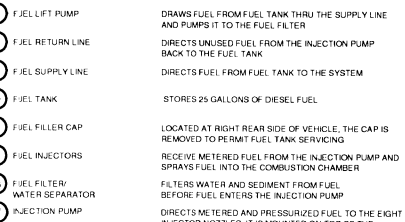

-

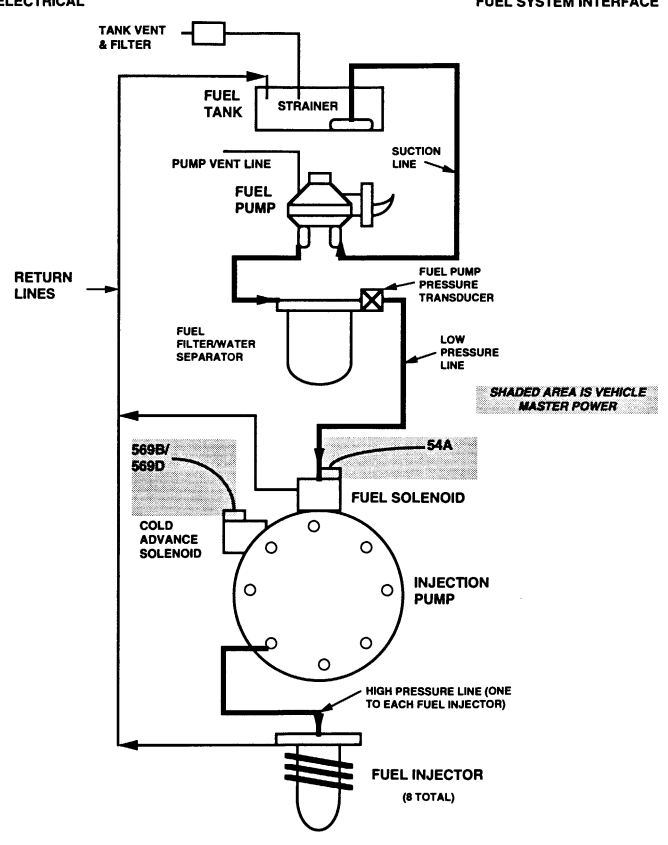

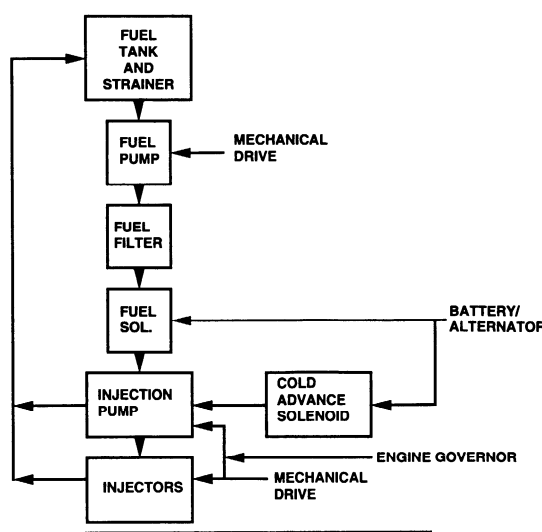

System - a collection of devices which are all related to each other because they depend on each other to do some function or job. For instance, the function of the fuel system is to inject fuel into the cylinders at the correct time in the correct amount and with the correct quality. The collection of devices that are required to do this include the fuel pump, fuel lines, lift pump, fuel filter, injection pump, and injectors.

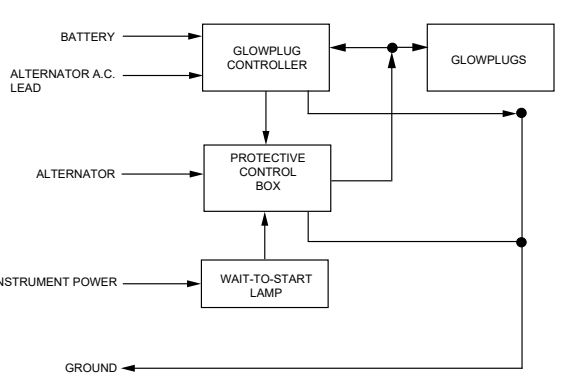

-

Functional flow schematic - a diagram which is much like a normal electrical circuit diagram, except that its purpose is to show the flow of information through the system (or the flow of a signal or the flow of some material such as the fuel). This kind of diagram shows how each component or device depends on the others. It is called functional flow because it shows the function (purpose of each component) and how the output of one component "flows" into the next. For troubleshooting, the functional flow schematic is better than the usual circuit diagram because it allows you to quickly see how the system works and what to expect when you make measurements on a system that has faults. You can't expect the output of a device to be good when it has a bad input.

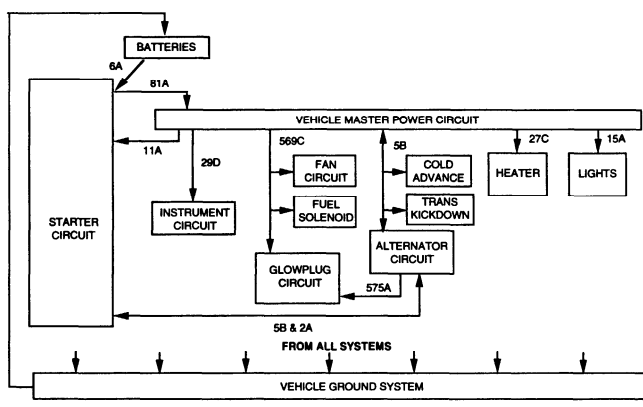

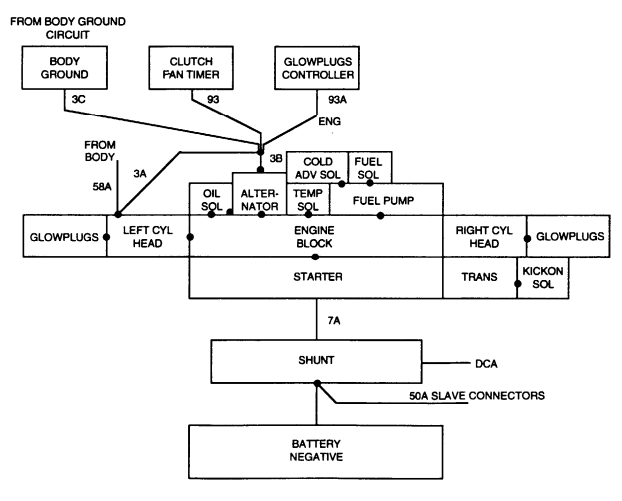

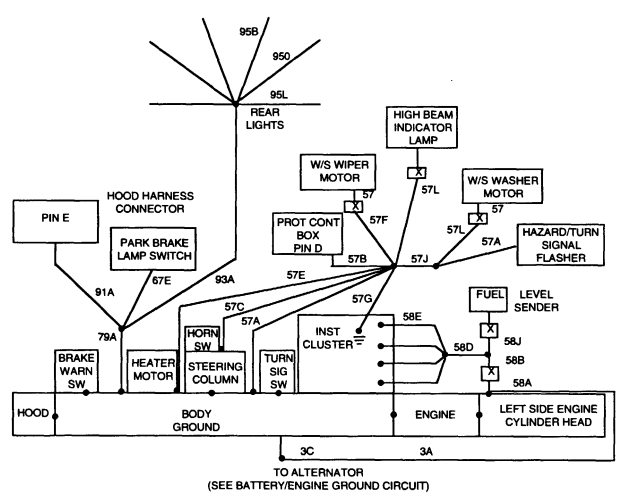

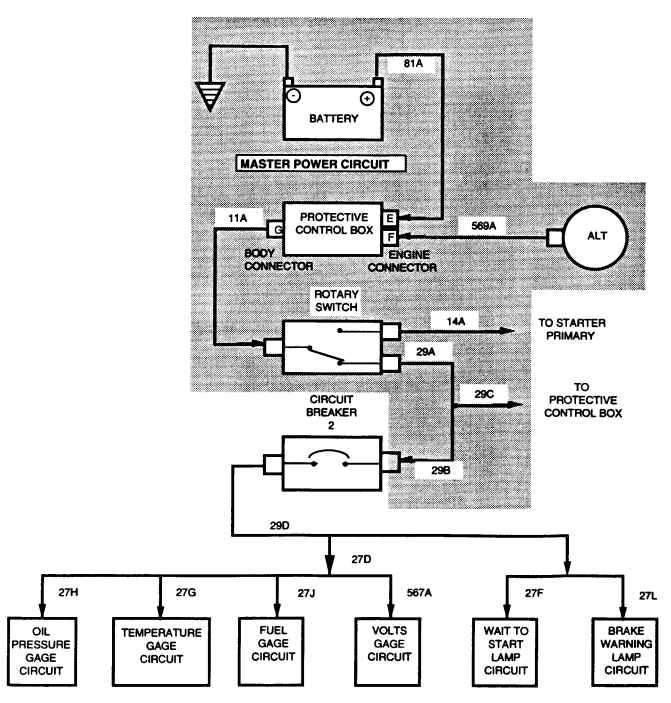

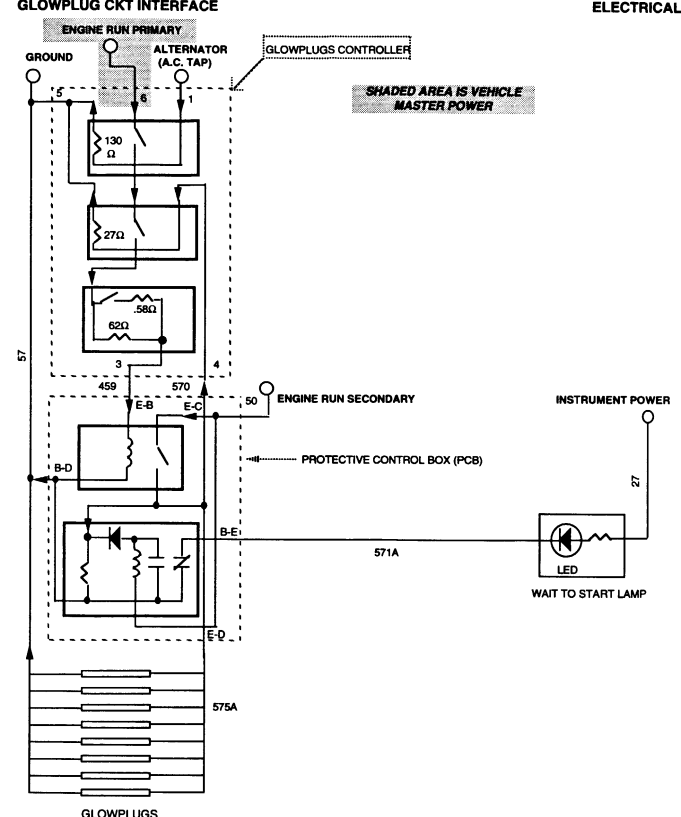

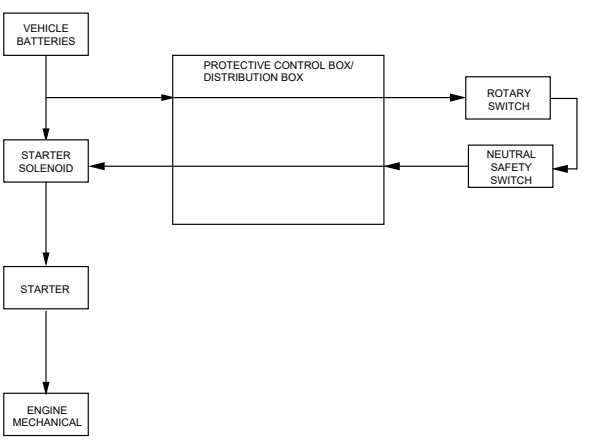

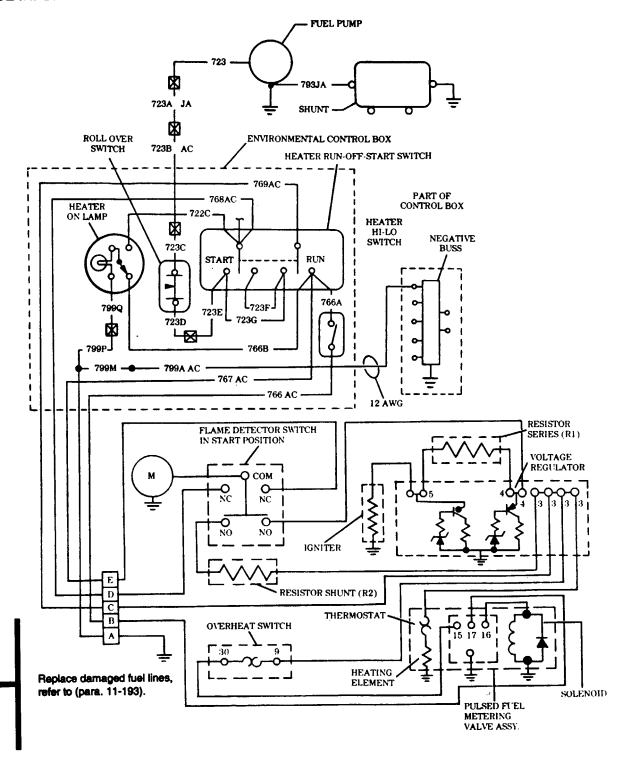

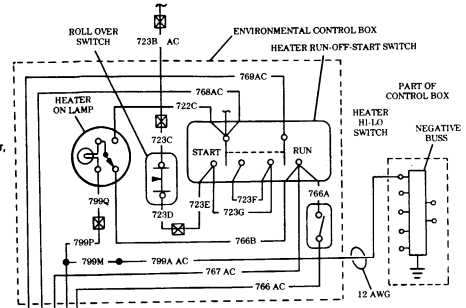

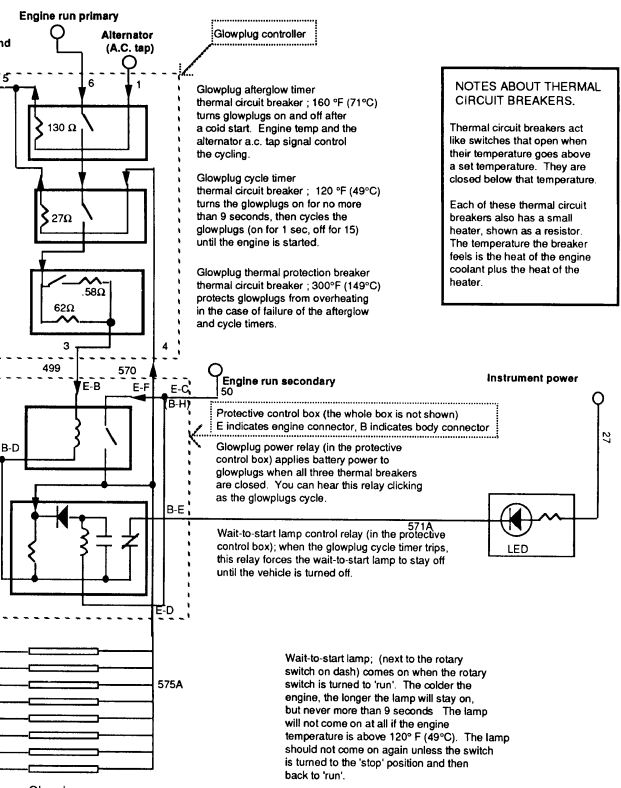

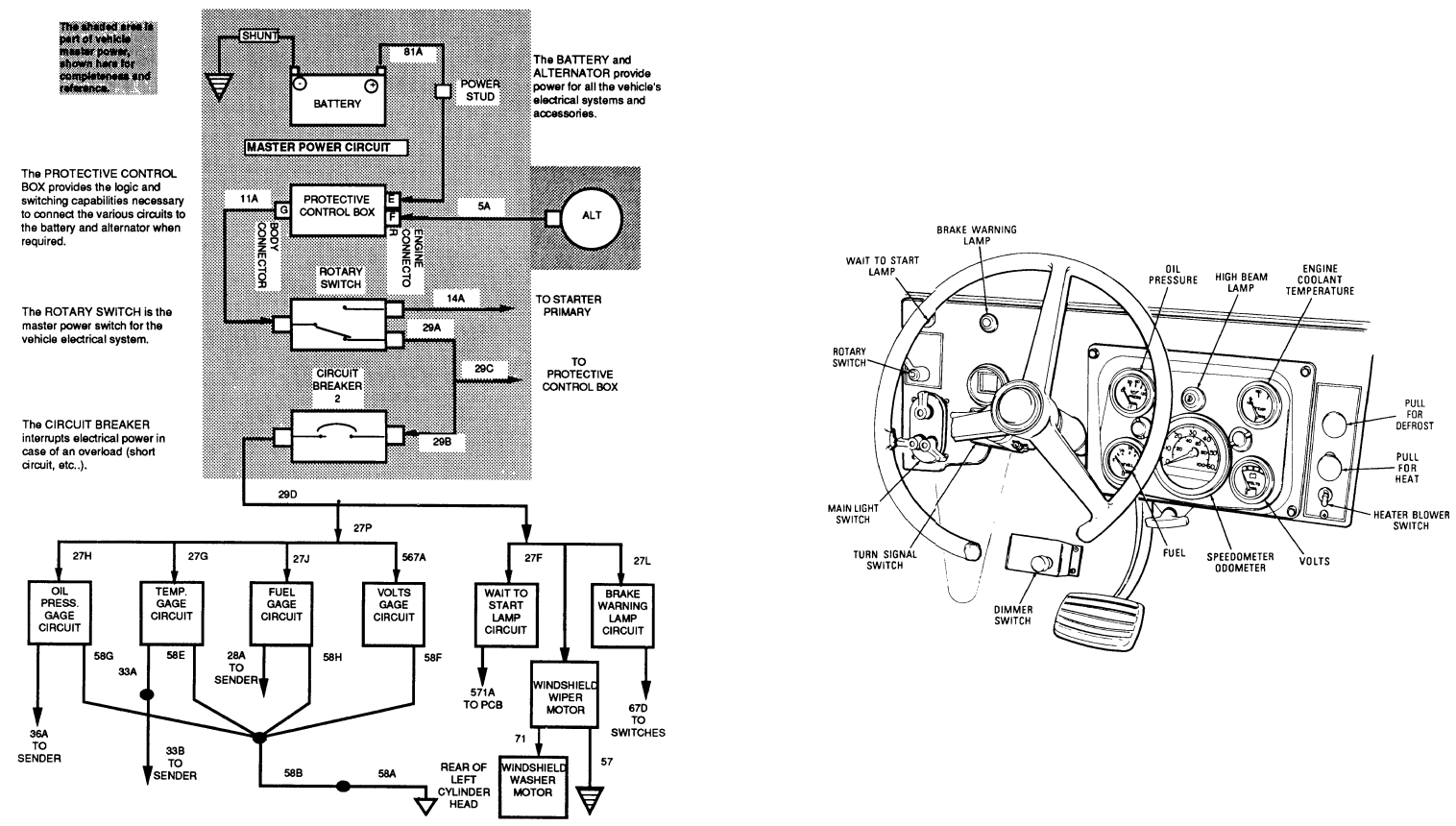

2-16. Electric Circuit Description

An electrical circuit is a collection of electrical devices which are connected in a loop from a positive voltage source (the battery positive) to a negative source ( the battery negative). It must be continuous, with no breaks (no opening in the loop) so that electrical current can flow from the positive to the negative. You can think of it like the plumbing in your house. There must be a source of water under pressure or nothing will flow through the pipes. Water pressure is like the positive voltage of the battery. There may be branches (tees) in the pipes going to several different places, but if you don't connect the pipes, you don't get water. The same thing is true with the electrical circuit. If the wires aren't connected, no electricity will flow through them.

In the plumbing of a house, all of the water must go to the drain (you won't permit it to be spilled on the floor). With the vehicle electrical circuit, the drain is the negative terminal of the battery. With the water pipes, the water always flows from high pressure to low pressure (another way of saying that water always flows downhill). The electrical current is the same as the water flow - it always goes from positive to negative voltage. Voltage is to electricity what pressure is to water. Just like the pressure in the water pipe, the greater the voltage, the more electricity will flow through the wires.

Unlike the water pipes that will spill the water if they break, you can't "spill" the electricity. The closest thing to this in an electrical circuit is when two wires touch that aren't supposed to and the current flows to some place that it shouldn't (this is called a "short circuit" or a "short"). Shorts often happen where the wire touches the vehicle body (the body is connected to the negative terminal of the battery). Since the current always flows through the easiest path to negative, it will bypass the rest of the circuit where it was supposed to go, and go through the short directly to the battery. Because this new path to the battery negative is shorter the malfunction is called a "short circuit" or a "short".

If you put a valve in a water pipe, you can control how much water flows by closing the valve. What you are doing is pinching off the pipe with the valve which restricts the flow. If you shut it off completely, you can stop all water from flowing. In the electrical circuit, a resistor acts like a valve. If you make the resistor extremely large, you can stop the current from flowing. The resistance is measured in "ohms".

2-16. ELECTRIC CIRCUIT DESCRIPTION (CONT'D) When there is no electrical connection, such as when a wire is disconnected, the resistance is infinite (too large to be measured). No current will flow through the wires, because the circuit is no longer continuously connected. This is referred to as an "open circuit" or simply an "open". Remember that an electrical circuit is formed by continuous loops of devices connected together. When you are troubleshooting you are often asked to check for "continuity", which simply means that you need to find out if there is a continuous path from one place in the circuit to another. Since you are trying to see if the path is continuous, you must check wires and switches rather than any special or active devices. You will usually just measure the resistance between two points. If the resistance is zero (or the value of any resistance that is supposed to be there), then there is continuity. In the case of looking for a short, this may mean that you have found the short. If the resistance is off-scale on the meter (infinite resistance) then there is no connection and you have found an open. A continuity test is the same whether you are looking for an open or a short, the only difference being what resistance values you are looking for and where you make the measurements. You are familiar with the typical light switch which allows you to turn a light on and off. A switch of any kind in an electrical circuit is simply a way of opening the loop so that no current will flow through it.

Something to remember while troubleshooting is that everything on the positive side of the switch still has full battery voltage while everything from the switch on through the rest of the circuit is (or should be) connected to the battery negative terminal and you will measure zero volts. This is easy to remember if you think of the faucet on a sink. If you shut off the faucet, there is no water flowing into the sink, but the water in the pipe is still under pressure.

Sometimes a switch is turned on and off automatically. An example is a "circuit breaker" which is a device that measures how much current is flowing through it. If the current goes too high (possibly damaging equipment or melting the wires) then it opens an internal switch to stop the current flow. A "relay" is another form of switch that is turned on and off under remote control using a signal in another wire. When a device which requires a very large amount of current (such as the starter motor), must be turned on and off, a "power relay" is used. The idea is to use a small switch to turn on a larger switch.

Thus, you don't have very large wires going all over the vehicle or large switches on the instrument panel.

In the case of the starter's power relay, it is also called a "solenoid". A solenoid is any device that changes the electrical current into a forward and backward motion. It is something like an electrical motor except that instead of continuously going around in the same direction, it goes in or out. For the starter, the solenoid is used to "push" a very large switch into the "on" position.

When testing a circuit, you will need to know how much current is flowing. Current is easilly measured with the STE/lCE-R. A device called a "shunt" is connected to the negative terminal of the battery. A shunt is a very precise resistor designed so that for every 1000 amps of current that flow through it there is a drop of .1 volts from one side of it to the other (different shunts may have different values). By measuring the voltage across the shunt you know how much current is flowing through the circuit. The shunt is placed on the negative side because it is safer (less chance of accidents which may short out the batteries). Since all of the current eventually goes through the negative battery terminal anyway, the shunt gives the same measurement as if it were connected to the positive terminal. You can think of the shunt as doing the same thing as the water meter in your house. As you turn devices such as lights on or off, you can use the shunt to measure how much current they are using.

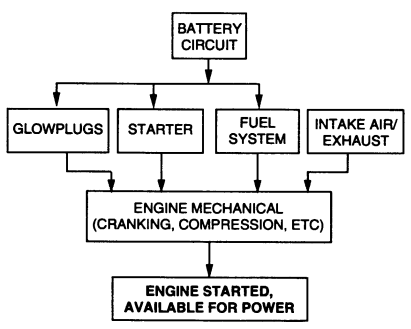

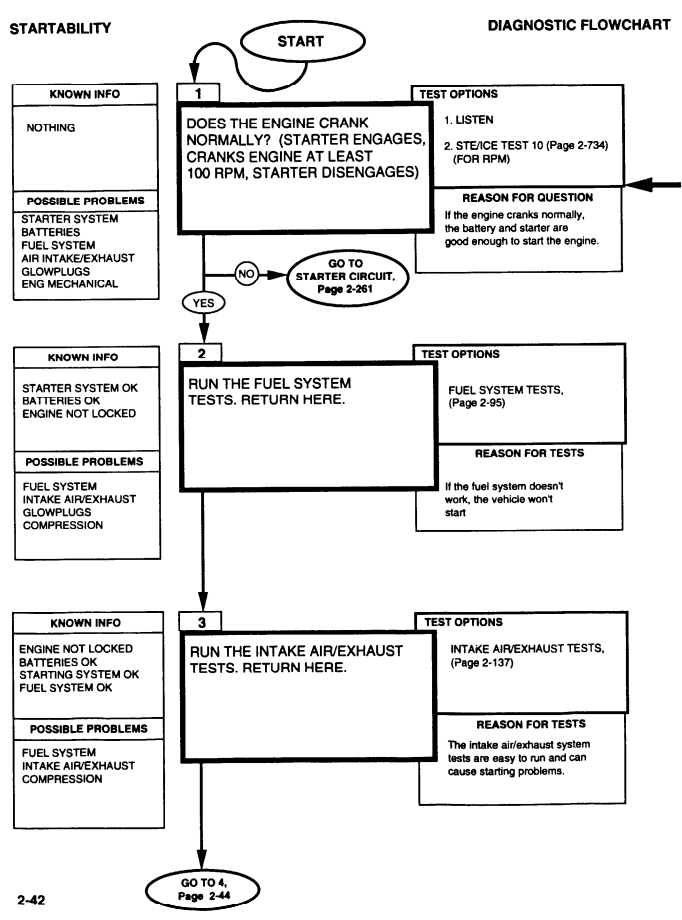

2-17. Startability Tests

This is a top level test for problems with an engine that doesn't start, or starts but immediately stops, or is very hard to start. If the engine starts but doesn't run well after starting. trv the "STARTABILITY" tests first.

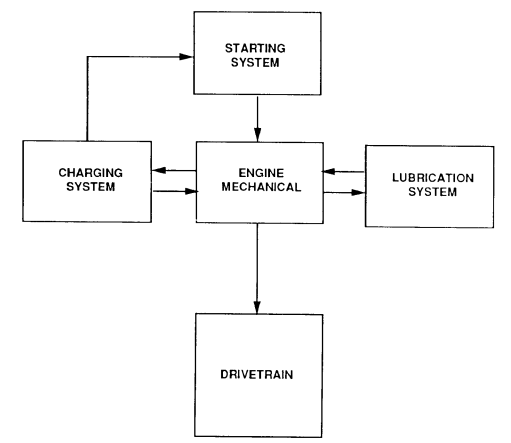

FOR THE ENGINE TO START, ALL OF THE BASIC SYSTEMS SHOWN BELOW MUST BE WORKING. THESE STARTABILITY TESTS WILL HELP YOU TO VERIFY THE CONDITION OF EACH OF THESE SYSTEMS.

A functional flow schematic is not applicable to this section.

However, so that you may refer to sections as you need them, a quick index to the systems required for starting is given here.

| PARAGRAPH | PAGE |

|---|---|

| BATTERY CIRCUIT | 2-251 |

| GLOWPLUGS CIRCUIT | 2-303 |

| STARTER CIRCUIT | 2-261 |

| FUEL SYSTEM | 2-95 |

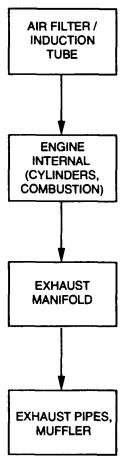

| INTAKE AIR/EXHAUST | 2-137 |

| COMPRESSION/MECHANICAL | 2-143 |

STARTABILITY Make sure all of the vehicle's fluids are at the proper level.

You could still have battery or starter problems with a cranking speed over 100 RPM, but that shouldn't stop the engine from starting.

Tests for the battery and starter can be run separately, if you want to run them.

| ENGINE RPM |

|---|

| STEACE-R TEST 10 |

| 2. Crank or start the engine. Displayed |

|---|

| roading in DDM Cranking DDM choo |

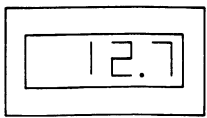

- Start Test 10, Engine RPM.

reading is RPM. Cranking RPM should be approximately 100-200. Idle RPM should be 625 - 675.

STARTABILITY

A HOT ENGINE MAY CAUSE SERIOUS BURNS. Always use caution when approaching a hot engine.

NOTE When using the vehicle's temperature gage to determine engine temperature, don't forget to turn the rotary switch to "RUN". The gages don't work when power is off.

The colder the engine (and air temperature).

the more you need the glowplugs for starting.

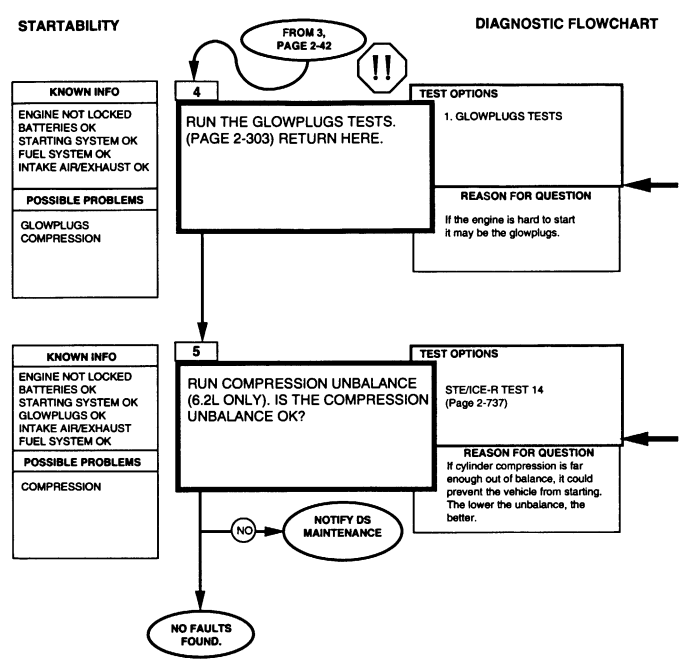

There are some times when you don't need to run the glowplugs test. If the engine is warm and the problem is there on a hot day, then the problem is probably NOT the glowplugs or cold start advance, and these tests may be bypassed. If it's colder than 50°F, run the glowplugs test, because just a few bad glowplugs can make a minor starting problem much worse.

If the vehicle passes the STE/ICE-R compression unbalance test, it may still have a compression problem, but it would mean that every cylinder has low compression. This is possible, but not too likely. If you're confident that everything else is working properly, notify DS maintenance.

Compression Unbalance Steace-R Test 14

- Run tests 72,73 and 74 to verify that the batteries are OK.

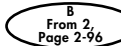

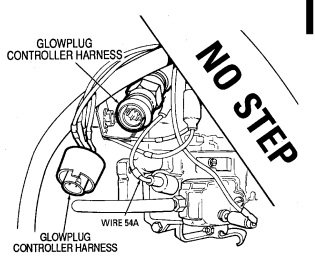

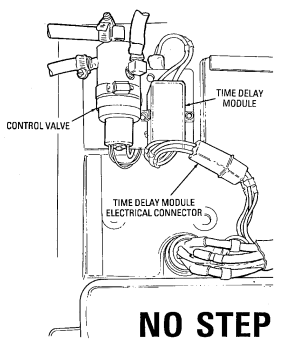

CAUTION THE GLOWPLUGS CONTROLLER AND THE CONTROL VALVE ELECTRICAL CONNECTOR MUST BE DISCONNECTED PRIOR TO RUNNING THIS TEST.

-

Disconnect wire 54A at injection pump to prevent starting.

-

Disconnect glowplugs controller and control valve electrical connector. (to keep waveform clean).

-

Start Test 14, compression unbalance.

-

Wait for the GO message. Crank the engine.

-

Release the rotary switch when the VTM displays OFF. A number less than 25% is passing.

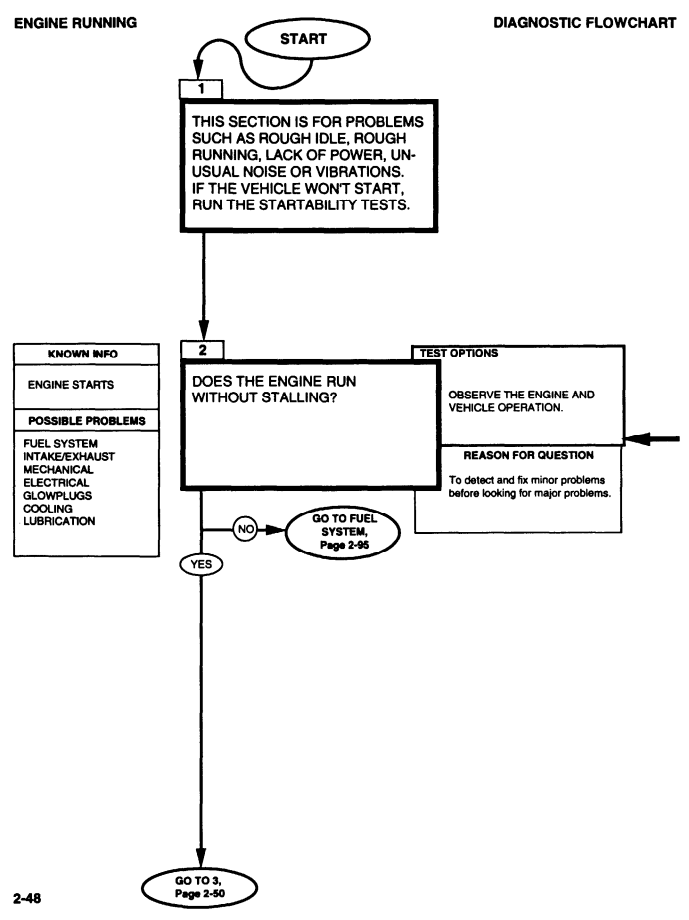

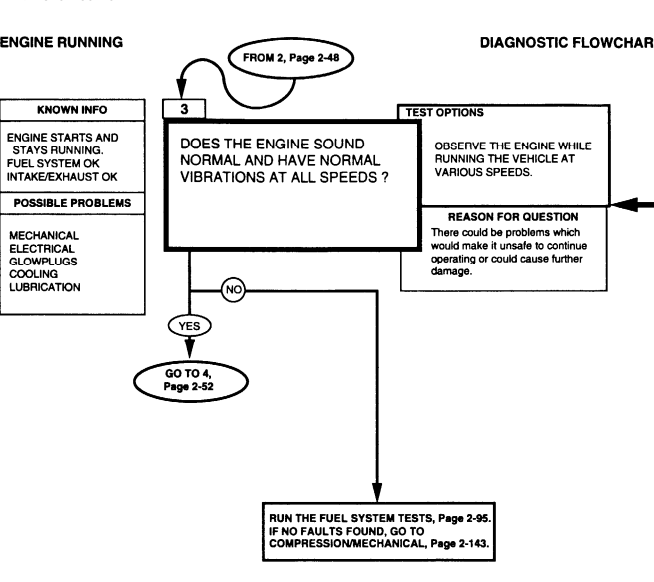

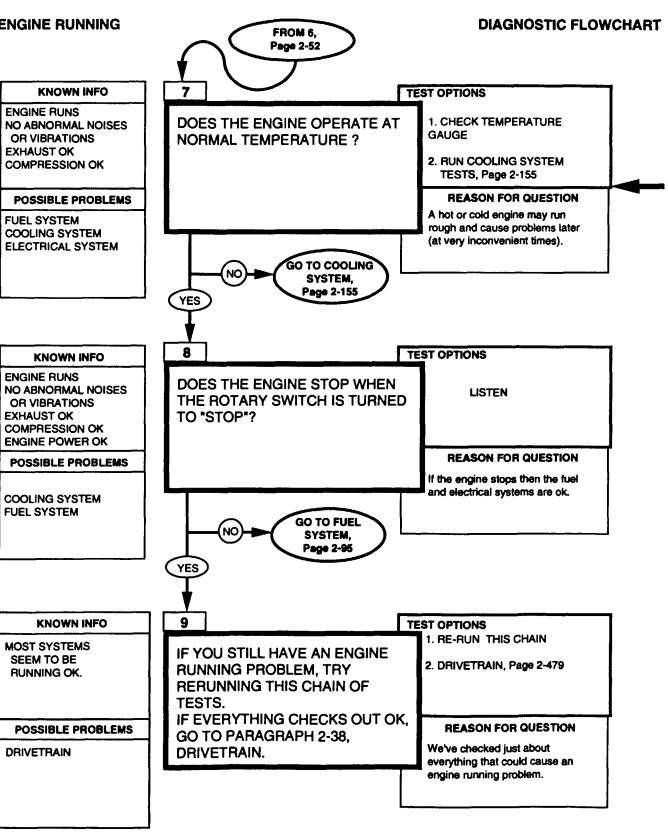

2-18. Engine Running Tests

This is a top level test for problems with an engine that starts but doesn't run well after starting. This includes an engine that starts but doesn't stay running for very long. If the engine doesn't start, or starts but immediately stops, or is very hard to start, try the "STARTABILITY" tests first.

A functional flow schematic is not applicable to this section.

However, so that you may refer to sections as you need them, a quick index to the systems relating to engine running is given here.

| PARAGRAPH | PAGE |

|---|---|

| FUEL SYSTEM | 2-95 |

| INTAKE AIRVEXHAUST | 2-137 |

| COMPRESSION/MECHANICAL | 2-143 |

REFERENCE INFORMATION ENGINE RUNNING This is a check for all of those problems which

can cause the engine to stop when it shouldn't.

This includes fuel, air, and electrical problems. If the engine starts and then stops immediately, run the STARTABILITY tests first.

REFERENCE INFORMATION ENGINE RUNNING

Reference Information Engine Running

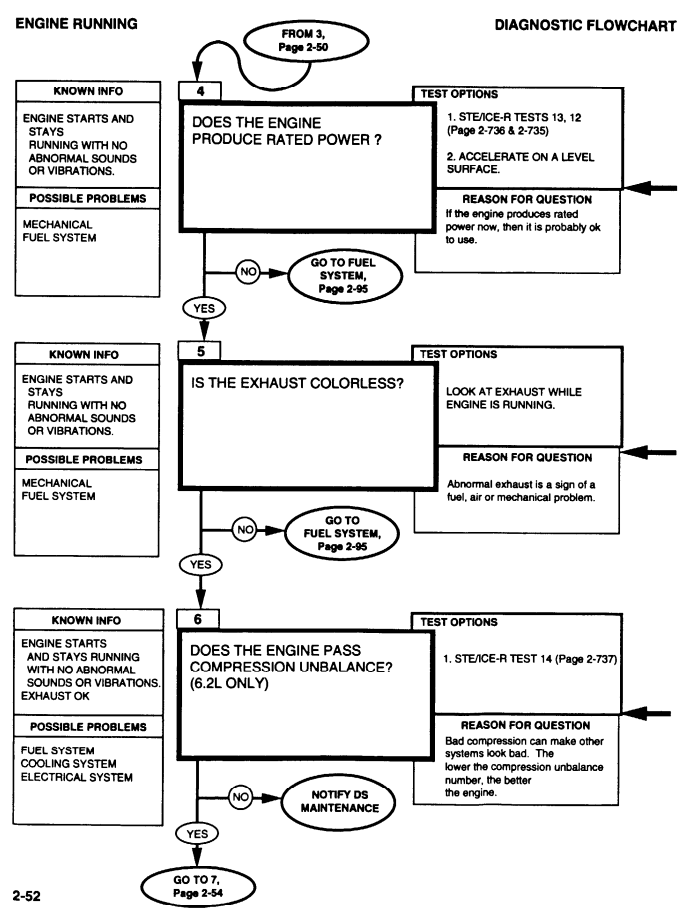

Engine Power Test (Percent) Steace-R Test #13

-

Set TEST SELECT switches to 13.

-

Press and release TEST button.

-

Wait for prompting message CIP to appear.

-

When CIP appears on display, press down sharply on engine accelerator and hold it to the floor. When VTM displays OFF, release accelerator.

-

A number will be displaved after the engine has returned to idle speed. This number is the test result in units of per cent of nominal rated power.

Engine Power Test (Rpm/Sec) Steace-R Test #12

-

Set TEST SELECT switches to 12.

-

Press and release TEST button.

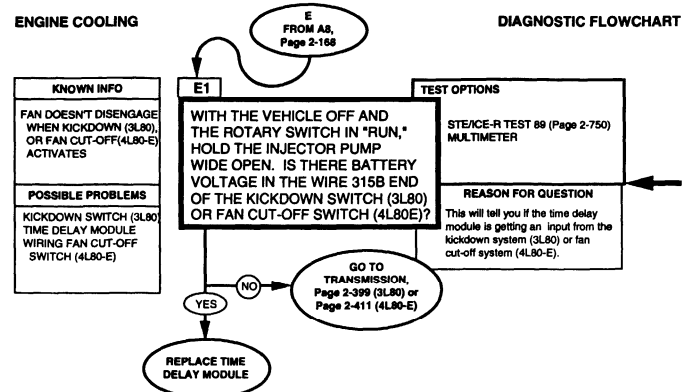

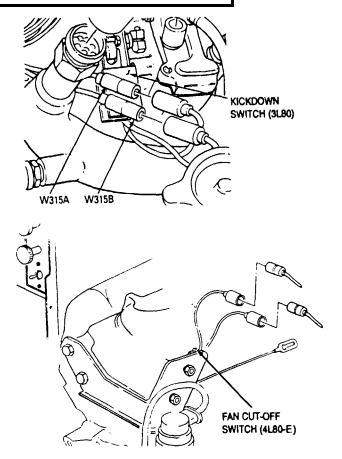

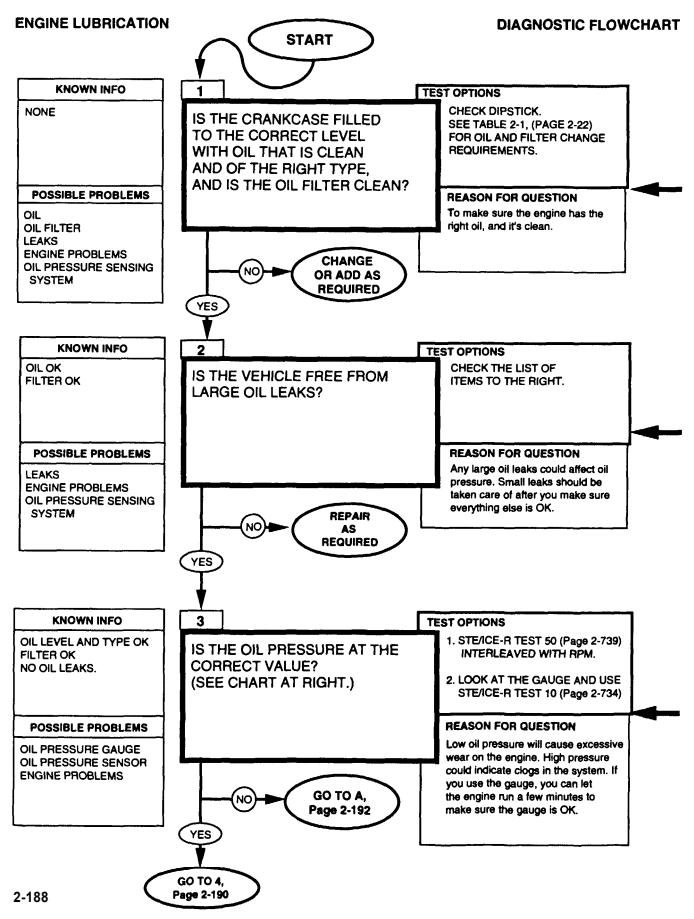

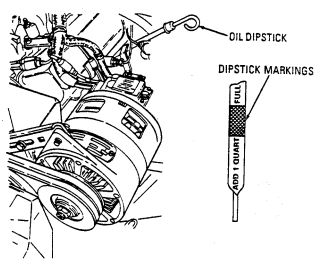

-